Mine gas, blasting fume and dust separation ventilation system

A technology for dust separation and coal mine gas, which is used in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc. It can solve problems such as harming workers' health and potential safety hazards, and avoid harming workers' health and various safety issues. Hidden danger, shortened ventilation distance, and the effect of solving air quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

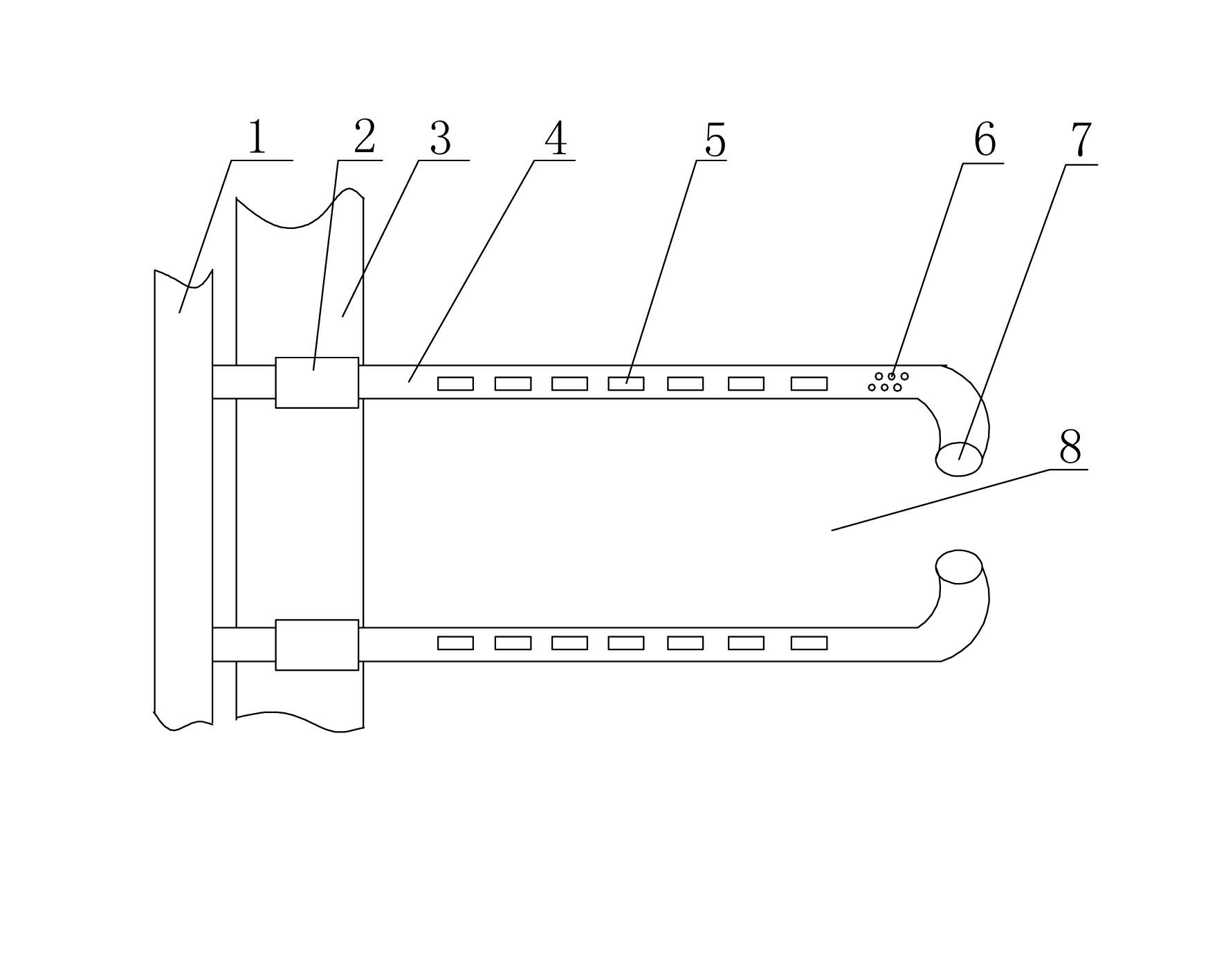

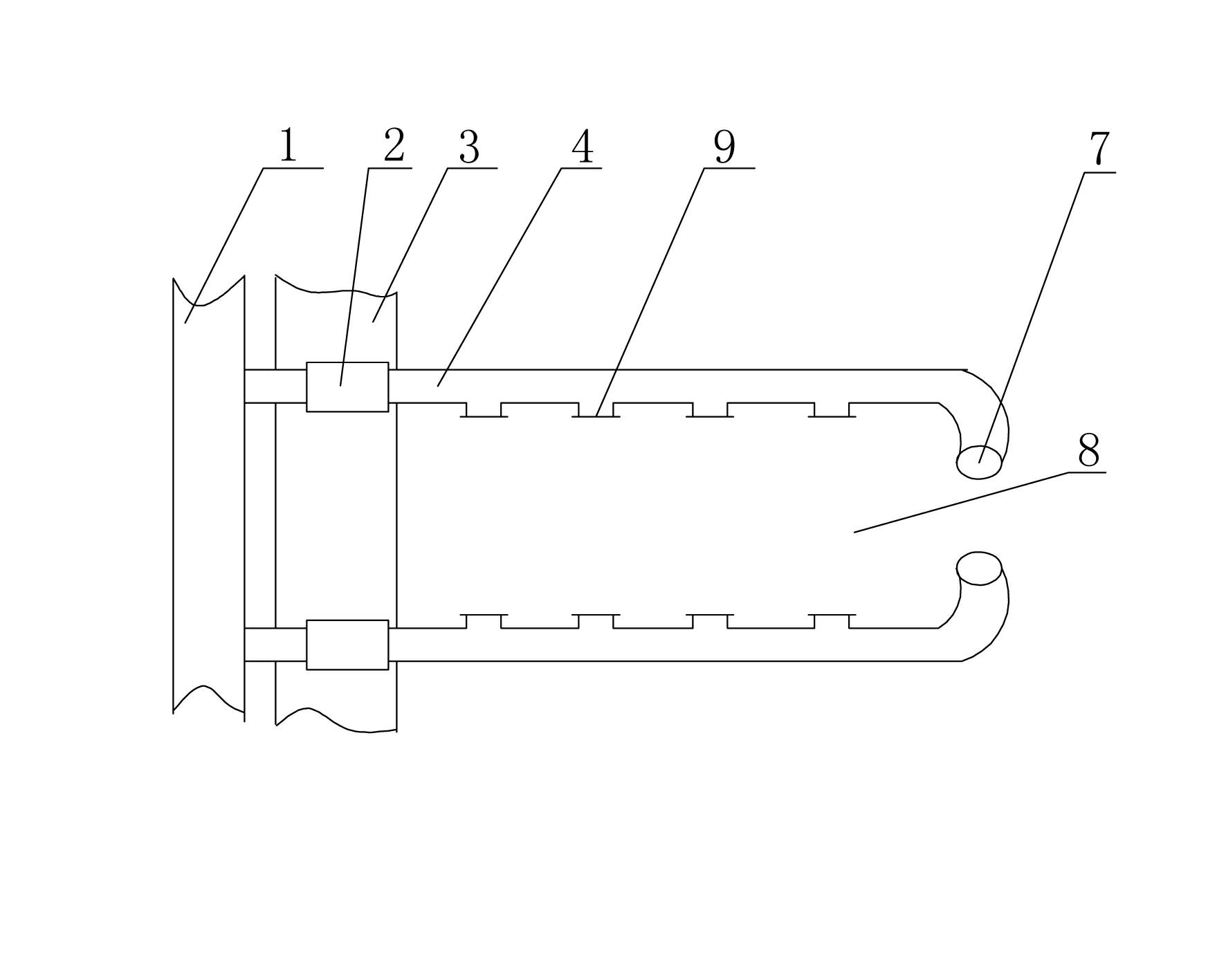

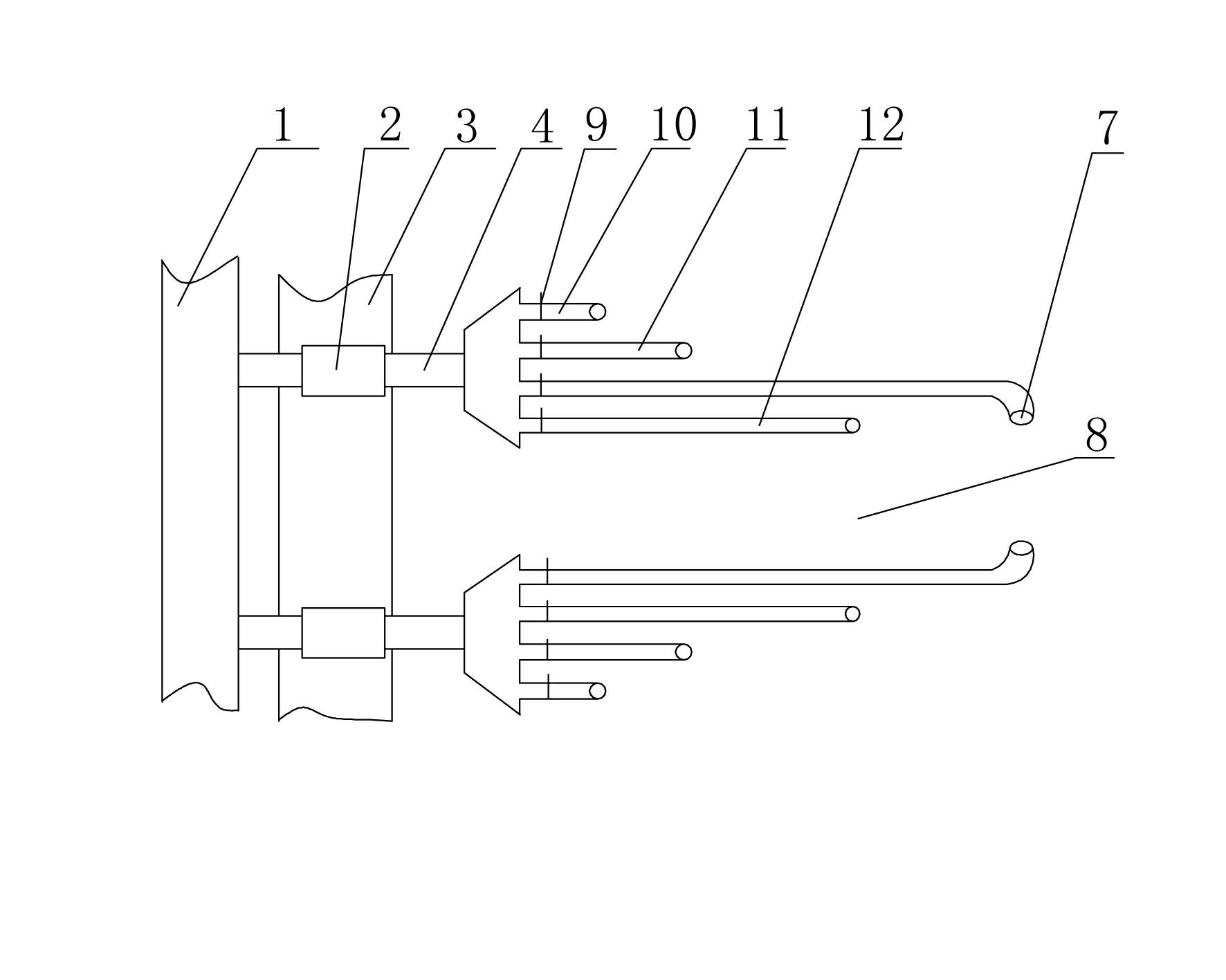

[0028] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as figure 1 , 2 , 3, the coal mine gas, gun smoke, and dust separation ventilation system of the present invention include a blower fan 2 and a discharge chimney, and are characterized in that the top of the coal mine main roadway 3 is provided with a main return air connected to the discharge chimney Passage 1, on the top of the branch roadway on both sides of each stope 8 of the coal mine, a branch return passage 4 connected with the main return air passage 1 is provided to form a multi-inlet and multi-return air system in the stope 8. The blower fan 2 is set at the connection between the return air channel 4 and the main return air channel 1,

[0030] The multi-inlet and multi-return system is a system composed of 2-5 air inlet channels and corresponding 2-5 return air channels. figure 1 , 2 , The embodiment show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com