High polymer grouting reinforcement material

A technology of grouting reinforcement and polymer, which is applied in the field of broken rock mass reinforcement materials in underground engineering, can solve the problems of difficult control of foaming, uneven foam, high reaction heat, etc., to reduce the possibility of smoldering and explosion, and reduce the The effect of low calorie and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare the polymer grouting reinforcement material according to the following ratio:

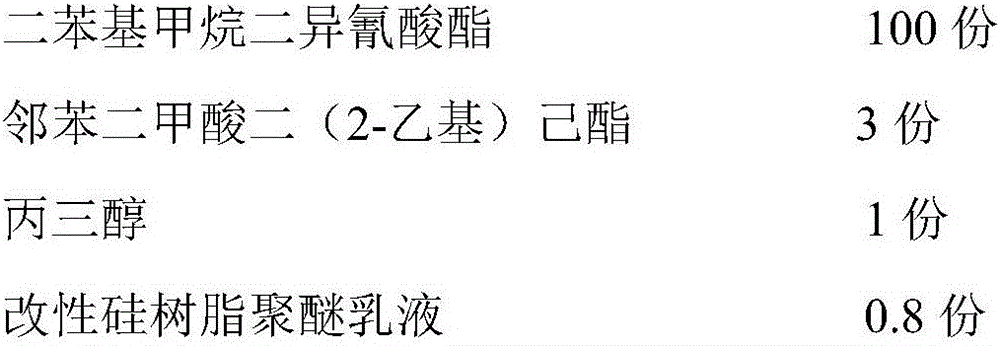

[0036] A component:

[0037]

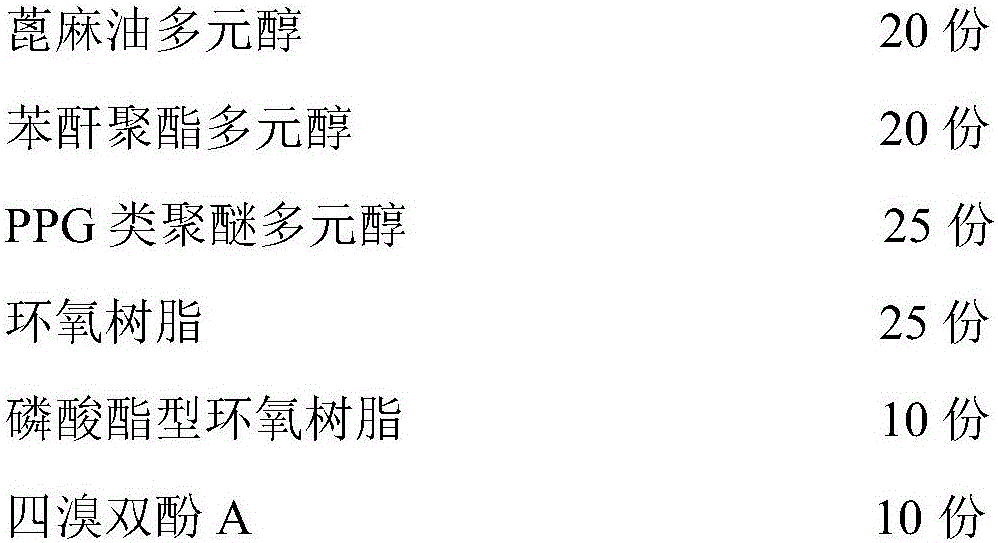

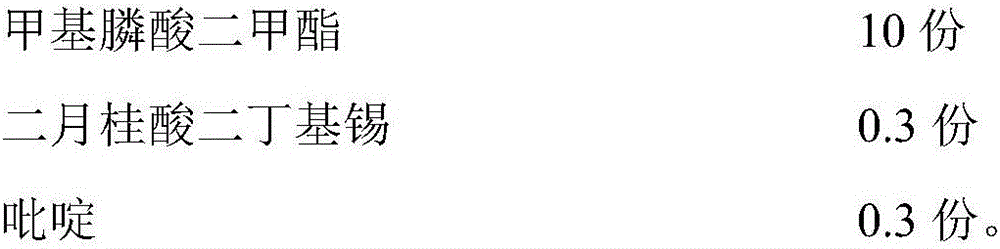

[0038] B component:

[0039]

[0040]

[0041] The components of component A and component B become two homogeneous liquids after being mixed and stirred. When using, component A and component B are mixed and poured to the position to be reinforced by a double-liquid pump at a volume ratio of 1:1. .

Embodiment 2

[0043] Prepare the polymer grouting reinforcement material according to the following ratio:

[0044] A component:

[0045]

[0046] B component:

[0047]

[0048] The components of component A and component B become two homogeneous liquids after being mixed and stirred. When in use, component A and component B are mixed and poured to the position to be reinforced by a double-liquid pump at a volume ratio of 1:1. .

Embodiment 3

[0050] Prepare the polymer grouting reinforcement material according to the following ratio:

[0051] A component:

[0052]

[0053]

[0054] B component:

[0055]

[0056] The components of component A and component B become two homogeneous liquids after being mixed and stirred. When in use, component A and component B are mixed and poured to the position to be reinforced by a double-liquid pump at a volume ratio of 1:1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com