Automatic spraying machine

A technology of automatic spraying and spraying columns, which is applied in coatings, spray booths, spraying devices, etc., can solve problems such as high labor intensity, strong health damage to workers, and unstable spraying quality, so as to improve efficiency and solve labor-intensive problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in combination with specific implementation methods and accompanying drawings.

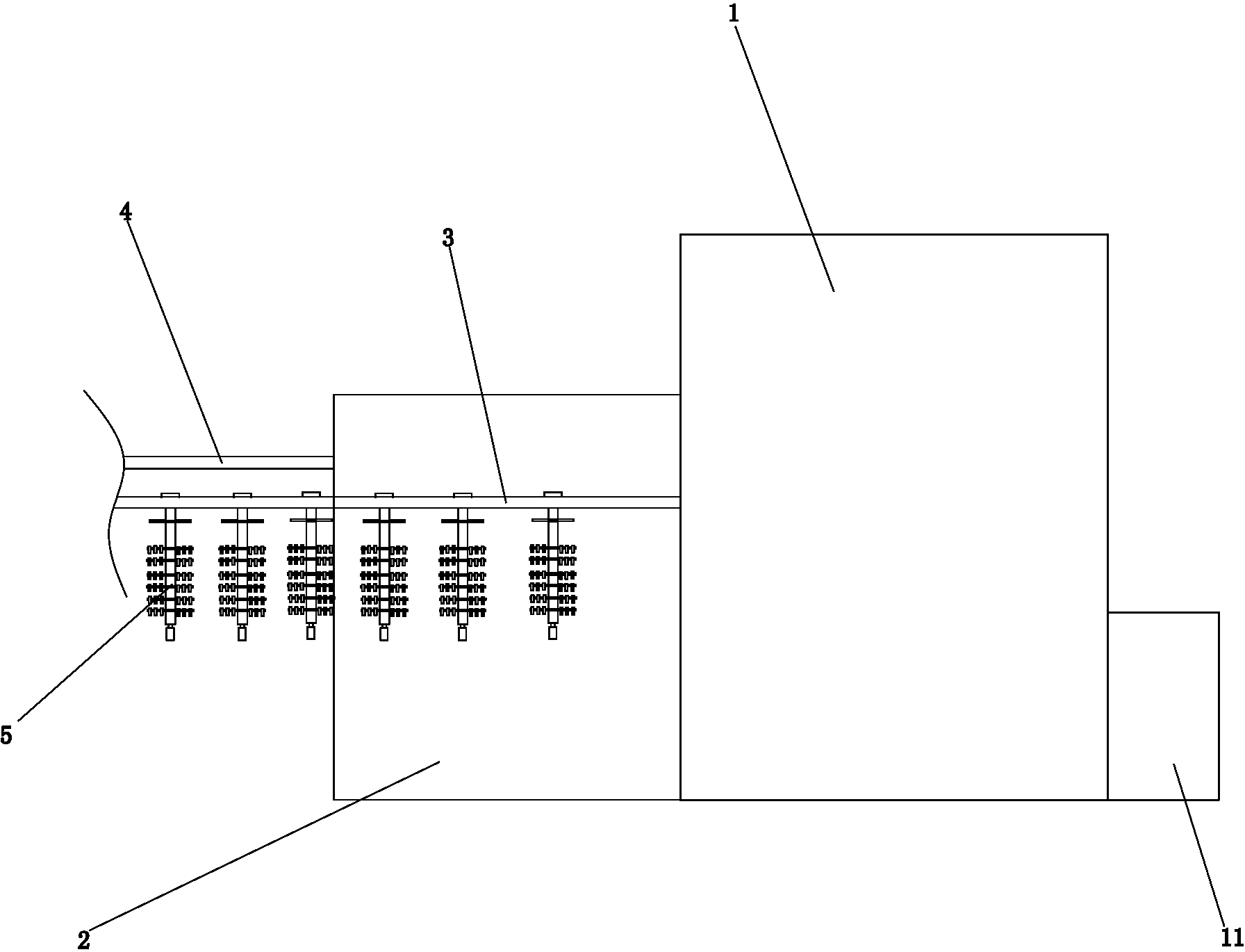

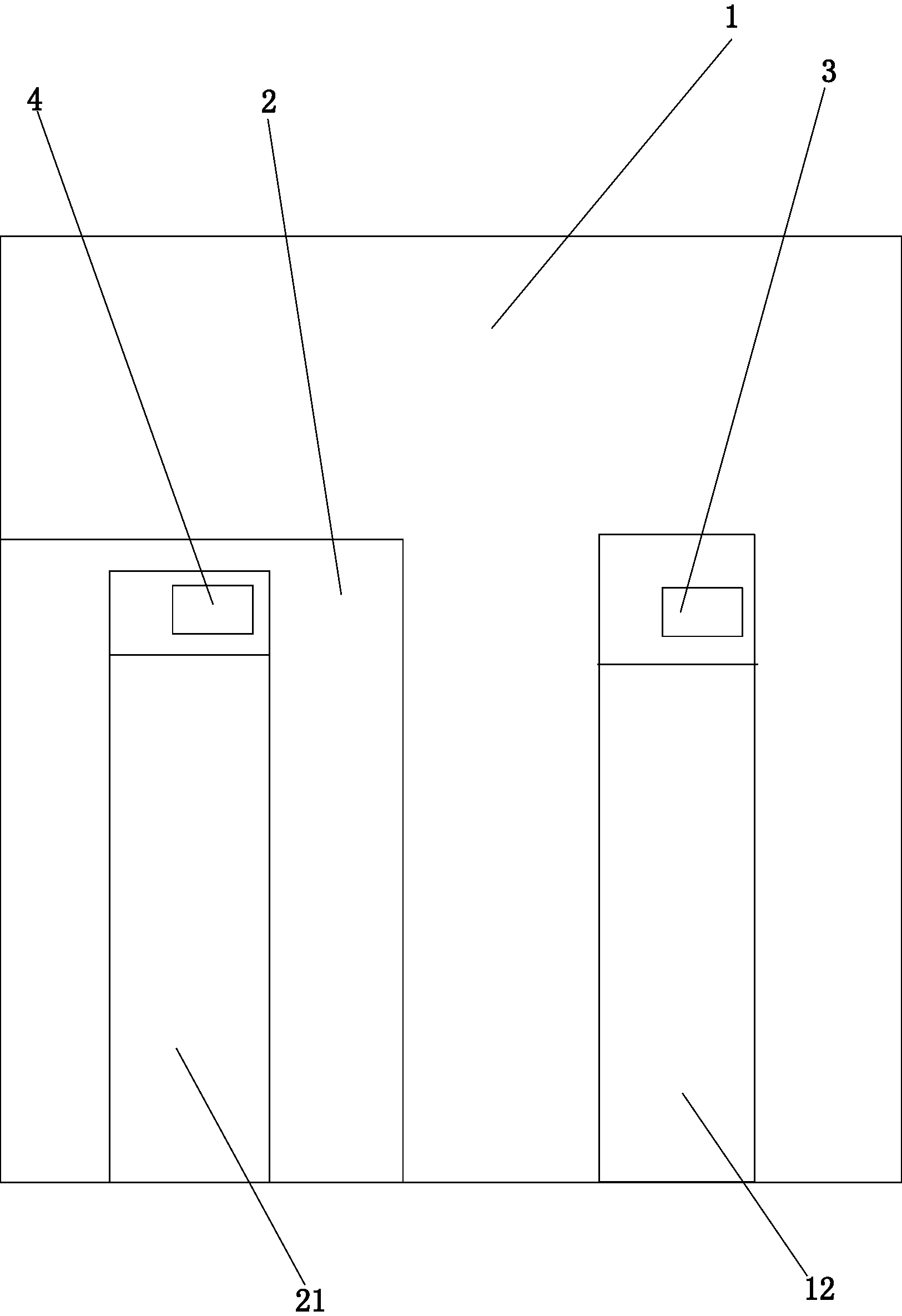

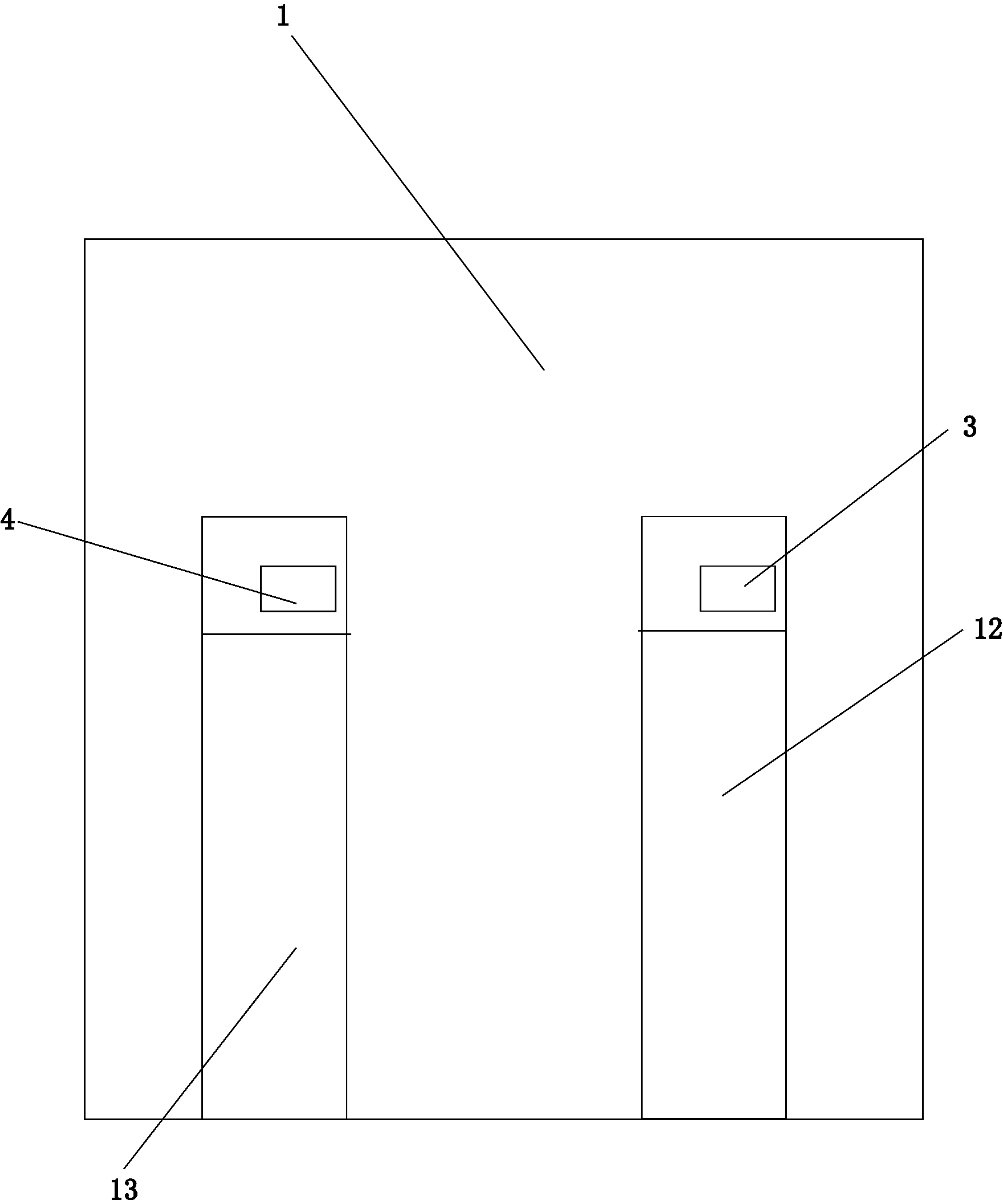

[0031] Such as Figure 1 to Figure 14 The automatic spraying machine includes a main body box 1 and a controller 11 , and the controller 11 includes a display screen 111 and an operation panel 112 . The front of the main body case 1 is provided with a transparent observation window 14 . Main body box 1 is provided with entering track 3 and leaving track 4, is also provided with drying box 2 on the main body box 1, leaves track 4 and stretches in drying box 2, and stretches out from drying box 2 other ends, in the oven Several dryers 22 are arranged in the dry box 2, and the dryers 22 are evenly placed on both sides of the track 4. Bottom of main body case 1 is provided with mesh plate 81, and mesh plate 81 below is provided with suction fan 82, and suction fan 82 below is provided with suction pipe 83, and filter cotton 84 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com