Preparation method of LaNi5 film and application thereof

A thin film and characteristic technology, which is applied in the preparation of LaNi5 thin film and the application field of hydrogen sensor, can solve the problems of unsatisfactory industrialization of sensors, difficulty in obtaining accurate stoichiometric ratio, insufficient hydrogen selectivity and sensitivity, etc., and achieve low compactness , easy to make, uniform grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Using the magnetron radio frequency sputtering method, the specific operation is as follows:

[0037] 1. Cleaning silicon chips

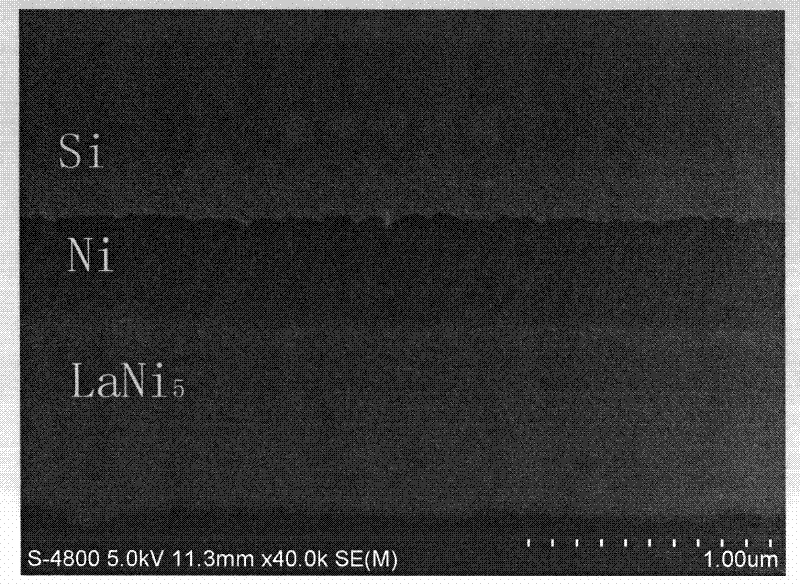

[0038] 2. A Ni film is deposited on the Si substrate by magnetron radio frequency sputtering as a buffer layer. The sputtering conditions were as follows:

[0039] 1. The Ni target with a purity of 99.95% is used as the cathode target; the base distance of the target is 4.55cm;

[0040] 2. The background vacuum is lower than 5.0*10 -4 the following;

[0041] 3. The working gas is an inert gas——Ar gas, and the working pressure is 0.5Pa;

[0042] 4. Pre-sputtering is required for about 15 minutes before depositing Ni to clean the surface of the Ni target; when depositing Ni, the power is 80W, and the temperature is room temperature; the deposition time is 10 minutes, and a Ni film with a thickness of about 450nm is prepared as a buffer layer.

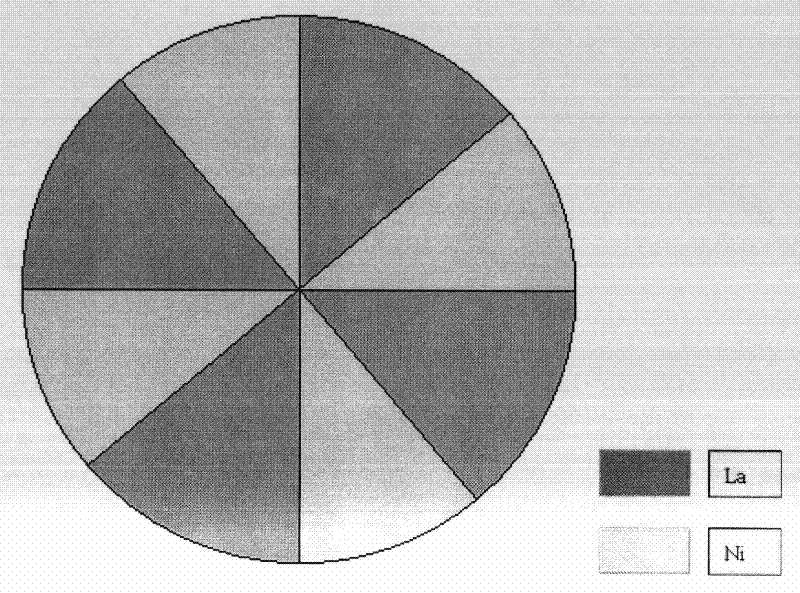

[0043] 3. Making lanthanum-nickel fan-shaped targets.

[0044] 1. Cut Ni sheets with a purity o...

example 2

[0052] Preparation of LaNi by Magnetron RF Sputtering 5 Thin film, the first, second, third steps are identical with example one. The sputtering conditions of the fourth step are: the lanthanum-nickel fan-shaped target is used as the cathode target, the background vacuum is lower than 5.0*10-4,

[0053] target base distance

Air pressure (Ar)

power

temperature

time

4.9cm

0.2Pa

150W

700℃

20min

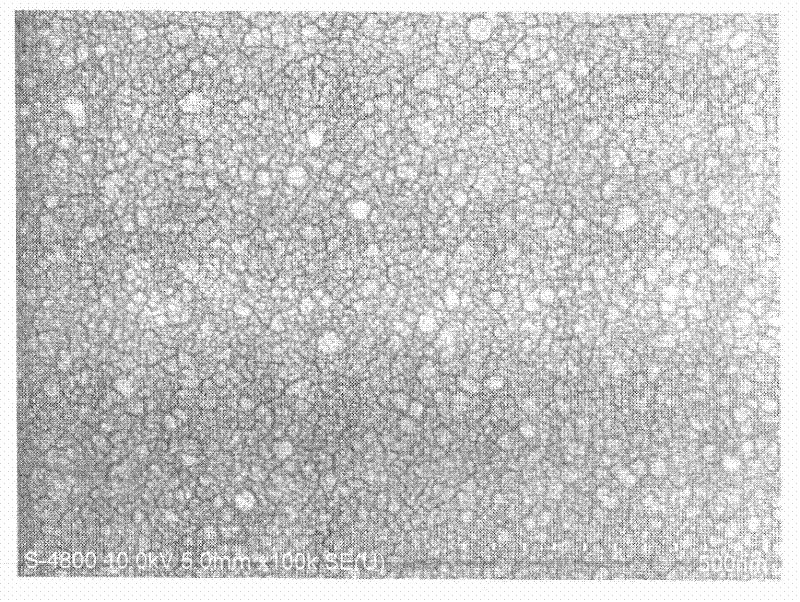

[0054] Prepared LaNi 5 The thickness of the film is 500nm, the density is low, the crystal grains are uniform, the grain size is about 50nm, and the specific surface area is large, which is beneficial to hydrogen absorption / desorption.

[0055] The prepared LaNi 5 After the surface treatment of the film, the sample is placed in the air atmosphere at room temperature, and when different flow rates of hydrogen (30ml / min, 60ml / min, 160ml / min) pass through the surface of the sample, record the time and the resistance of the sample, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com