Preparation method of organic pre-lithiated material

An organic and organic technology, applied in the field of preparation of organic pre-lithiation materials, can solve problems such as unfavorable industrial production, complex process, gas production from electrolyte decomposition, and achieve easy mass production, high specific capacity for delithiation, and lithium intercalation. Bit suitable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

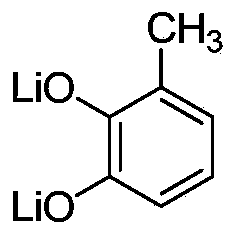

[0040] Synthesize and prepare 3-methylcatechol material according to the method reported in the literature, take 10mmol of 3-methylcatechol and add it to 100ml of anhydrous toluene, stir evenly, cool the solution to -20°C, and argon Pump and change the air three times, slowly add 24 mmol of lithium diisopropylamide solution to the above solution dropwise under an argon atmosphere, after the addition of lithium diisopropylamide is completed, slowly raise the temperature to 0°C, and set the temperature at 0°C Fully stir the reaction for 6 hours; add excess n-hexane to the above reaction solution, filter to obtain a solid powder product, then use a mixed solvent of n-hexane / tetrahydrofuran with a volume ratio of 1:3 to fully wash the solid powder, repeat three times, and remove impurities. The resulting solid powder was placed in a vacuum drying oven and dried in vacuum at 140°C for 12 hours to obtain the final positive electrode organic pre-lithiated material product 3-methyl-1,2...

Embodiment 2

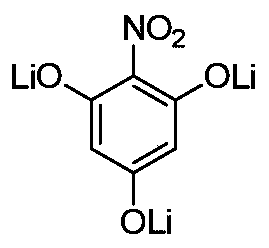

[0043] Synthesize and prepare 2-nitrophloroglucinol material according to the method reported in the literature, take 15mmol of 1-nitro-2,4,6-triphenolylbenzene and add it to 150ml of anhydrous tetrahydrofuran, stir evenly, and cool the solution To 0°C, argon gas was pumped three times, and 47.25mmol of lithium hydride powder was slowly added dropwise to the above solution under an argon atmosphere. After the addition of lithium hydride was completed, the temperature was slowly raised to 25°C, and fully stirred at 25°C React for 36 hours; add excess n-hexane to the above reaction solution, filter to obtain a solid powder product, then use a mixed solvent of n-hexane / tetrahydrofuran with a volume ratio of 2:1 to fully wash the solid powder, repeat three times, and remove impurities. The resulting solid powder was placed in a vacuum drying oven and dried in vacuum at 50°C for 48 hours to obtain the final positive electrode organic pre-lithiated material product 1-nitro-2,4,6-trip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com