Smelting apparatus and method for smelting metal materals

A technology of metal materials and smelting equipment, applied in the field of smelting, can solve problems such as high cost, unstable quality of alloy materials, complex process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

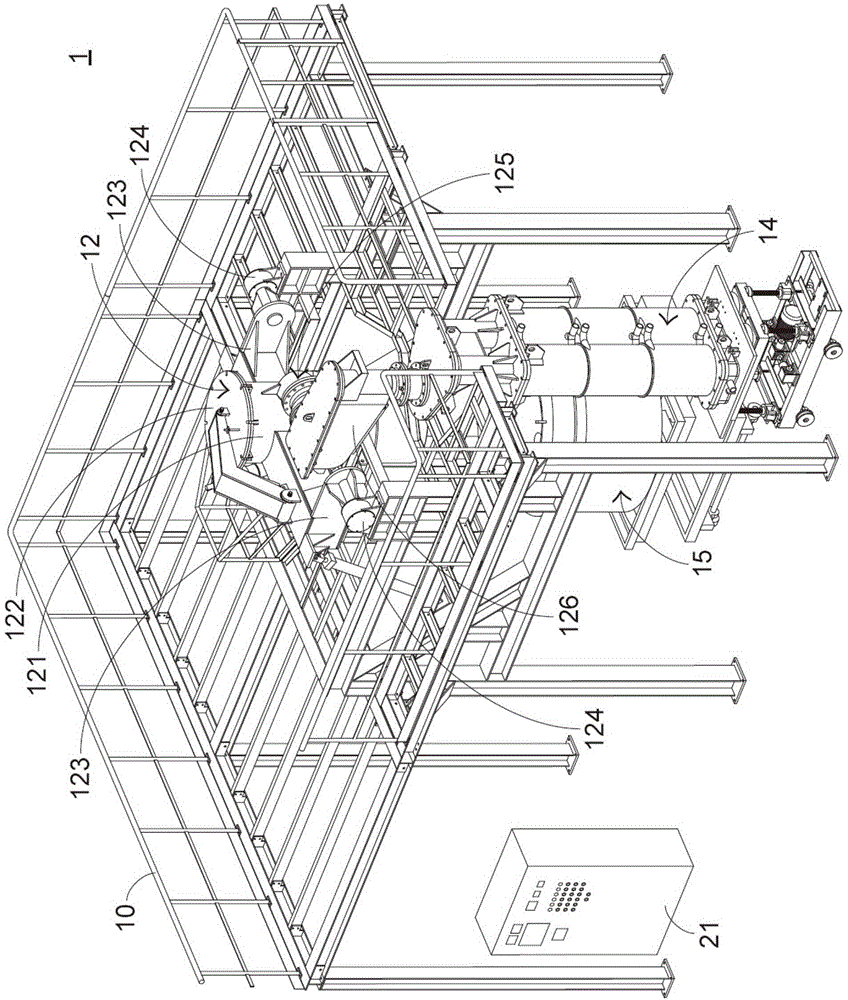

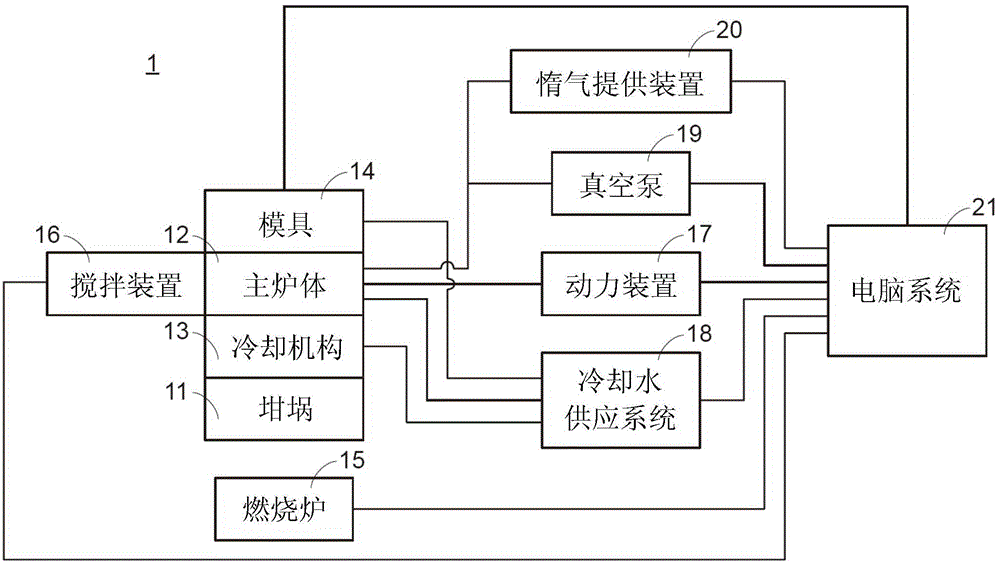

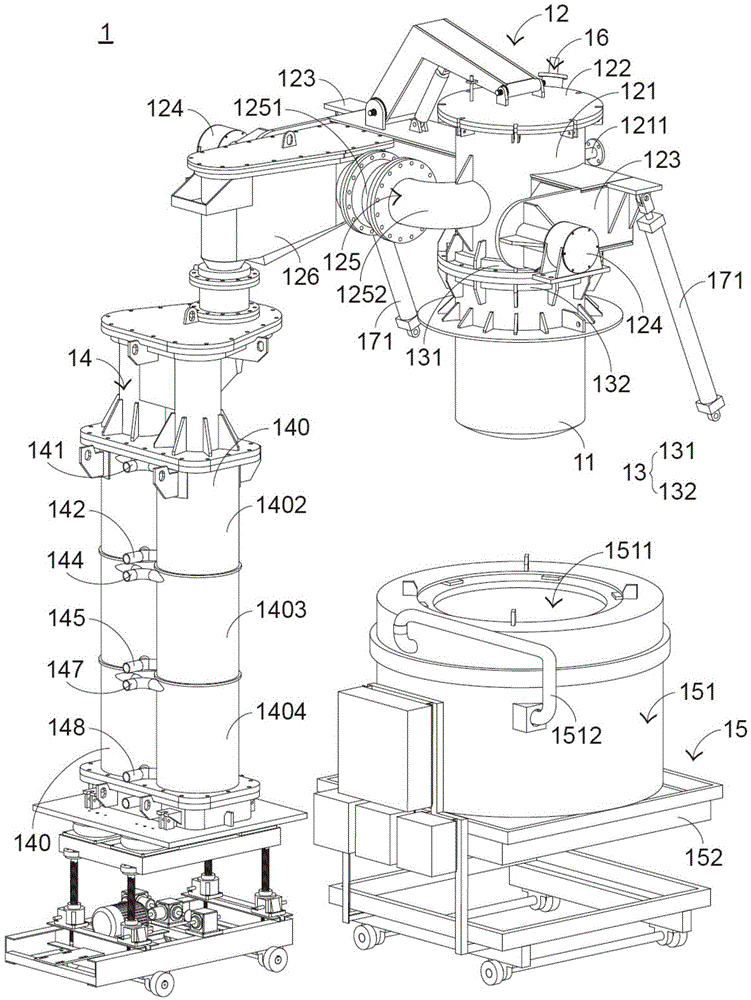

[0089] In view of the problems caused by the prior art, the present invention provides a smelting equipment and a method for smelting metal materials. Firstly, the structure of the smelting equipment is explained, please also refer to figure 1 , figure 2 as well as image 3 , figure 1 It is a schematic structural view of the smelting equipment of the present invention in the first preferred embodiment, figure 2 It is a schematic block diagram of the smelting equipment of the present invention in the first preferred embodiment, and image 3 It is a partial structural schematic diagram of the first preferred embodiment of the smelting equipment of the present invention. The smelting equipment 1 of the present invention includes a working platform 10, a crucible 11, a main furnace body 12, a cooling mechanism 13, a mold 14, a combustion furnace 15, a stirring device 16, a power device 17, a cooling water supply system 18, a vacuum pump 19, and an inert gas supply device 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com