Steel structure active fire retardant coating and preparation method thereo

A technology for fire-resistant coatings and steel structures, applied in fire-resistant coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as loss of bearing capacity, inability to continue to use, poor fire resistance of steel structures, etc., and achieve thin coating thickness , Improve the activity, the effect of superior fire resistance limit performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

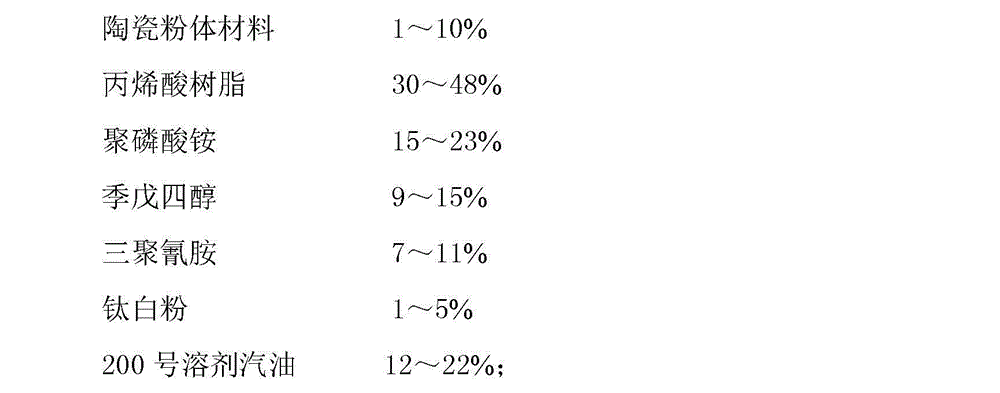

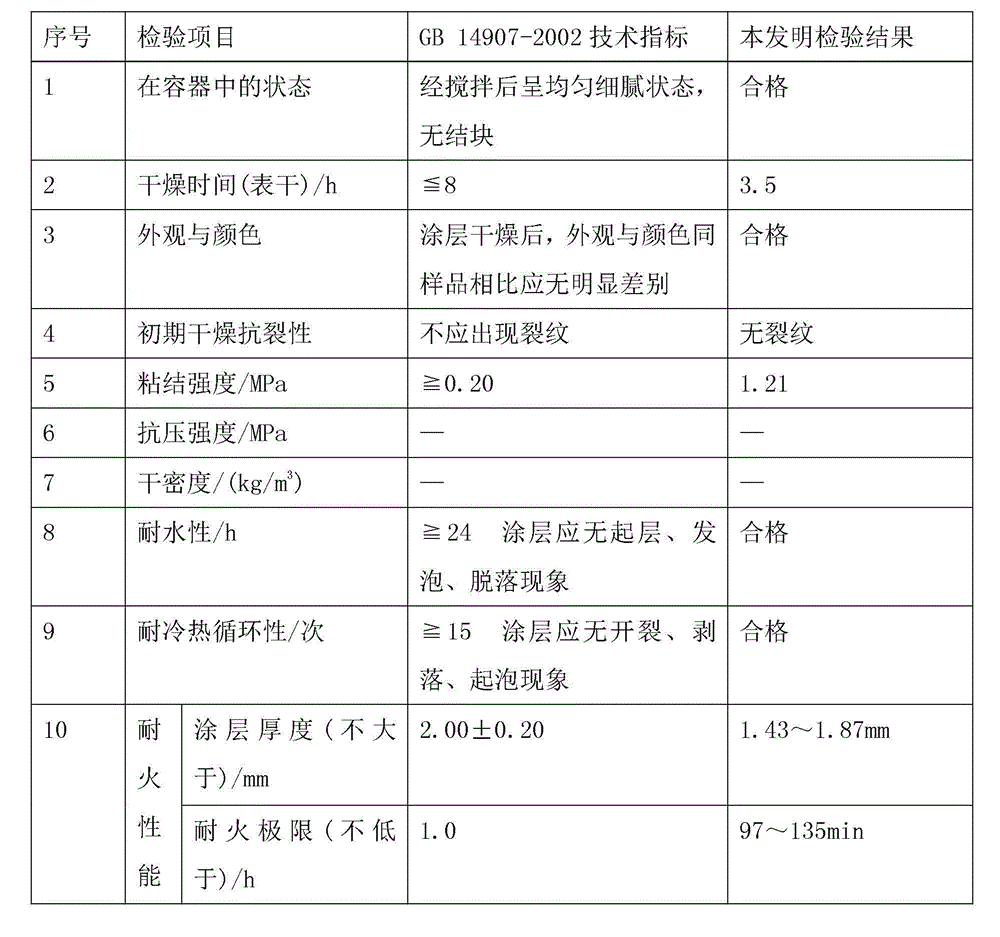

Method used

Image

Examples

Embodiment 1

[0029] Put 40 grams of ferrite tourmaline powder, 30 grams of ferrite powder, 8 grams of quartz porphyry powder, 20 grams of Suzhou soil powder, and 2 grams of silicate inorganic antibacterial material powder containing 0.5% silver. Mill in a ball mill for 4 hours, mix evenly, so that the particle size of the powder reaches 325 mesh; spray 0.8 g of water evenly on the above powder, press the powder with a press to form a ceramic blank with a diameter of 50 mm and a thickness of 6 m body; the green body was sintered at 930°C for 4 hours to obtain a ceramic sintered body; the ceramic sintered body was crushed, pulverized, and ground to produce a ceramic powder material with a median diameter (D50) of 3.4 microns.

Embodiment 2

[0031] 35 grams of iron lithium tourmaline powder, 42 grams of strontium ferrite powder, 5 grams of marble porphyry powder, 15 grams of Suzhou soil powder, 3 grams of borate inorganic antibacterial material powder containing 1.0% silver, Put it in a ball mill and mill it for 6 hours, mix evenly, so that the particle size of the powder reaches 325 mesh; spray 1.2 grams of water evenly on the above powder, press the powder with a press, and make a ceramic with a diameter of 50mm and a thickness of 6m The green body is sintered at 1150°C for 1.5 hours to obtain a ceramic sintered body; the ceramic sintered body is crushed, pulverized, and ground to produce a ceramic powder material with a median diameter (D50) of 1.2 microns .

Embodiment 3

[0033] 22 grams of quartz powder, 45 grams of NdFeB powder, 3 grams of cerium ytterbium phosphate powder, 27 grams of Suzhou soil powder, 3 grams of phosphate inorganic antibacterial material powder containing 0.5% silver and 0.5% cerium , put it in a ball mill and mill it for 4 hours, mix evenly, so that the particle size of the powder reaches 325 mesh; spray 0.8 g of clear water evenly in the above powder, and press the powder with a press to make a powder with a diameter of 50 mm and a thickness of 6 m. Ceramic sheet green body; sinter the green body at 1050°C for 2.5 hours to obtain a ceramic sintered body; crush, pulverize and grind the ceramic sintered body to make a ceramic powder with a median diameter (D50) of 1.93 microns Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com