Continuous glass fiber reinforced halogen-free fire retardation nylon 6 prepreg tape and preparation method thereof

A glass fiber, flame retardant nylon technology, used in belts, other household appliances, applications, etc., can solve the problems of releasing carcinogenic substances, production and secondary environmental disasters, etc., to reduce corrosion, reduce production costs, and improve product surface. The effect of finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

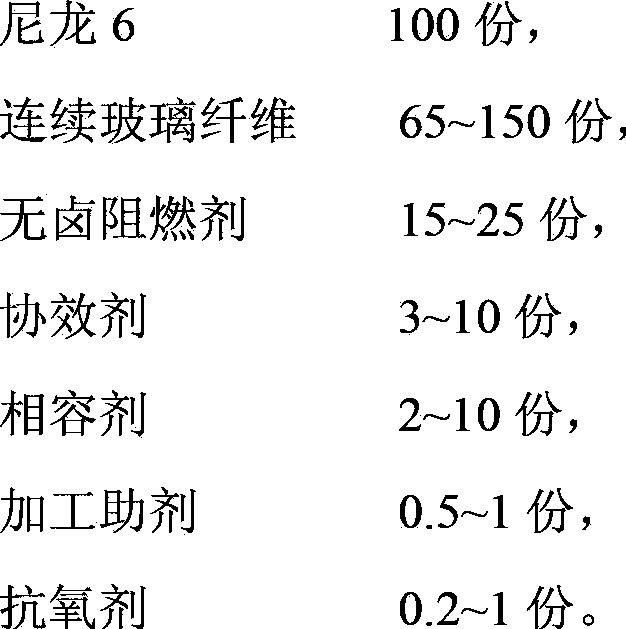

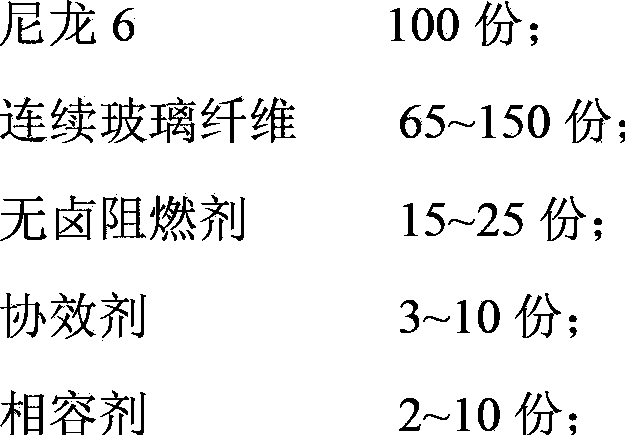

[0039] (1) Weigh nylon 6, halogen-free flame retardant, synergist, compatibilizer, processing aid, and antioxidant according to the ratio in Table 1 and add them to the high-mixer, and mix well;

[0040] (2) Add the mixture obtained in step (1) into a single-screw extruder, melt blend and extrude through a die for film coating; where the temperature of the barrel of the extruder is 210°C, 210°C, 250°C, 250°C, 250°C, 250°C, 250°C, 250°C, the main frequency of the extruder is 16Hz;

[0041] (3) The continuous glass fiber is led out from the creel unit, after the tension adjustment device, the spreading device, and the preheating device, the nylon 6 film extruded from the die is impregnated in the composite unit, and the flattening unit, the traction unit , and finally wind up to obtain a continuous glass fiber reinforced halogen-free flame-retardant nylon 6 prepreg tape; the preheating device is an infrared heating device, and the heating temperature is 190°C.

[0042] Nylon 6 ...

Embodiment 2

[0044] (1) Weigh nylon 6, halogen-free flame retardant, synergist, compatibilizer, processing aid, and antioxidant according to the ratio in Table 1 and add them to the high-mixer, and mix well;

[0045] (2) Add the mixture obtained in step (1) into a single-screw extruder, melt blend and extrude through a die for film coating; the barrel temperature of the extruder is 220°C, 220°C, 260°C, 260°C, 260°C, 260°C, 260°C, 260°C, the main frequency of the extruder is 12Hz;

[0046](3) The continuous glass fiber is led out from the creel unit, after the tension adjustment device, the spreading device, and the preheating device, the nylon 6 film extruded from the die is impregnated in the composite unit, and the flattening unit, the traction unit , and finally wind up to obtain a continuous glass fiber-reinforced halogen-free flame-retardant nylon 6 prepreg tape; in this step, the preheating device is an infrared heating device, and the heating temperature is 190°C.

[0047] Nylon 6 ...

Embodiment 3

[0049] (1) Weigh nylon 6, halogen-free flame retardant, synergist, compatibilizer, processing aid, and antioxidant according to the ratio in Table 1 and add them to the high-mixer, and mix well;

[0050] (2) Add the mixture obtained in step (1) into a single-screw extruder, melt blend and extrude through a die for film coating; where the temperature of the barrel of the extruder is 225°C, 225°C, 255°C, 255°C, 255°C, 255°C, 255°C, 255°C, the main frequency of the extruder is 14Hz;

[0051] (3) The continuous glass fiber is led out from the creel unit, after the tension adjustment device, the spreading device, and the preheating device, the nylon 6 film extruded from the die is impregnated in the composite unit, and the flattening unit, the traction unit , and finally wind up to obtain a continuous glass fiber reinforced halogen-free flame-retardant nylon 6 prepreg tape; the preheating device is an infrared heating device, and the heating temperature is 190°C.

[0052] In embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com