Cobalt phosphide nanoparticle embedded carbon nanosheet array material as well as preparation and application thereof

A carbon nanosheet and nanoparticle technology, applied in the field of cobalt phosphide nanoparticle inlaid carbon nanosheet array materials, can solve the problems of poor stability, excessive size, unfavorable lithium storage reaction, etc., and achieve the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

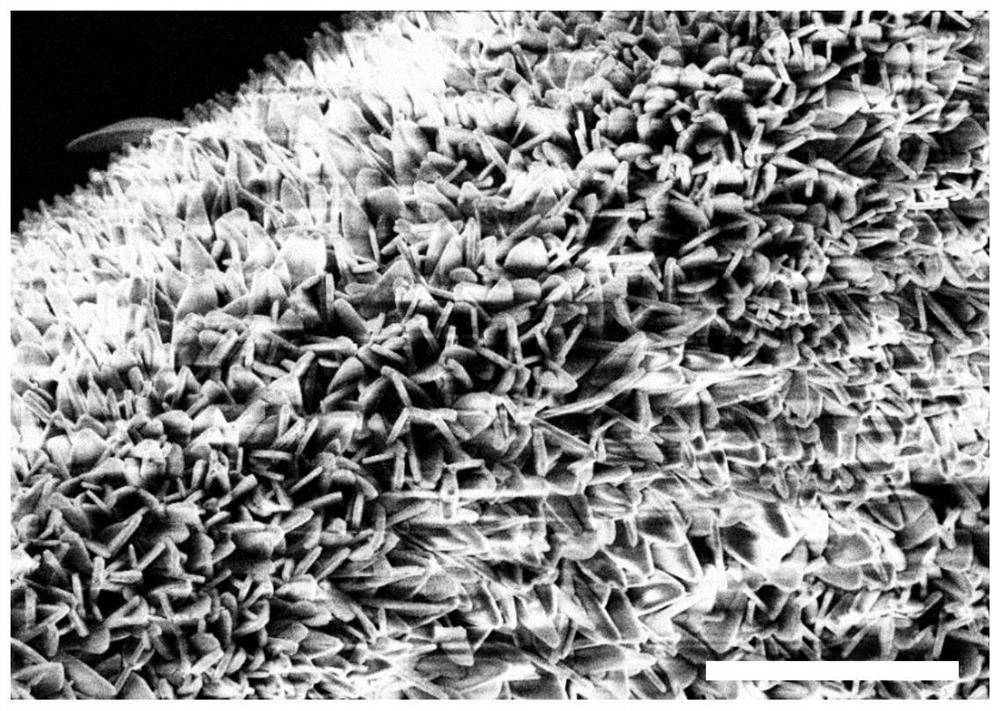

[0033] (1) The nickel foam is cleaned with dilute hydrochloric acid and deionized water, and dried in vacuum. 0.73g Co(NO 3 ) 2 ·6H 2 O was dissolved in 50mL of deionized water, 1.64g of 2-methylimidazole was dissolved in 50mL of deionized water, the two solutions were quickly mixed, and nickel foam was suspended in the mixed solution at a temperature of 35°C, left to stand for 60min, and then taken out. After washing with deionized water for several times, put it in an oven and dry it at 80°C to obtain ZIF-67 nanosheet array@foam nickel;

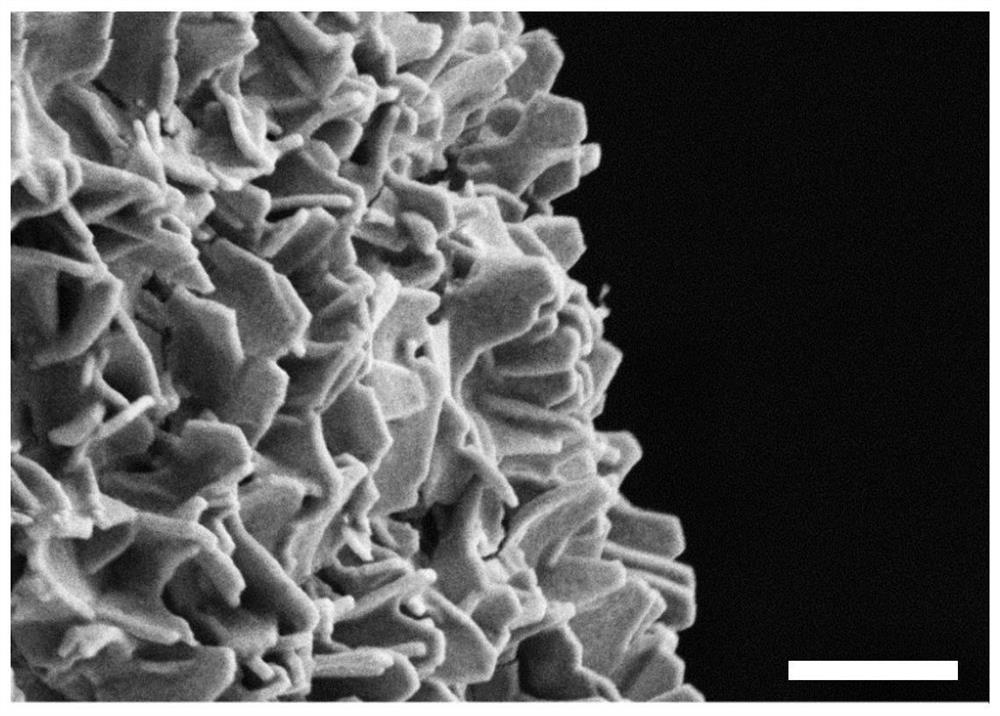

[0034] (2) Place the ZIF-67 nanosheet array @ nickel foam obtained in step (1) in a quartz tube furnace, and heat it at a rate of 1°C min under the protection of argon. -1 Heating to 550°C, keeping it warm for 60 minutes, cooling down to room temperature with the furnace, and obtaining cobalt nanoparticle-embedded carbon nanosheet array@foam nickel;

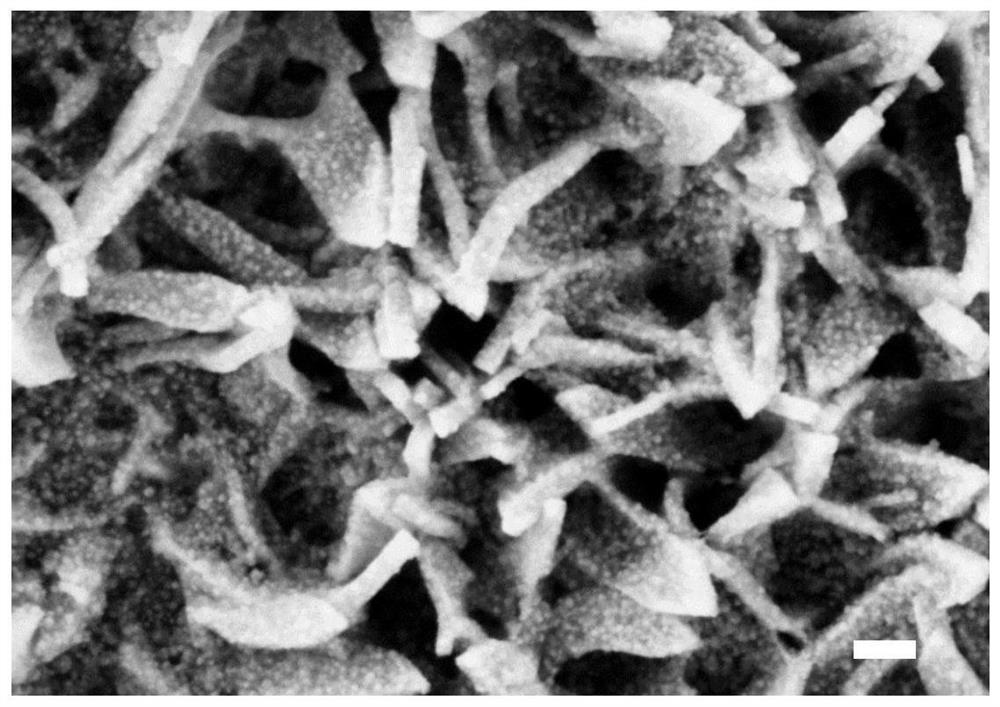

[0035] (3) Embed the cobalt nanoparticle-embedded carbon nanosheet array@foam nickel o...

Embodiment 2

[0042] Nickel foam is cleaned with dilute hydrochloric acid and deionized water, and dried in vacuum. 0.73g Co(NO 3 ) 2 ·6H 2 O was dissolved in 50mL of deionized water, 1.64g of 2-methylimidazole was dissolved in 50mL of deionized water, the two solutions were quickly mixed, and the nickel foam was suspended in the mixed solution at a temperature of 35°C, left to stand for 120min, and then taken out. After washing with deionized water for several times, place it in an oven and dry at 80°C to obtain ZIF-67 nanosheet array@foam nickel; the subsequent process is the same as that in Example 1.

[0043] The microstructure of the product cobalt phosphide nanoparticle-embedded carbon nanosheet array is similar to that of Example 1, the main difference being that the thickness of the carbon nanosheet is changed to 150 nm.

[0044] Adopt the same technology as embodiment 1 to make lithium ion battery negative electrode, assemble into lithium ion battery, with current density 200mA ...

Embodiment 3

[0046] Nickel foam is cleaned with dilute hydrochloric acid and deionized water, and dried in vacuum. 0.73g Co(NO 3 ) 2 ·6H 2 O was dissolved in 50mL of deionized water, 1.64g of 2-methylimidazole was dissolved in 50mL of deionized water, the two solutions were quickly mixed, the nickel foam was suspended in the mixed solution, the solution temperature was 25°C, and stood for 60min, then taken out, After washing with deionized water for several times, place it in an oven and dry at 80°C to obtain ZIF-67 nanosheet array@foam nickel; the subsequent process is the same as that in Example 1.

[0047] The microstructure of the product cobalt phosphide nanoparticle-embedded carbon nanosheet array is similar to that of Example 1, the main difference being that the thickness of the carbon nanosheet is changed to 90nm.

[0048] Adopt the same technology as embodiment 1 to make lithium ion battery negative electrode, assemble into lithium ion battery, with current density 200mA g -1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com