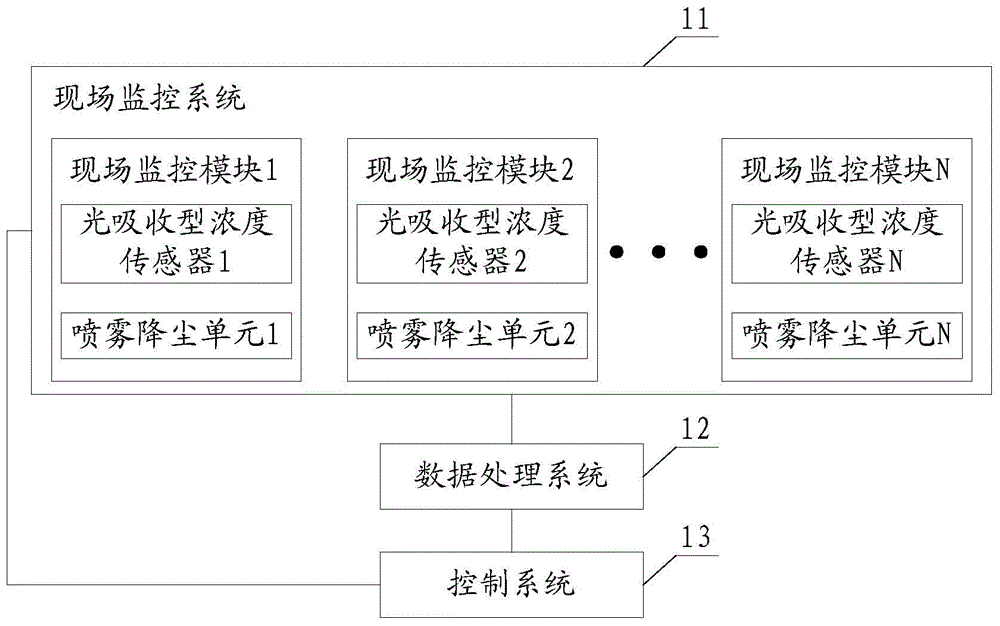

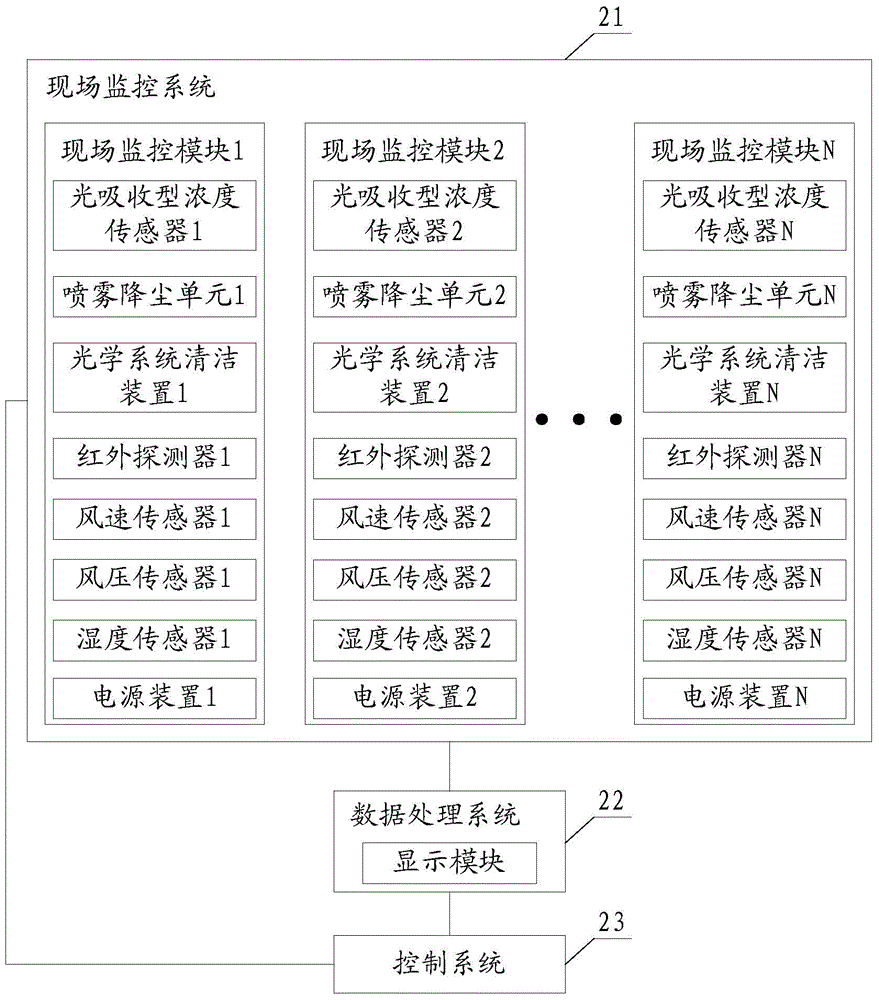

Coal mine dust monitoring system and method

A monitoring system and control system technology, applied in the fields of dust prevention, mining equipment, mining equipment, etc., can solve the problems of poor real-time average dust concentration data, dust explosion, waste of water resources, etc., to avoid long-term spraying state, improve utilization The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the coal mine dust monitoring system disclosed in Embodiment 1, the light absorption type concentration sensor is a sensor that has undergone error correction processing in advance, so that the accuracy of the measured dust concentration data is higher; in addition, the light absorption type concentration sensor in this embodiment is Developed based on Lambert-Beer's law, in the case of low dust concentration on site, the optical absorption type concentration sensor developed based on Lambert-Beer's law can also maintain a high measurement accuracy; secondly, the sampling period of the optical absorption type concentration sensor For the self-adjusting sampling period, in different dust concentration environments, the light absorption concentration sensor can adopt an appropriate sampling period, which reduces unnecessary power consumption and is conducive to improving the working life of the sensor; further, the on-site monitoring module It also includes an infrared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com