Silicon monoxide/carbon composite material and preparation method and application thereof

A technology of carbon composite materials and silicon oxide, which is applied in the direction of electrochemical generators, active material electrodes, electrical components, etc., can solve the problems of uneven thickness of carbon layer, increase of material cost, exposed particle interface, etc., and achieve improved coating The effect of uniformity, improved contact, and reduced coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of pre-lithiated silicon oxide / carbon composite material of the present invention, comprises the following steps:

[0031] S1. Mix silicon oxide and modifier evenly, put it into a rotary crucible, heat to a certain temperature, and keep it warm for a period of time.

[0032] S2. Put the above-mentioned obtained materials into a rotary kiln, raise the temperature to a certain temperature and keep it warm, feed a certain amount of pyrolysis gas, and carry out carbon coating to obtain a silicon oxide / carbon composite material.

[0033] Preferably, the mass ratio of silicon oxide to modifier in step S1 is 1-0.01;

[0034] Preferably, the modifying agent in the step S1 is chemical paraffin, polyethylene with molecular weight less than 10,000, animal and vegetable wax, higher fatty acid, glyceryl tristearate or hardened oil.

[0035] Preferably, the method of mixing materials in the step S1 is ball milling, VC mixing or stirring;

[0036] Prefer...

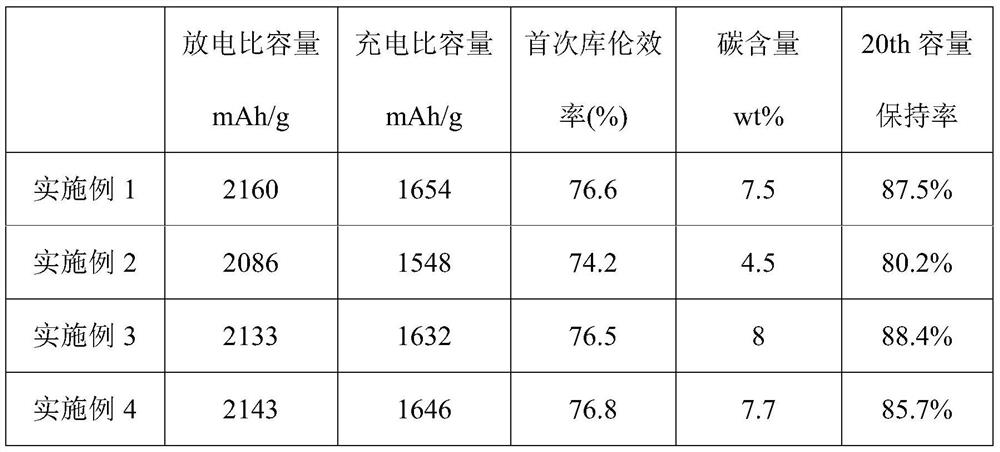

Embodiment 1

[0044] A preparation and application of a silicon oxide / carbon composite material, comprising the following steps:

[0045] 1) Weigh 100g of SiO and 10g of chemical paraffin (100 mesh) in a ball milling tank at a speed of 400rpm / min, and the ball milling time is 2h to ensure uniform mixing. Put the evenly mixed materials into the rotary pot at a speed of 5rpm, under nitrogen protection The temperature was raised from room temperature to 60 °C at a rate of 3 °C / min, the rotation speed was adjusted to 15 rpm, and the temperature was kept for 3 hours. After cooling to room temperature, the materials were taken out.

[0046] 2) Put the material obtained in step 1) into a rotary kiln, raise the temperature to 800° C., feed acetylene gas, and keep it warm for 1 hour to obtain a silicon oxide / carbon composite material.

Embodiment 2

[0048] Compared with Example 1, no paraffin is added in Step 1, and all other step parameters remain unchanged.

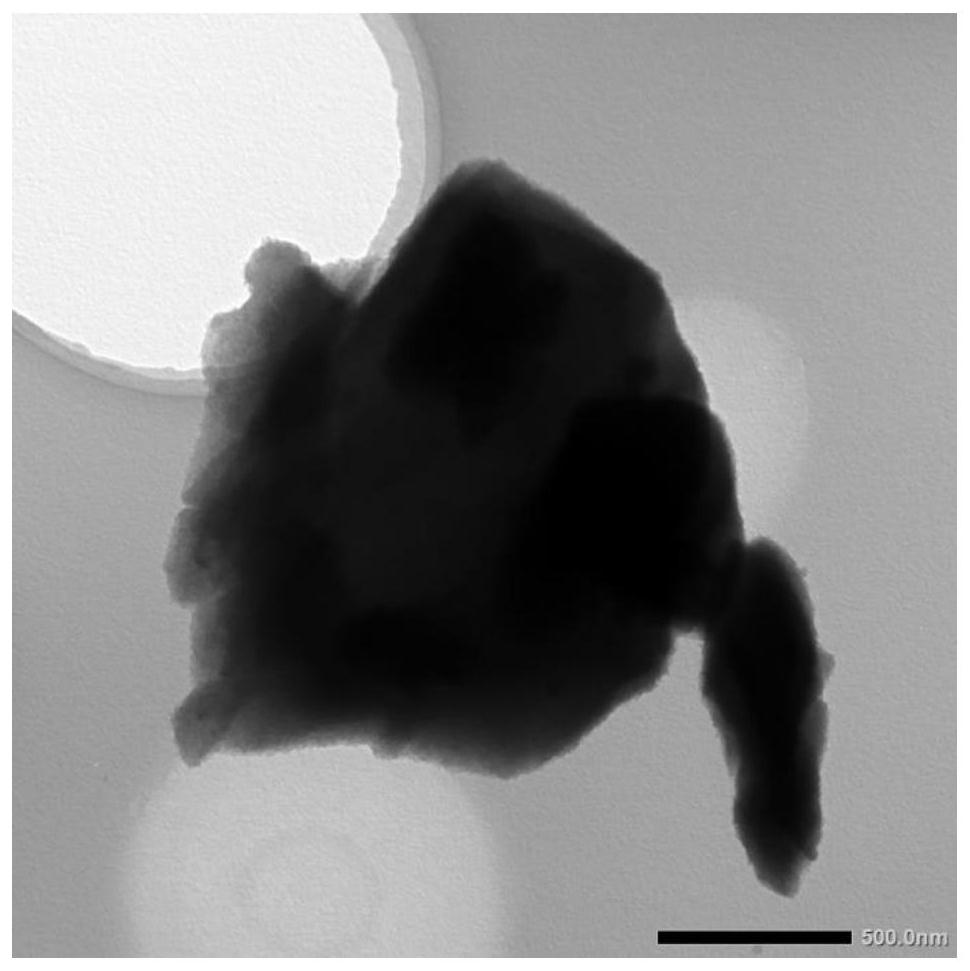

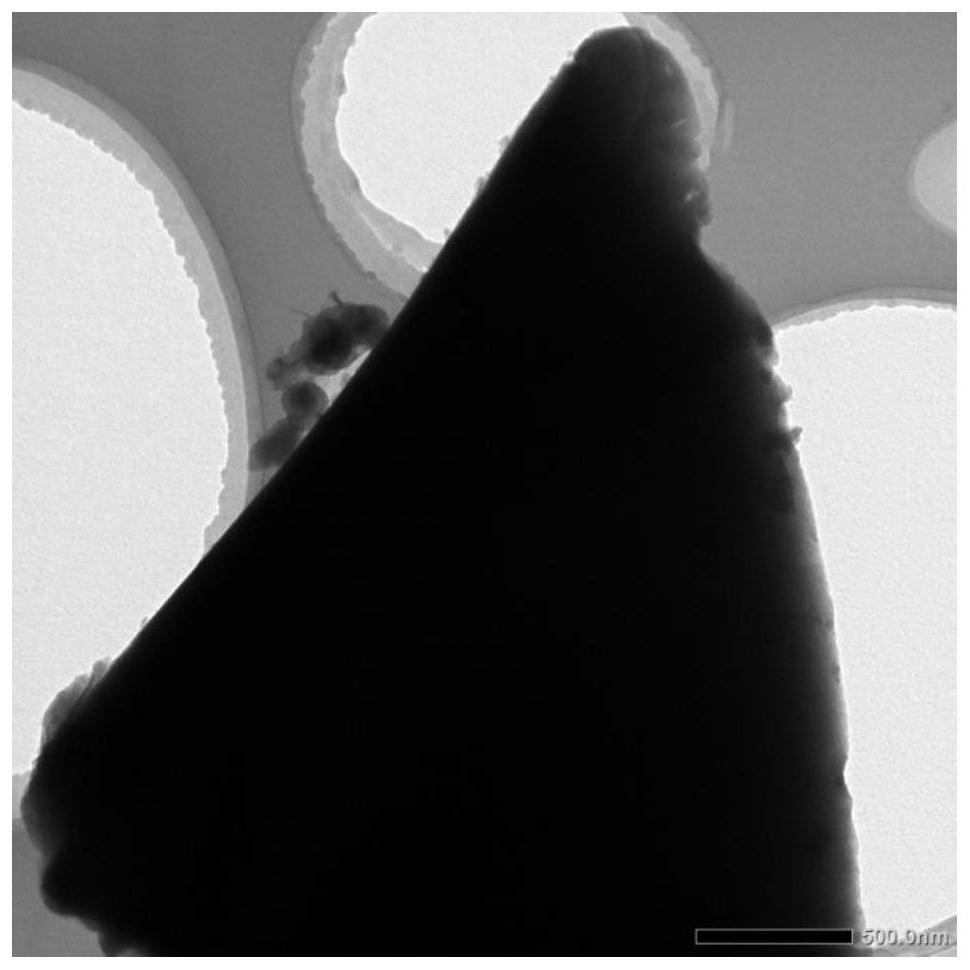

[0049] from figure 1 with figure 2 It is not difficult to see from the figure that during the vapor deposition process of silicon oxide that has not been modified, there are exposed parts on the surface, and the coating of the carbon layer is not very uniform, but after the modification treatment, the uniformity of the coating is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com