Silicon carbon anode material and preparation method thereof

A technology of negative electrode material and carbon nanomaterial, which is applied in the field of silicon carbon negative electrode material and its preparation, can solve the problems of battery capacity attenuation, limitation, electrode pulverization, etc., and achieves the effect of reducing the expansion rate, suppressing the expansion, and solving the problem of pulverization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

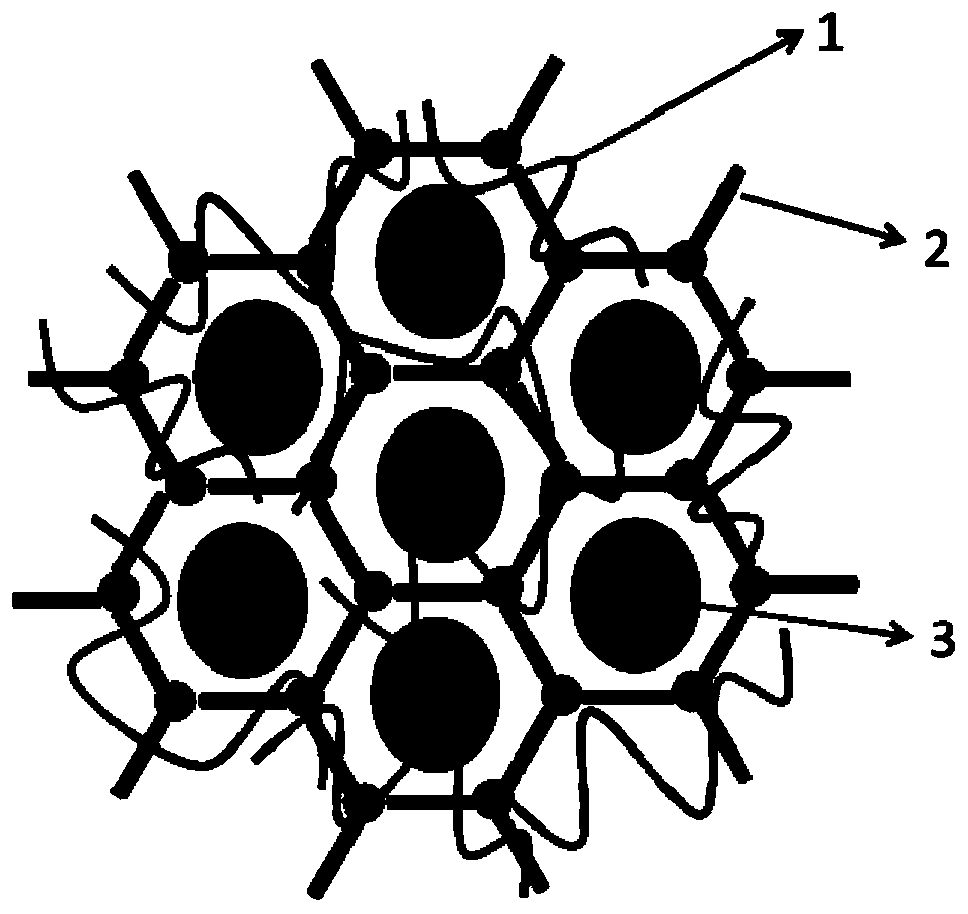

[0080] According to another aspect of the present invention, a method for preparing a silicon-carbon negative electrode material is provided, comprising:

[0081] Step S1: After mixing the covalent organic framework material and the silicon nanomaterial, a mixture is obtained;

[0082] Step S2: adding the mixture into the slurry of carbon nanomaterials, stirring for 20-50 minutes and then filtering, and drying the filtrate at 60-100° C. for 1-3 hours.

[0083] The preparation method of the silicon-carbon negative electrode material of the present invention obtains the silicon-carbon negative electrode material of the present invention, and the obtained silicon-carbon negative electrode material has silicon nanoparticles dispersed in the pores of the covalent organic framework material, effectively inhibiting the charging and discharging process of the battery , the expansion of silicon nanoparticles.

[0084] In step S1, the covalent organic framework material is selected fro...

Embodiment 1

[0104] In this embodiment, the preparation method of silicon carbon negative electrode material includes:

[0105] Step S1: After mixing the covalent organic framework material and the silicon nanomaterial, a mixture is obtained;

[0106] Among them, the covalent organic framework material is TF-Py COF, which has a specific surface area of 3000 m 2 / g, the pore diameter of its pore is 4nm, and the addition amount is 100mg; The silicon nanomaterial is silicon nanoparticle, and the particle diameter of silicon nanoparticle is 3nm, and the addition amount is 2500mg; The ratio between the pore diameters is 1:1.3; the mass ratio of covalent organic framework material to silicon nanoparticles is 1:25;

[0107] Step S2: adding the mixture into the slurry of carbon nanomaterials, stirring for 30 minutes and then filtering, and drying the filtrate at 80° C. for 2 hours;

[0108] The solvent of the carbon nanomaterial slurry is water, the carbon nanomaterial is a multi-walled carbon ...

Embodiment 2

[0113] Other conditions of this example are the same as those of Example 1, the only difference being that the covalent organic framework material is COF-43.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com