Graphite crucible aluminum evaporation process for semiconductor production

A graphite crucible and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, metal material coating process, vacuum evaporation plating, etc., can solve low product quality, low quality control ability of aluminum film thickness, and unsatisfactory aluminum film uniformity and other problems, to achieve the effect of low transformation cost, improve product cost competitiveness, and reduce product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

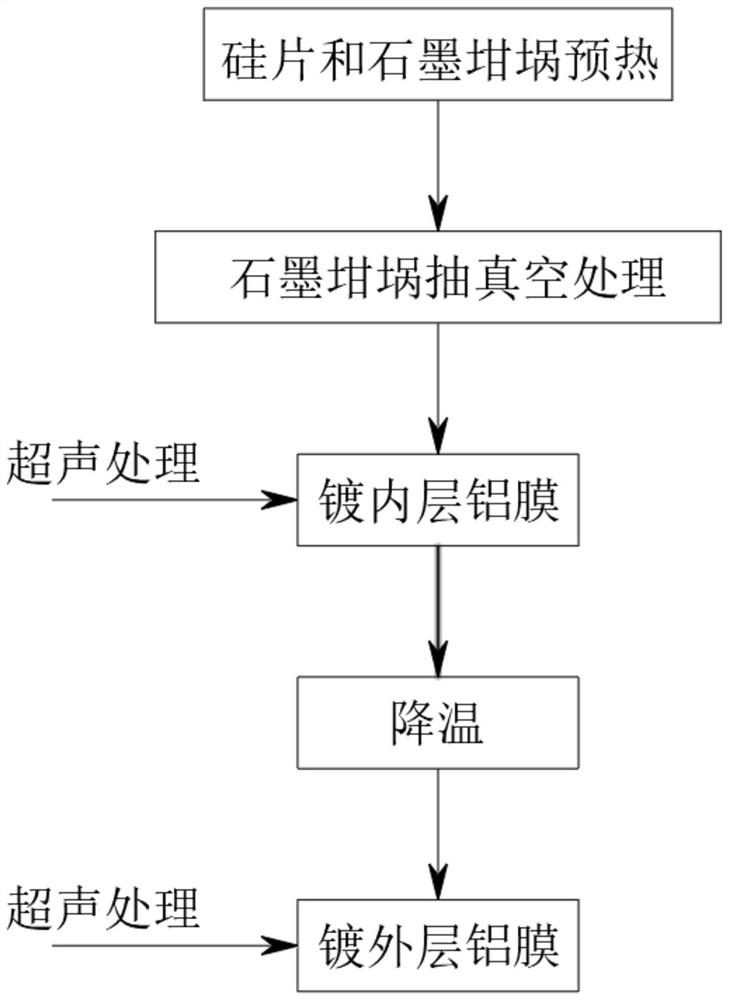

[0028] see figure 1 Shown, the present invention is a kind of technology that graphite crucible steams aluminum for semiconductor production, comprises the following steps:

[0029] S1: Preheat both the silicon wafer and the graphite crucible to 45°C. A temperature sensor is installed in the graphite crucible. The temperature in the crucible is collected through the temperature sensor, and the signal is amplified by the amplifier and then sent to the microprocessor. The microprocessor operates and controls After the algorithm, the control command is output to adjust the temperature of the graphite crucible and display the temperature value in real time. The graphite crucible is also equipped with a heating coil and a microwave generator. When the graphite crucible is preheated, the coil is used to preheat. Microwave generator to increase the temperature in the graphite crucible;

[0030] S2: placing the preheated silicon wafer on the stage of the graphite crucible, and then v...

Embodiment 2

[0035] see figure 1 Shown, the present invention is a kind of technology that graphite crucible steams aluminum for semiconductor production, comprises the following steps:

[0036] S1: Preheat both the silicon wafer and the graphite crucible to 55°C. A temperature sensor is installed in the graphite crucible. The temperature in the crucible is collected through the temperature sensor, and the signal is amplified by the amplifier and then sent to the microprocessor. The microprocessor operates and controls After the algorithm, the control command is output to adjust the temperature of the graphite crucible and display the temperature value in real time. The graphite crucible is also equipped with a heating coil and a microwave generator. When the graphite crucible is preheated, the coil is used to preheat. Microwave generator to increase the temperature in the graphite crucible;

[0037] S2: placing the preheated silicon wafer on the stage of the graphite crucible, and then v...

Embodiment 3

[0042] see figure 1 Shown, the present invention is a kind of technology that graphite crucible steams aluminum for semiconductor production, comprises the following steps:

[0043] S1: Preheat both the silicon wafer and the graphite crucible to 50°C. A temperature sensor is installed in the graphite crucible. The temperature in the crucible is collected through the temperature sensor, and the signal is amplified by the amplifier and then sent to the microprocessor. The microprocessor operates and controls After the algorithm, the control command is output to adjust the temperature of the graphite crucible and display the temperature value in real time. The graphite crucible is also equipped with a heating coil and a microwave generator. When the graphite crucible is preheated, the coil is used to preheat. Microwave generator to increase the temperature in the graphite crucible;

[0044] S2: placing the preheated silicon wafer on the stage of the graphite crucible, and then v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com