Camera installation mechanism with anti-explosion function

A technology of installation mechanism and camera, applied in the camera body, photography, camera and other directions, can solve the problem of inability to meet the needs, and achieve the effect of perfect explosion-proof effect, improve camera effect, and excellent monitoring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

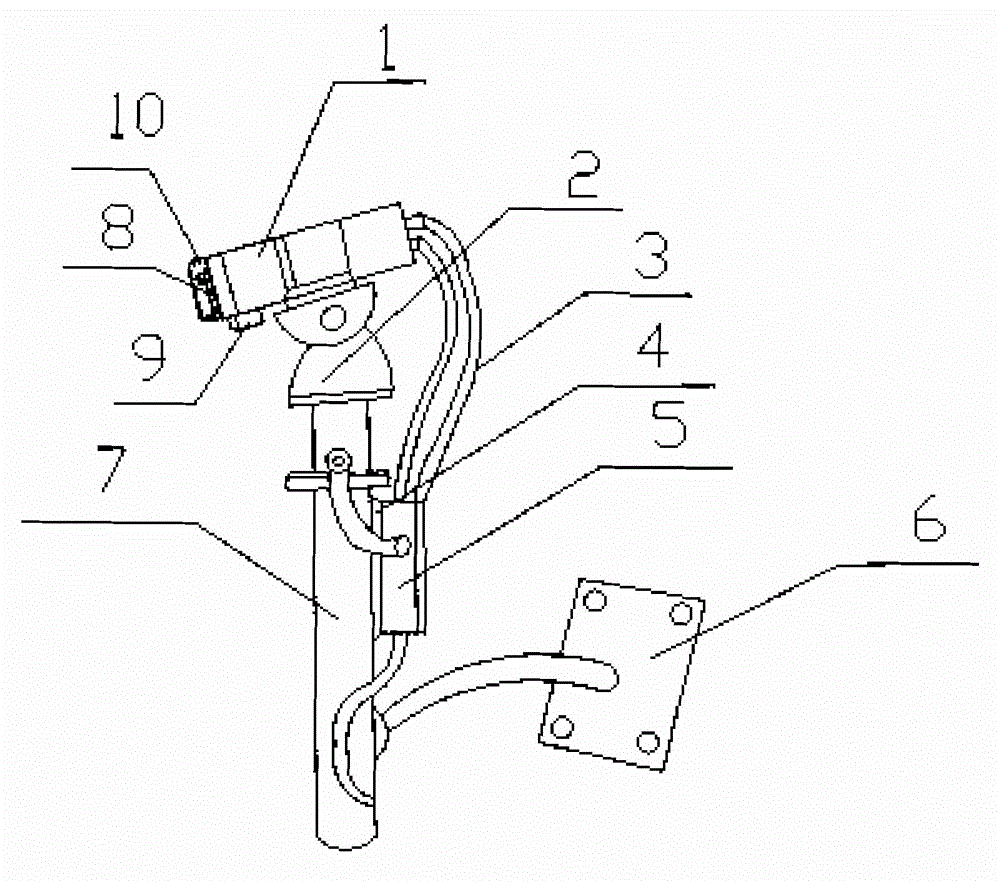

[0018] Such as figure 1 As shown, the present invention includes an explosion-proof shield 1, an explosion-proof electric platform 2, a junction box 5, a mounting base plate 6, a mounting bracket 7 and a wiper 8, and the explosion-proof shield 1 is installed on the top of the explosion-proof electric platform 2, and the explosion-proof electric platform The bottom of the cloud platform 2 is installed on the mounting bracket 7, and a wiper 8 is also installed on the end face of the explosion-proof shield 1; a fixed steel plate 4 is also welded on the side of the mounting bracket 7, and the junction box 5 is fixedly installed on the fixed steel plate 4. The bottom side wall of the mounting bracket 7 is also provided with a mounting base plate 6, and the mounting bracket 7 can rotate around the connection end of the mounting base plate 6; the explosion-proof flexible pipe is connected between the explosion-proof shield 1 and the explosion-proof electric pan-tilt 2 and the junction...

Embodiment 2

[0021] The preferred specific structure of this embodiment on the basis of Embodiment 1 is as follows: the explosion-proof shield 1 is a hollow cuboid shield, and the infrared lamps 10 are distributed around the inner wall of the explosion-proof shield 1 and evenly distributed. Ensure that there is enough space inside to install the camera and infrared lamps. The uniformly distributed infrared lamps can give uniform infrared light to the camera installed in the middle of the explosion-proof shield to ensure the best monitoring effect at night.

[0022] The light sensor 9 is an HA2003 light sensor.

[0023] The thickness of the fixed steel plate 4 is between 6-7mm. It can better realize the fixing of the junction box, and make the junction box have better explosion-proof ability.

[0024] The junction box 5 is also connected with power lines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com