Patents

Literature

68 results about "Worker health" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

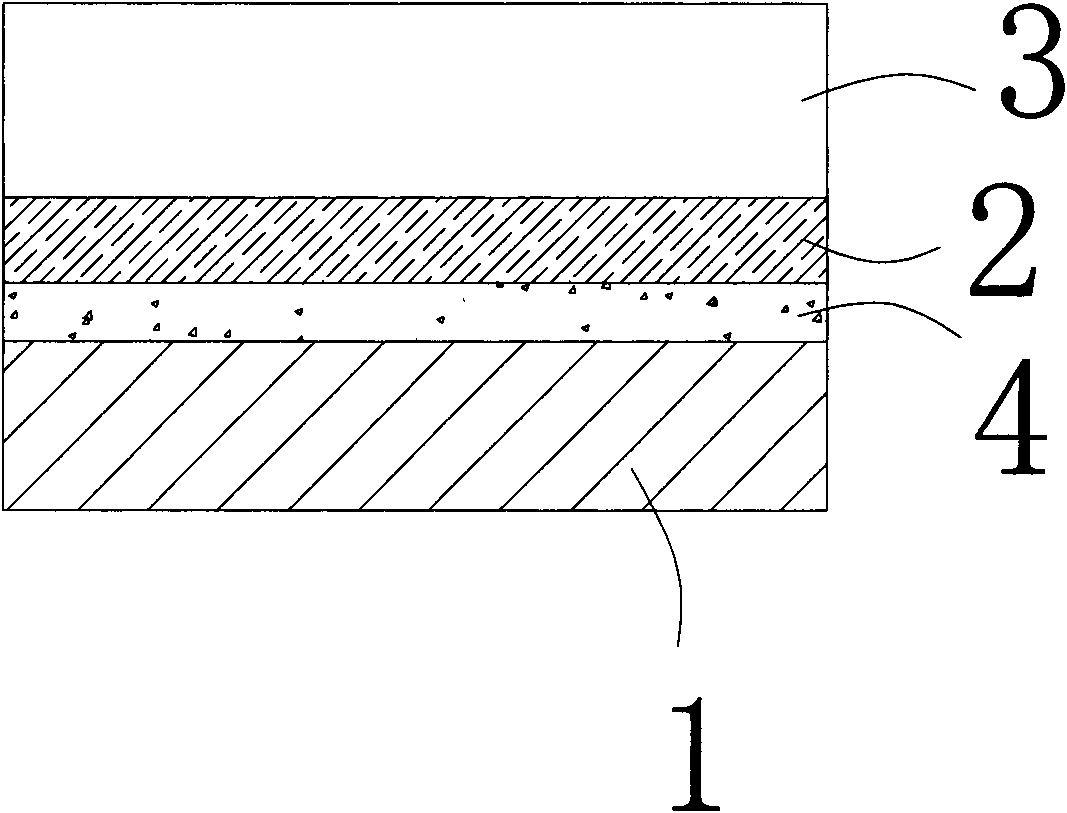

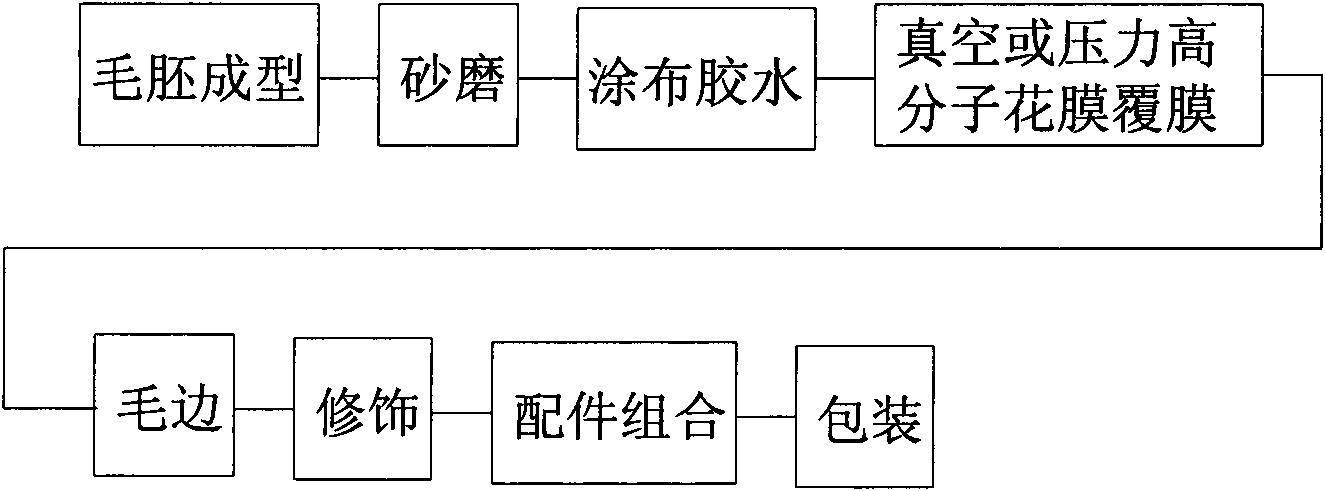

Toilet cover and surface coating technique thereof

InactiveCN101664289ASave storage spaceEasy to rule outDecorative surface effectsSpecial ornamental structuresEngineeringRoughcast

The invention relates to a toilet cover and a surface coating technique of other complete bathroom accessories. The technique comprises the following steps: rough machining, sanding, coating and gluing, vacuum coating or pressure high polymer printing film applying, burr trimming, decorating, accessories assembling and packaging. In respect of the production technique, the original high polymer printing film is taken as a production mold, thus causing the mold to be the external surface of a product, without painting for surface finishing and decorating. In such a way, environmental pollutionand impact on worker health caused by sanding and painting spraying and decorating can be avoided during the manufacturing process of a wooden closestool and other complete bathroom accessories, thuscompletely overcoming the disadvantages of sanding and spraying of traditional technique, simplifying production processes and beautifying the surface decoration of the product. An LED illuminant canalso be embedded to beautify the surface of the product.

Owner:周廷芳

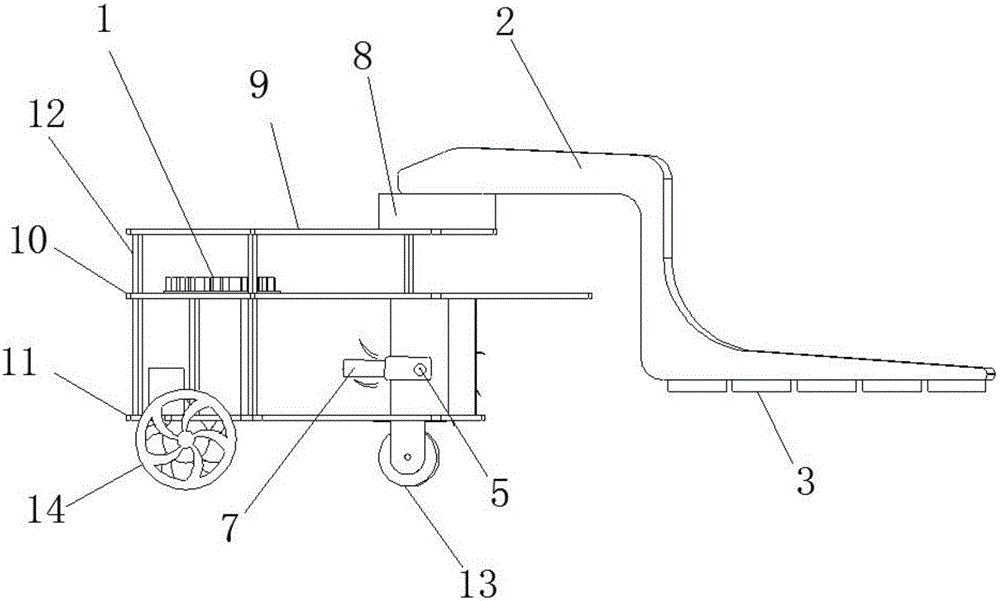

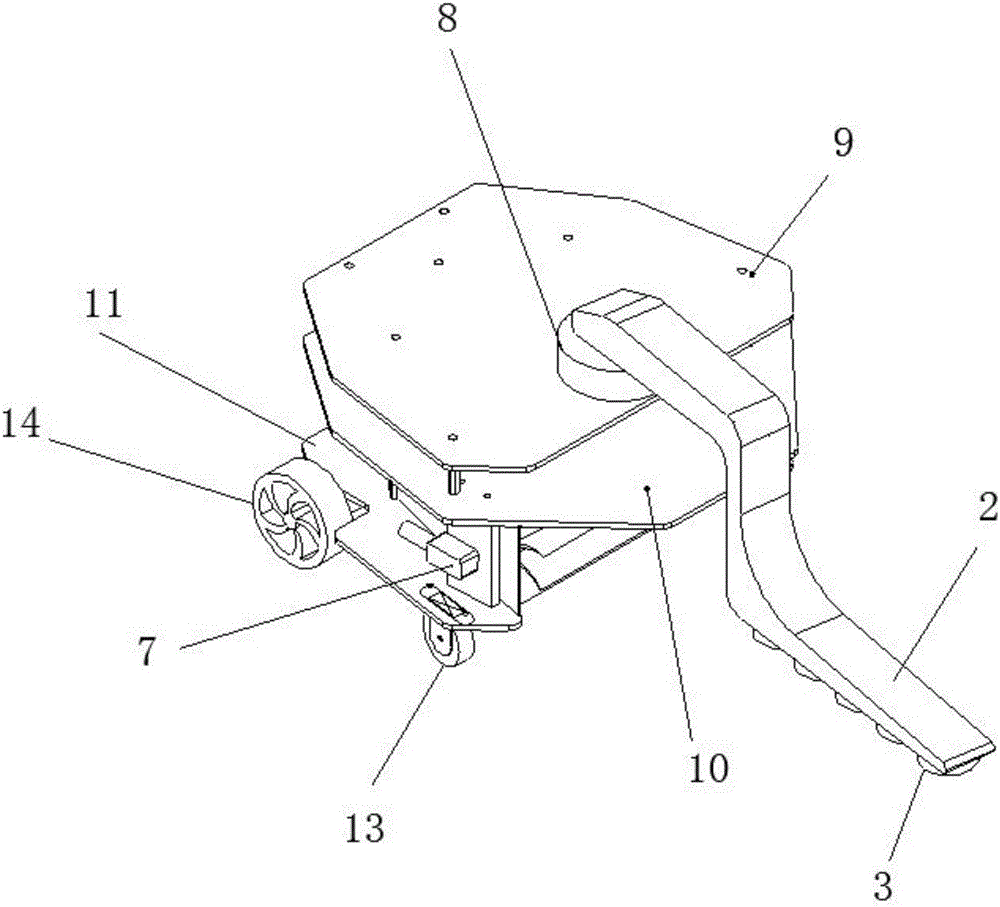

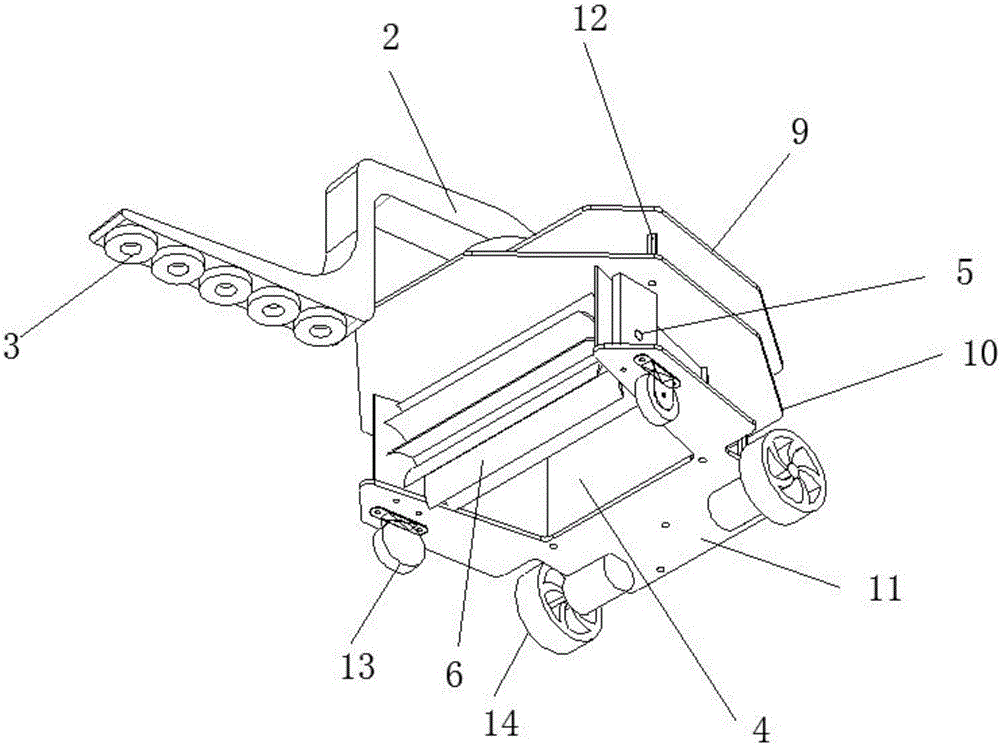

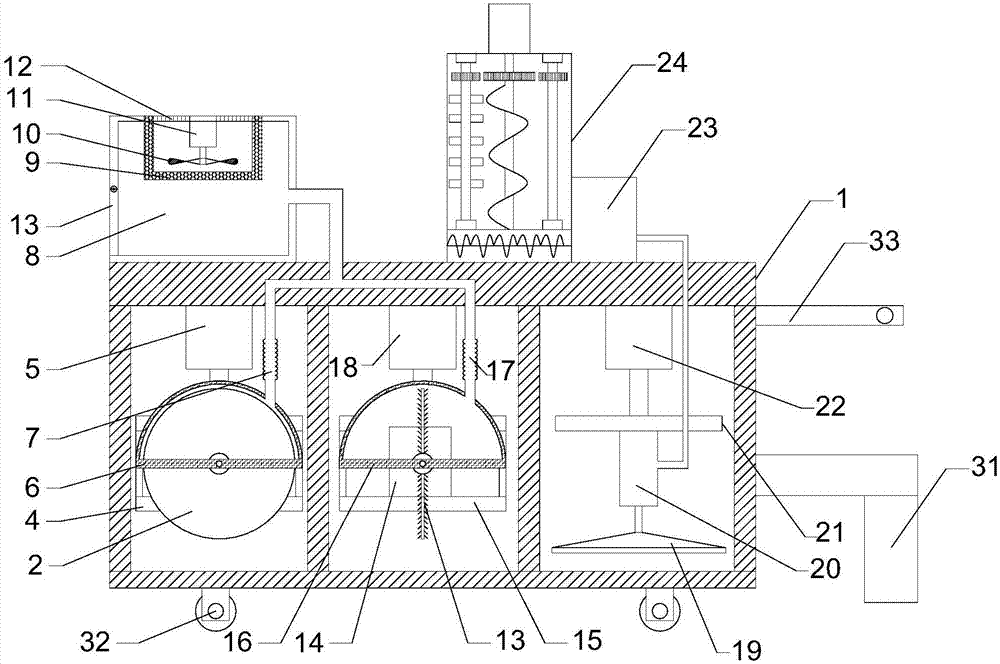

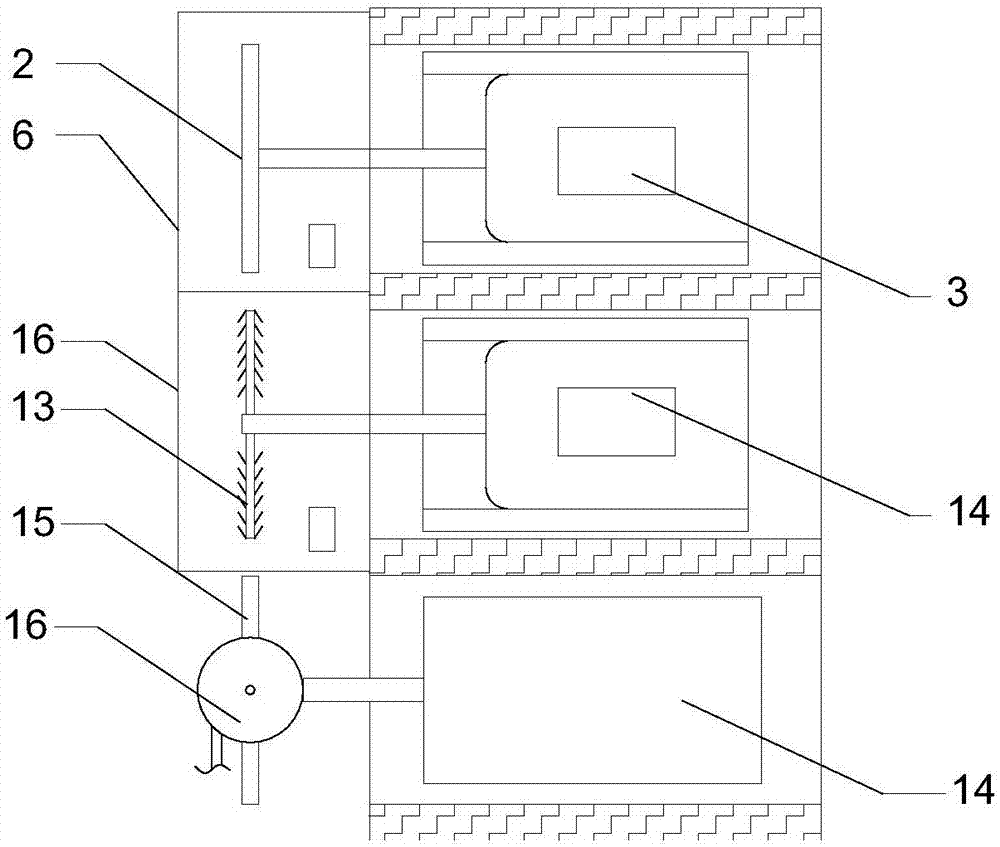

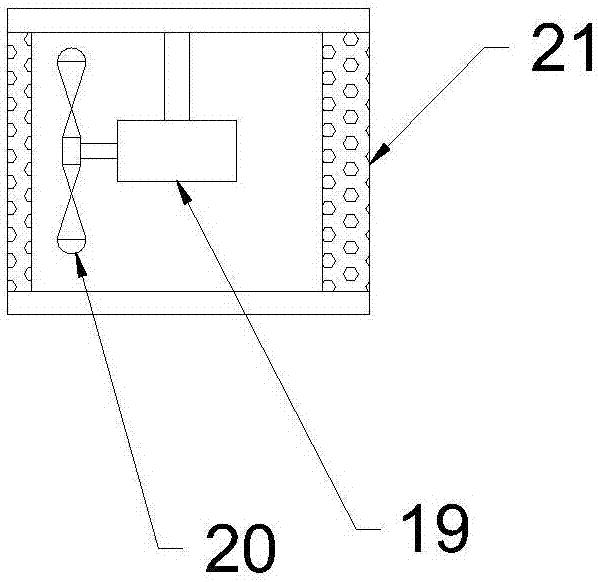

Workshop intelligent ground cleaning robot

The invention relates to a workshop intelligent ground cleaning robot which includes a walking vehicle body, a sweeping apparatus and a collection mechanism. The sweeping apparatus includes a robot arm which rotates towards the two sides of the vehicle body so as to absorb iron fillings on the ground in the periphery of the vehicle body through a first electromagnet. The sweeping apparatus also includes the collection mechanism which is disposed below the front part of the vehicle body and at a place corresponding to the robot arm. Inside the vehicle body, a collection cabin is arranged corresponding to the position of the collection mechanism. The collection mechanism is intended for collecting the iron fillings absorbed by the first electromagnet to the inside of the collection cabin. An electric control apparatus is also arranged inside the vehicle body for controlling the walking of the vehicle body, the rotation of the robot arm, the on and off of the first electromagnet, and operation of the sweeping mechanism. According to the invention, the cleaning robot has the following beneficial effects: the cleaning robot can conduct thorough cleaning on the workshop ground, improves working environment of the workshop, is conductive to guaranteeing worker health, saves labor in the entire cleaning work, and has high working efficiency.

Owner:GUILIN UNIV OF ELECTRONIC TECH

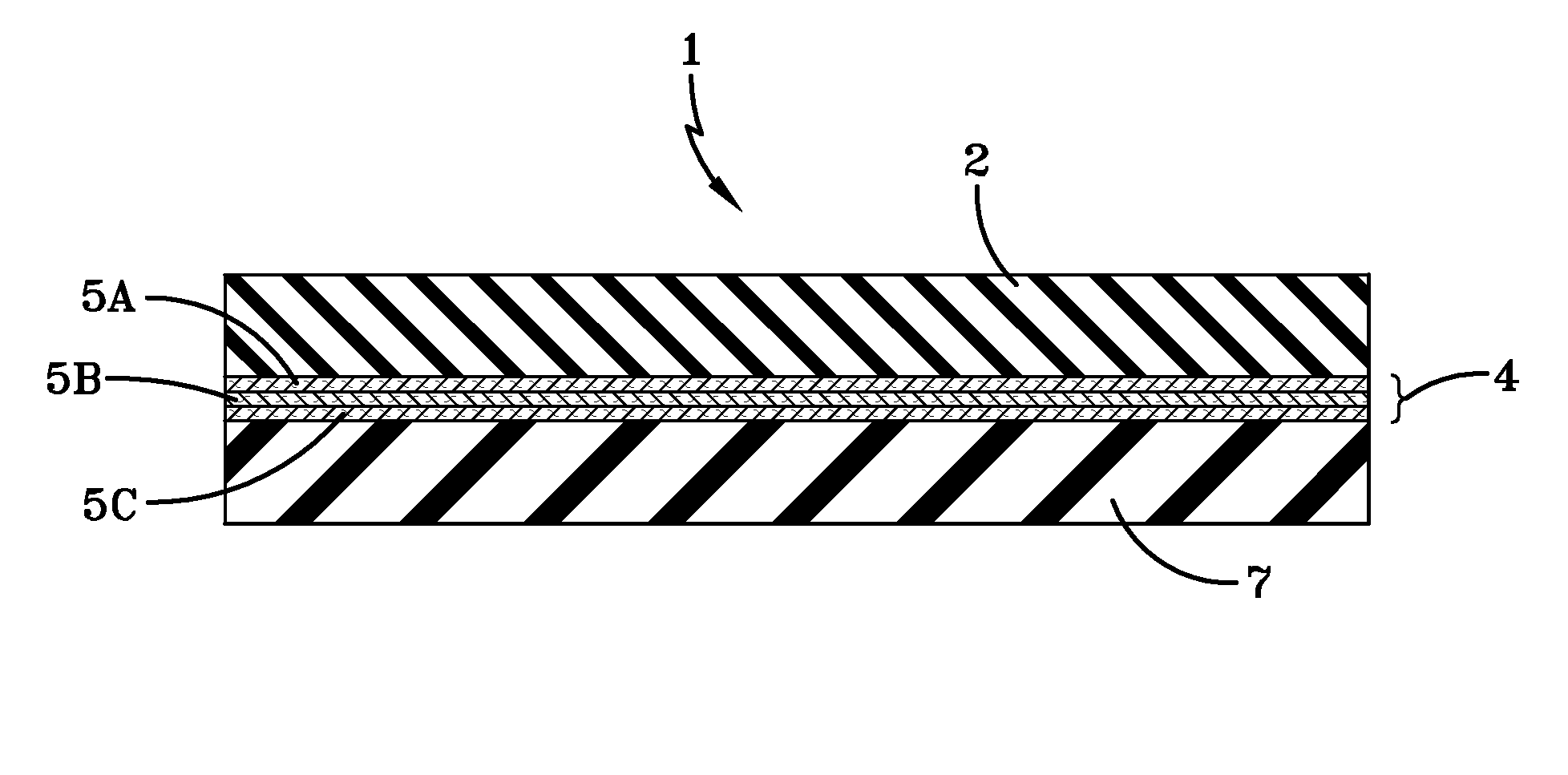

Conveyor belt

The present invention is based upon the discovery that neodymium polybutadiene rubber can be built onto heavy duty conveyor belts as a carry cover layer to greatly improve the wear resistance of the belt. Such heavy duty conveyor belts are of particular value for utilization in the mining of iron ore, copper ore, coal, and other abrasive materials. These belts accordingly offer a longer service life, reduce mine down-time, reduce costs, and improve overall mine productivity without having an adverse effect on worker health or safety, and without detrimentally impacting the environment. The present invention more specifically discloses a conveyor belt which is comprised of a carry cover layer, a reinforcement layer which is situated below the carry cover layer, and a pulley cover layer which is situated below the reinforcement layer, wherein the carry cover layer is comprised of neodymium polybutadiene rubber.

Owner:CONTITECH USA INC

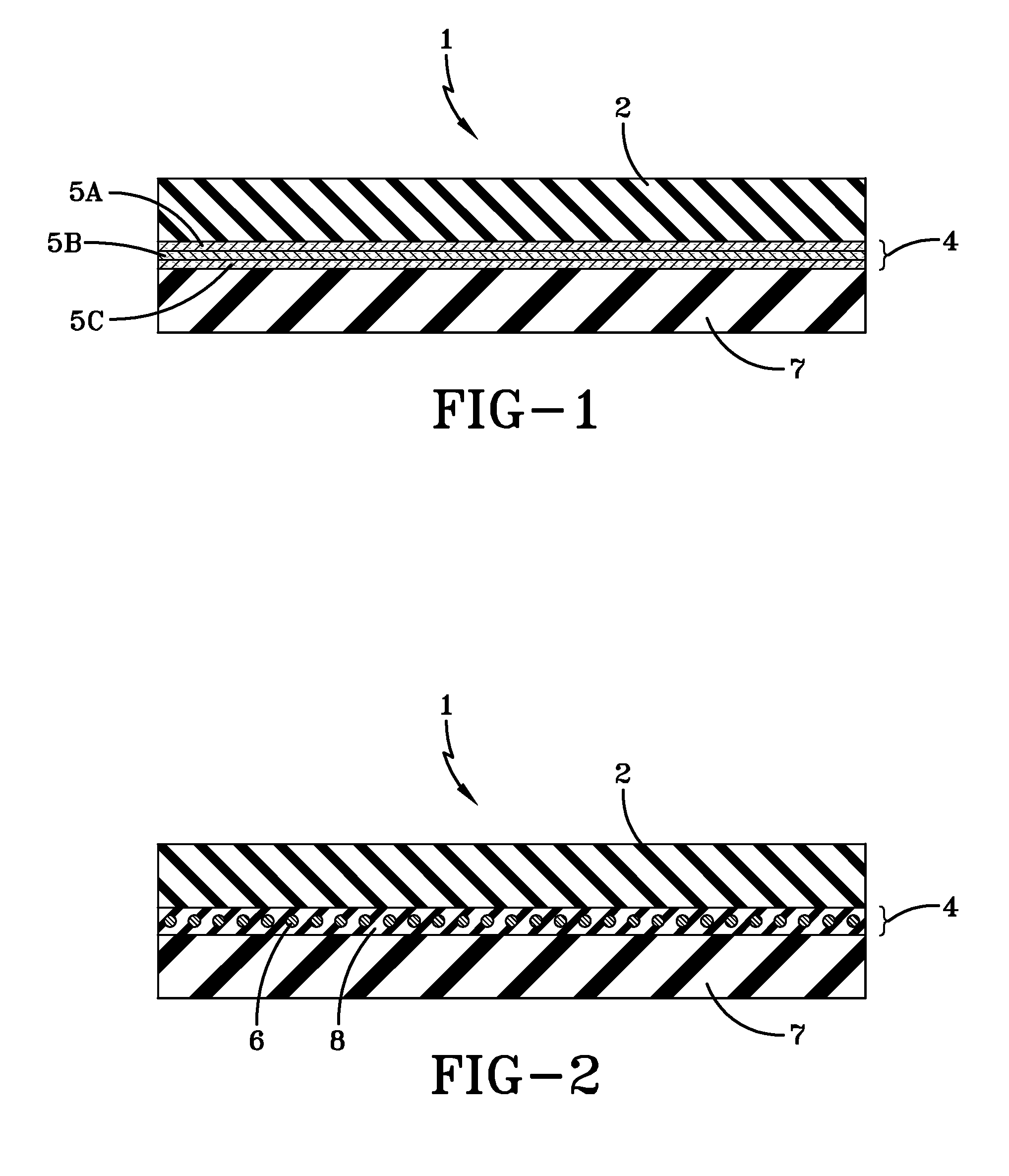

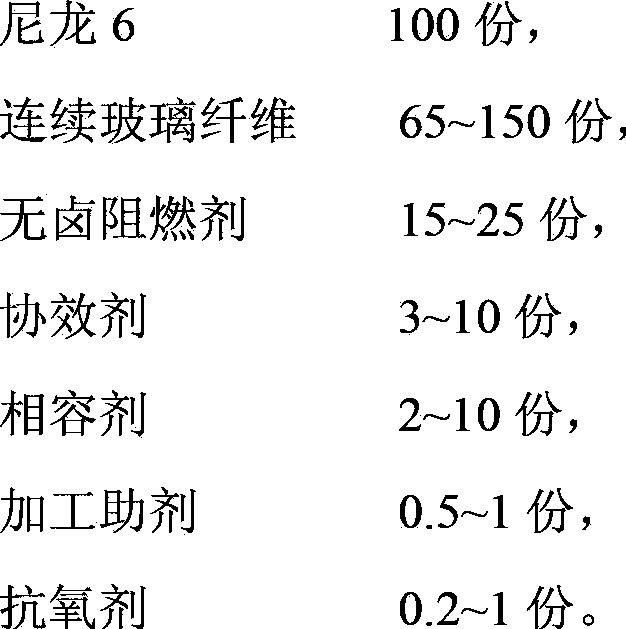

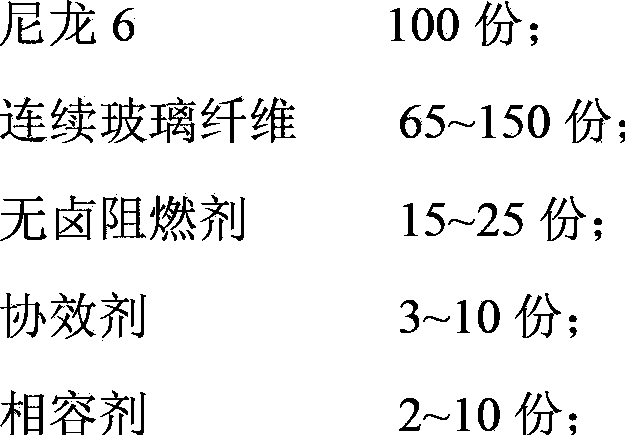

Continuous glass fiber reinforced halogen-free fire retardation nylon 6 prepreg tape and preparation method thereof

InactiveCN103865255ASolve the \"Secondary Disaster\"Solve the technical problem of releasing carcinogenic substancesBeltsGlass fiberHydrogen halide

The invention belongs to the field of polymer materials and molding processing thereof, and relates to a continuous glass fiber reinforced nylon 6 prepreg tape and a preparation method thereof. The continuous glass fiber reinforced halogen-free fire retardation nylon 6 prepreg tape is prepared from the following components by weight: 100 parts of nylon 6, 15-25 parts of a halogen-free fire retardation agent, 3-10 parts of a synergist, 2-10 parts of a compatibilizer, 0.5-1 part of a processing auxiliary agent, and 0.2-1 part of an antioxidant. Compared with the continuous glass fiber reinforced halogen-free fire retardation nylon 6 prepreg tape, the continuous glass fiber reinforced halogen-free fire retardation nylon 6 prepreg tape of the present invention has the following characteristics that: the technical problem of secondary disaster and carcinogenic substance release on production and environment due to dense smoke and hydrogen halide gas produced during fire retardation can be solved, and the production process does not require the solvent so as to reduce environmental pollution and hazard on production worker health and reduce corrosion on equipment.

Owner:LIAONING LIAOJIE SCI & TECH

Municipal road cutting and joint filling device

InactiveCN107366216AImprove perfusion effectImprove liquidityRoads maintainenceEngineeringMechanical engineering

The invention discloses a municipal road cutting and filling device, which comprises a car body; a cutting wheel is arranged on the left side of the car body, and a first dust collecting cover is set on the outer side of the cutting wheel, and the first dust collecting cover passes through the first The bellows is connected with a vacuum box; the right side of the cutting wheel is provided with a brush strip; the right side of the brush strip is provided with a caulking agent injection gun. The present invention is equipped with a cutting wheel and a caulking agent pouring device, and completes the cutting of the road and the pouring of the caulking agent in one operation, with higher operating efficiency and better effect of filling the caulking agent; the present invention is provided with a brush strip The dust cleaning device matched with the dust collection cover and the dust collection box can efficiently collect the dust generated by cutting and clean the cutting seam efficiently, which not only protects the working environment and the health of workers, but also keeps the cutting seam clean and can be Fill the caulk directly to ensure the quality of the filling.

Owner:卢杰

Stainless steel pickling passivation paste and preparation method thereof

InactiveCN103225087AHarm reductionKeep healthyMetallic material coating processesHydrofluoric acidMaterials science

The invention discloses a stainless steel pickling passivation paste and a preparation method thereof. The technical point of the invention is that: the stainless steel pickling passivation paste is mainly composed of, by weight, 10-30 parts of a corrosion agent, 20-60 parts of a passivation agent, 10-30 parts of a gelling agent, 40-60 parts of an inorganic filling material, and 1-5 parts of a penetration agent. The invention also discloses a preparation method of the stainless steel pickling passivation paste. During an application process, the stainless steel pickling passivation paste does not release hydrofluoric acid, causes low harm to the environment, and does not harm the skin. Therefore, worker health is ensured, and various welds, oxide scales and rust on the surface of stainless steel can be effectively removed. The stainless steel pickling passivation paste is a green, environment-friendly, and highly efficient product.

Owner:HENAN NORMAL UNIV

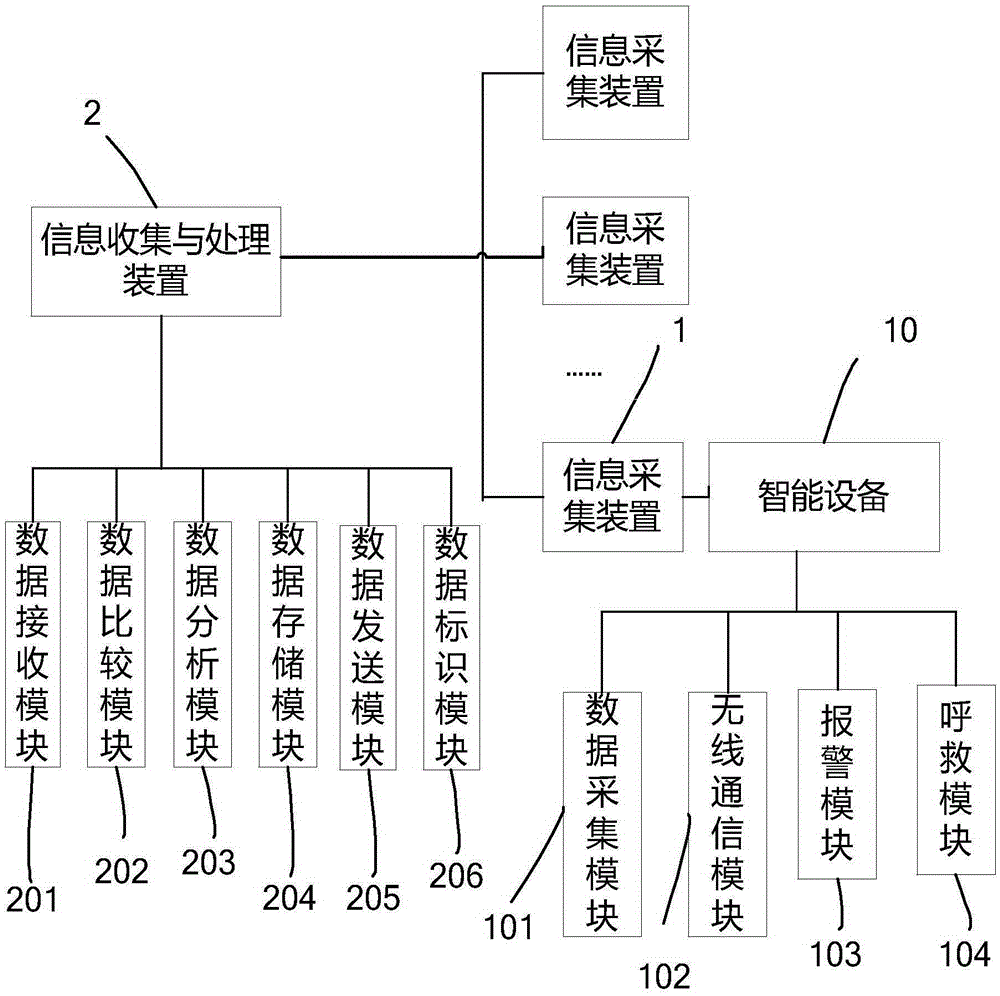

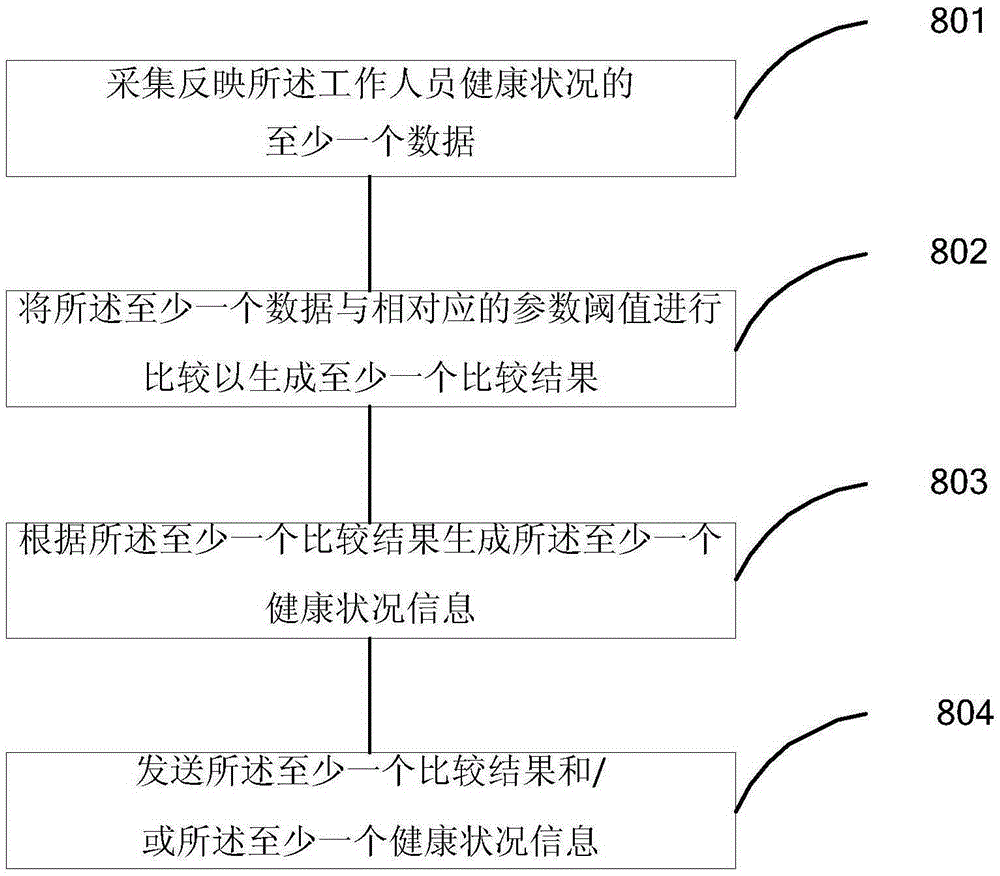

Rail transit train worker health condition monitoring system and method

The invention relates to a rail transit train worker health condition monitoring system, which comprises an information acquisition device and an information collection and processing device, wherein the information acquisition device acquires and sends at least one datum reflecting health conditions of a worker; the information collection and processing device receives the at least one datum from the information acquisition device to generate a corresponding at least one piece of health condition information; and the information acquisition device and the information collection and processing device are connected in a wireless mode. The invention also relates to a method of executing the above system.

Owner:BEIJING JIAOTONG UNIV

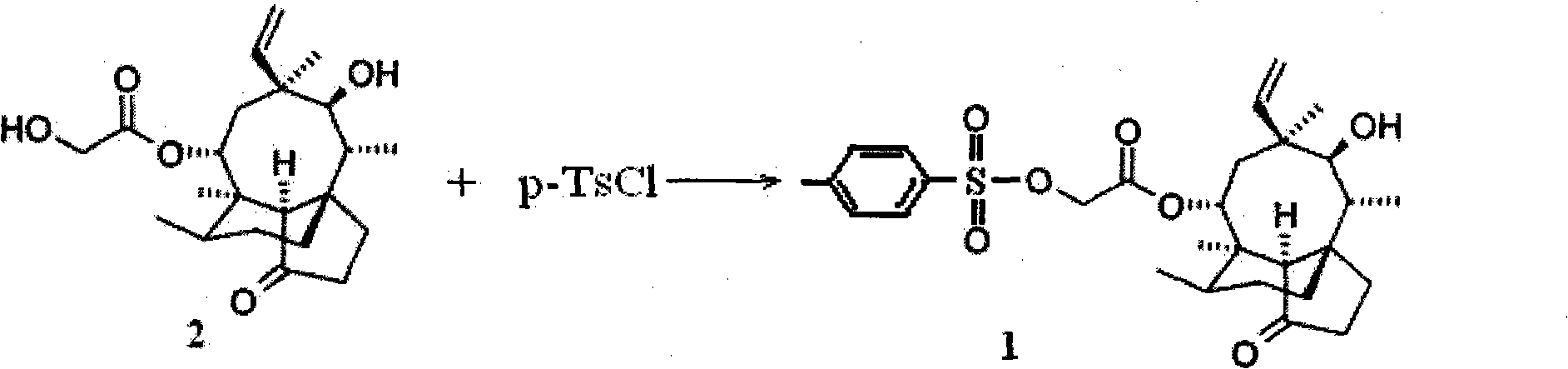

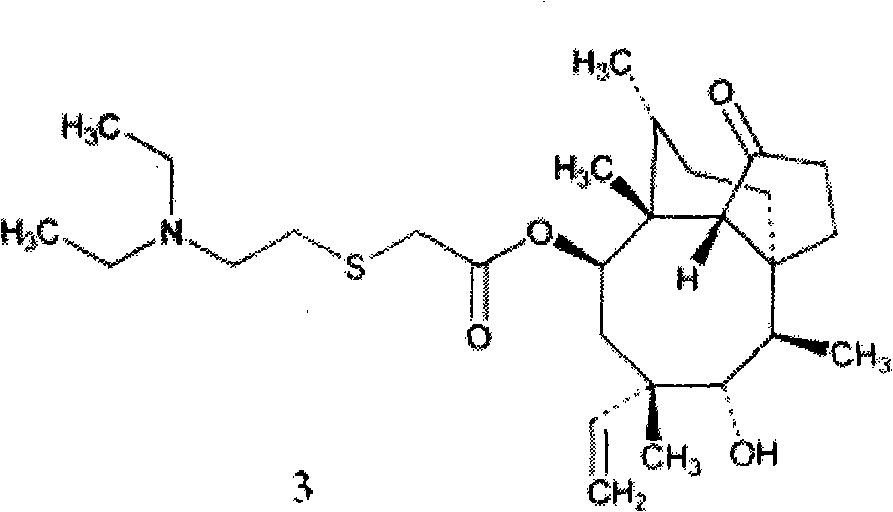

Synthesis method of p-toluene sulfonic acid pleuromutilin ester

InactiveCN103450057AGood for healthLow priceSulfonic acid esters preparationTosylic acidDistillation

The invention relates to a synthesis method of p-toluene sulfonic acid pleuromutilin ester. Especially, the method includes: under catalysis of three inorganic alkalis, i.e. sodium hydroxide, potassium hydroxide or sodium carbonate, reacting pleuromutilin with p-toluenesulfonyl chloride for 0.5-1.5h in a methyl isobutyl ketone solvent at 50-65DEG C, conducting washing and distillation of the solvent, thus obtaining the p-toluene sulfonic acid pleuromutilin ester with yield of 95-96.5% and chromatographic purity of 97-98.1%. The method has the advantages of environmental-friendliness, worker health promotion, low production cost, short synthesis reaction time and high yield.

Owner:大英九合药业有限公司

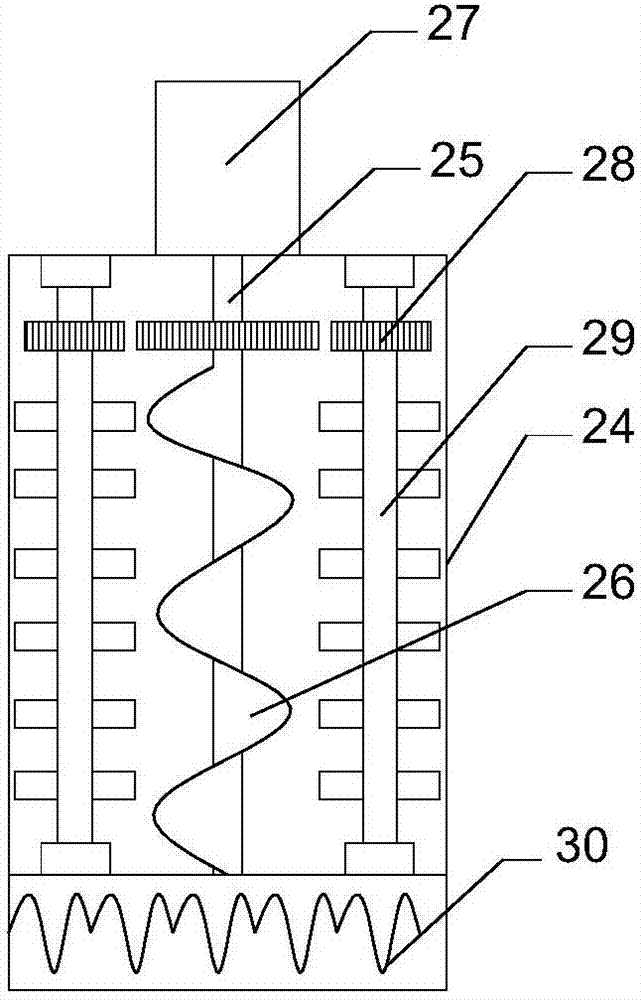

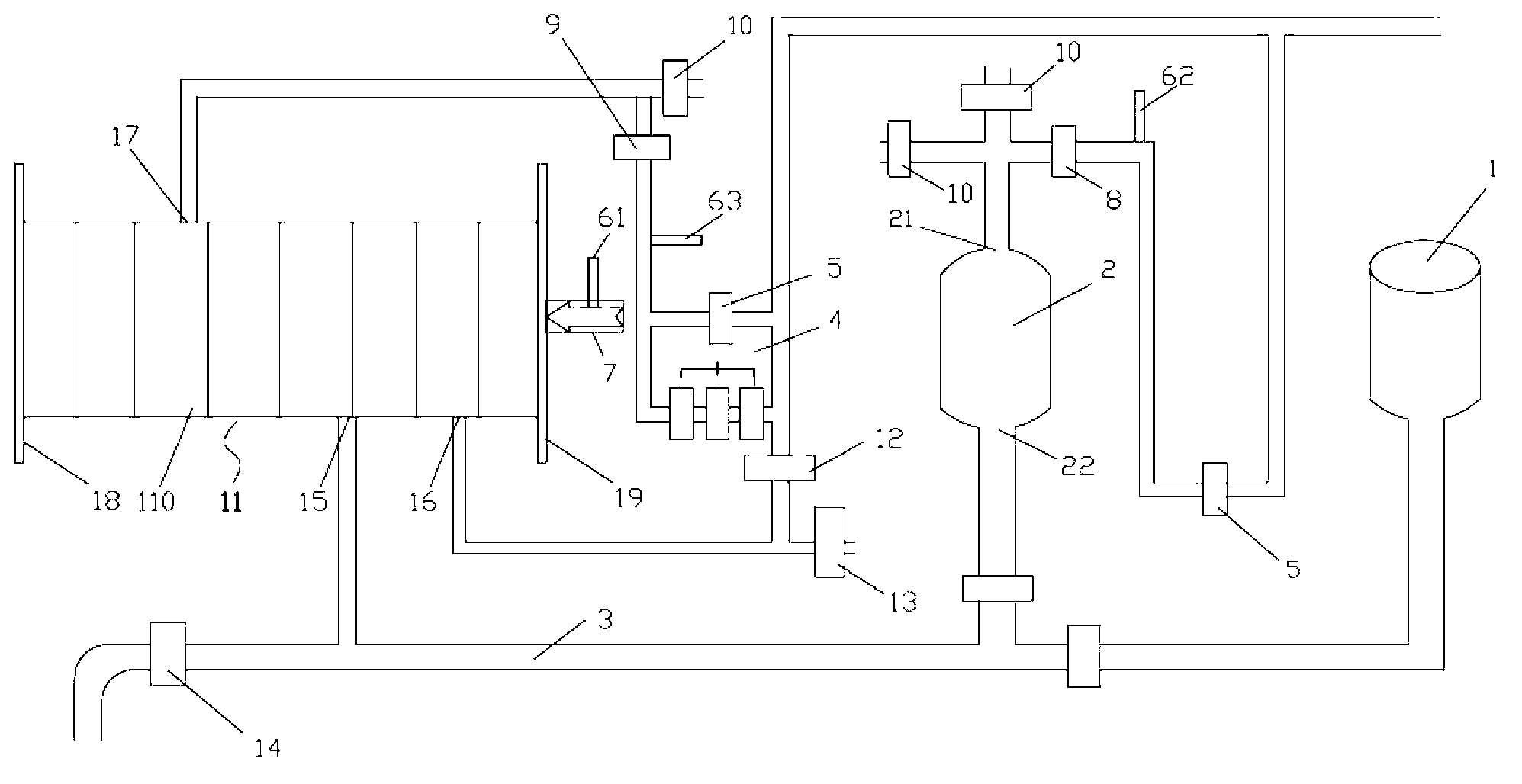

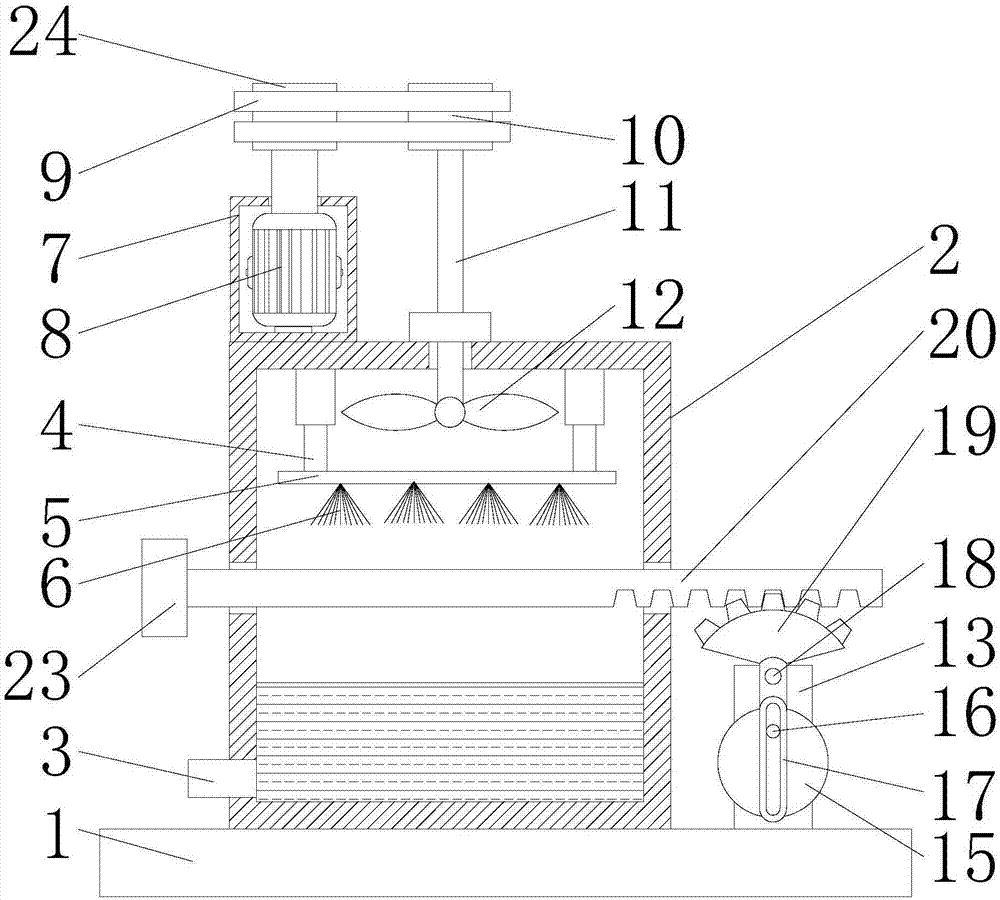

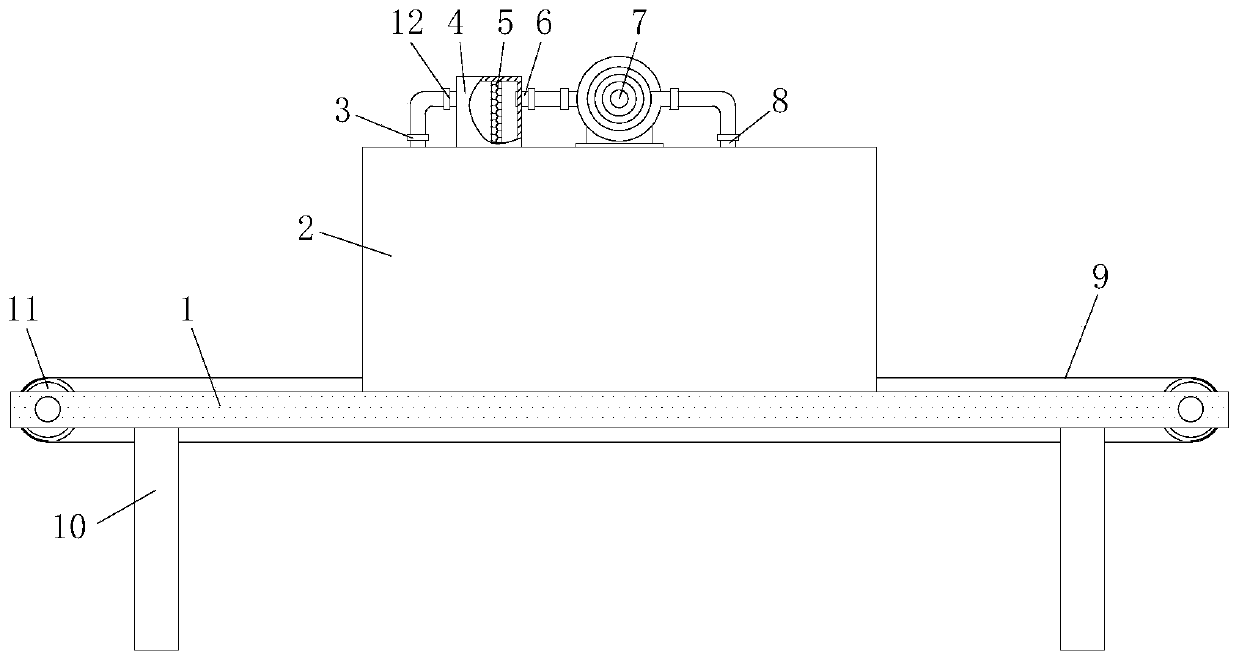

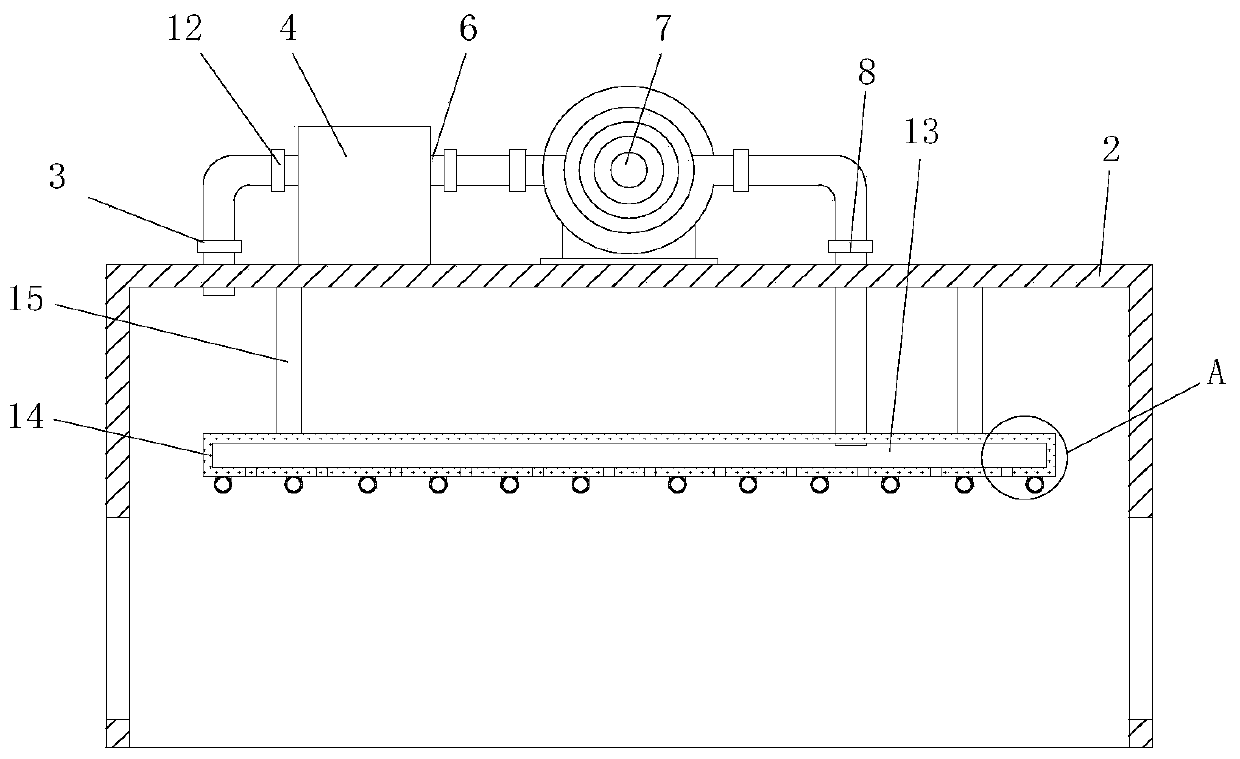

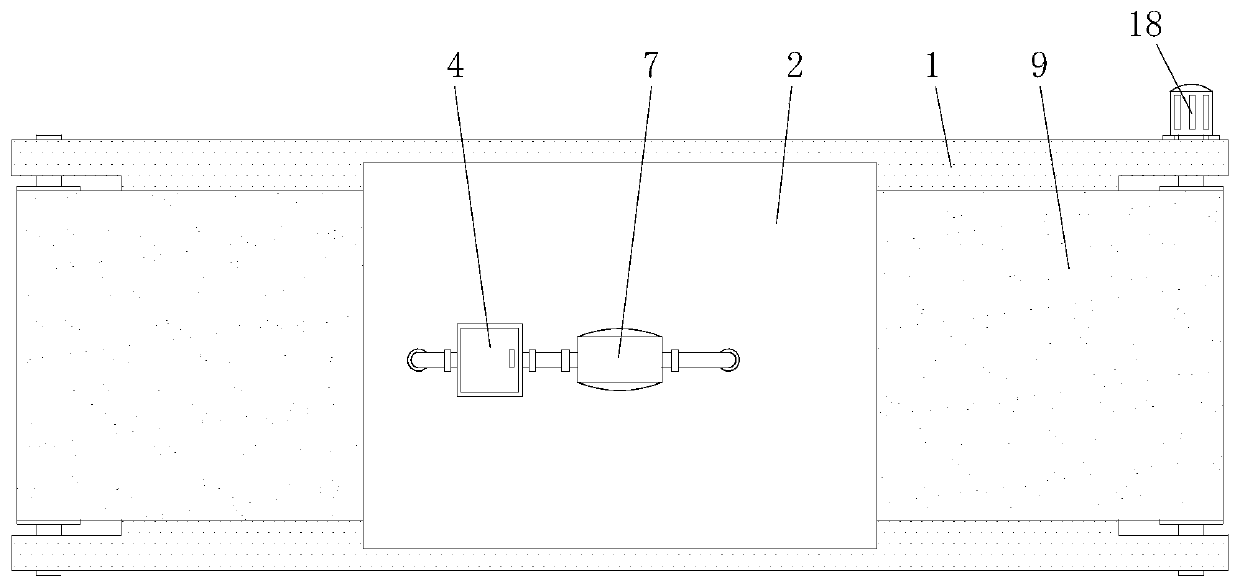

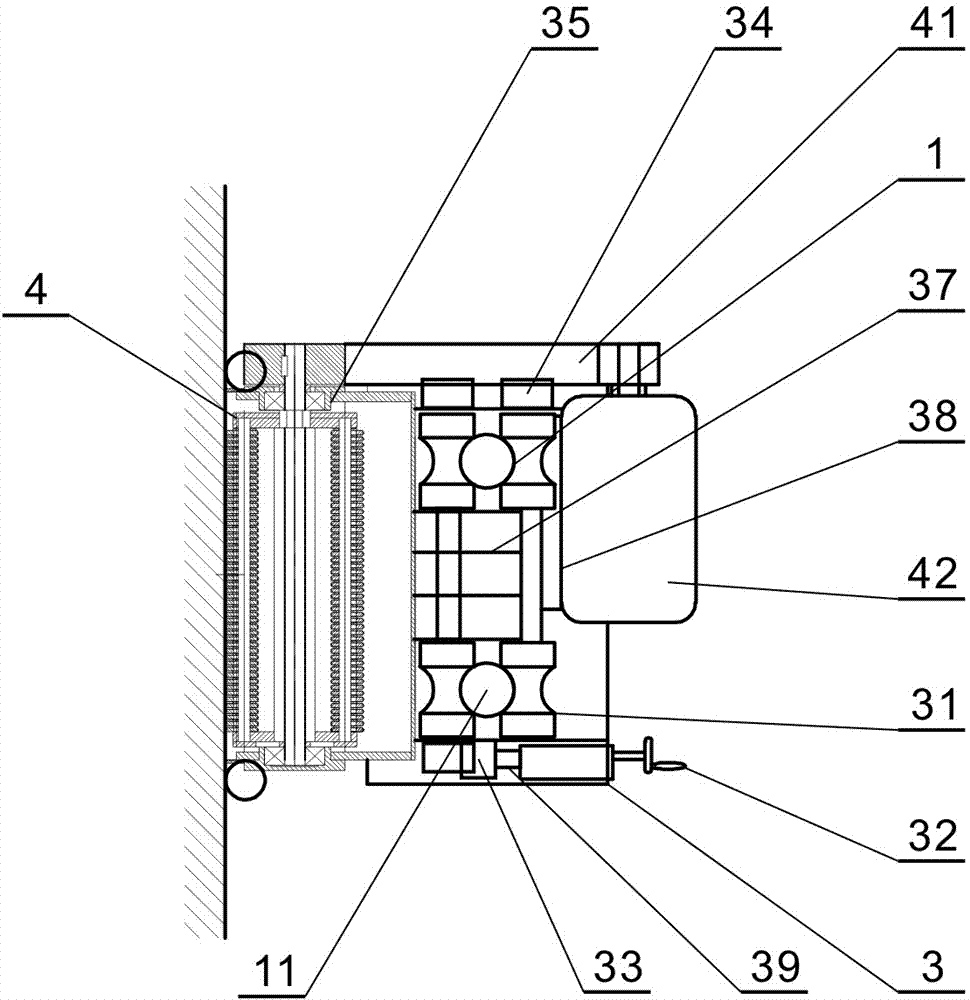

Ceramic medium-and-low pressure slip-casting device

InactiveCN103231430AProtect healthIncrease productivityCeramic shaping apparatusWorking environmentSlurry

The invention relates to a ceramic medium-and-low pressure slip-casting device. The ceramic medium-and-low pressure slip-casting device comprises a constant-pressure slurry tank, a pressurized slurry tank, a mould group, a control unit, a pushing unit for pressing the mould group tightly, a first pressure sensor for detecting pressure inside the mould group and an execution unit for issuing an instruction to the control unit, wherein the constant-pressure slurry tank, the pressurized slurry tank and the mould group are connected in sequence through slurry delivering pipes. The execution unit and the first pressure sensor are connected with the control unit, and the pushing unit is connected with the execution unit. The slip-casting device adopts the control unit to control the slip-casting process, enables the slip-casting process to be finished automatically, and greatly reduces the labor cost while improving the production efficiency. Compared with the prior art, the device is small in occupied area, short in moulding time, free of dust in a work environment and low in labor intensity, ensures worker health, and has the advantages of being durable, long in service life and convenient to maintain and dismantle.

Owner:广州市奈迪自动化设备有限公司

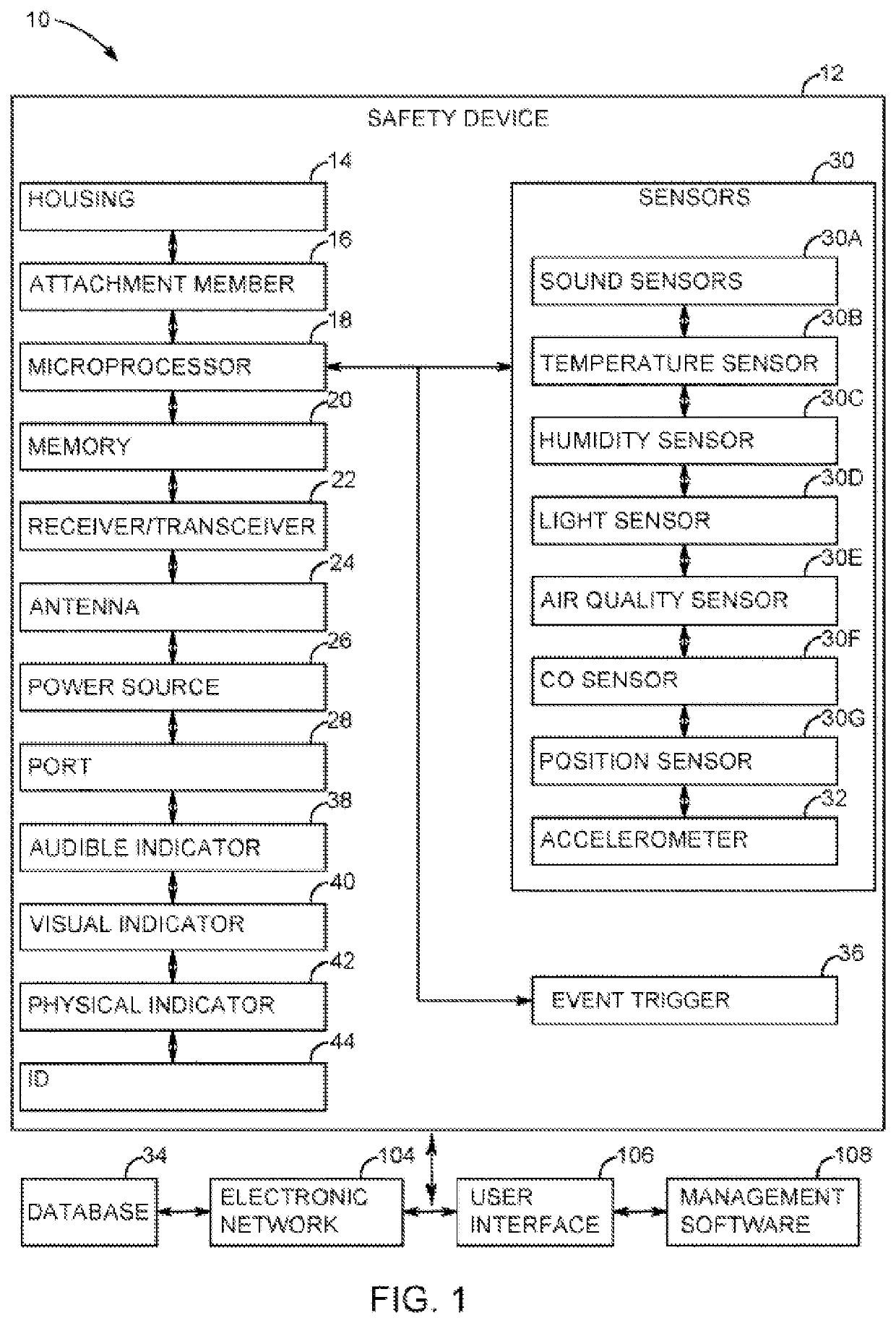

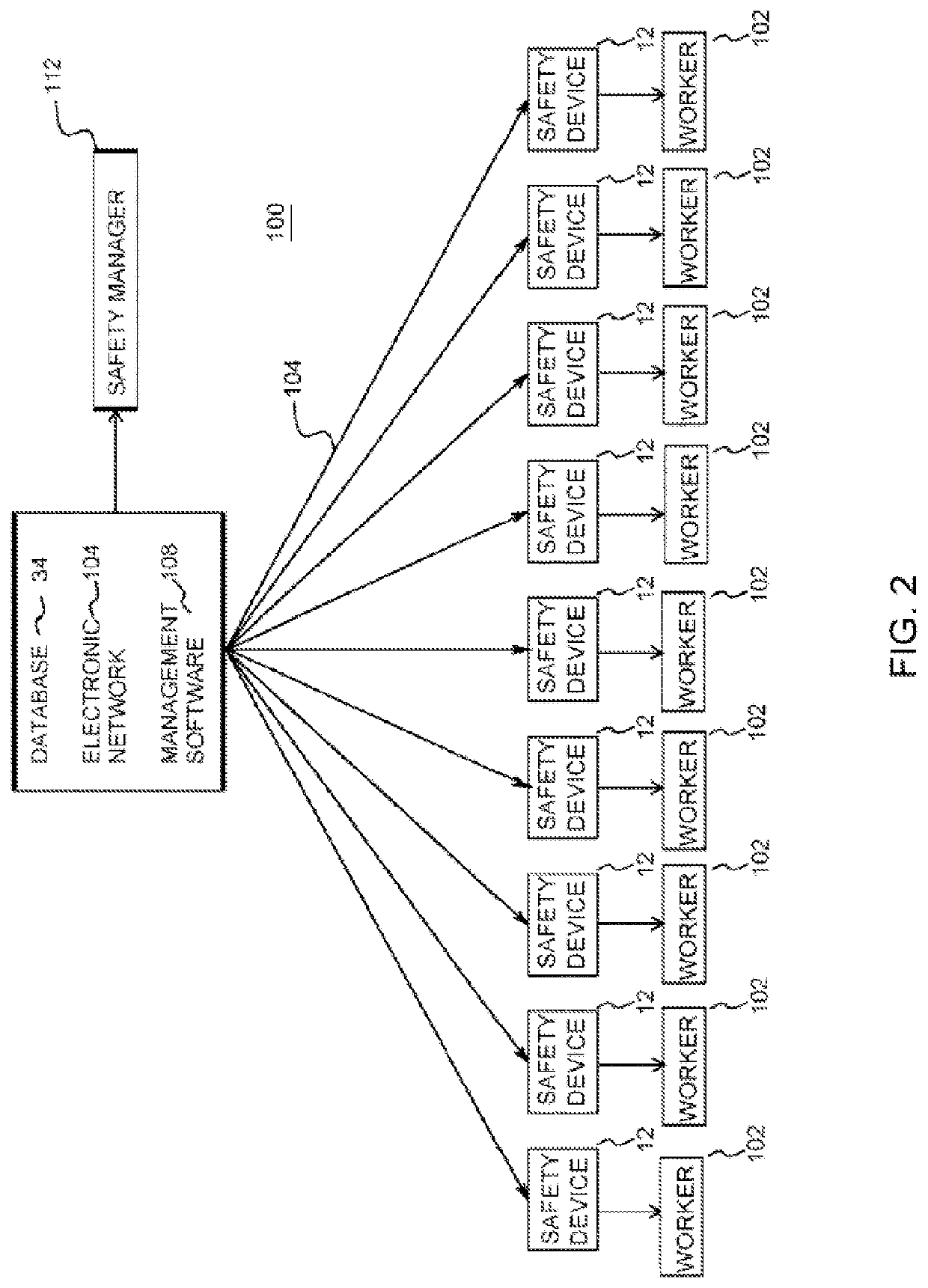

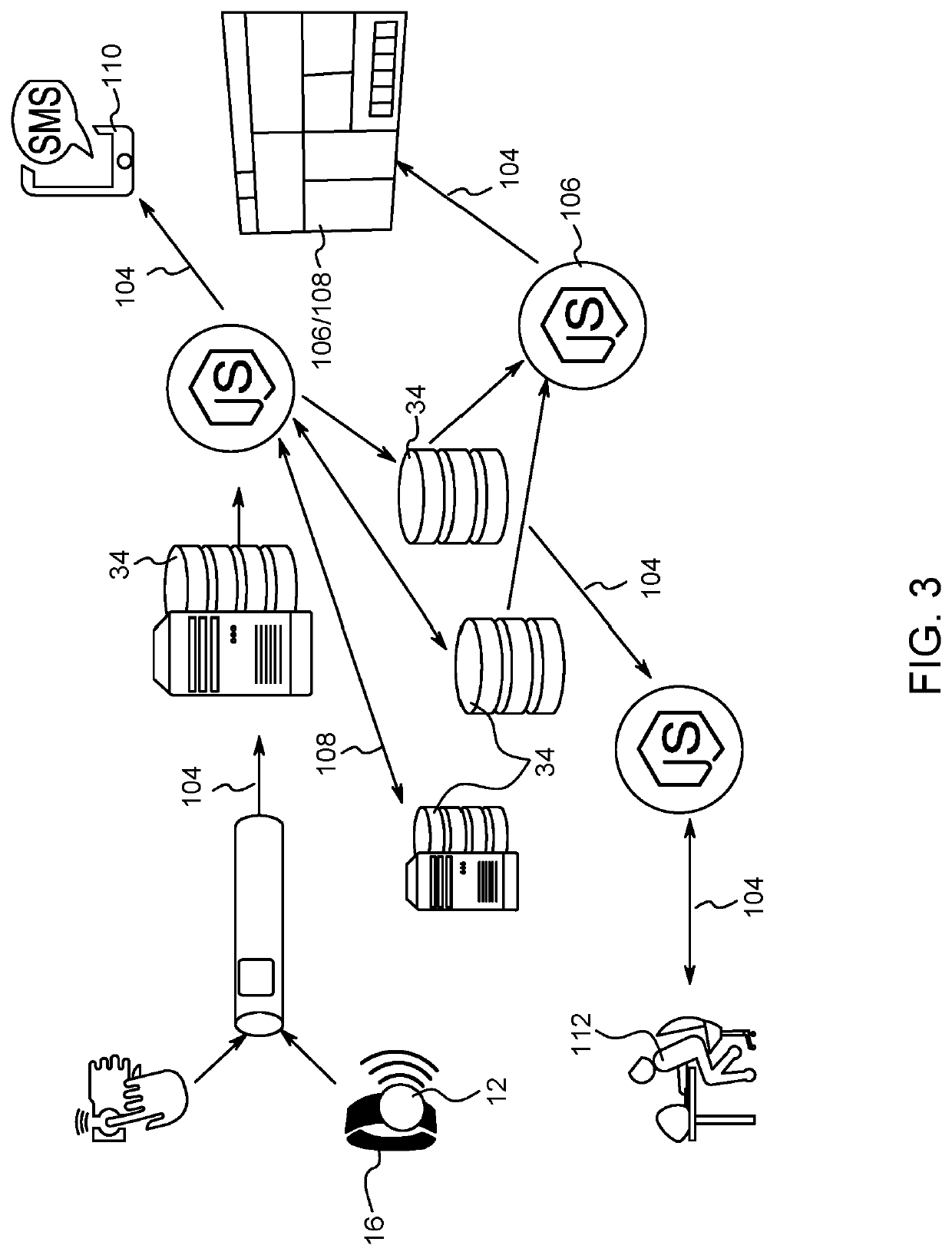

Device, system and method for health and safety monitoring

ActiveUS20210264764A1Facilitate health monitoringFacilitate mitigationAlarmsBiometric dataSafety monitoring

A system for monitoring health and safety of workers in a manufacturing facility is presented. The system a user interface, a set of sensors, a database, management software and / or a health monitoring system, among other components. The system is configured to monitor health of workers using biometric data gathered by the set of sensors. In one or more arrangements, the system also tracks the position and motion of the worker. In one or more arrangements, the data gathered is aggregated in a database for datamining purposes so as to facilitate health monitoring and mitigation of identified illness. The system may be configured to screen and identify workers who are not in normal health. The system may be configured to screen workers health when clocking into or out of the time keeping system. The system may be configured to perform contact tracing.

Owner:MAKUSAFE CORP

Textile dust extraction device

InactiveCN107326635ANo pollutionNo harm doneMechanical cleaningPressure cleaningWorking environmentEngineering

The invention discloses a textile dust extraction device. The textile dust extraction device comprises a base, a box is fixedly connected with the top of the base, a water outlet pipe is communicated with the bottom on the left side of the box, electric telescopic rods are fixedly connected with the two sides on the top of an inner cavity of the box respectively, and a cross rod is fixedly connected with the tops of the electric telescopic rods. In the textile dust extraction device, the base, the box, the electric telescopic rods, the cross rod, brushes, a first motor, a belt, a second belt plate, a rotary shaft, fan blades, a supporting plate, a second motor, a disc, a cylinder, an arc-shaped rod, an arc-shaped gear, a toothed plate and a first belt plate are used cooperatively, the problems that currently, dust extraction for a textile machine is conducted through manual shaking, dust can float away in air, the work environment can be polluted, and the body health of workers can be harmed are solved, the textile dust extraction device has the advantage of achieving automatic dust extraction, no environmental pollution can be caused, and the body health of the workers cannot be harmed.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

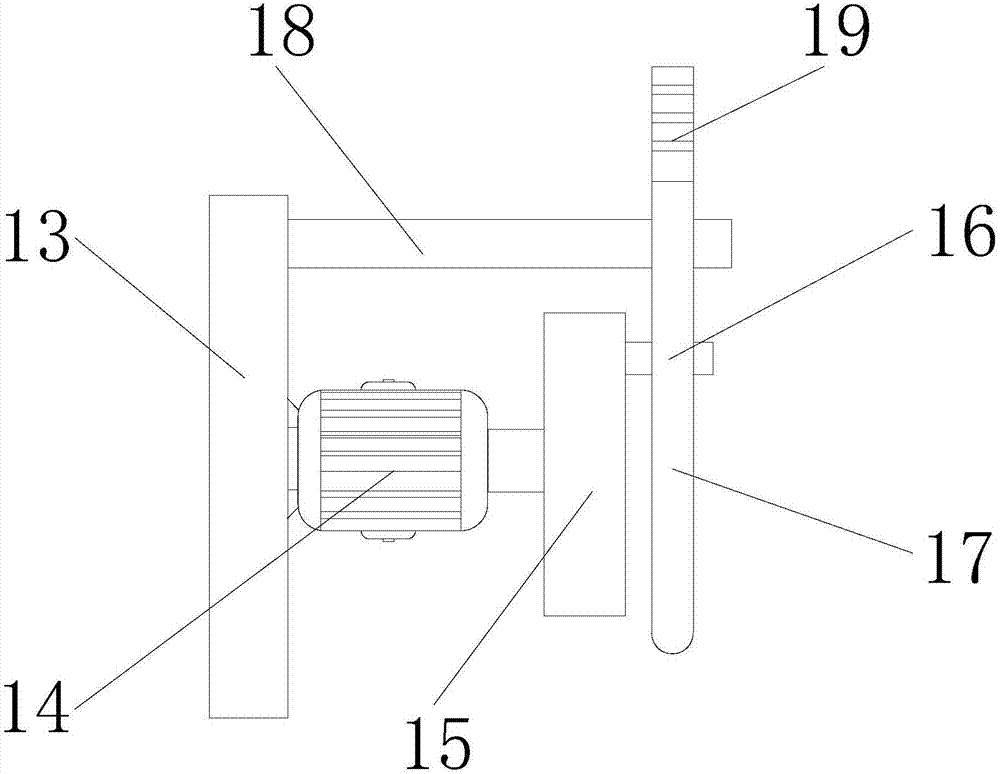

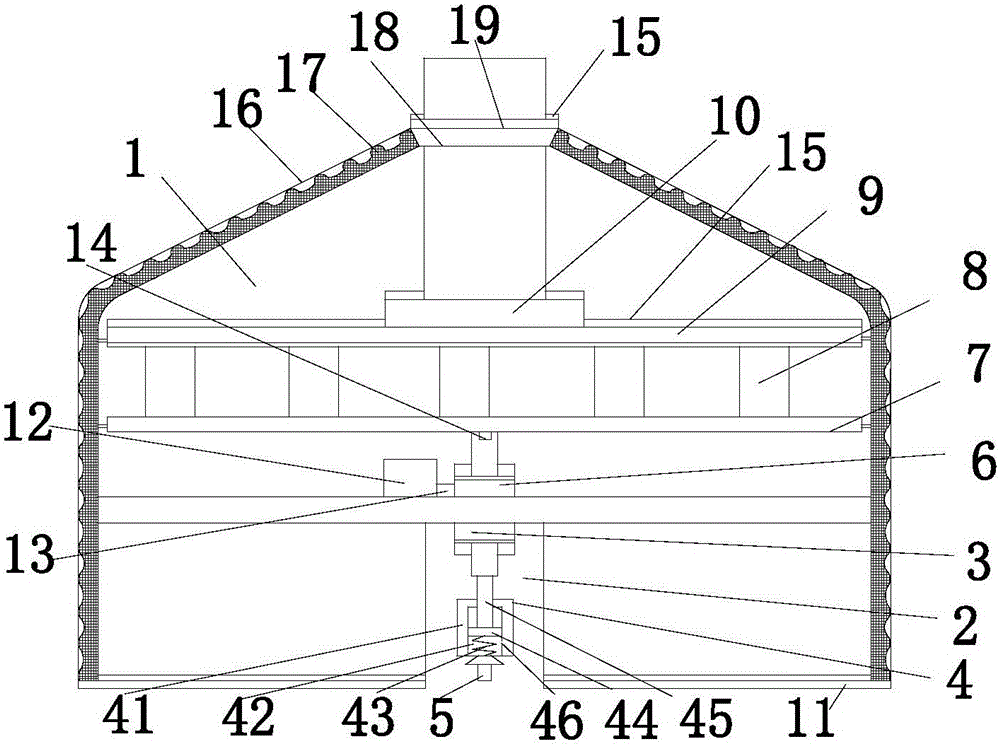

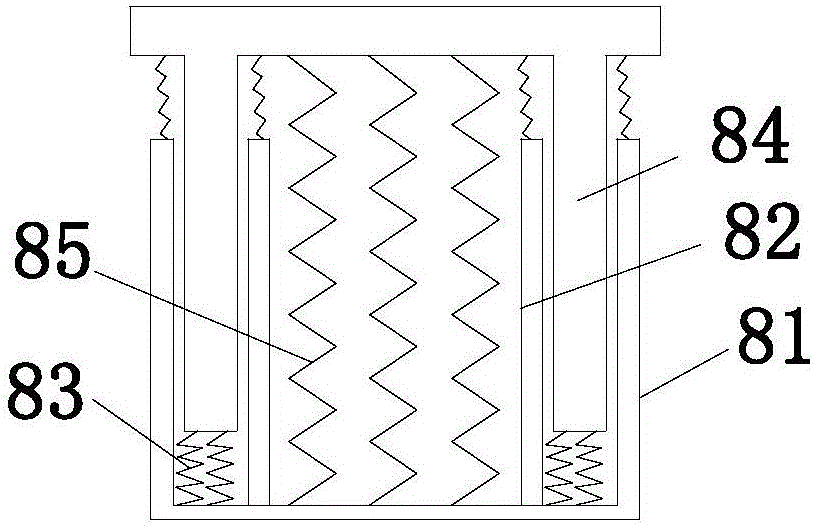

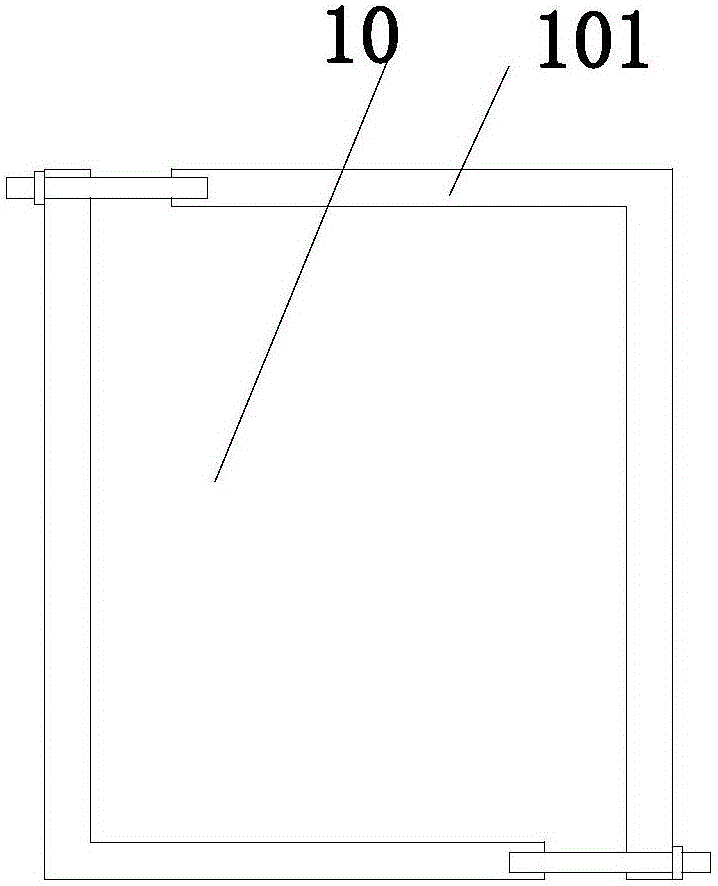

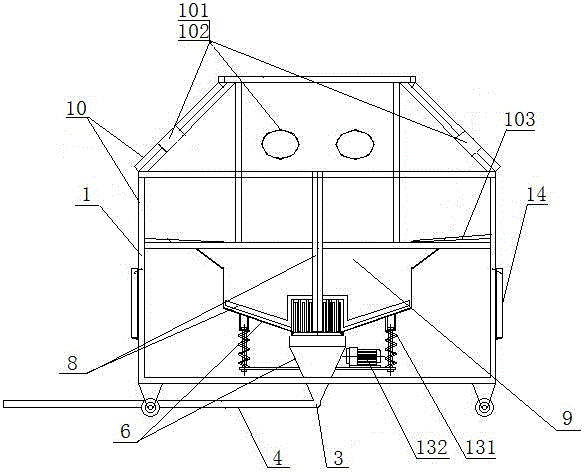

Textile machine shock-absorbing seat with moving function

InactiveCN105736629AEasy to moveImprove shock absorptionNon-rotating vibration suppressionStands/trestlesHydraulic cylinderMechanical engineering

The invention discloses a textile machine shock-absorbing seat with a moving function. The textile machine shock-absorbing seat is characterized by comprising a fixing seat (1). A mounting cavity (2) is arranged at the lower end of the fixing seat (1). A first hydraulic cylinder (3) is arranged in the mounting cavity (2) and connected with a shock-absorbing device (4). Moving wheels (5) are arranged below the shock-absorbing device (4). A second hydraulic cylinder (6) is arranged in the fixing seat (1). A first support plate (7) is arranged at the protruding end of the second hydraulic cylinder (6). A plurality of shock-absorbing cylinders (8) are circularly arranged on the first support plate (7). A second support plate (9) is arranged above the shock-absorbing cylinders (8). A first clamp (10) is arranged above the second support plate (9). The textile machine shock-absorbing seat is convenient to move, good in shock-absorbing effect, capable of lowering noise and facilitating equipment height adjusting, simple in structure, simple to manufacture, and capable of lowering influence on worker health.

Owner:海安凯美纺织科技有限公司

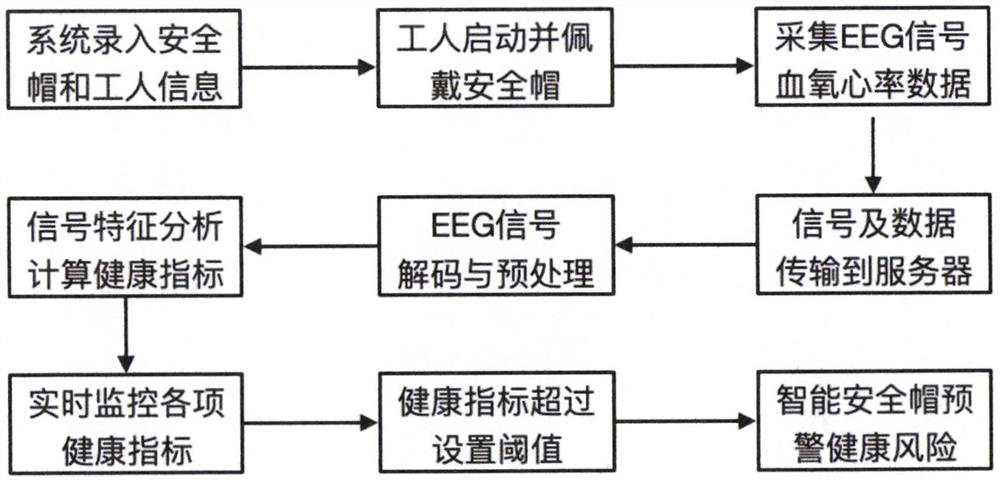

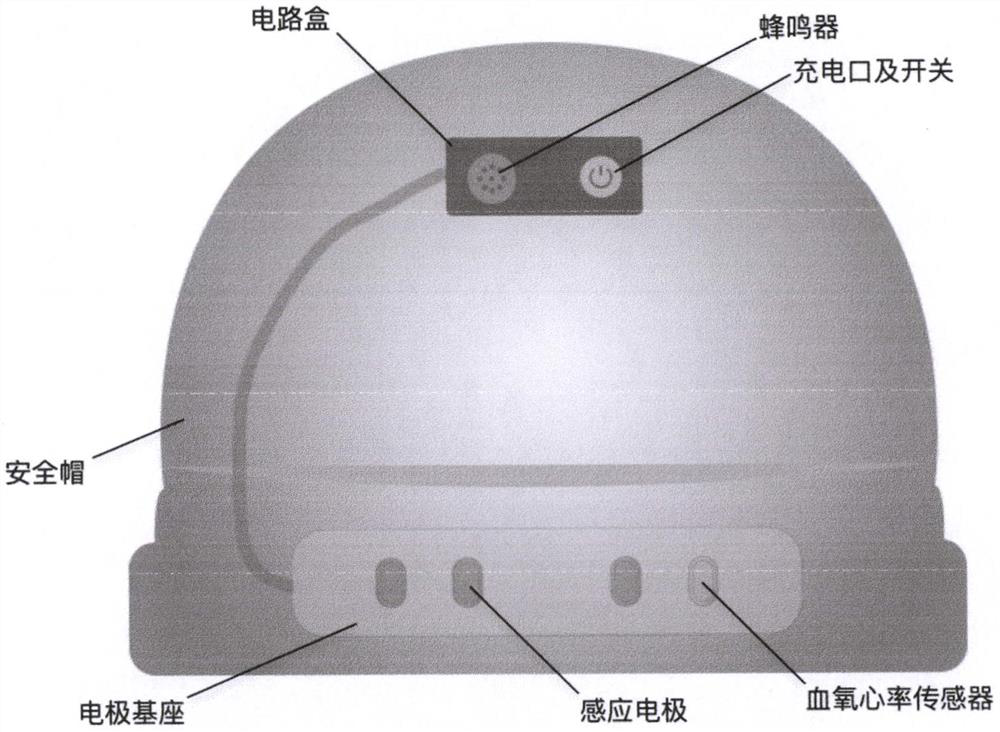

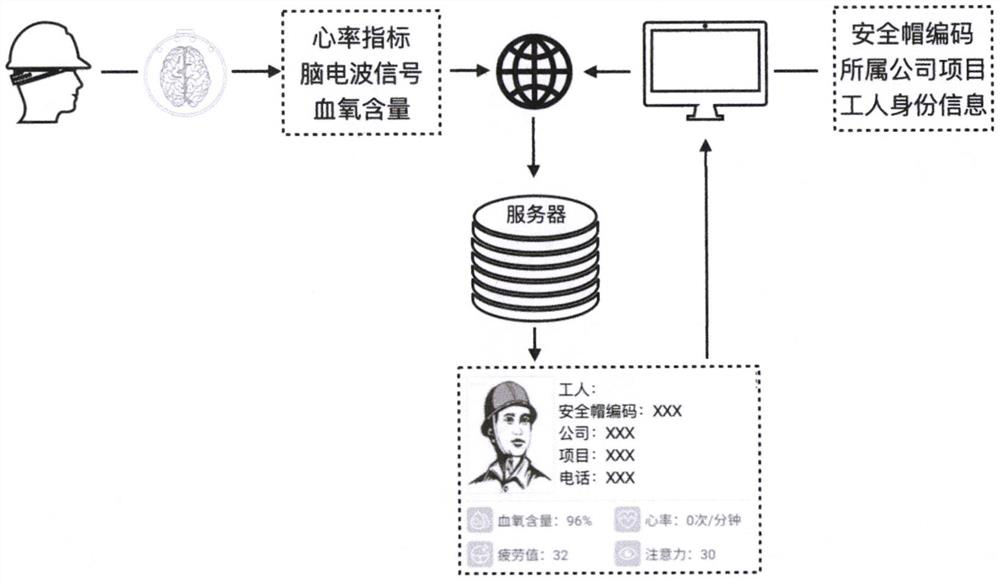

Worker health monitoring method based on intelligent safety helmet

InactiveCN111904079AReal-time acquisitionImprove efficiencySensorsPsychotechnic devicesHealth indexEngineering

The invention discloses a worker health monitoring method based on an intelligent safety helmet. According to the method, an intelligent safety helmet, a health data module, a specially-made analysismodule and a state management module are included. The working principle of the method is as follows: (1) enabling an intelligent safety helmet provided with a brain wave and blood oxygen and heart rate module to collect sign information of a worker in real time and uploads data; (2) performing real-time data analysis on the sign information data of the workers, and calculating fatigue, attentionconcentration, blood oxygen content and heart rate indexes of the workers; and (3) recording the health state of the worker and giving a prompt and early warning to the worker when the health index exceeds a threshold value. The intelligent safety helmet is designed according to the form and the use mode of the intelligent safety helmet, a special health state monitoring method for workers duringwork is developed by applying circuits such as brain wave acquisition circuits, monitoring, analysis and feedback of blood oxygen, heart rate, fatigue and attention indexes of the workers are achieved, and risk early warning can be actively carried out based on the health condition of the worker.

Owner:北京脑陆科技有限公司

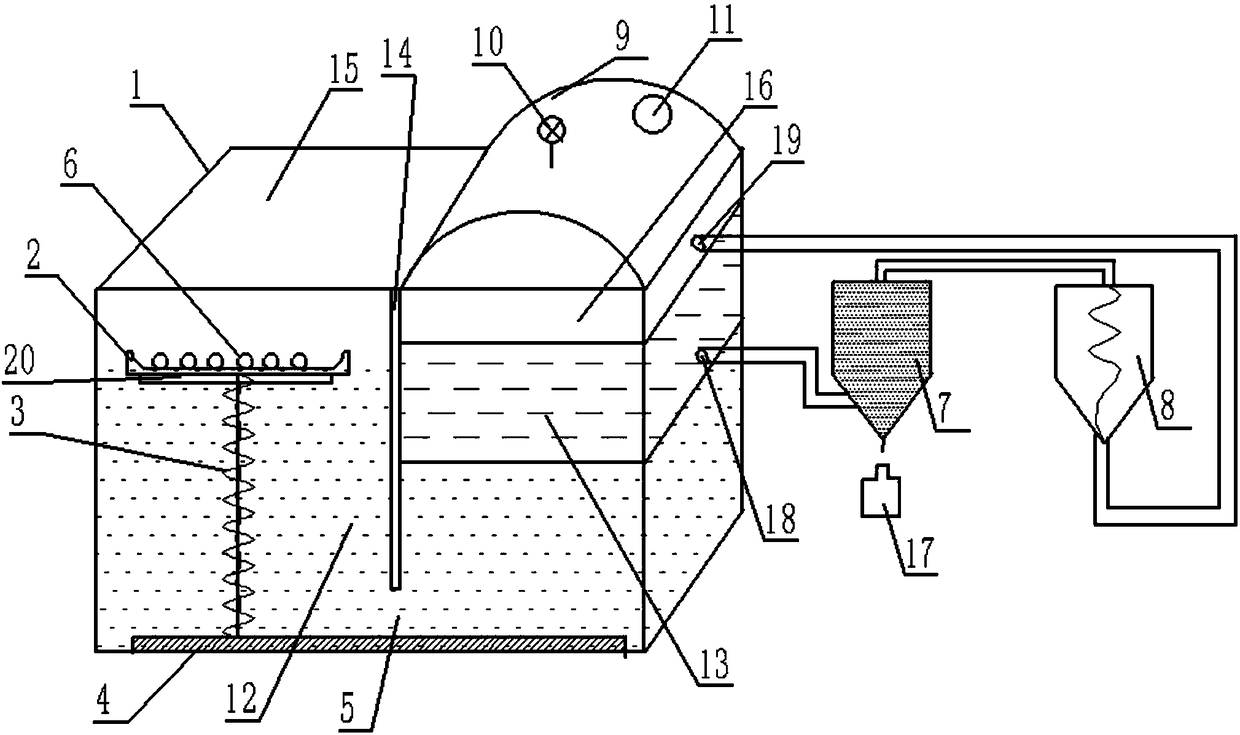

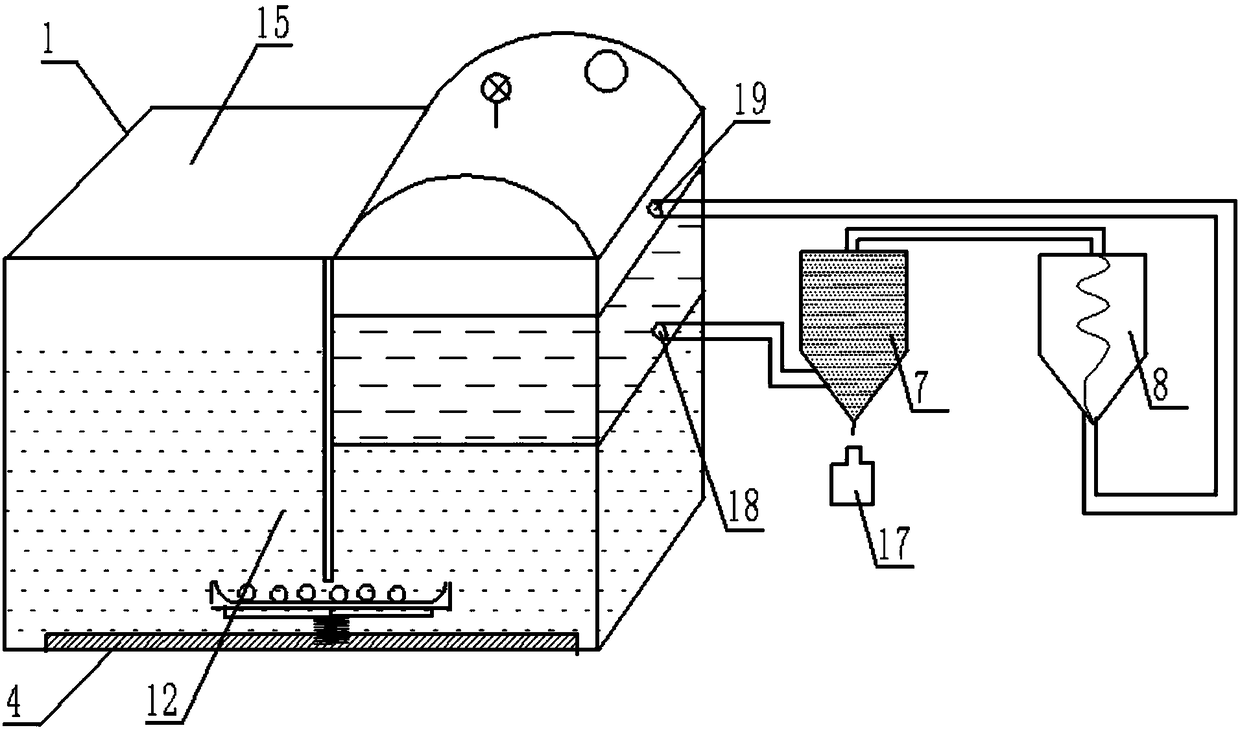

Zero-emission metal environment-friendly circulating oil removal method and device capable of recycling waste oil

ActiveCN108587763ANo secondary pollutionAvoid pollutionCleaning using liquidsLubricant compositionWastewaterSolvent

The invention relates to the field of metal oil removal method and oil removal, in particular relates to a zero-emission metal environment-friendly circulating oil removal method and device capable ofrecycling waste oil and solves the key technical problems of environment pollution and worker health hazards caused by volatilization easiness of a solvent oil removal agent in a traditional oil removal method. Due to the adoption of a structure of the zero-emission metal environment-friendly circulating oil removal device, a solvent and a workpiece are sealed in an oil removal working region anda sealing liquid when equipment is in a working state, and thus, the phenomenon that the solvent is evaporated to pollute the environment is avoided, and the cleaned workpiece cannot be secondarily polluted. In addition, the two steps including oil removal and regeneration are circularly operated in the whole system, waste oil on the workpiece is continuously eluted along with the continuous oilremoval of the workpiece, while the solvent oil removal agent continuously works and is continuously regenerated and recycled in the whole system and can be repeatedly and permanently recycled if being fed once. In the whole oil removal process, no wastewater, waste oil and waste solvents are discharged, subsequent environment protection investment is not needed, and no environment protection worries exist, so that the cost is very low.

Owner:王麒钧 +1

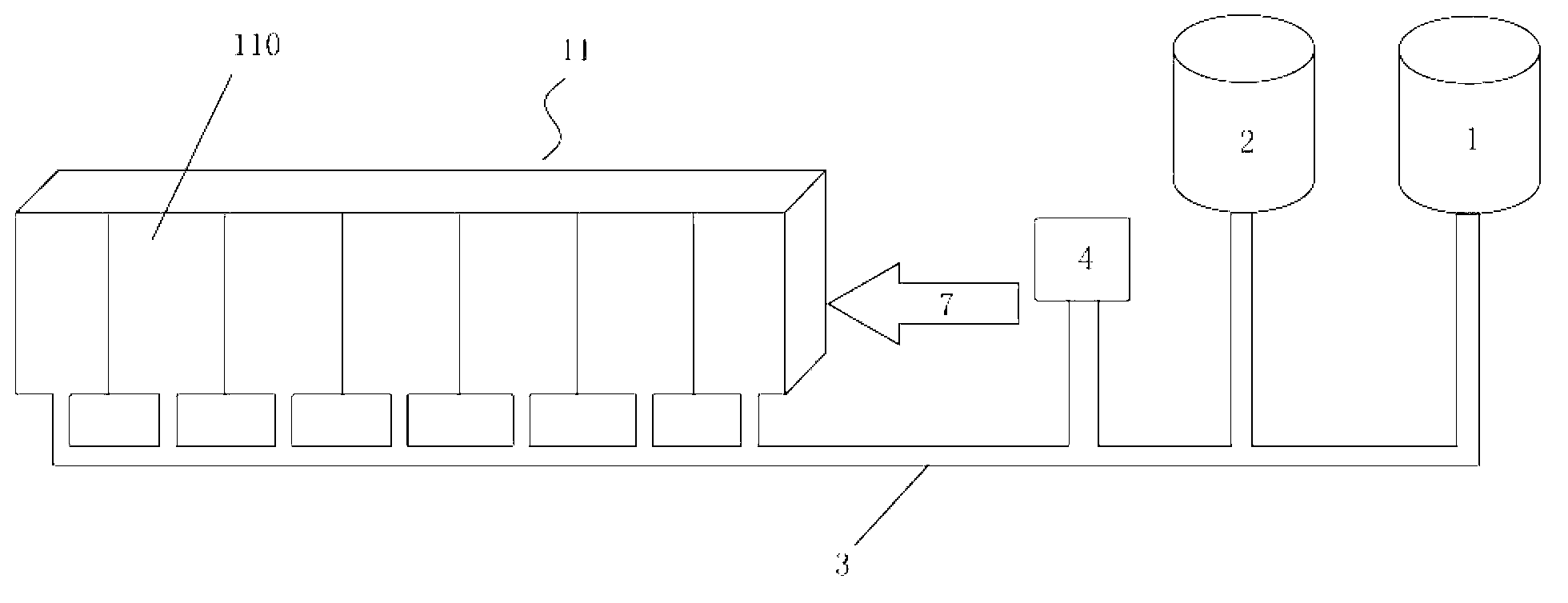

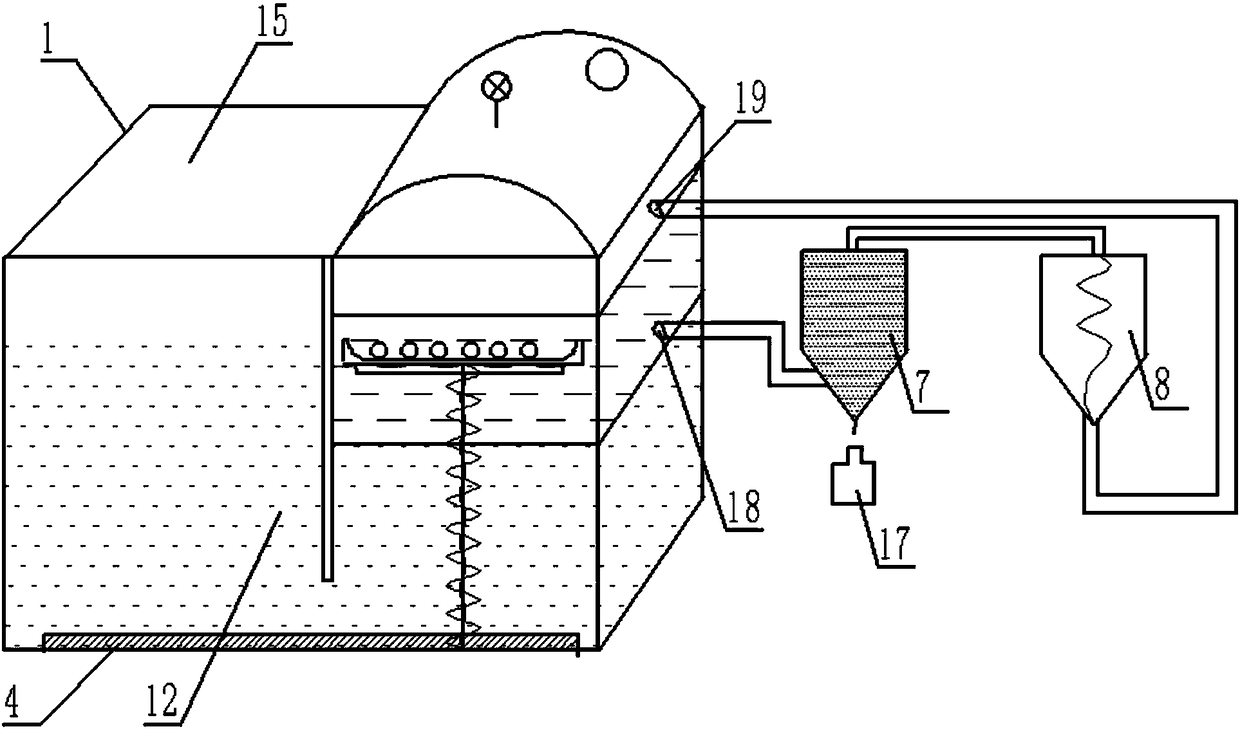

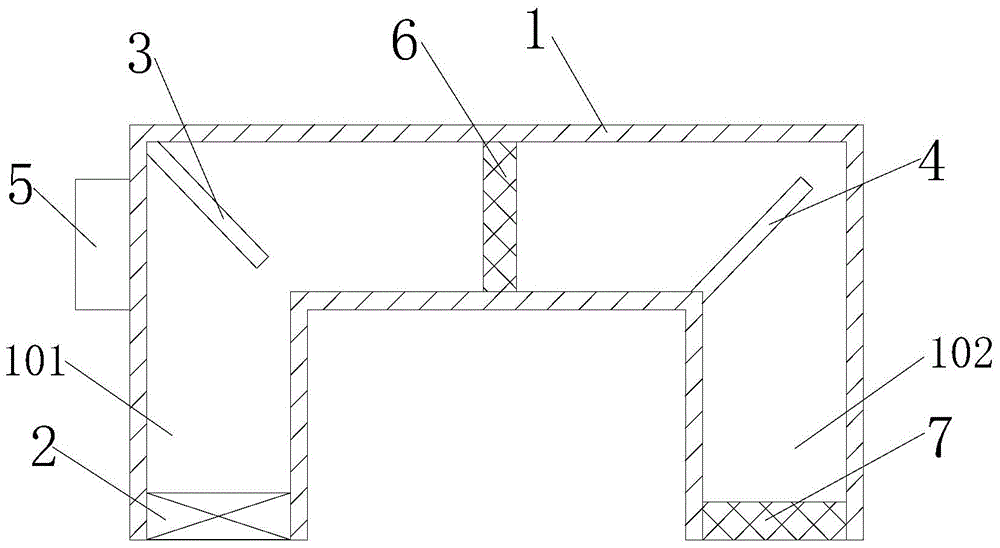

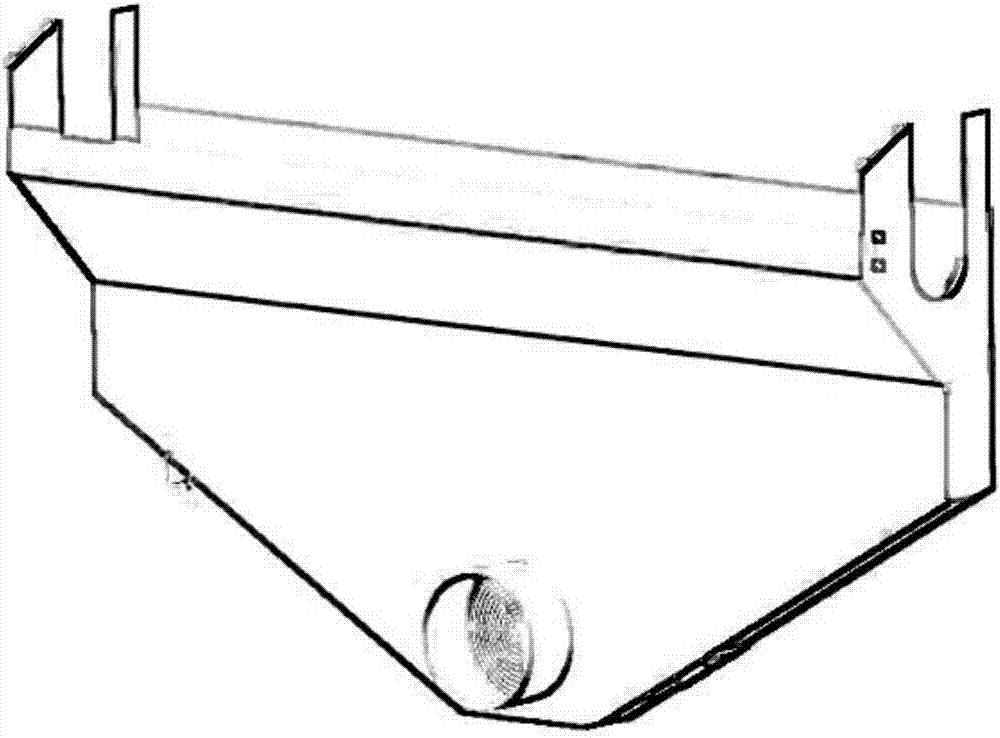

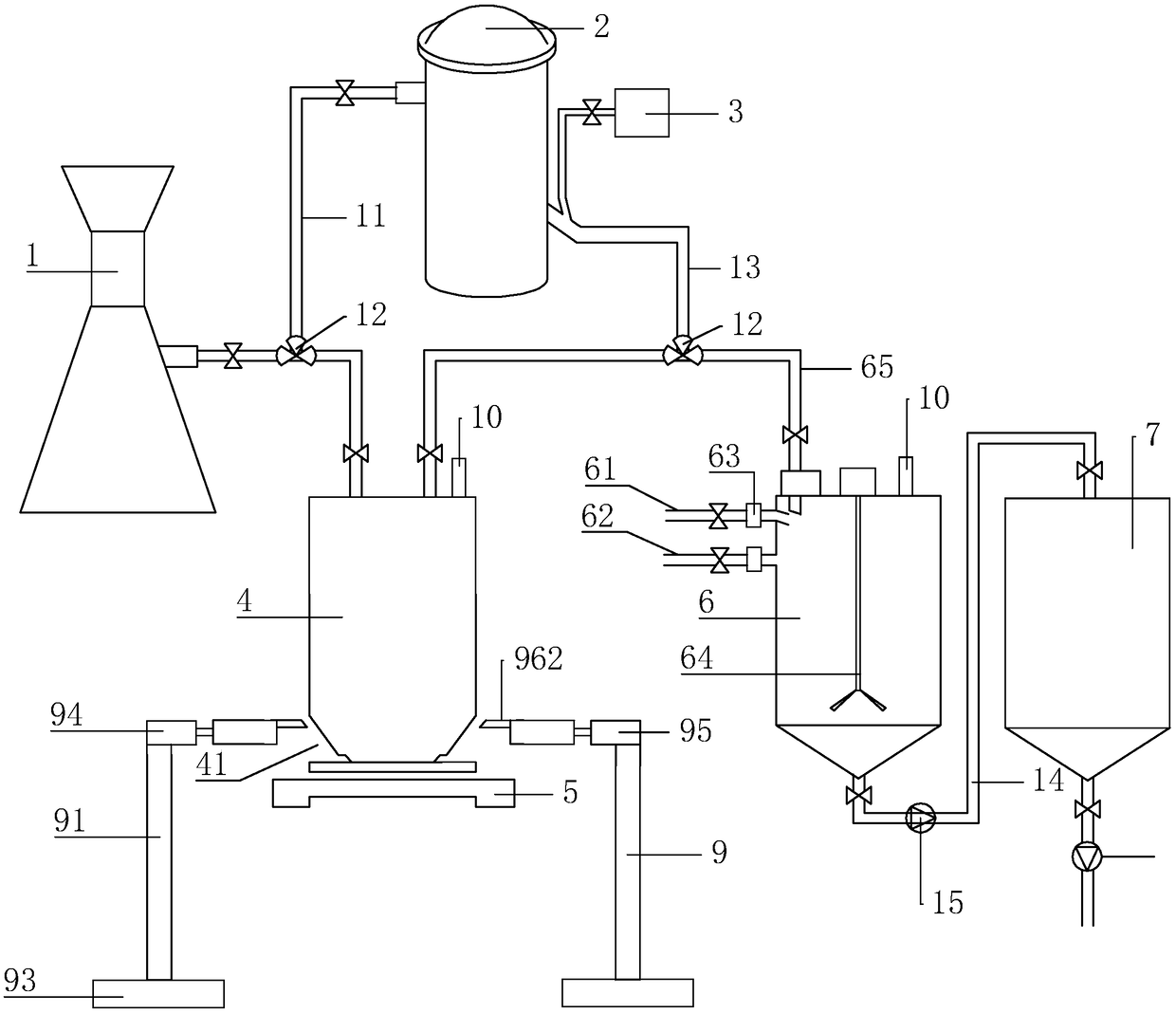

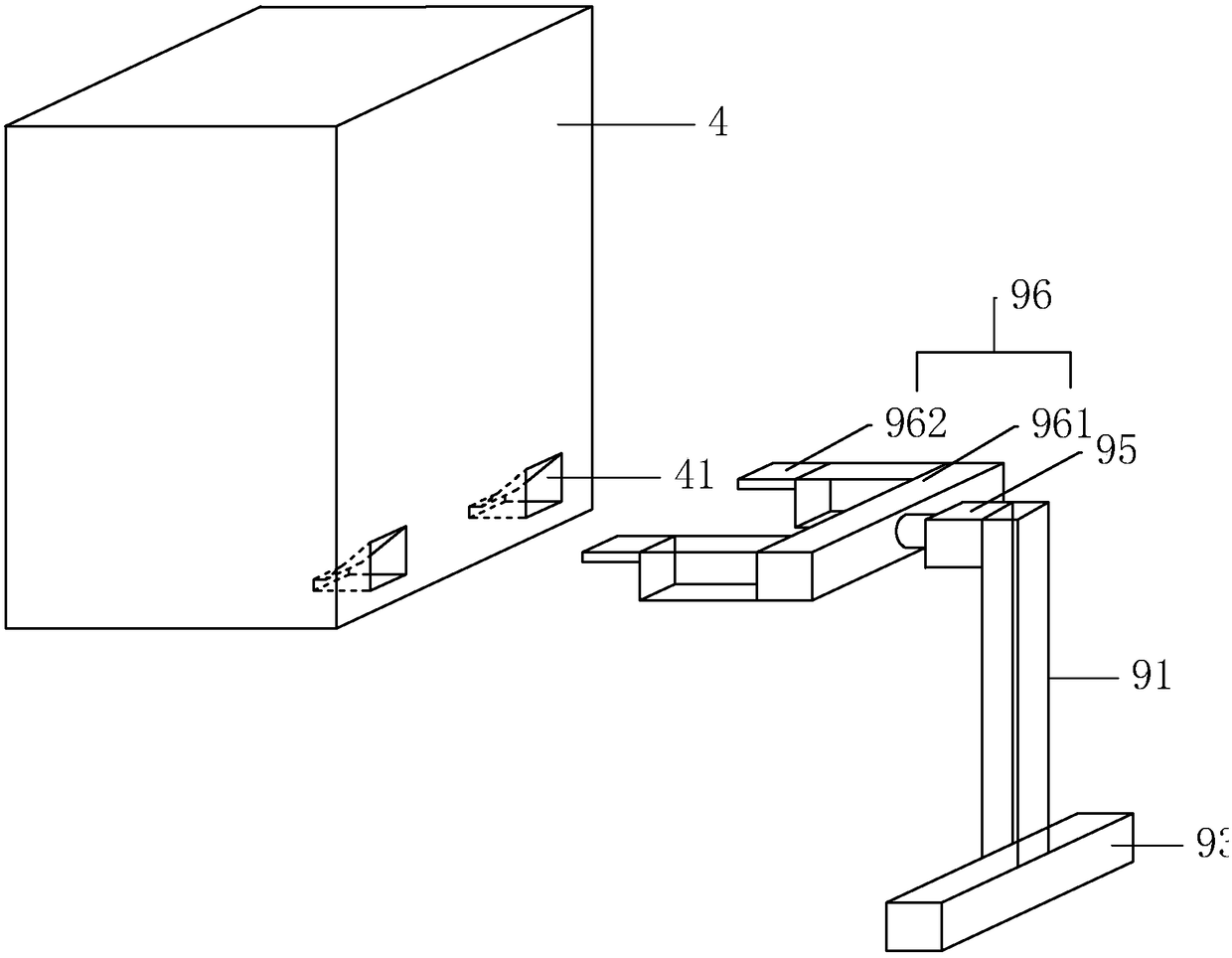

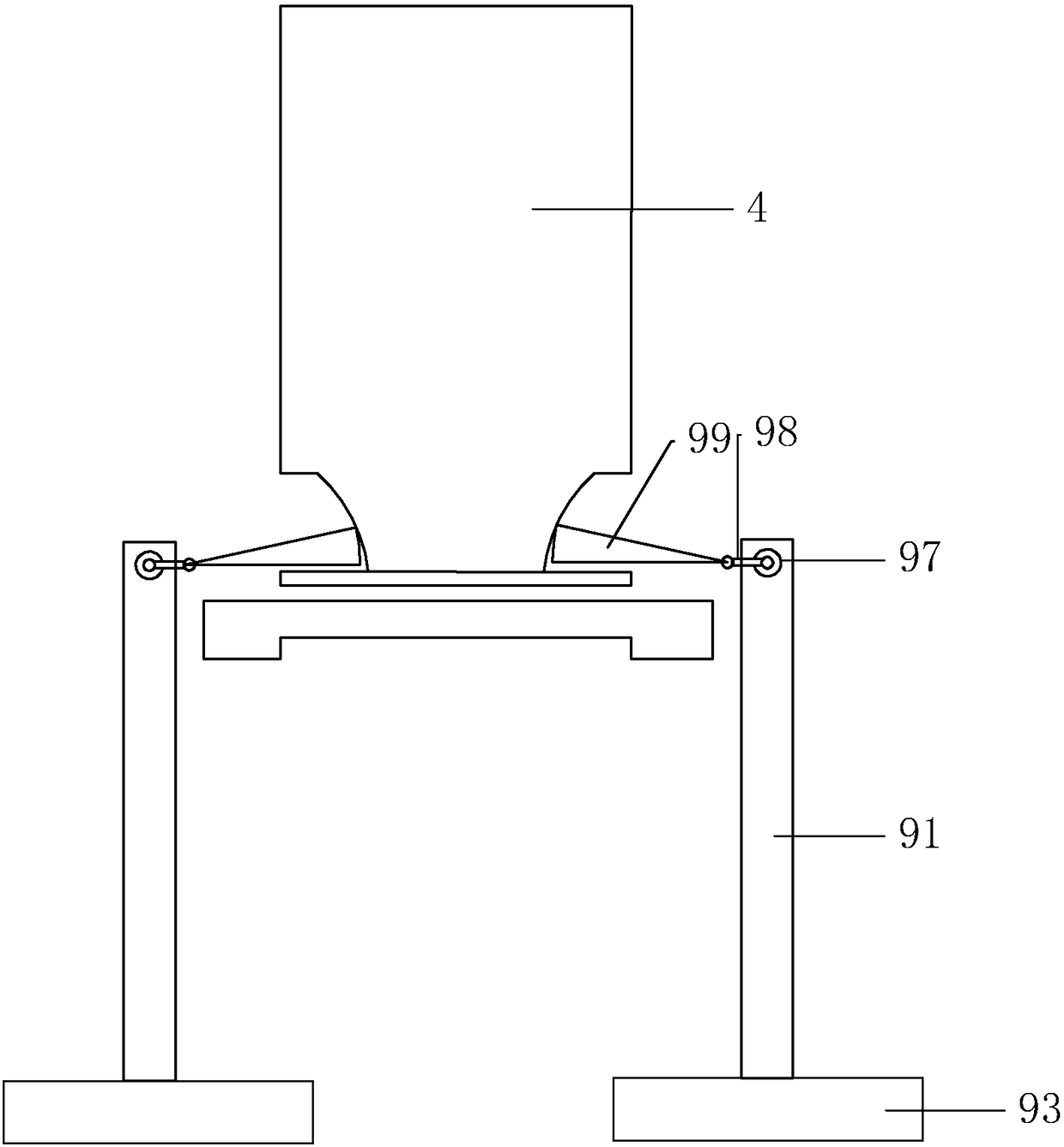

Loading device and pulp mixing device

InactiveCN106185079ASolve the cumbersome loading processSolve efficiency problemsRotary stirring mixersCell electrodesPhysical well beingEngineering

The invention discloses a loading device and a pulp mixing device. The pulp mixing device comprises a pulp mixing barrel and the loading device; a sucking pipe for communicating the pulp mixing barrel with the loading device is arranged between the pulp mixing barrel and the loading device; the loading device includes a bin; the bin has a feed port, and a discharge port communicated with the sucking pipe; the feed port of the bin is covered with a glove box; the box wall of the glove box is provided with a feeding port in the lower side of the glove hole; and the box wall of the glove box or the side wall of the bin is provided with an emptying table on the lower side of the feeding port. The pulp mixing device not only can solve the problems of complex loading process, low loading efficiency, high equipment starting load caused by accumulation of powder in the pulp mixing machine and easy generation of faults in a traditional manual loading mode, and can solve the defects of harm of worker health and environmental pollution by powder dust flying. Further, a vibration device, a discharge bin and a discharge funnel guarantee more continuous and smooth loading; and a stirring device can distribute powder falling from the emptying table more uniformly.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Mine timber substitute material and preparation method thereof

Relating to the technical field of novel building materials, the invention discloses a mine timber substitute material and a preparation method thereof. The mine timber substitute material is mainly composed of a main material, fiber and a composite admixture three components. Specifically, the main material contains 100 parts of magnesium oxide powder, 70-90 parts of a magnesium chloride hexahydrate solution, 10-15 parts of fly ash, 12-15 parts of sawdust, and 5-8 parts of water. The composite admixture includes 1-4 parts of a water reducing agent, 0.2-0.4 part of a retarder, and 2-4 parts of a modifier. The fiber contains 2-4 parts of glass fiber and 25-45 outers of bamboo. According to the invention, magnesium oxychloride cement with high compressive strength and high bending strength is combined with sawdust, fly ash and other solid waste together, the material cost is low, the preparation method is simple and practicable, and has low requirements for production equipment and staff, also the production cycle is short, and the whole process does not produce the three wastes, thus having no influence to the environment and worker health.

Owner:HENAN POLYTECHNIC UNIV

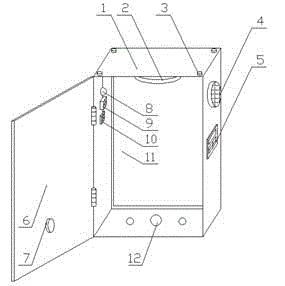

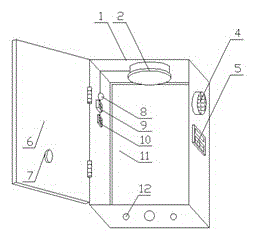

Novel type safe distribution box

InactiveCN105119163AAvoid failureAffect healthSubstation/switching arrangement detailsEngineeringLiquid carbon

The present invention provides a novel type safe distribution box including a box body, a lifting ring and the like. The novel type safe distribution box is characterized in that the novel type safe distribution box includes a liquid carbon dioxide storage tank, an electromagnetic radiation detector, a full-automatic static electricity eliminator, a temperature sensing probe, a controller and a buzzer. The lifting ring is arranged on the top of the box body, a box door is arranged on one side of the box body, and the full-automatic static electricity eliminator is arranged on the box door, an exhaust fan is arranged on one side of the box body, and the electromagnetic radiation detector is installed below the exhaust fan. The electromagnetic radiation detector detects whether electromagnetic radiation leaks or not so as to avoid an inaccurate instrument reading caused by the electromagnetic radiation leakage and an influence on worker health. The full-automatic static electricity eliminator can eliminate the static electricity within a certain range of the outside world, and prevent the static electricity of the outside world from contacting with apparatuses in the distribution box. The temperature sensing probe triggers the controller so that the buzzer gives an alarm with a ming sound when the inner of the distribution box is on fire, and simultaneously, the liquid carbon dioxide storage tank pours out the inner carbon dioxide for extinguishing the fire source in the distribution box.

Owner:TIANJIN YINGLIAN ELECTRIC EQUIP CO LTD

Environment-friendly dust removal device

The invention relates to an environment-friendly dust removal device comprising a device body. An air inlet is arranged on one side of the device body, and an air outlet is arranged on the other side. The device body has a U-shaped structure. An induced draft fan is arranged on the device body and positioned at the air inlet. A first adsorption plate is arranged at a first right-angle-corner of the device body. A second adsorption plate is arranged at a second right-angle corner. The first adsorption plate and the second adsorption plate are connected with a negative ion generator. A first filtering mesh and a second filtering mesh are arranged in the device body. According to the invention, air is sucked from the air inlet through the induced draft fan, and at that time the negative ion generator generates negative ions which cover the first and second adsorption plates. Therefore, air passes through the first adsorption plate, the first filtering mesh, the second adsorption plate and the second filtering mesh sequentially, and is discharged from the air outlet. With the process, dust in air is greatly reduced, and worker health is protected. The device has good practicality.

Owner:SUZHOU GENSHENG COATING ENG

Antirust aqueous cutting fluid and preparation method thereof

InactiveCN105296130AAccelerated corrosionImprove the lubrication effectLubricant compositionEnvironmental resistancePolyvinyl alcohol

The invention discloses an antirust aqueous cutting fluid and a preparation method thereof. The antirust aqueous cutting fluid is prepared from 18-26 parts by weight of polyaniline, 5-12 parts by weight of serine, 6-14 parts by weight of polyvinyl alcohol, 2-5 parts by weight of sebacic acid, 1-5 parts by weight of a calcium-magnesium ion softener, 5-11 parts by weight of a lubricant, 1-4 parts by weight of an antiseptic, 3-9 parts by weight of sodium cumenesulfonate, 5-10 parts by weight of triethylamine, 2-5 parts by weight of an antirust agent and 20-35 parts by weight of tap water. The antirust aqueous cutting fluid has good corrosion resistance and lubricity, solves the problems of the traditional aqueous cutting fluid, has the advantages of environmental protection, no toxicity, cleaning easiness and no nitrite, is conducive to cutting operation environment and worker health and has a wide application value.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

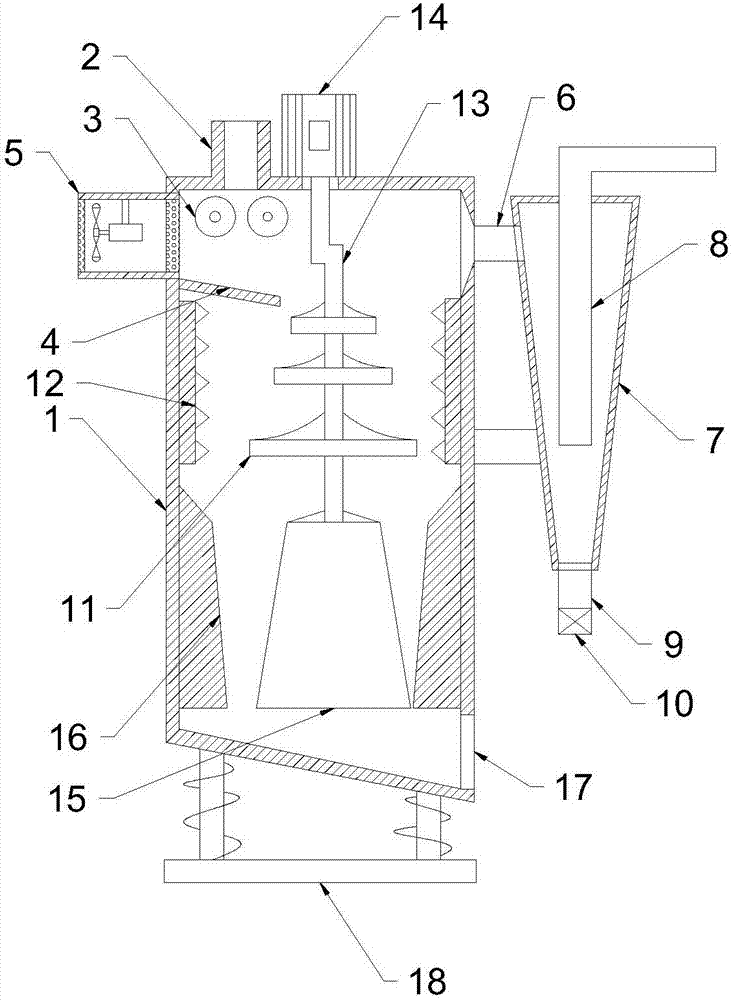

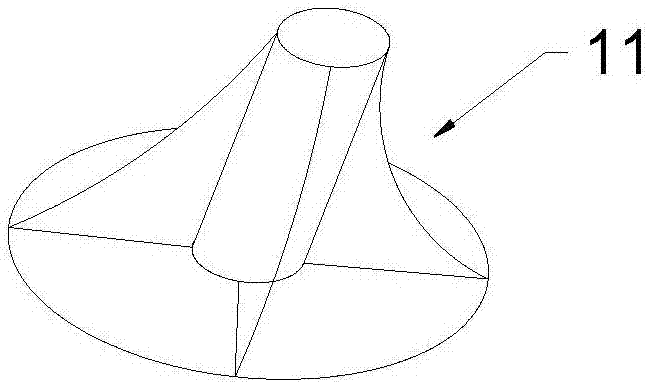

Raise dust preventing cement block treatment device

InactiveCN107971111AActive collectionAvoid pollutionVortex flow apparatusGrain treatmentsWorking environmentEngineering

The invention discloses a raise dust preventing cement block treatment device. The raise dust preventing cement block treatment device comprises a box. A feeding pipe is arranged on the top of the box. The position, located below the feeding pipe, of the box is provided with symmetric extrusion rollers. A material guiding plate is arranged below the extrusion rollers. The position, located above the material guiding plate, of the box communicates with an air inlet pipe. The position, opposite to the air inlet pipe, of the box is provided with an air outlet pipe, and the air outlet pipe communicates with a conical barrel in the tangential direction. A plurality of sets of rotation discs distributed up and down are arranged below the material guiding plate. Through the arrangement of the airinlet pipe, the air outlet pipe and the conical barrel, dust generated through crushing is actively collected, and the situation that raise dust generated through crushing pollutes the work environment, and the worker health is threatened is avoided. According to the raise dust preventing cement block treatment device, the rotation discs and collision plates are arranged and collide with and crush preliminarily-crushed cement blocks, the crushing effect is improved, later grinding and pulverizing are convenient, and the cement block pulverizing efficiency is improved.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

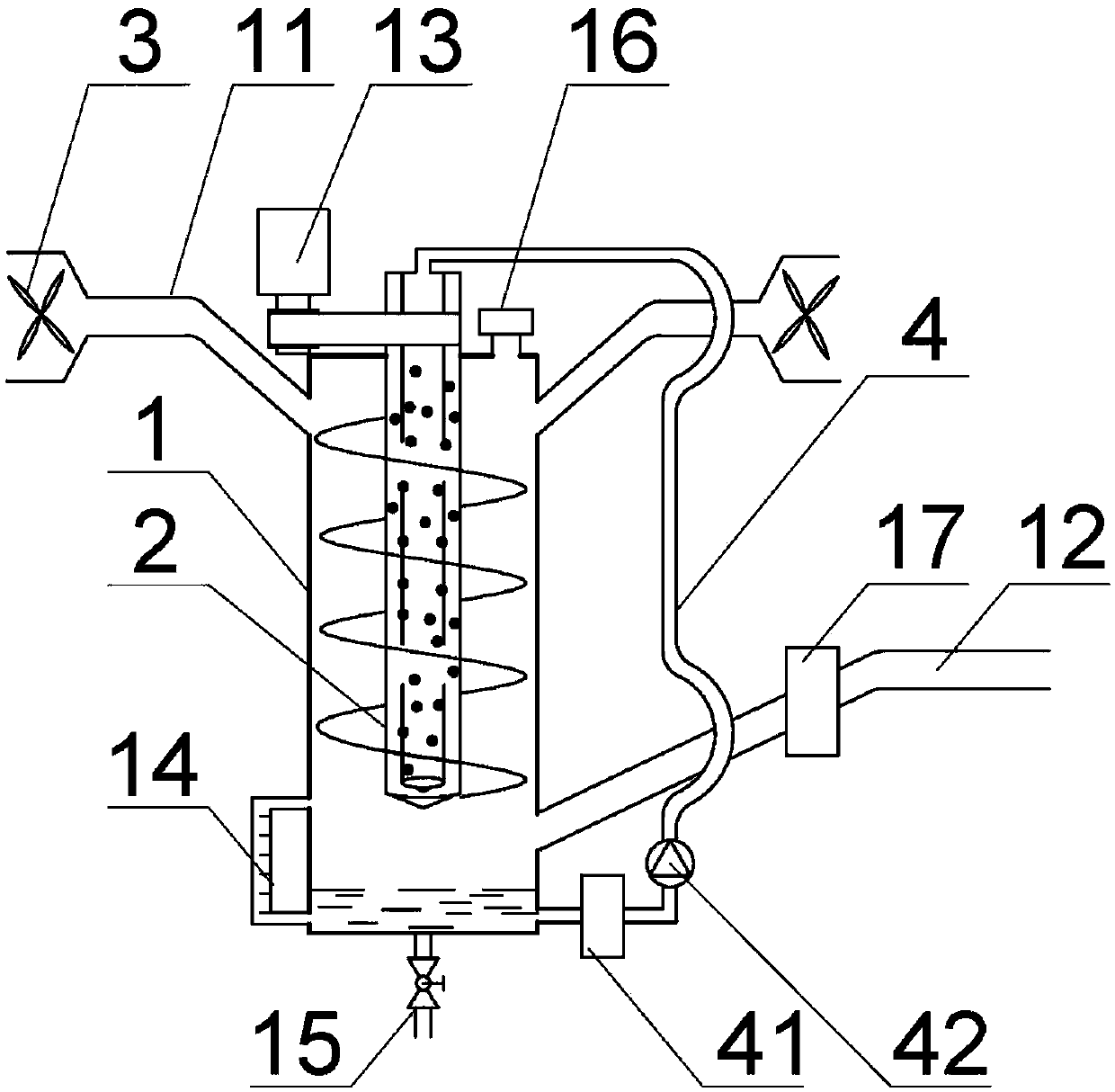

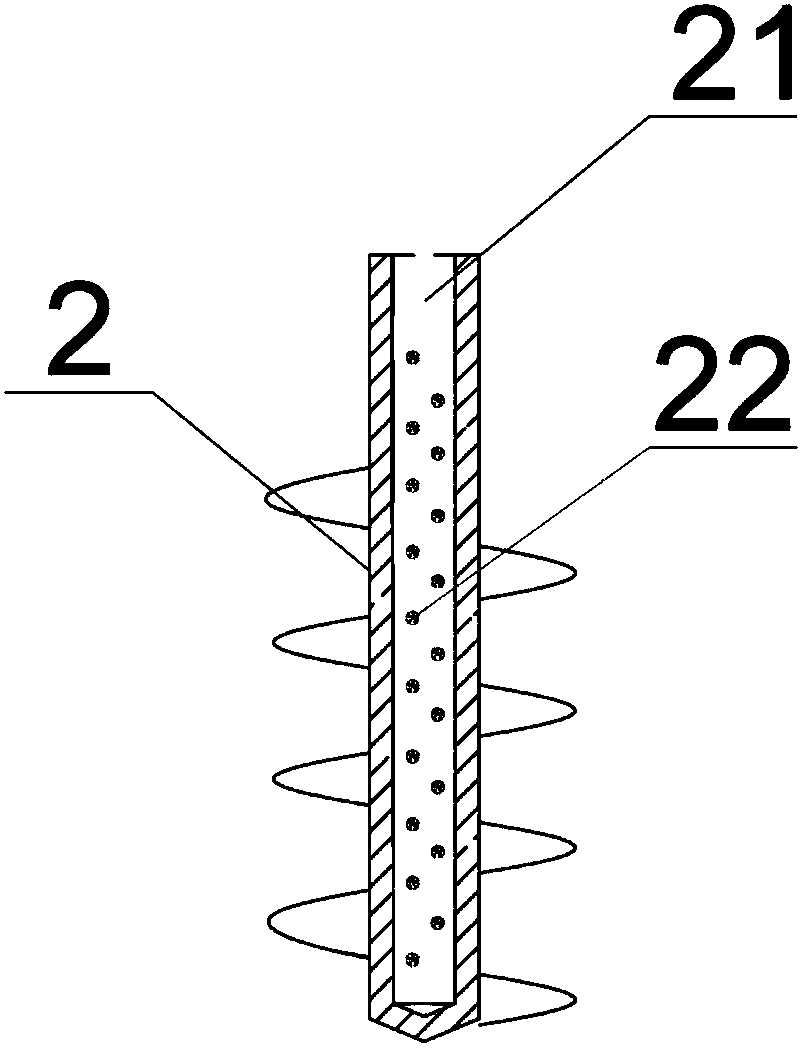

Dust removing device for wheat flour processing factory

PendingCN107754541AGood for physical and mental healthReduces the possibility of dust explosionsCombination devicesDust explosionEngineering

The invention discloses a dust removing device for a wheat flour processing factory. An air supply packing auger is rotationally arranged in a dust removing tank; an axial cavity for accommodating water is formed inside a rotating shaft of the air supply packing auger; a plurality of atomizing holes are formed in the rotating shaft of the air supply packing auger and communicated with the cavity;a plurality of air inlet pipelines are communicated with the dust removing tank and connected parts of the air inlet pipelines and the dust removing tank are close to the starting end of the air supply packing auger; an air outlet pipeline is communicated with the dust removing tank and a connected part of the air outlet pipeline and the dust removing tank is close to the tail end of the air supply packing auger; air containing wheat flour dust is sucked into the dust removing tank; the air supply packing auger in the dust removing tank rotates at high speed for spirally pushing the air to theair outlet pipeline; meanwhile, water in the cavity of the air supply packing auger is sprayed out from the atomizing holes; atomized water is combined with dust particles in the air; under the action of a centrifugal force, the dust particles are attached to the inner wall of the dust removing tank and flow to the bottom of the dust removing tank; the dust in exhausted gases subjected to dust removal is greatly reduced, so that physical and psychological health of workers in the factory is benefited, and the possibility of dust explosion is also reduced.

Owner:安徽省老家好食品有限公司

Automatic spraying machine

InactiveCN103949365AImprove efficiencyImprove production efficiencyLiquid surface applicatorsSpray nozzlesEngineeringUltimate tensile strength

The invention discloses an automatic spraying machine and relates to an automatic comb paint spraying device. The automatic spraying machine comprises a main body box and a controller, wherein an enter rail and an exit rail are arranged on the main body box; the main body box is internally provided with an annular rail connecting the enter rail with the exit rail; a plurality of paint spraying columns matched with the annular rail is further arranged in the main body box in an up-and-down movement manner; the main body box further comprises a plurality of rotating brackets capable of moving on the enter rail, the exit rail and the annular rail; cross overturn rods are arranged on the rotating brackets; and limiting rods matched with the cross overturn rods are further arranged in the main body box.Compared with the prior art, the machine can automatically carry out paint spraying treatment on a comb, and greatly improves the efficiency of a whole manufacturing process.The machine solves the problems that the existing manual spraying is high in labor intensity, and unstable in spraying quality and has great damages to worker health.

Owner:NINGBO CHUNGFAT BRUSHES

Method for using single component low-temperature zinc-based phosphatization liquid

InactiveCN102051613AImprove bindingImprove corrosion resistanceMetallic material coating processesToxic materialBond Force

The invention relates to a method for using single component low-temperature zinc-based phosphatization liquid, comprising the steps of removing oil, rinsing,, removing rust, rinsing, tempering, parkerising, rinsing, drying and coating, wherein the tempering technology is as follows: firstly, using a frosting material to frost the surface, then using a fan to blow the frosted fragments on the surface away, using magnet to further absorb the fragments on the surface, and finally, using an air-heater or a thermal radiation device to heat the surface to at least 35 DEG C is ordinarily reached to prepare for phosphatization treatment. The method has the beneficial effects that the phosphatization speed is fast: phosphatization is carried out for 2-5 minutes to obtain high quality phosphatization film with the depth of 1-3 microns / cm<2> under the tempering process condition of 25-40 DEG C; the single component is supplied, the same liquid is adopted during tanking and replenishing, and the regulation is extremely convenient; the bonding force between the phosphatization film and a paint film is firm, and a coating layer has good corrosion resistance; and the phosphatization liquid does not contain toxic substances such as heavy metals, nitrites and the like, is in favor of worker health and environment protection, has the characteristic of less sediment amount, and can be used for a long term.

Owner:缪克忠

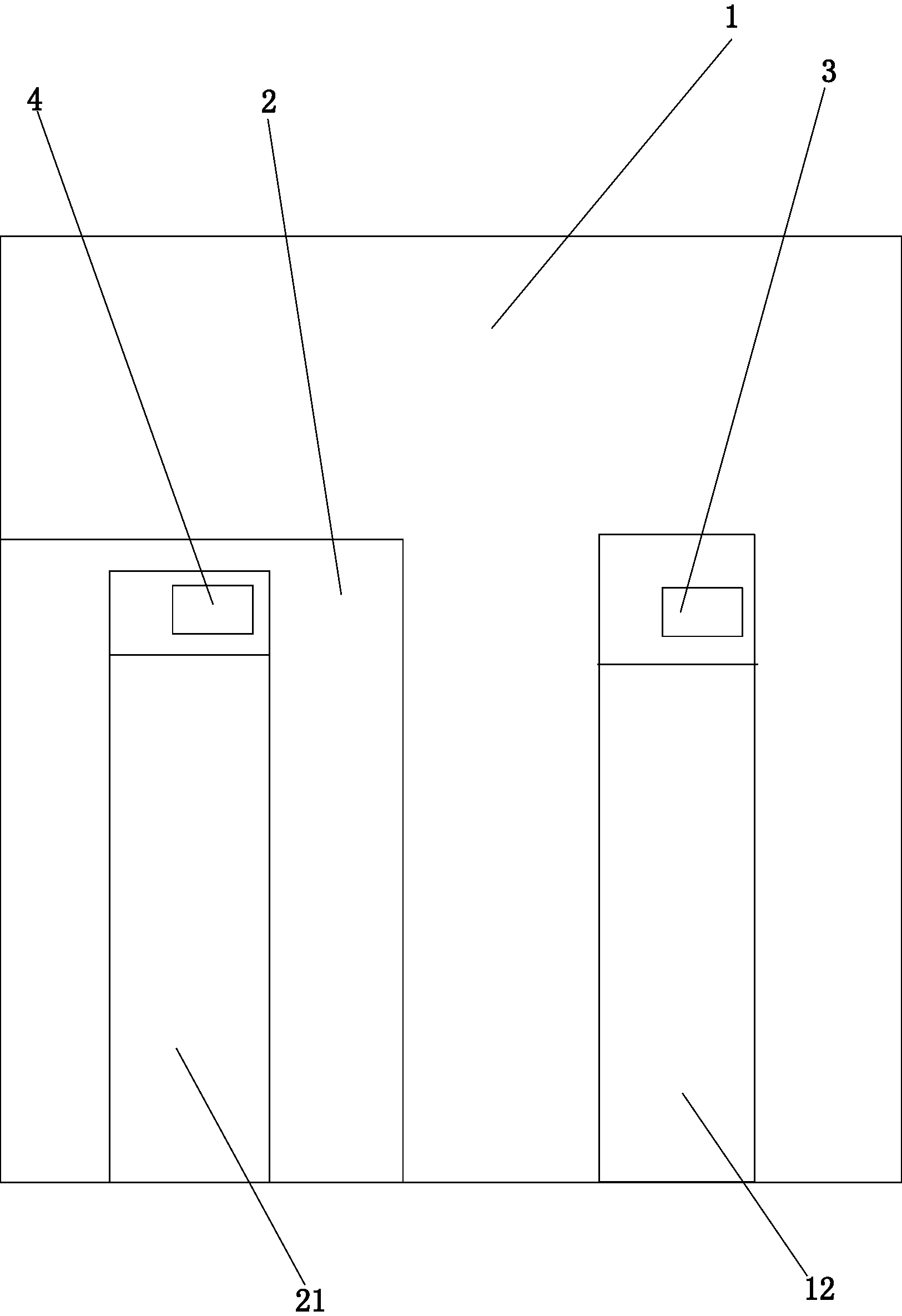

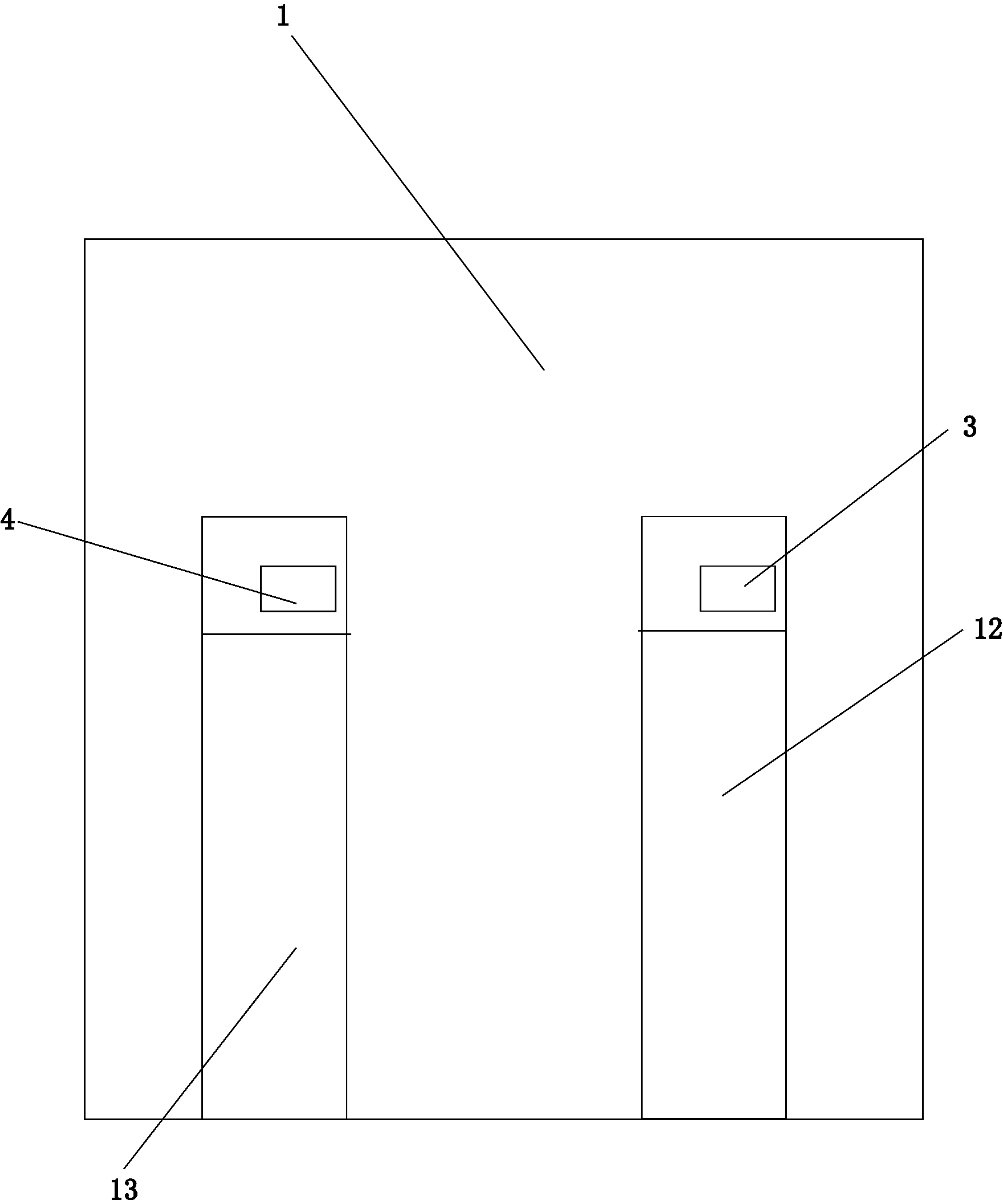

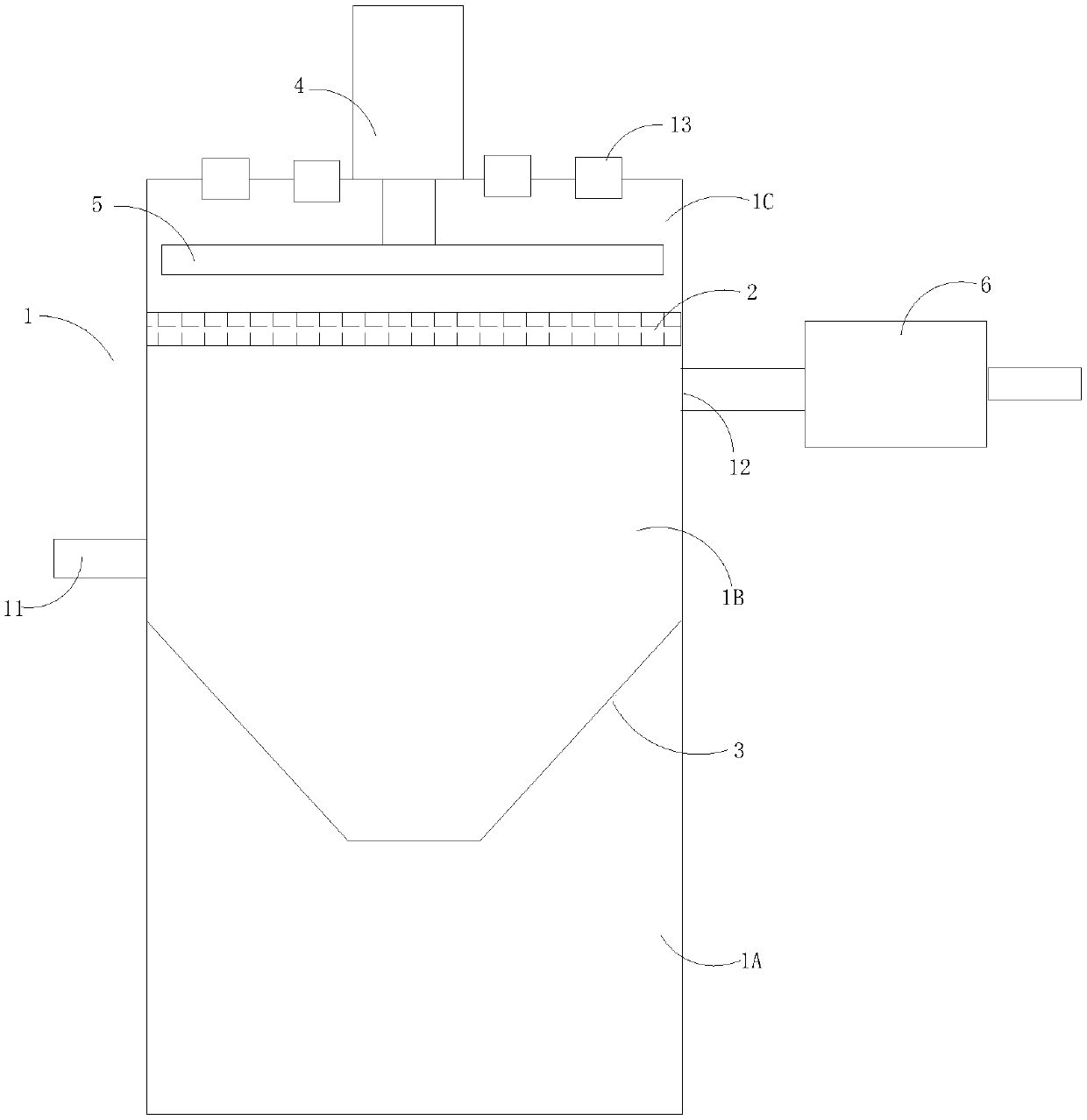

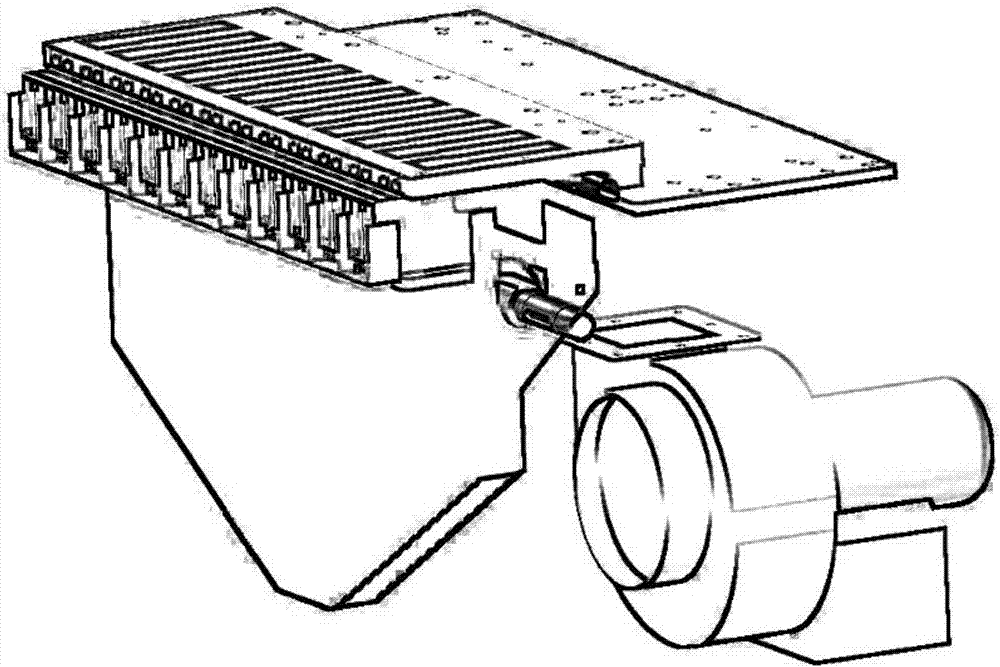

Dust removing component

InactiveCN109550344AImprove dust removal effectImprove efficiencyCombination devicesDispersed particle filtrationImpellerEngineering

The invention discloses a dust removing component. The dust removing component comprises a box body (1), a draught fan (4) and an impeller (5); the interior of the box body is provided with an accommodating cavity, the box body is sequentially provided with an air inlet (11), a first air outlet (12) and second air outlets (13) from the bottom to the top, wherein the air inlet (11), the first air outlet (12) and the second air outlets (13) communicates with the accommodating cavity, the interior of the accommodating cavity is provided with a guiding plate (3) and a filter plate (2), the accommodating cavity is divided into a first chamber (1A), a second chamber (1B) and a third chamber (1C), the air inlet (11) and the first air outlet (12) are located in the second chamber (1B), the secondair outlets (13) are located in the third chamber (1C), and the first air outlet is connected with a filter screen (6); and the impeller (5) is fixedly connected with the draught fan (4), and wind generated by the impeller flows upwards from the air inlet to the first air outlet and the second air outlets. The dust removing component disclosed in the invention has good dust removing effects, highefficiency and a simple structure, and provides green environmentally-friendly environment, thereby avoiding harm to worker health.

Owner:徐州博源科技有限公司

Ash and dust removing method for macadamia nut production

The invention relates to the technical field of nut production, in particular to an ash and dust removing method for macadamia nut production. The method includes the steps of firstly, an air curtain is arranged in front of a macadamia nut slitting device, and air is fed into the air curtain to blow away shell dust and fragments generated by slitting; secondly, a dust collecting tank is arranged on the periphery of the slitting device and can centralize the shell dust and fragments generated by the slitting in a dust collecting tank section; thirdly, the dust collecting tank is provided with an axial flow fan which is used for constantly sucking away the shell dust and fragments collected in the dust collecting tank; fourthly, the shell dust and fragments are sucked into a dust collecting device through the axial flow fan. Slitting needs to be performed on the shells of macadamia nuts during macadamia nut production to facilitate subsequent screening and processing, and a large amount of dust and shell fragments are generated during the production. The ash and dust removing method has the advantages that the dust and fragment pollution generated during the macadamia nut production can be reduced or eliminated, and the method is significant to production worker health guaranteeing, dust pollution reduction and equipment service life prolonging.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS +1

Environment-friendly printing drying device based on green printing technology

InactiveCN109968808AReduce lossesUniform wind volumeGas treatmentDispersed particle filtrationAir volumeQuality of work

The invention discloses an environment-friendly printing drying device based on green printing technology. The device comprises a platform, a drying box, an air outlet joint, a filter box, an air filter net, a filter box air outlet head, a centrifugal fan, an air inlet pipe, a conveying belt, supporting feet, a conveying belt roller, a filter box air inlet head, a cavity, a drying plate, a connecting column, a heating wire, an air outlet hole and a motor. The drying plate is provided with the cavity, the air outlet hole communicating with the cavity is formed in the bottom face of the drying plate, when the blowing mechanism works, air with heat in the drying box is exhausted out, then, the air is blown to the objected surface through the air outlet hole in the drying plate, in the whole process, heat losses are small, the objected wind amount is uniform, the drying efficiency is improved, the device contains the filter box, pungent taste generated by drying of a printed objected is absorbed and filtered by the air filter net in the filter box, environment quality of work by a worker is improved, and the threat of the taste to the worker health is reduced.

Owner:SUZHOU TONGLI PRINTING TECH

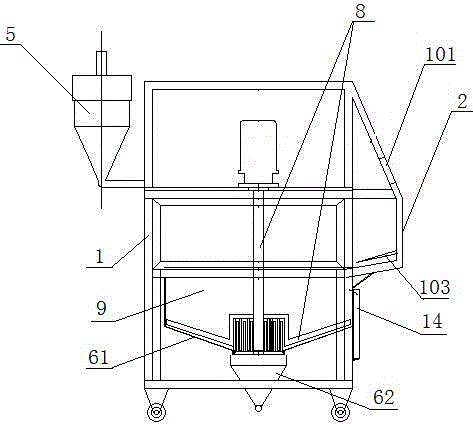

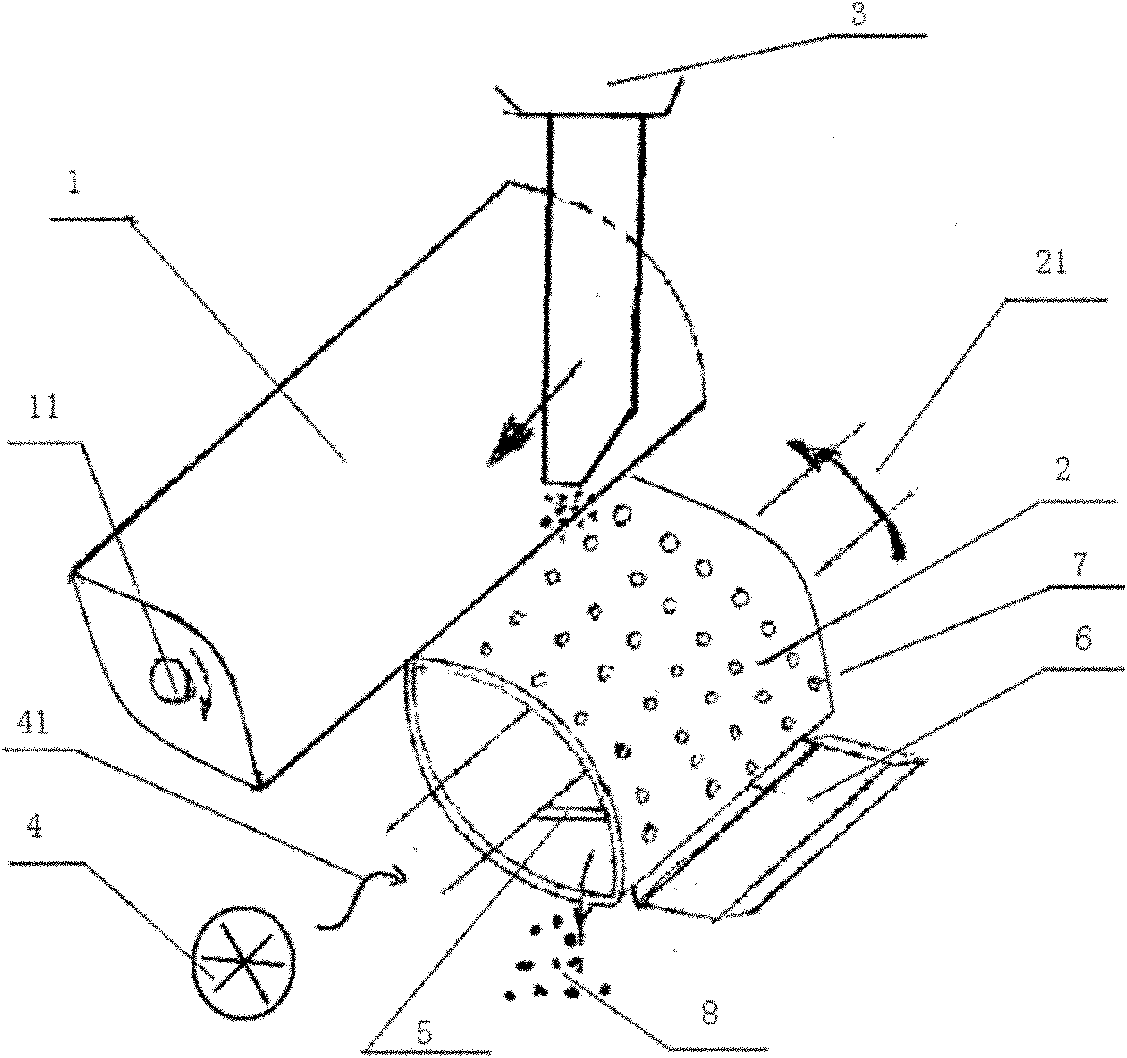

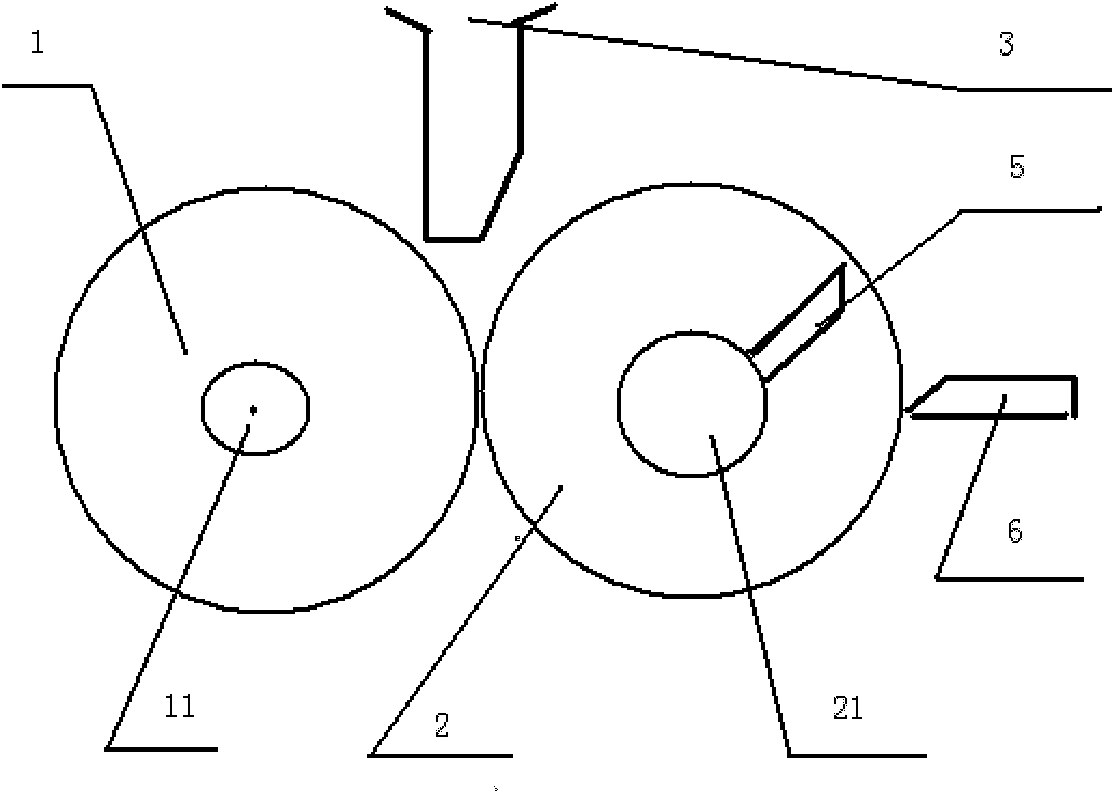

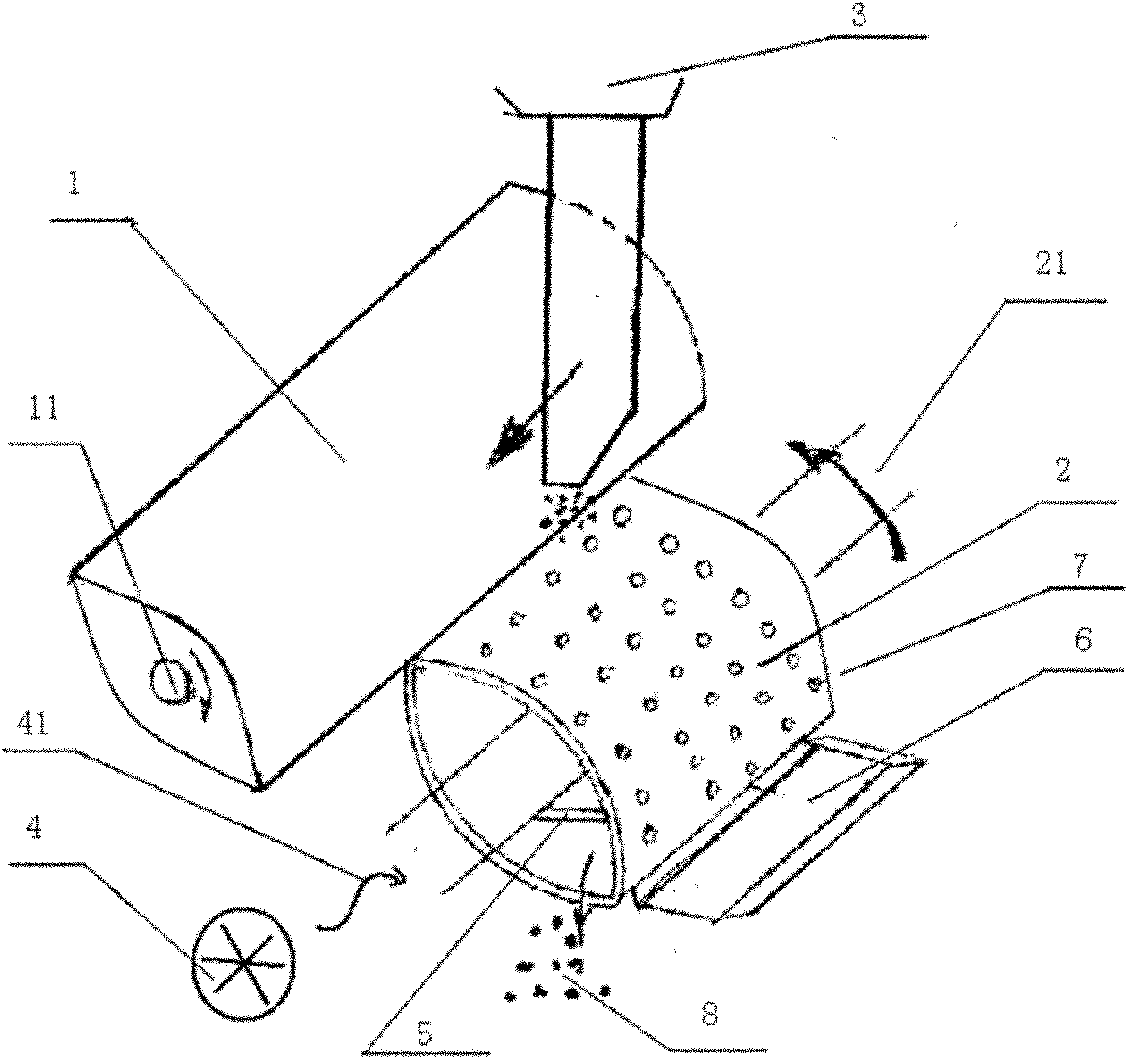

Thermo-setting plastic pelleting method and device

The invention discloses a thermo-setting plastic pelleting method and a thermo-setting plastic pelleting device. The pelleting method comprises the steps of charging, extrusion feeding, pelleting by scraping, discharging by air blow and the like. The pelleting device comprises a charge port, a squeeze roller, a pelleting drum, a cold air blowing device, an inner wall scraper, an outer wall scraper and the like, wherein the pelleting drum is externally tangential to the circumference of the squeeze roller, and the pelleting drum and the squeeze roller can rotate in opposite directions; and the cold air blowing device blows cold air to the position which material particles falls down onto of the inner wall of the pelleting drum and blows material particles pelleted out of the pelleting drum and collects the same. The method and the device have the advantages that: the prepared thermo-setting plastic particles are uniform; dust is greatly reduced in a processing process; environment is protected and worker health is improved.

Owner:WUXI CHUANGDA ELECTRONICS

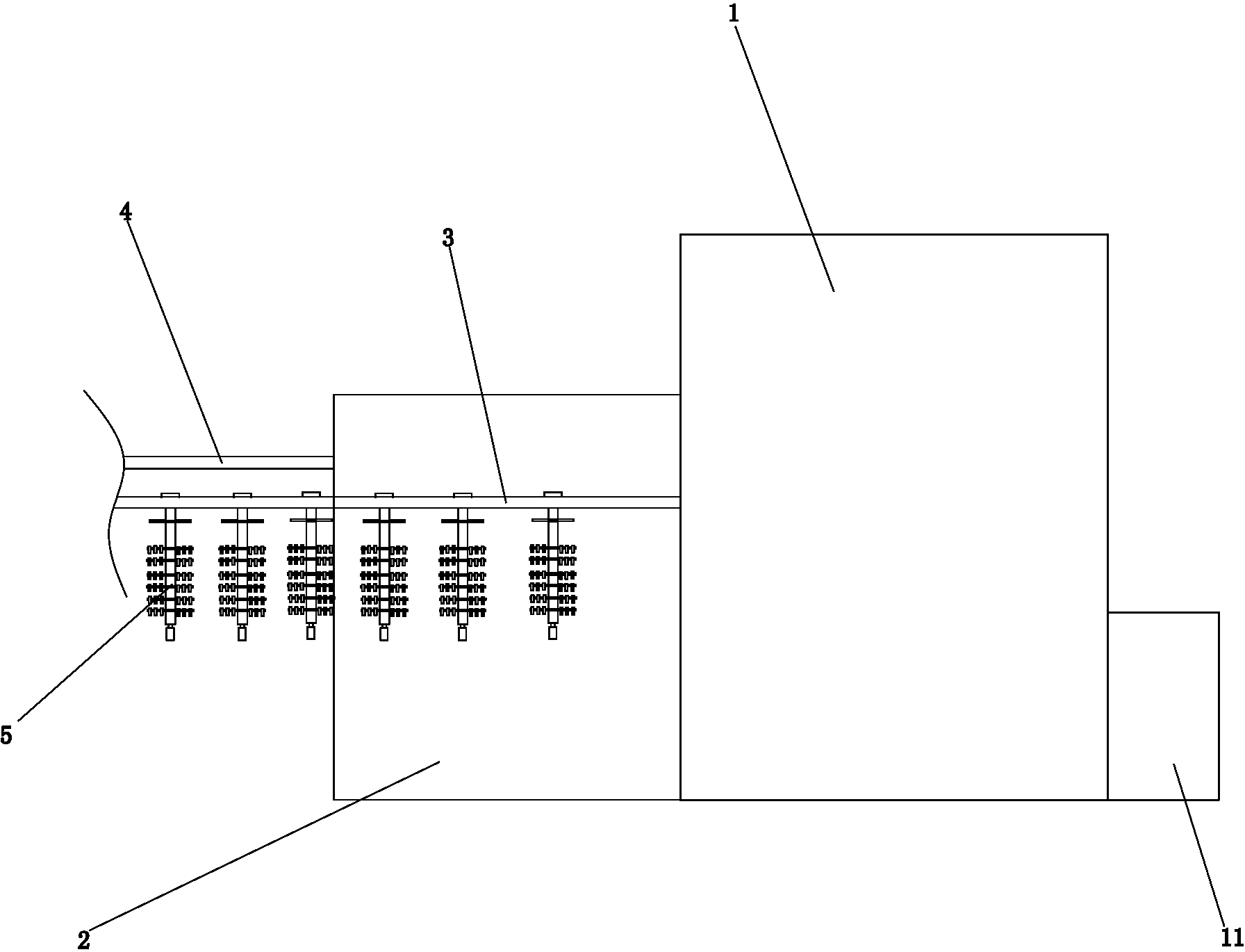

Indigo blue automatic delivery method

InactiveCN108246151AHealth threatImprove compliance rateRotary stirring mixersTransportation and packagingHigh concentrationEngineering

The invention discloses an indigo blue automatic delivery method. The indigo blue automatic delivery method comprises several main steps of unpacking, weighing, feeding, compounding, storing and material conveying. Indigo blue powder in a material collector of an unpacker is sucked out and transferred into a weighing barrel through a vacuum feeding machine, and the indigo blue powder in the weighing barrel is sucked out and transferred into a chemical barrel through the vacuum feeding machine after weighing is completed. The whole feeding process is highly automated, the dust of the indigo blue powder is prevented from dispersing in a workshop to cause threat to worker health, the indigo blue powder is compounded to be a high-concentration formula solution in the chemical barrel, then thehigh-concentration formula solution is conveyed to each dyeing machine according to practical demands, the whole process is uniform in execution standard, uncontrollable factors in the compounding andconveying processes are decreased, so that the product quality is more stable, and the product control rate is higher.

Owner:HANGZHOU FANTENG TECH

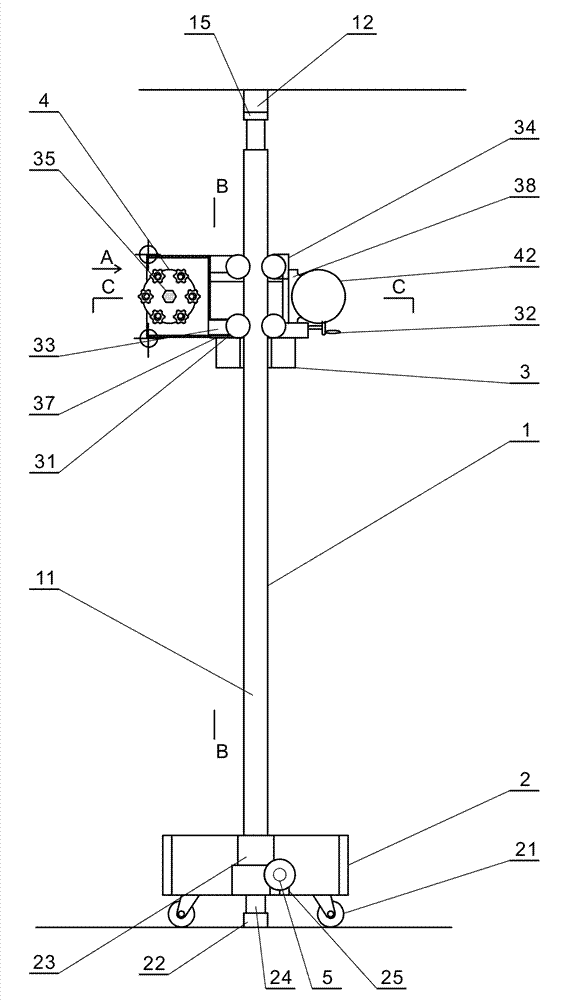

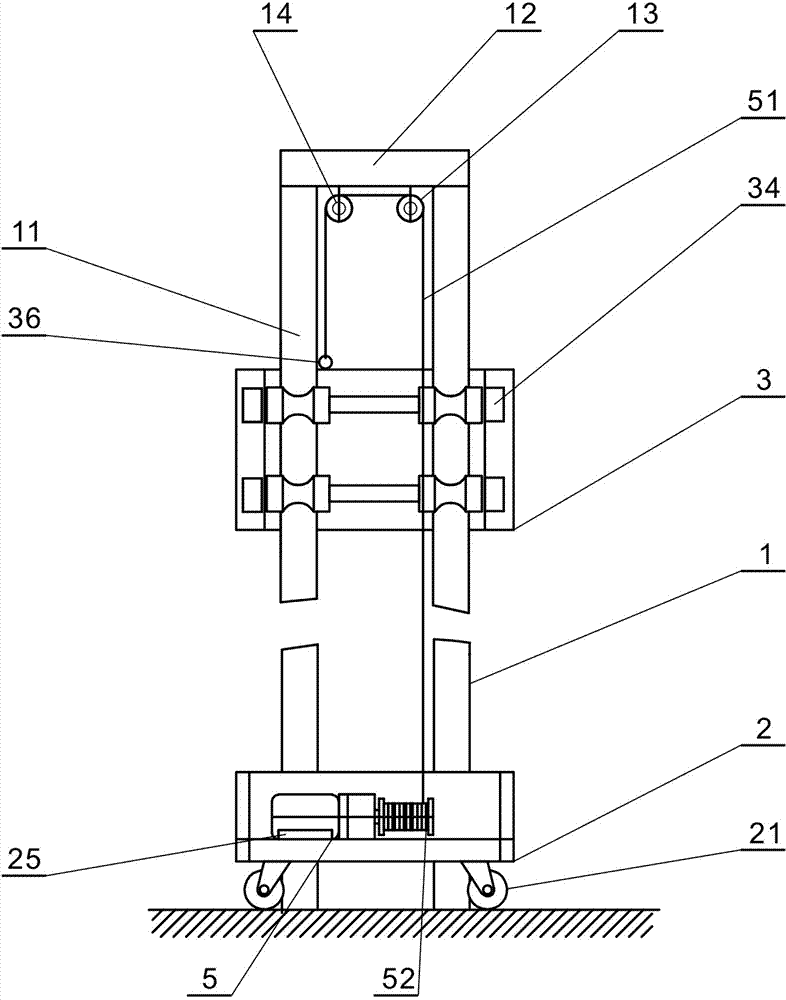

Automatic wall surface milling machine

InactiveCN103452299BGood for healthImprove protectionBuilding repairsSurface cleaningBlock and tackle

The invention discloses an automatic wall surface milling machine which comprises a rack, a base, a supporting plate box, a milling head and an elevator. The rack is composed of two extensible uprights, a cross beam and a pulley block, the supporting plate box comprises guide wheels, a moving supporting plate and a feed mechanism, the elevator is composed of a lifting steel wire rope and a winch, the rack is arranged on the base through the extensible uprights, the supporting plate box is looped on the extensible uprights through the guide wheels, the winch of the elevator is arranged on the base, one end of the lifting steel wire rope is connected with the winch while the other end of the same is connected with the supporting plate box, and the milling head is arranged on the moving supporting plate. By the automatic wall surface milling machine, mechanized construction like wall surface roughening and old wall surface removing is realized; the automatic wall surface milling machine has the advantages of thoroughness in wall surface cleaning, reduction of labor intensity and improvement of construction quality and working efficiency; a dust absorbing device is arranged, so that dustless construction can be realized, and worker health improvement and environment protection are facilitated.

Owner:上海晶湛机电有限公司

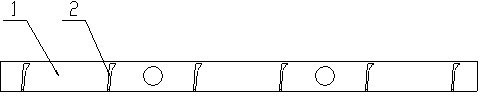

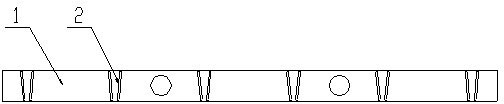

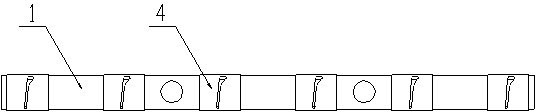

Interchangeable wear-resistant compact spinning special-shaped suction pipe

InactiveCN102286813AReduce production processExtended service lifeDrafting machinesWear resistantEngineering

The invention relates to a suction pipe for spinning equipment, in particular to a replaceable wear-resistant compact spinning special-shaped suction pipe, which belongs to the technical field of spinning. It includes a suction pipe body (1), the front of the suction pipe body (1) is provided with several diversion ports (3), and the diversion ports (3) are covered with a suction cover (4). The air suction hood (4) is fixedly connected with the air suction pipe body (1), and the air suction hood (4) is provided with an accumulation groove (2). The invention is an exchangeable wear-resistant compact spinning special-shaped suction pipe, which shortens the manufacturing process of the suction pipe, reduces production costs, and has positive effects on energy saving, environmental protection and worker health. When changing the spinning process, there is no need to replace the whole set of special-shaped suction pipe, only the suction cover on the suction pipe needs to be replaced, which greatly reduces the customer's use cost and management cost.

Owner:江阴市华方新技术科研有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com