Device and method for smoke simultaneous desulfurization and denitrification based on hydrogen peroxide catalytic oxidation

A catalytic oxidation, desulfurization and denitrification technology, applied in the fields of chemical technology and gas pollutant treatment, can solve the problems of explosion and low oxidation efficiency, and achieve the effect of improving the removal rate, enhancing the oxidation efficiency and reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

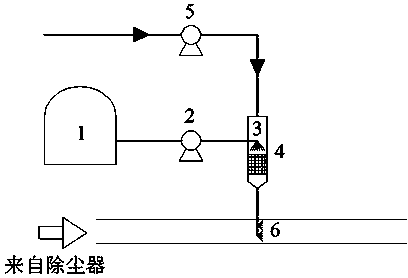

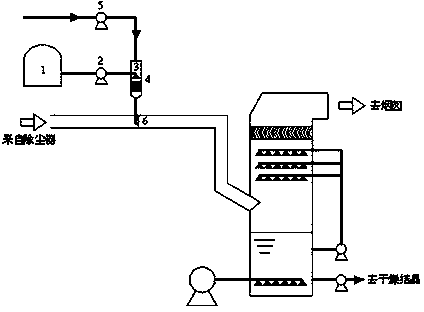

[0044] A H-based 2 o 2 A device for simultaneous desulfurization and denitrification of flue gas by catalytic oxidation, the device includes H 2 o 2 Tank 1, Syringe Pump 2, H 2 o 2 Nozzle 3 and H 2 o 2 Catalytic decomposition device 4, air blower 5 and active material nozzle 6; The H 2 o 2 Storage tank 1 is connected to syringe pump 2, and syringe pump 2 is connected to H 2 o 2 Nozzle 3 connected, H 2 o 2 Nozzle 3 installed with H 2 o 2 Inside the catalytic decomposition unit 4, H 2 o 2 One end of the catalytic decomposition device 4 is connected to the air blower 5, and the other end is connected to the active material nozzle 6 (such as figure 1 figure 2 ). h 2 o 2 into H via syringe pump 2 2 o 2 The catalytic decomposition device 4 reacts with the catalyst to produce a large amount of active substances. The active material is injected into the flue through the active material nozzle 6 along with the air from the air blower 5 to oxidize SO 2 and NO X ...

Embodiment 2

[0047] Such as Figure 4 As shown, the difference from Example 1 is that in the H 2 o 2 A preheating device 7 is arranged between the catalytic reaction device 4 and the blower 5, and the preheating device 7 is a shell-and-tube heat exchanger or a plate heat exchanger or a tube-sheet heat exchanger or a volumetric heat exchanger, etc., the The preheating device 7 mainly heats up the bypass airflow, and the bypass airflow with a higher temperature is more conducive to H 2 o 2 The dispersion of the solution on the surface of the catalyst also makes it easier for the active species and H on the surface of the catalyst to 2 o 2 The solution is injected into the flue, and the hot air flow of the preheating device comes from the flue gas.

[0048] When using the system of Example 2 to perform desulfurization and denitrification operations, wherein, H 2 o 2 The number of moles of solution injected is twice the number of moles of NO, and the oxidation time is 1 second. In this ...

Embodiment 3

[0050] Such as Image 6 As shown, the difference from Example 1 is that in the H 2 o 2 The outside of the catalytic reaction device 4 wraps a heating device 8, the heating device 8 is electric heating or steam heating or flue gas heating, etc., and the heating device 8 is mainly for H 2 o 2 The catalytic decomposition device heats up to make the H 2 o 2 Decomposition accelerates to produce more active substances, and more active substances are injected into the flue along with the bypass airflow to oxidize NO X and SO 2 . The electric heating or steam heating energy comes from the outside, and the flue gas in the flue gas heating comes from the part before the dust collector.

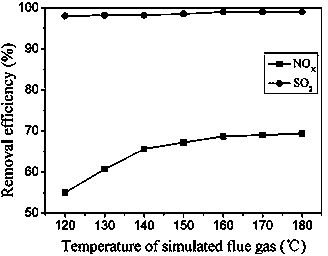

[0051] When using the system of Example 3 for desulfurization and denitrification operations, wherein, H 2 o 2 The number of moles of the injected amount of NO is twice the number of moles of NO, and the oxidation time is 1 second. In this embodiment, the flue gas temperature in the flue is 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com