Patents

Literature

119results about How to "Improve compliance rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

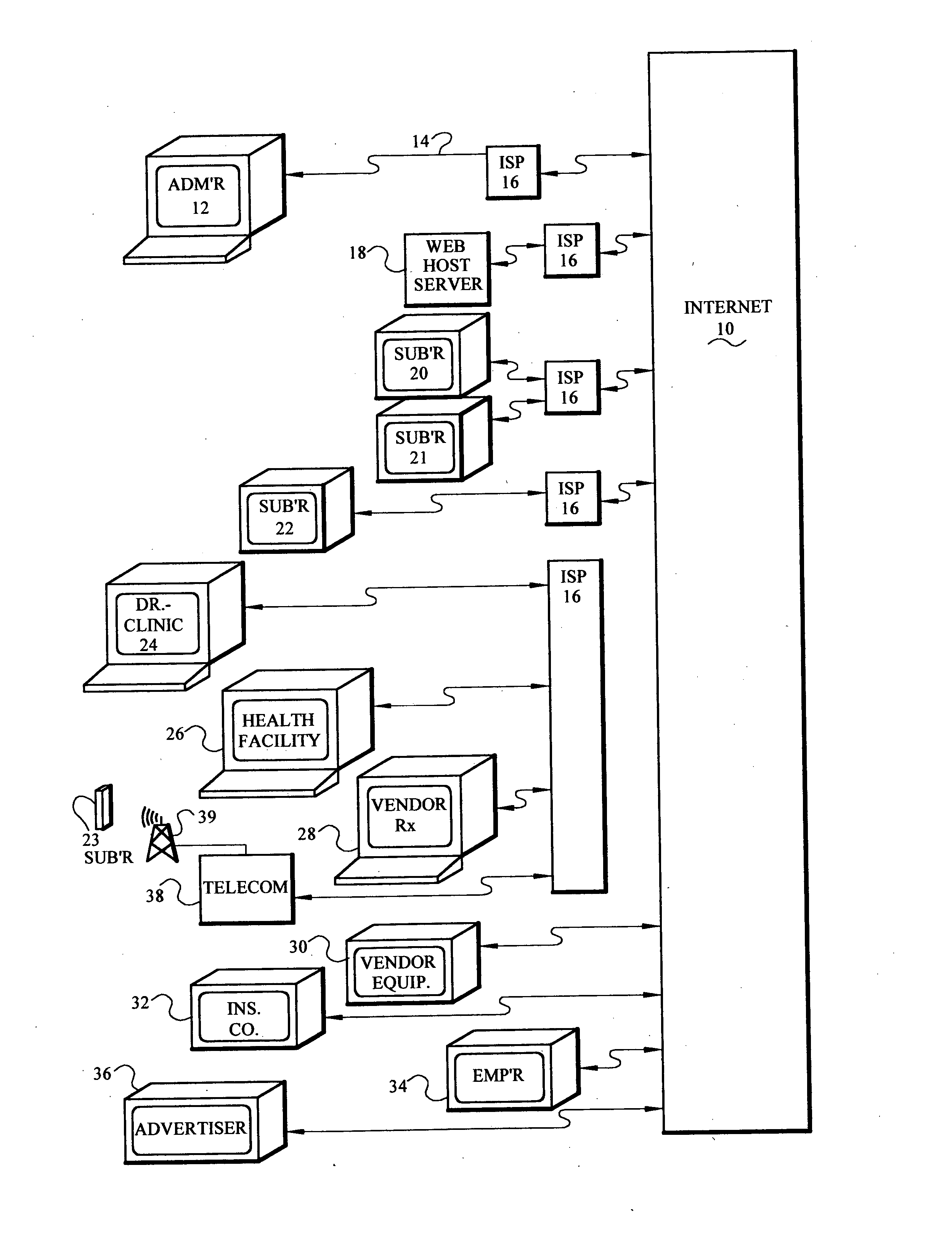

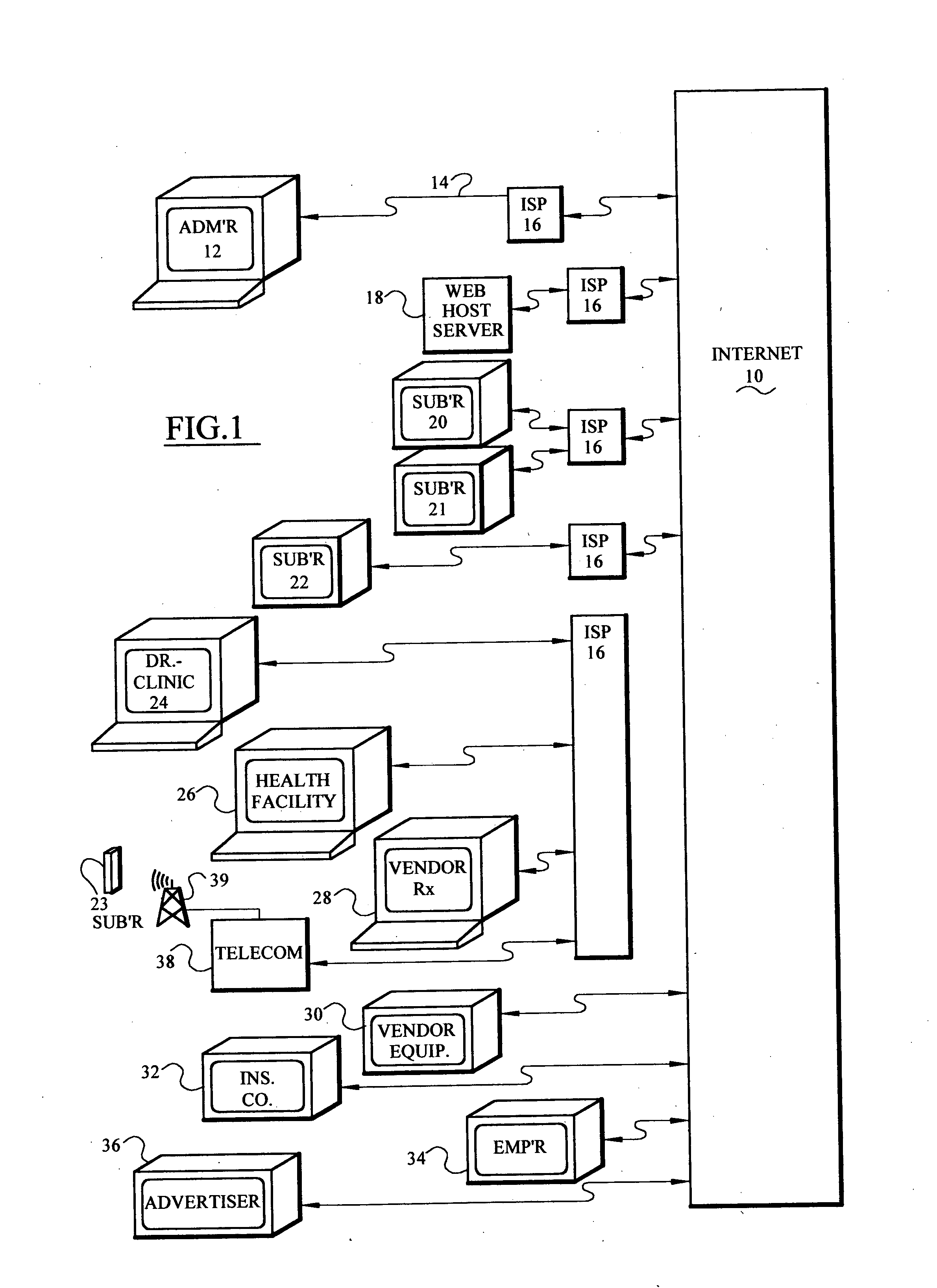

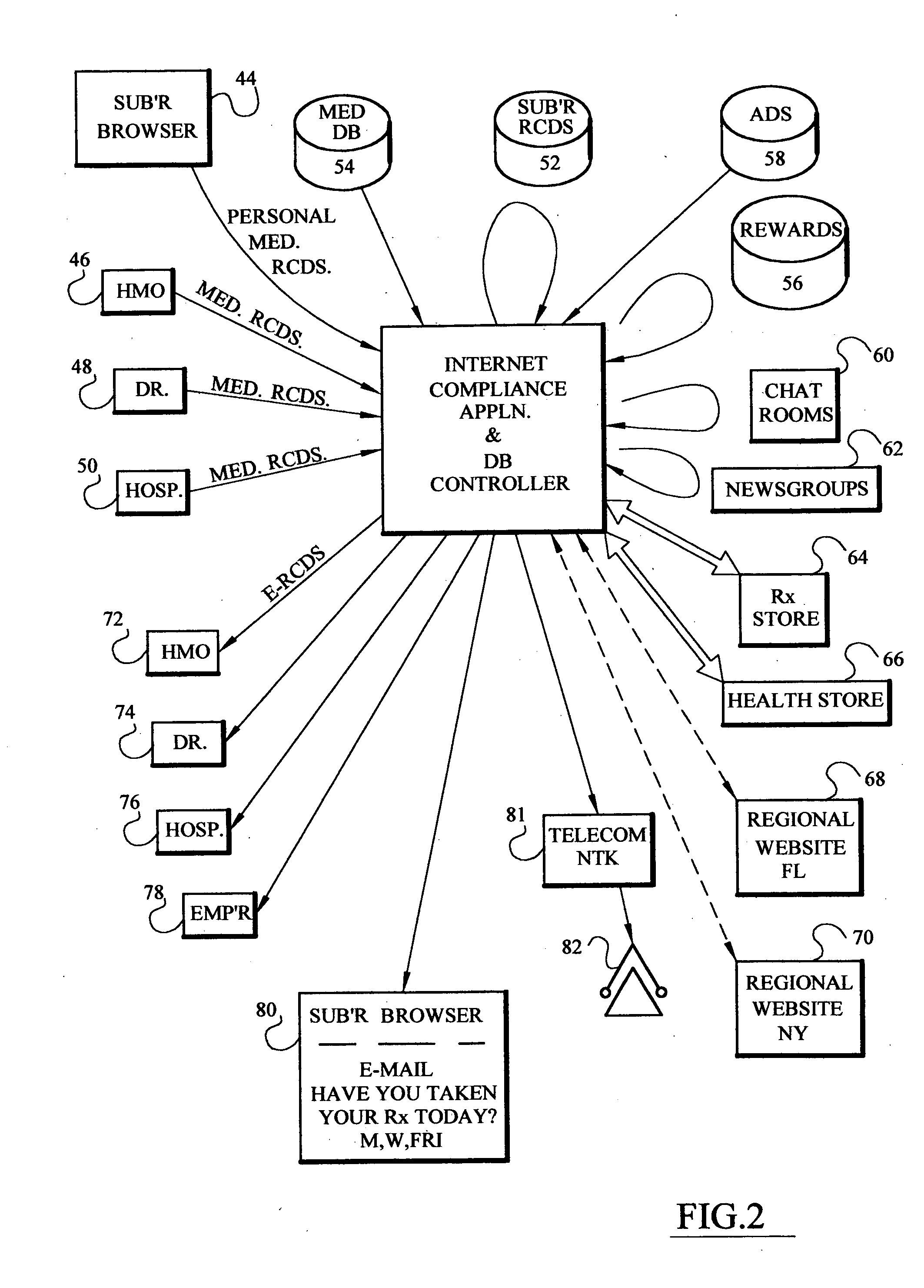

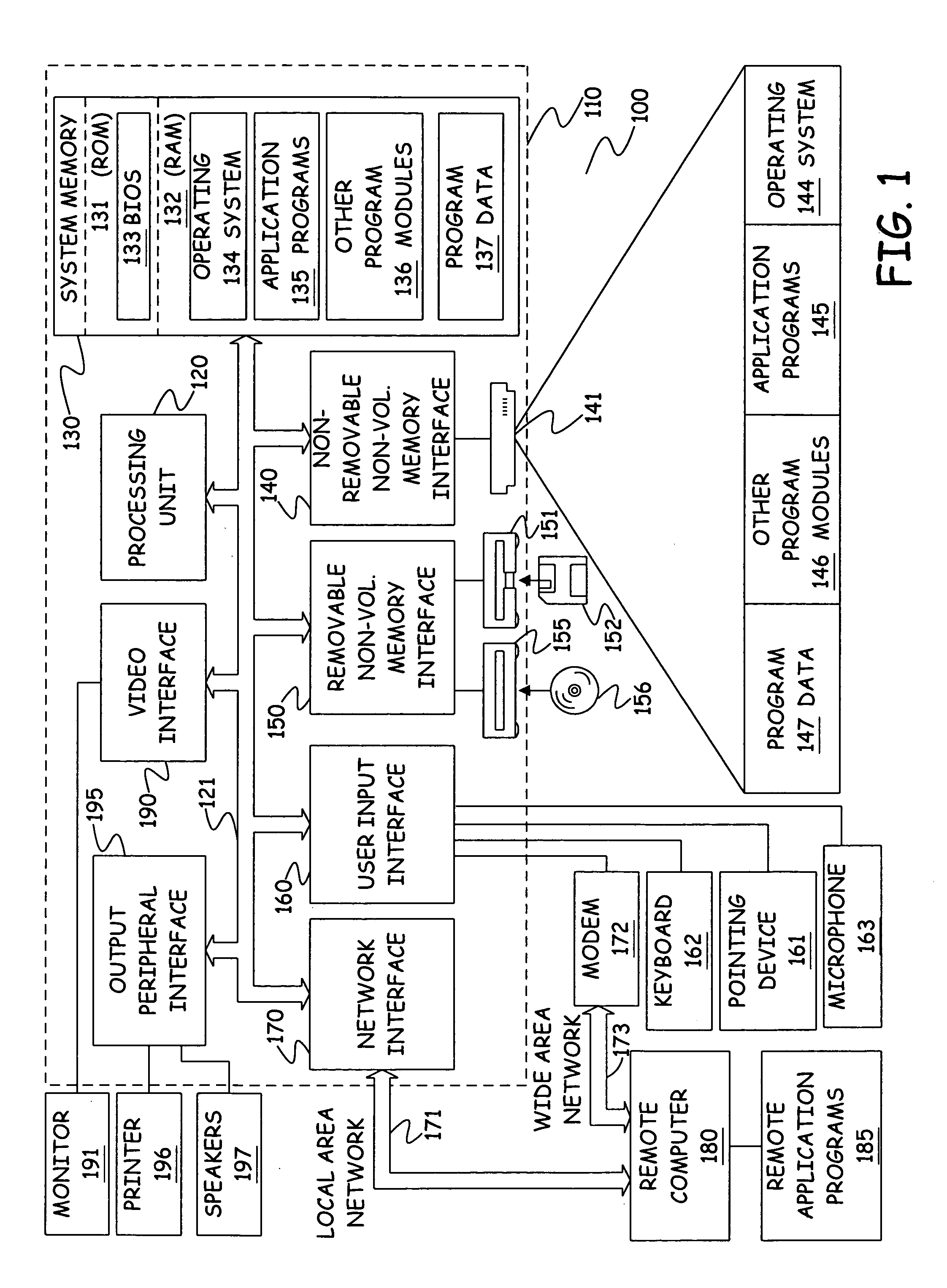

Computer based risk level monitor and patient compliance method and system

InactiveUS20050102159A1Improve compliance rateVAR reductionData processing applicationsHealth-index calculationRisk levelTotal risk

The risk monitor, as a computer-based method, program or system, monitors medical compliance by a plurality of patients having a corresponding plurality of medical compliance plans. The plans for each patient are displayed and the system accepts input from the patient indicative and / or heathcare providers of the patient's compliance with the plan. The system then assesses or analyzes the input and assigns a corresponding risk value based upon a range of risk values for various degrees of compliance. In addition, the patient's lifestyle inputs can be added to determine the risk value. The assessment continues for a plurality of patients thereby providing an indication of the risk value (a total risk value) for a patient, doctor, group of healthcare providers, a clinic or a hospital. By implementing various communication episodes (telephone calls, e-mails, letters), the system seeks to reduce the risk value for a particular patient and for the plurality of patients by altering the communication episodes and monitoring the resulting risk values both individually and as a group.

Owner:MONDSHINE ROBERT B

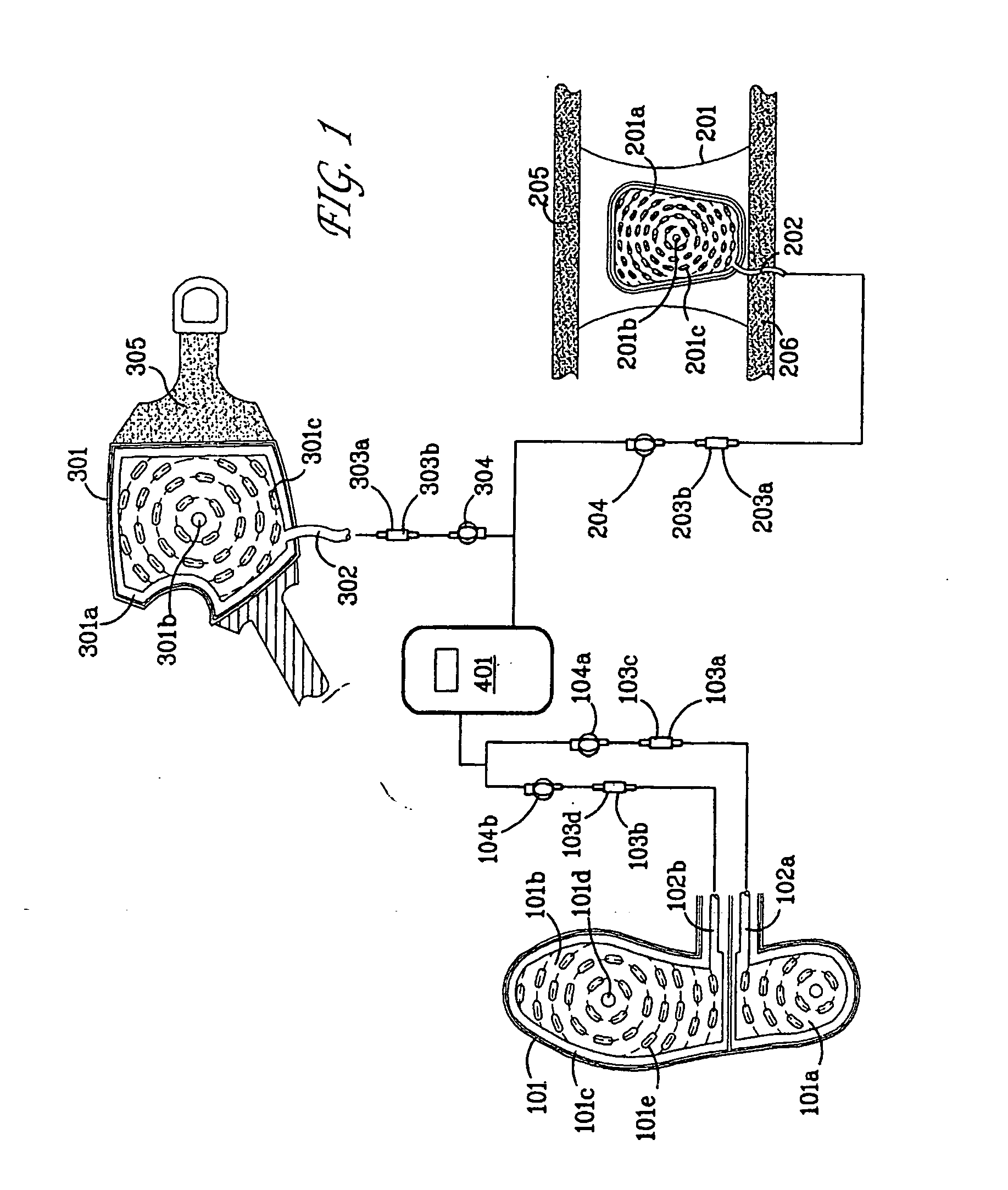

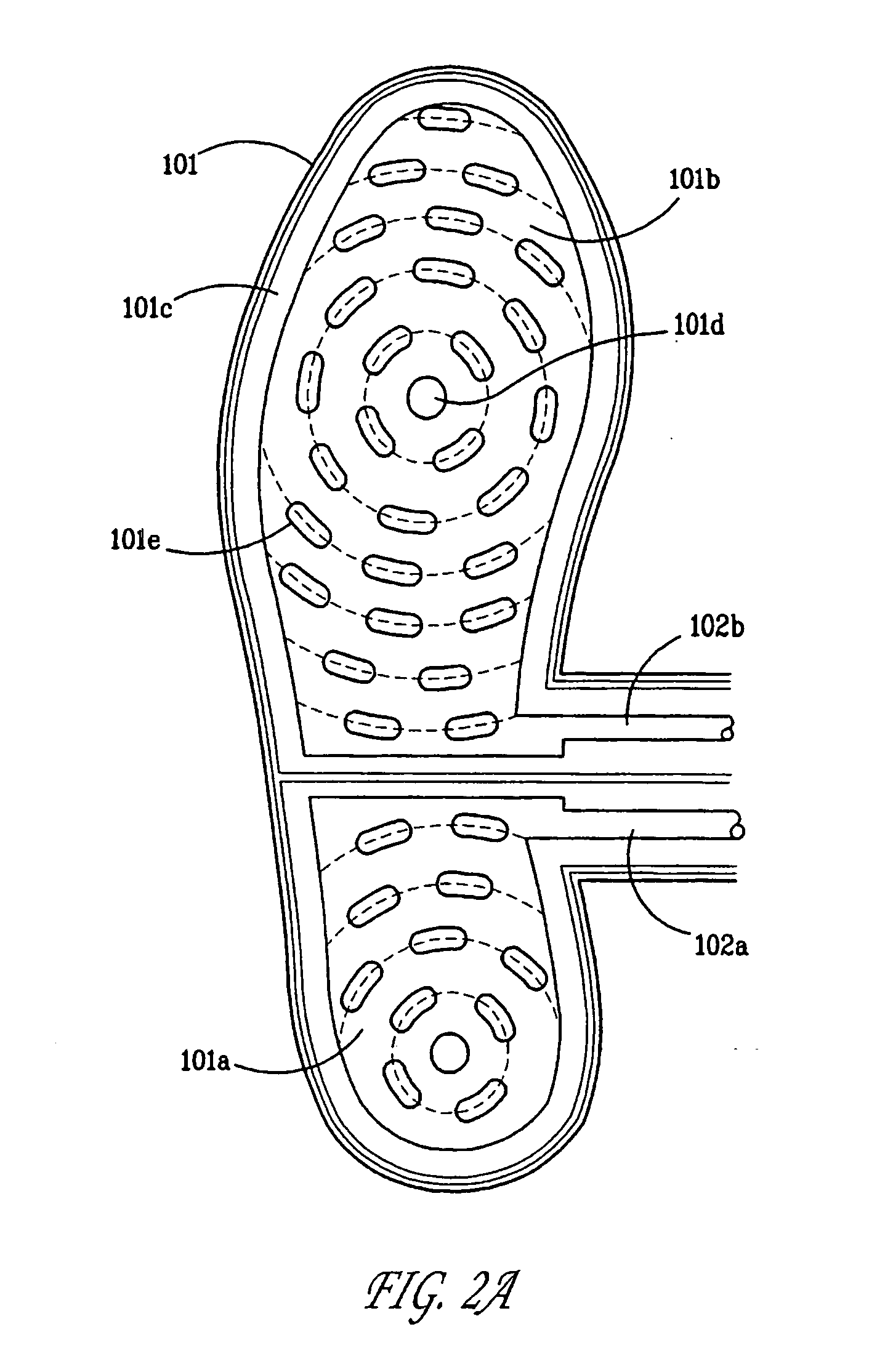

Force sensor system for use in monitoring weight bearing

InactiveUS20060282017A1Quality improvementNormalize gait patternElectrotherapySolesEngineeringBiological activation

A force sensor system for use in monitoring weight bearing on a location. The force sensor system comprises at least one a foot force sensor, a palm force sensor, and a knee force sensor. The foot force sensor comprises a flexible insole containing a plurality of inflatable pockets that are inflated with air or liquid. The palm force sensor and knee force sensor each comprise a wrap to be worn around the palm and knee, respectively. Each wrap comprises a pocket. Each pocket is connected to a tube that, in turn, connects with a pressure sensor and a connector coupling that is remote from the pocket. Each coupling contains a valve. The valve opens to allow inflation and deflation of each inflatable pocket. The pressure sensors measure the air or liquid pressure within each of the inflatable pockets, and convert the corresponding pressure signal into a suitable output signal medium, usually electrical signals. The output signal from the sensors provides accurate real time input data to a weight bearing biofeedback system or to control a stimulator for activation of an electronic orthosis to normalize dynamic gait patterns.

Owner:ANDANTE MEDICAL DEVICES

Novel method for feeding egg newborn chick with high efficiency

InactiveCN101642077AMake up for the shortcoming of "physiological stage feeding method"Improve uniformityFood processingAnimal feeding stuffBreeding chickenMortality rate

The invention discloses a method for feeding an egg newborn chick with high efficiency in the field of agricultural pasturage breeding. The method takes a mode that body type indexes reach the standard as a standard and finds out the body type indexes that the determining degree of the brooding period of layers to the laying performance is maximum. The breeding process comprises the following steps: a preventive medicine of one treatment course is added in the feed of 3-5 days before 20 ages in days in the 7-11 ages in days of a newborn chick; within 1-2 days before and after immunization of each time, a stress-resisting additive is added into the drinking water of the newborn chick; the nutritional level of rations of 0-3 ages in week or 0-4 ages in week is higher than that of rations atthe later period of brooding; the newborn chick is fed with a feed to 8 ages in week; and after 8 weeks, the feed is replaced by rations for raising grown chickens. Compared with a conventional breeding method, the method enhances the standard reaching rates of the body weight and the shank length of the newborn chick with 8 ages in week by 12.4% and 9.3% respectively, enhances the uniformity of chick colonies by 8.4%, enhances the egg yield by 7.2%, lowers the mortality rate of the laying period by 4.3% and enhances the benefit of breeding chickens by 18.7%; and the input-output ratio averagely reaches 1:8.1.

Owner:NORTHWEST A & F UNIV

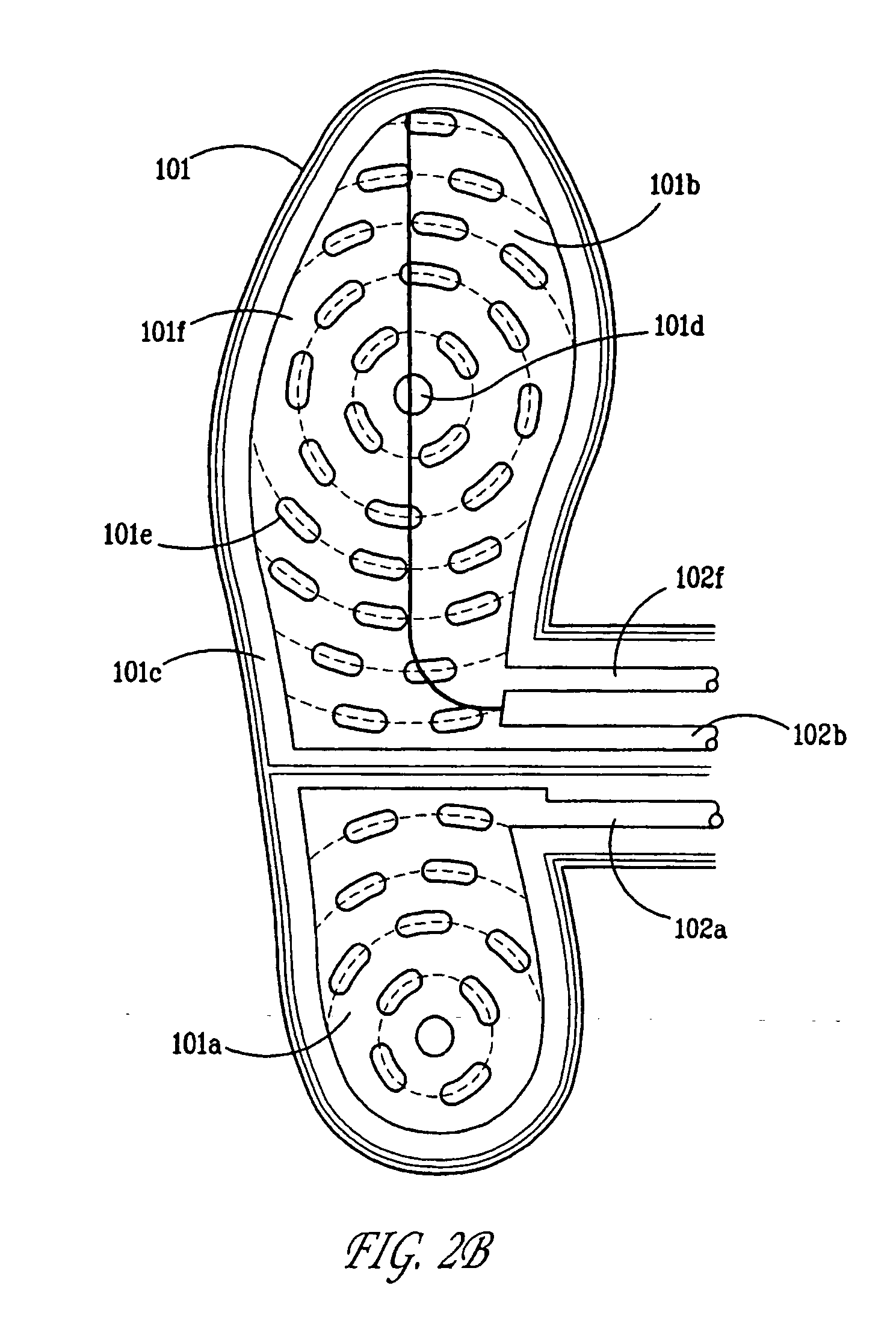

Method for applying a skin treatment

ActiveUS9511034B1Effective treatmentEncourage high user compliance rateCosmetic preparationsToilet preparationsSkin treatmentsKeloid

The invention is generally a skin treatment for managing skin conditions ranging from scars, including keloids, to burns and wrinkles. The skin treatment may comprise of several components including a cleansing solution, a silicone elastomer, and a mineral powder that may be utilized to treat and camouflage the affected skin. In one embodiment, a cleansing component is used to prime a skin area, cleansing and treating the area so that a silicone component can heal the skin.

Owner:DIRECT COMPONENTS INC

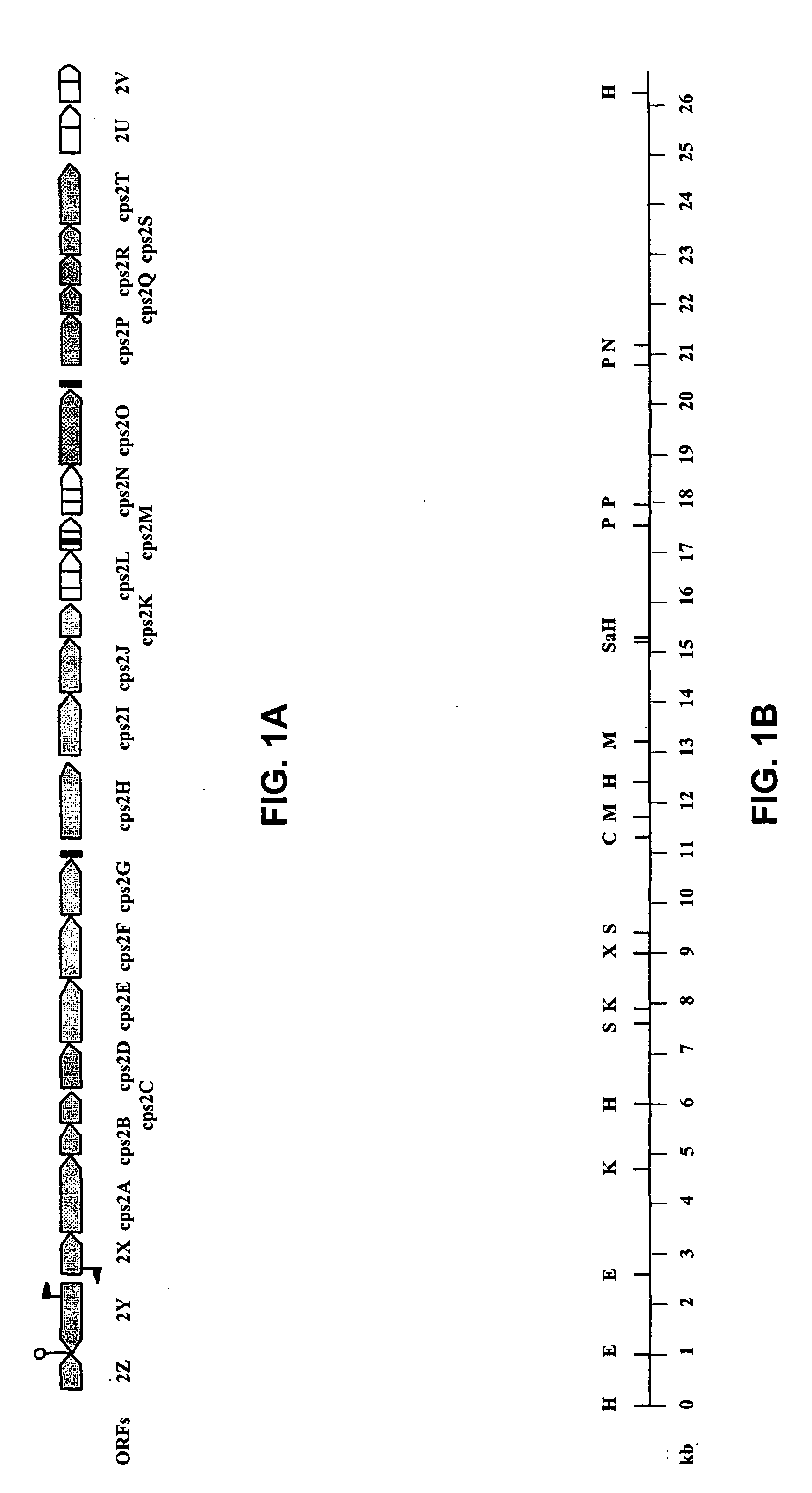

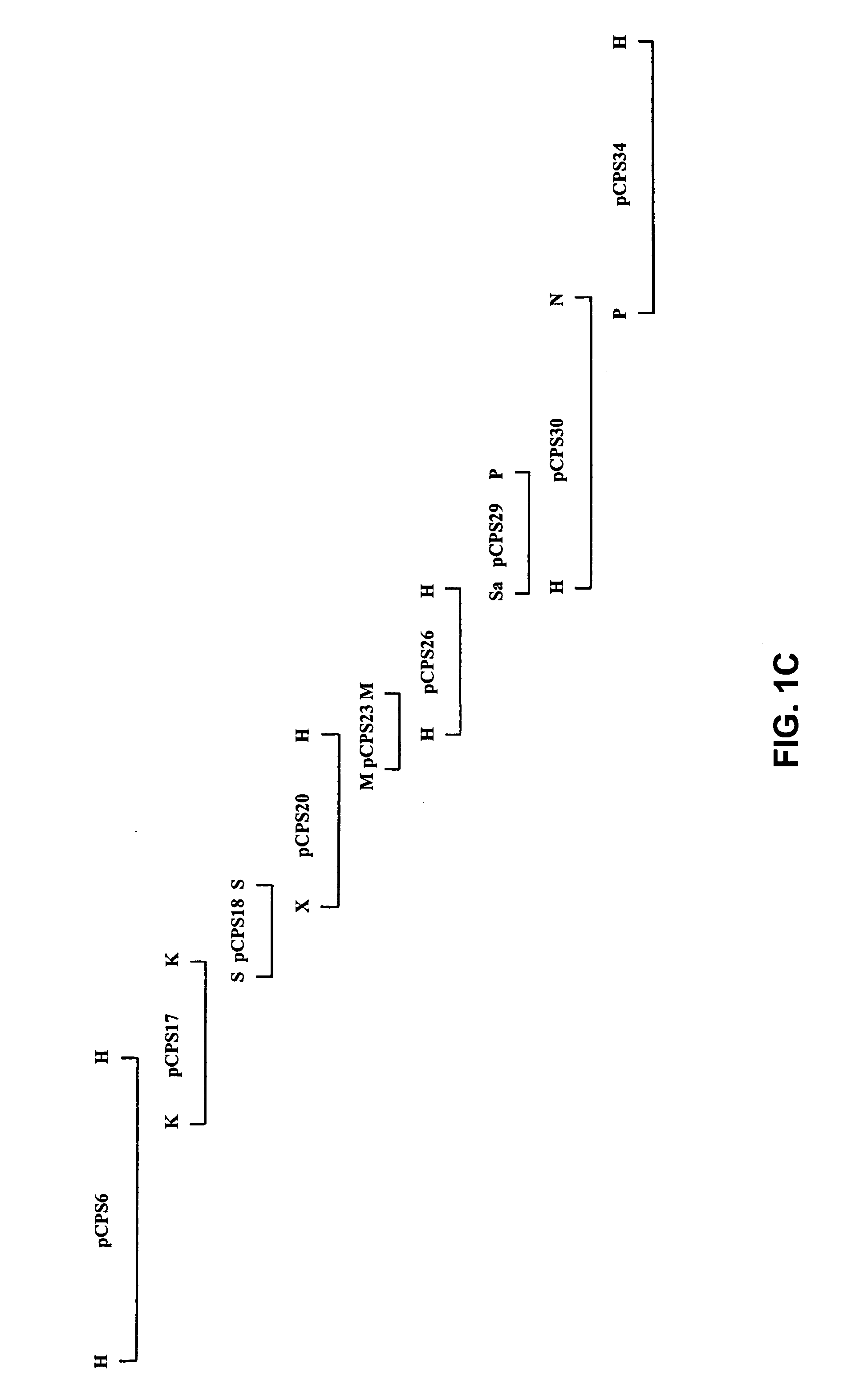

Streptococcus suis vaccines and diagnostic tests

InactiveUS7125548B2ImmunogenicityImproving immunogenicityAntibacterial agentsBacteriaAntigenSpecific detection

The invention relates to Streptococcus suis infection in pigs, vaccines directed against those infections and tests for diagnosing Streptococcus suis infections. The invention provides an isolated or recombinant nucleic acid encoding a capsular gene cluster of Streptococcus suis or a gene or gene fragment derivated thereof. The invention further provides a nucleic acid probe or primer allowing species or serotype-specific detection of Streptococcus suis. The invention also provides a Streptococcus suis antigen and vaccine derived thereof.

Owner:STICHTING DIENST LANBOUWKUNDIG ONDERZOEK

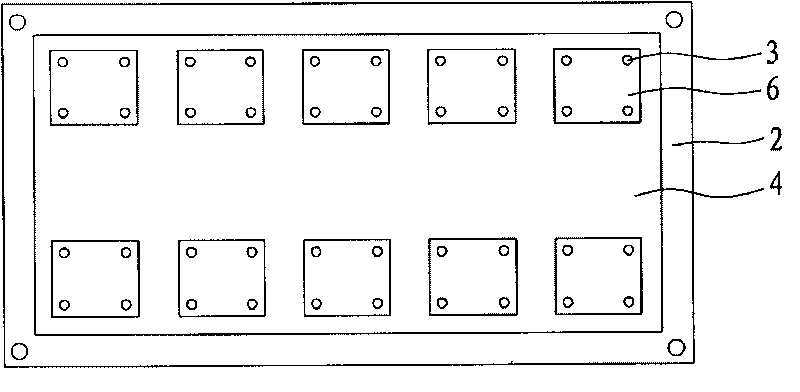

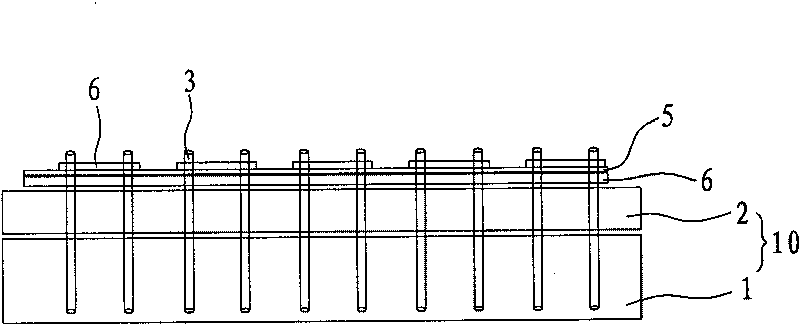

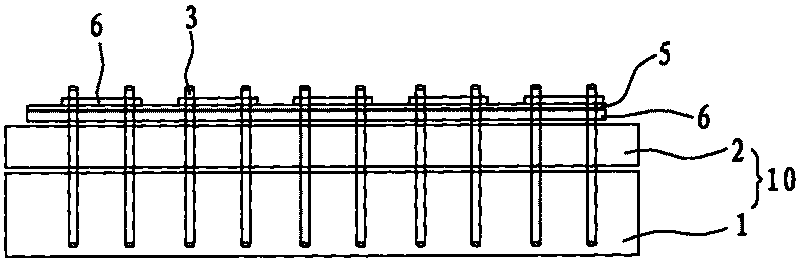

Flexible printed circuit board steel disc reinforcing hot-pressing making process

InactiveCN101720169ANot easy to fall offPromote sheddingPrinted circuit manufactureFlexible circuitsPrinted circuit board

The invention discloses a flexible printed circuit board steel disc reinforcing hot-pressing making process, including that pure glue is firstly adhered on the steel disc reinforcing position of the flexible printed circuit board and then steel disc is adhered, lamination curing is carried out to complete steel disc reinforcing, and the steel disc is fixed by steel disc adhesion jig. The invention adopts electric iron to preheat the steel disc firstly, so that certain stickiness is kept between the steel disc and the flexible printed circuit board and the steel disc can not drop in the process that the flexible printed circuit board is taken out and transferred; and the pure glue used for adhering the flexible printed circuit board and reinforcing the steel disc in steel disc hot-pressing process is thermosetting glue, namely glue system capable of being molten and cohered under heating condition and can be cured after curing at certain temperature for a while, so that the steel disc is firmly adhered on the flexible printed circuit board and can not drop in post making processes. The invention has simple making process and strong feasibility, can thoroughly avoid steel disc dropping and deviation problems and has wide applicability and higher production efficiency.

Owner:XIAMEN HONGXIN ELECTRON TECH

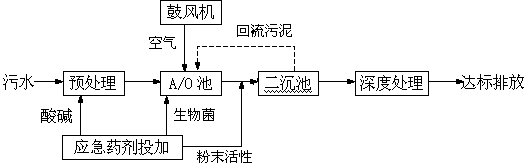

Emergency control method for sewage treatment system for treating abnormal influent/effluent quality

InactiveCN103864194ALess investmentImproved resistance to shock loadsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentTreatment effectEngineering

The invention relates to an emergency control method for a sewage treatment system for treating abnormal influent / effluent quality. The emergency control method comprises the steps of firstly, judging weather a sewage treatment plant is impacted by abnormal influent; secondly, judging weather an effluent quality index belongs to abnormal effluent; if detecting to find abnormal influent within a certain period of time, regulating an operation condition according to different exceeding conditions; if detecting to find abnormal effluent within a certain period of time, starting up emergency agent addition to improve the treatment effect in time. The method is realized according to the overall regulation thinking that the impact of influent impact to the sewage treatment system is reduced through regulating process control parameters when abnormal influent of a sewage plant appears, and the system function is restored in time through adding an emergency agent when abnormal influent of the sewage plant appears; in addition, the real-time control for front feed and back feed is realized by sufficiently utilizing online monitored data. The method is low in investment and capable of effectively handling the influent impact load, rapidly improving and restoring a system treatment effect, exerting the treatment capability of a sewage treatment facility to the maximum extent and increasing the rate of reaching the standard.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI

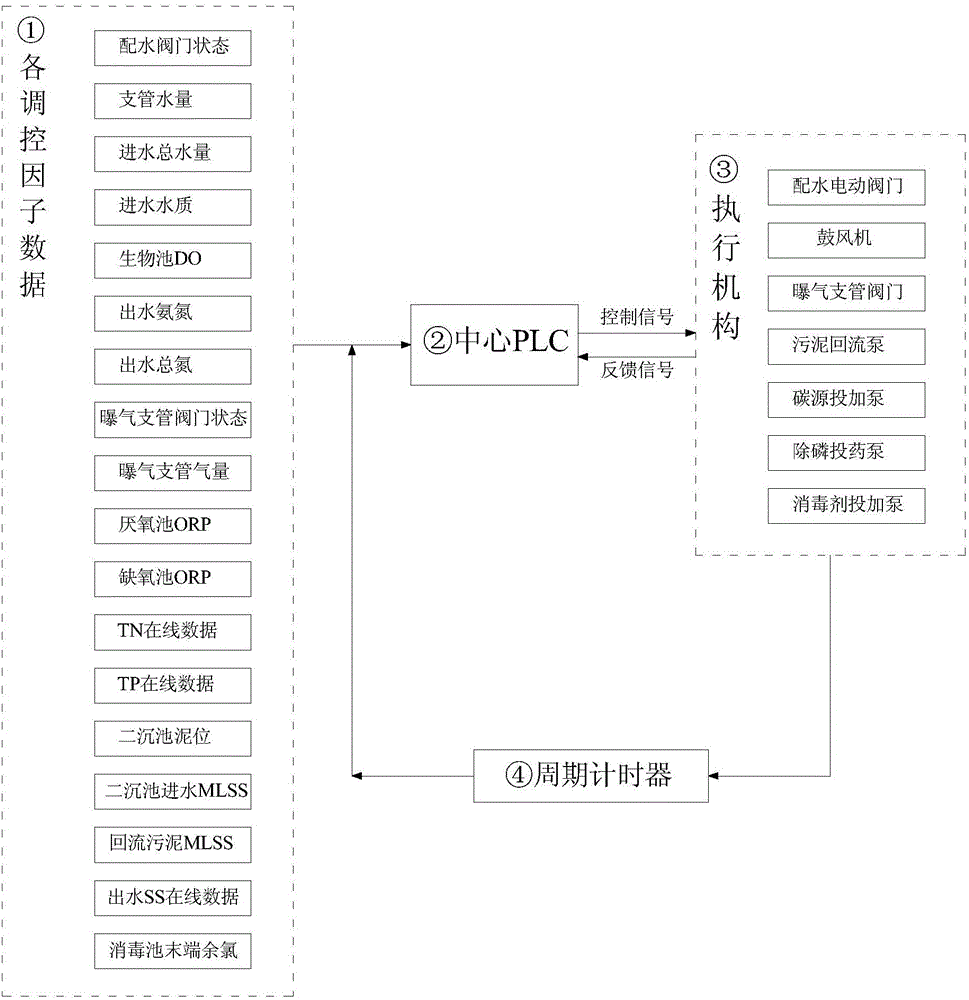

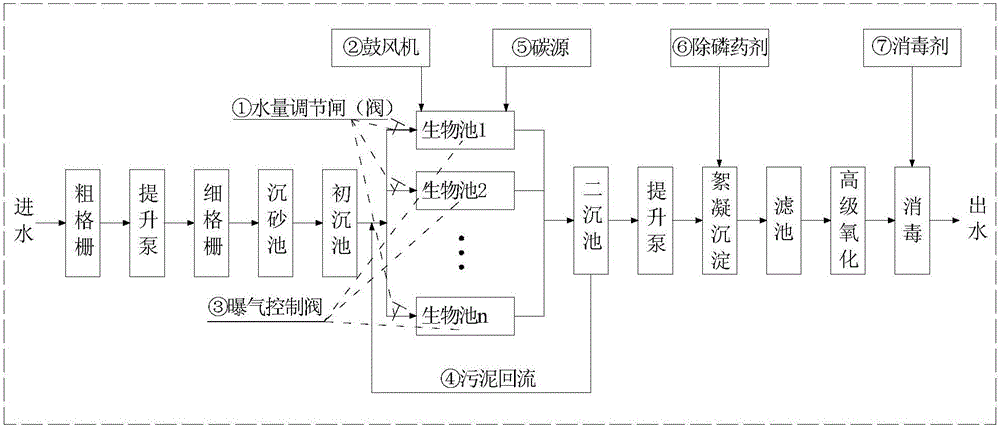

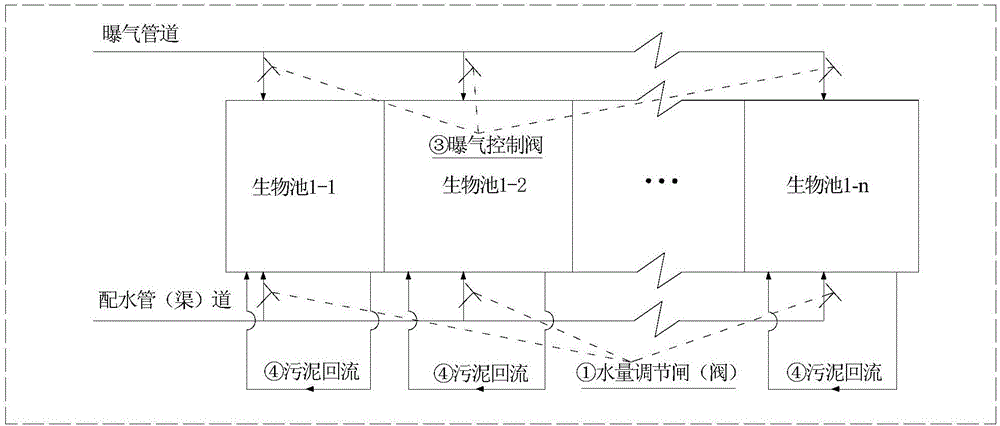

Intelligent control system for sewage treatment plant key process parameters and control method of intelligent control system

InactiveCN106007202AImprove adaptabilityGood regulationWater treatment parameter controlTreatment involving filtrationSludgeData acquisition

The invention relates to an intelligent control system for sewage treatment plant key process parameters. Biological tanks are connected with water amount regulation sluice valves respectively, aeration control valves are arranged between an air blower and the biological tanks and between an aeration pipeline and the biological tanks, a secondary sedimentation tank is connected with the biological tanks through sludge reflow control valves, regulation and control factor online data acquisition instrument terminals of the biological tanks, the secondary sedimentation tank, a flocculating sedimentation tank and a disinfection tank are connected with a central PLC, the central PLC is connected with an execution mechanism, and the execution mechanism is connected with the central PLC through a regulation and control period timer. The control method includes the steps that different weights and periods are distributed according to the characteristics of various regulation and control factors and the influence degrees of the regulation and control factors on control values, and periodic step regulation is carried out. The intelligent control system for the sewage treatment plant key process parameters and the control method of the intelligent control system have the advantage that the adaptability to process changes and regulation and control timeliness are improved. A large amount of theoretical calculation is omitted in the regulation and control mode of the system, so that the requirements for the accuracy and completeness of on-line meters are greatly lowered, and the running stability of the system is greatly improved on the basis of existing hardware.

Owner:张芳

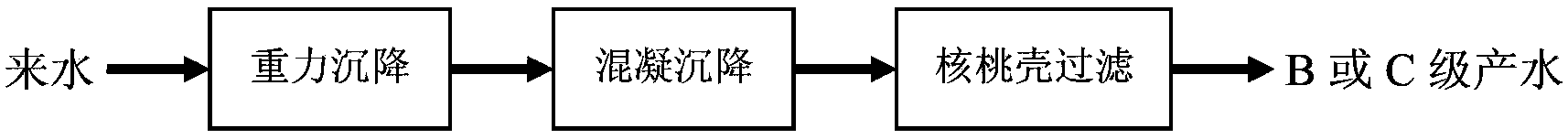

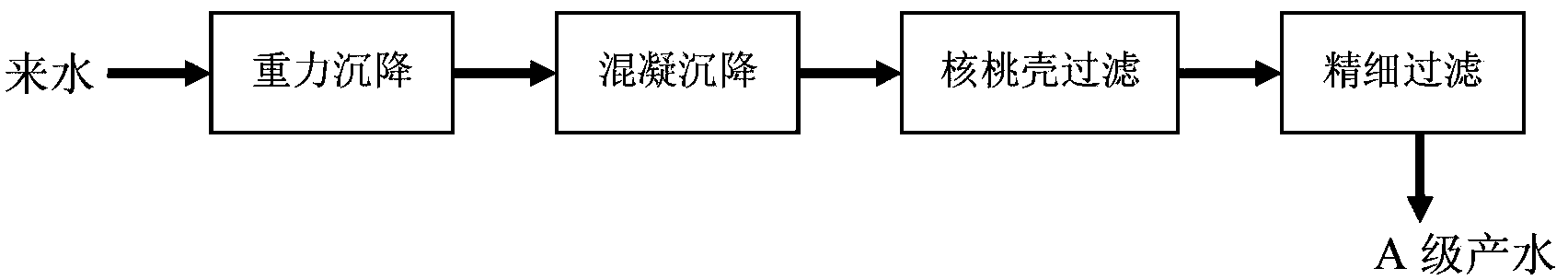

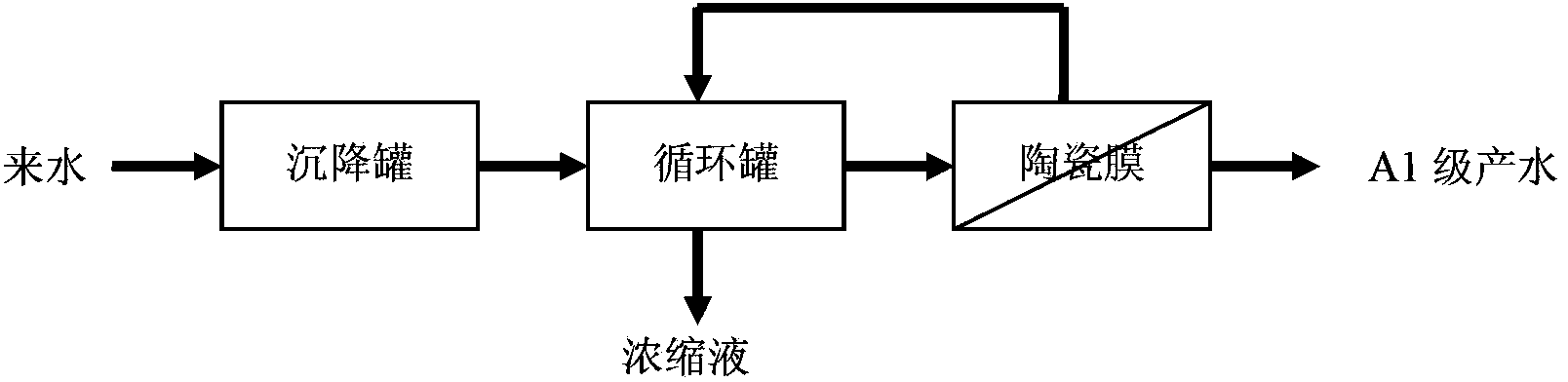

Purification method for oilfield reinjection water

ActiveCN103663624AHigh structural integrationNarrow filter pore size distributionWaste water treatment from quariesWater/sewage treatment bu osmosis/dialysisPurification methodsFiltration

The invention discloses a purification method for oilfield reinjection water. According to the method, at least one level of membrane filtration treatment is carried out on oilfield produced water through a cellular carrier type inorganic carbon membrane component so as to prepare the reinjection water suitable for low permeability and extra-low permeability oil reservoirs, wherein the filter precision of the membrane component for membrane filtration treatment is 0.001-100mu m. The purification method has high filtration accuracy, the membrane flux of the compound carbon membrane carrier is large, the capacity of the membrane in resisting oil contamination is strong, the integration level of the structure of the membrane core is high, the quality of the prepared reinjection water is stable, and fine filtrated oilfield reinjection water meets the requirement of the reinjection water for the oil reservoirs in low permeability and extra-low permeability block, and meets the A-grade standard of 'recommended index and analysis method for quality of oil reservoir injection water of clastic rock' (SY / T 5329-94).

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

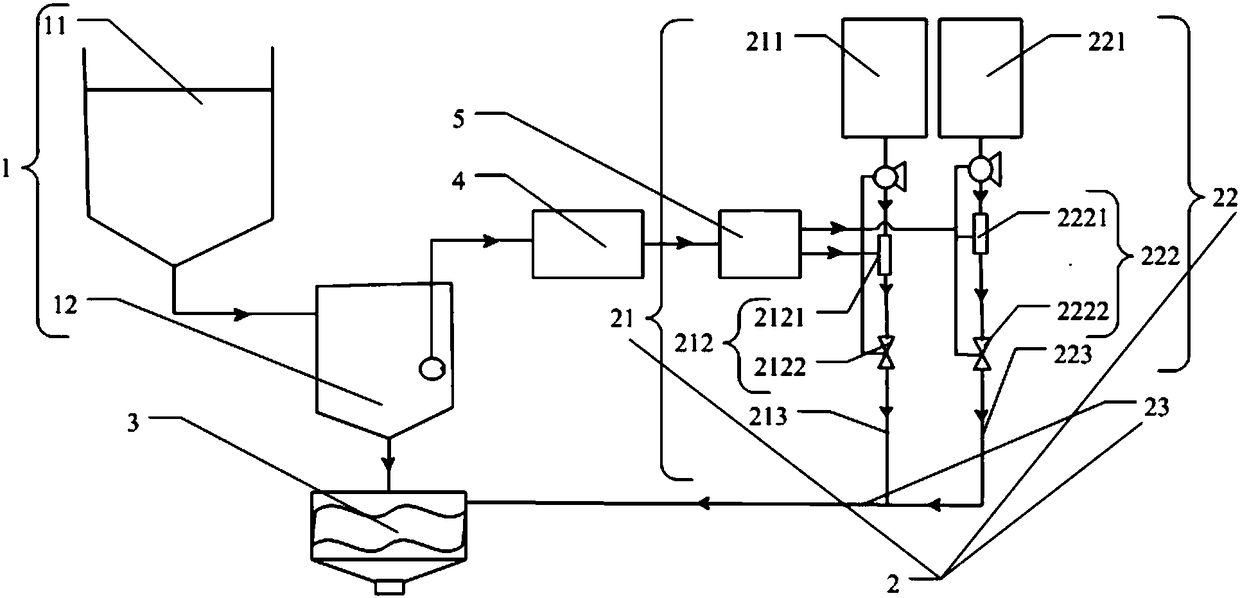

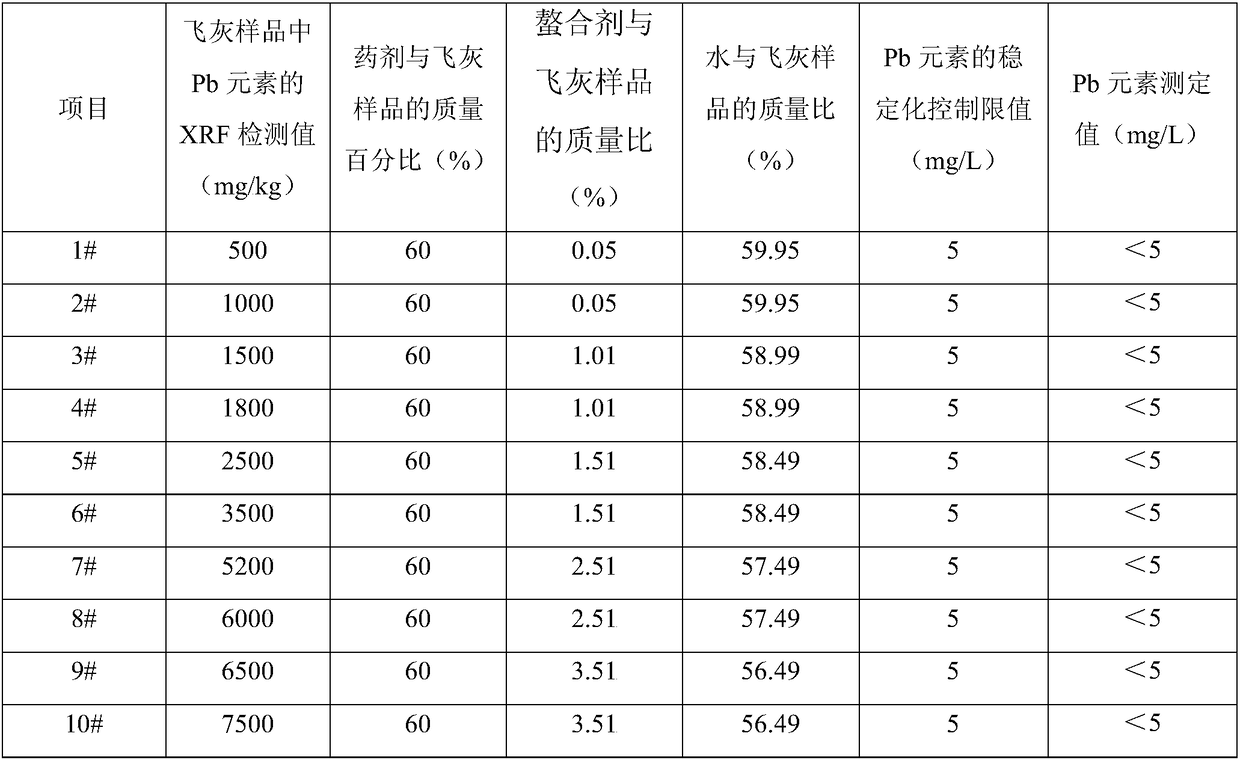

Fly ash stabilizing treatment agent refined adding method based on XRF detection

ActiveCN108246770AAvoid Stabilization FailuresAvoid wastingMaterial analysis using wave/particle radiationSolid waste disposalProcess engineeringEnvironmental engineering

The invention provides a fly ash stabilizing treatment agent refined adding method based on XRF detection, also provides a fly ash stabilizing agent adding system based on XRF detection, and further provides a using method of the fly ash stabilizing agent adding system based on XRF detection. By means of the fly ash stabilizing treatment agent refined adding method based on XRF detection, real-time detection can be carried out on the total amount of each batch of fly ash heavy metal in the fly ash stabilizing treatment process, the fly dust substandard stabilization caused by insufficient adding agent amount can be effectively avoided, the agent waste phenomenon caused by too much adding agent amount can be avoided, the reaction speed of the system for treating problems is increased, the manual operation working strength is reduced, and fly ash stabilizing treatment can be is improved from the extensive form into refined management.

Owner:SHANGHAI ENVIRONMENTAL & SANITARY ENG DESIGN INST CO LTD +1

Production method for producing low-carbon low-silicon and aluminum-containing steel through short process

The invention belongs to the field of metallurgy processes and particularly relates to a p roduction method for producing low-carbon low-silicon and aluminum-containing steel through a short process. The low-carbon low-silicon and aluminum-containing steel is composed of, by weight, 0.04-0.06% of C, 0-0.03% of Si, 0.15-0.25% of Mn, 0-0.02% of P, 0-0.015% of S, 0.015%-0.050% of Als and the balance Fe and inevitable impurities. An LF link is omitted, the problem of silicon reversion caused by LF process treatment for reducing slag is solved under the condition that the purity of molten steel is not influenced, so that the target rate of Si content in the low-carbon low-silicon and aluminum-containing steel is increased, and the product yield is increased; and through CAS station strong deoxidation, the molten steel is completely deoxidized in short time, the molten steel castability is improved, sprue flocculating flow is reduced, and mass stable continuous casting production of the low-carbon low-silicon and aluminum-containing steel is achieved.

Owner:SHANDONG IRON & STEEL CO LTD

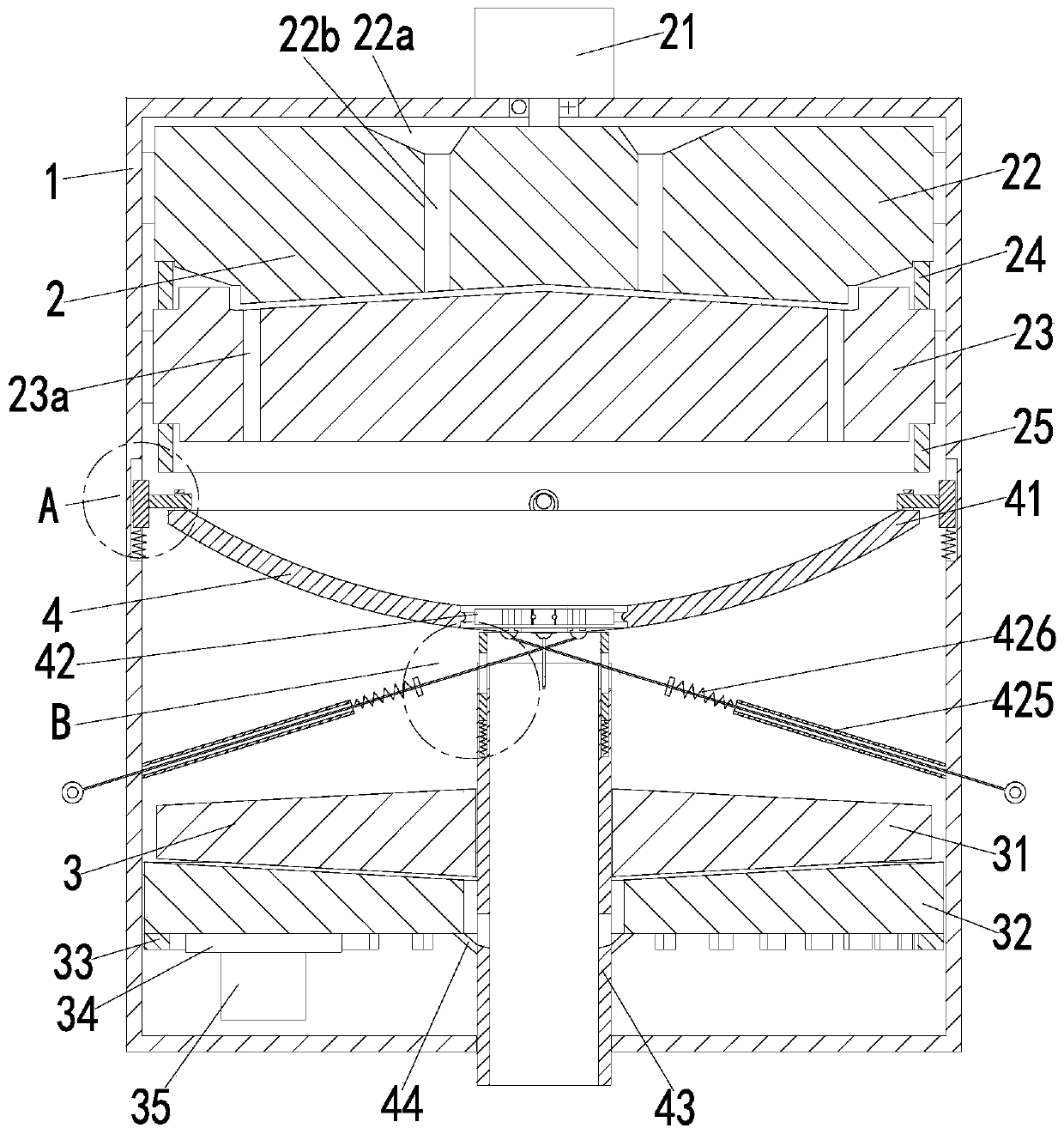

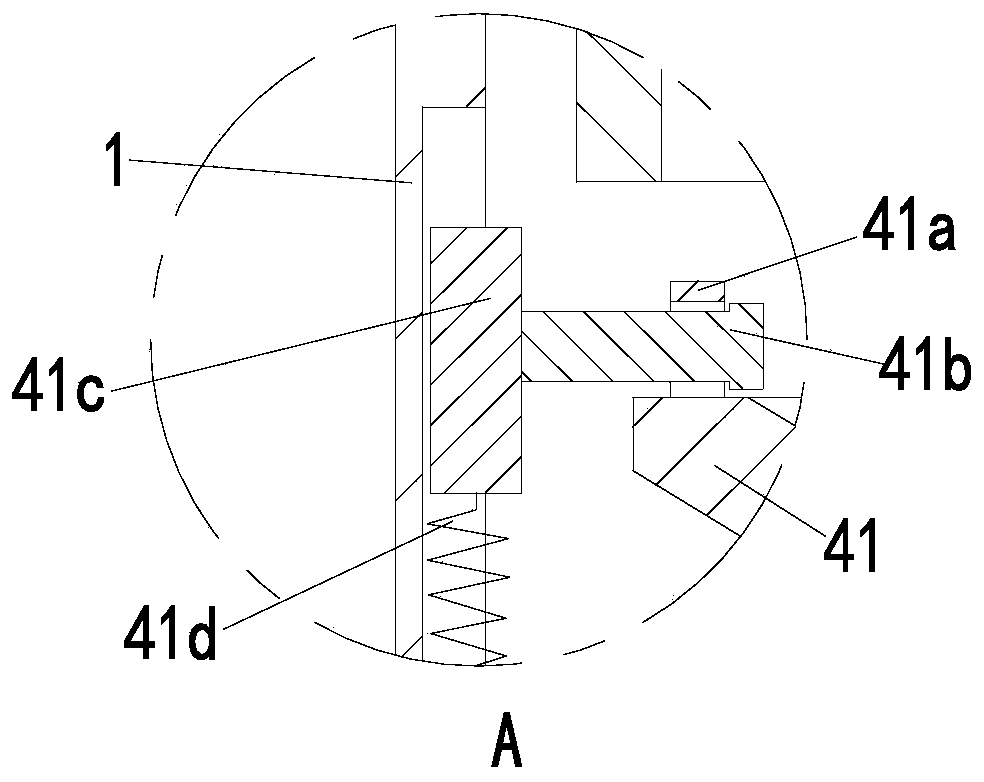

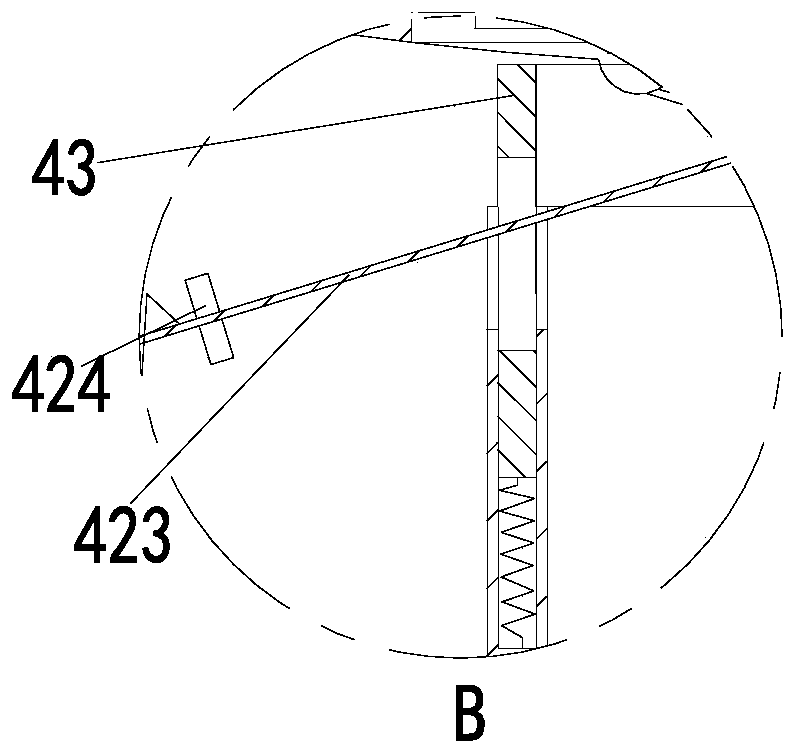

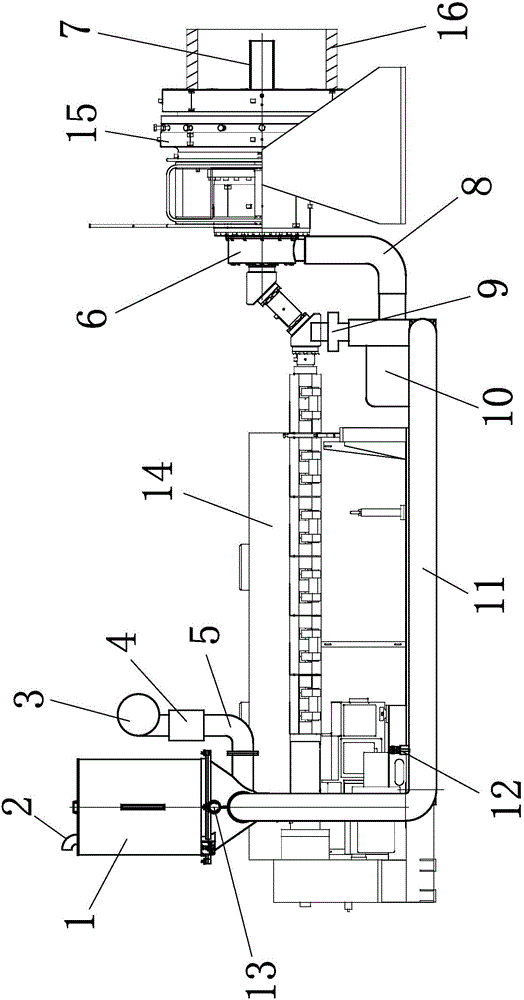

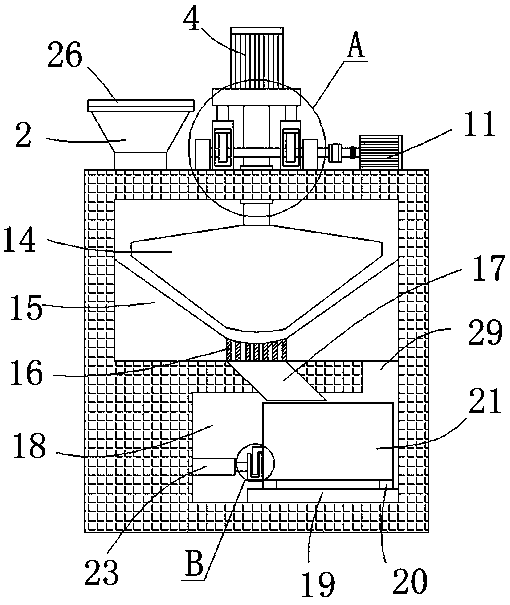

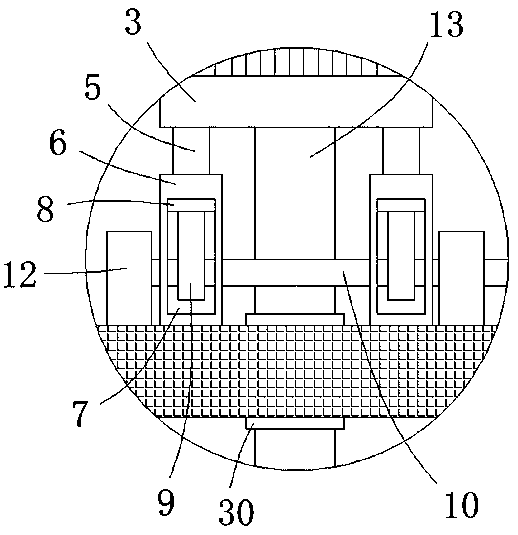

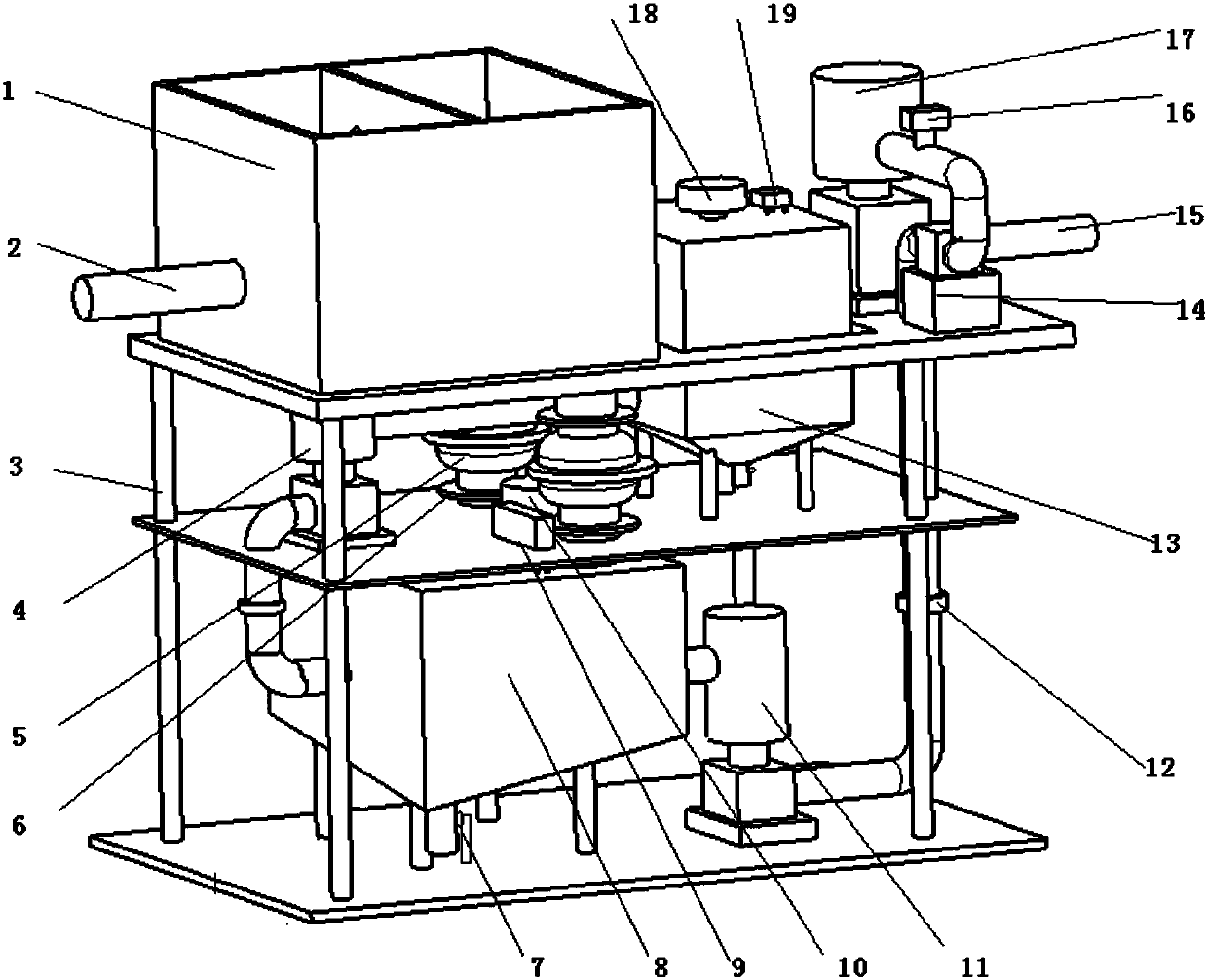

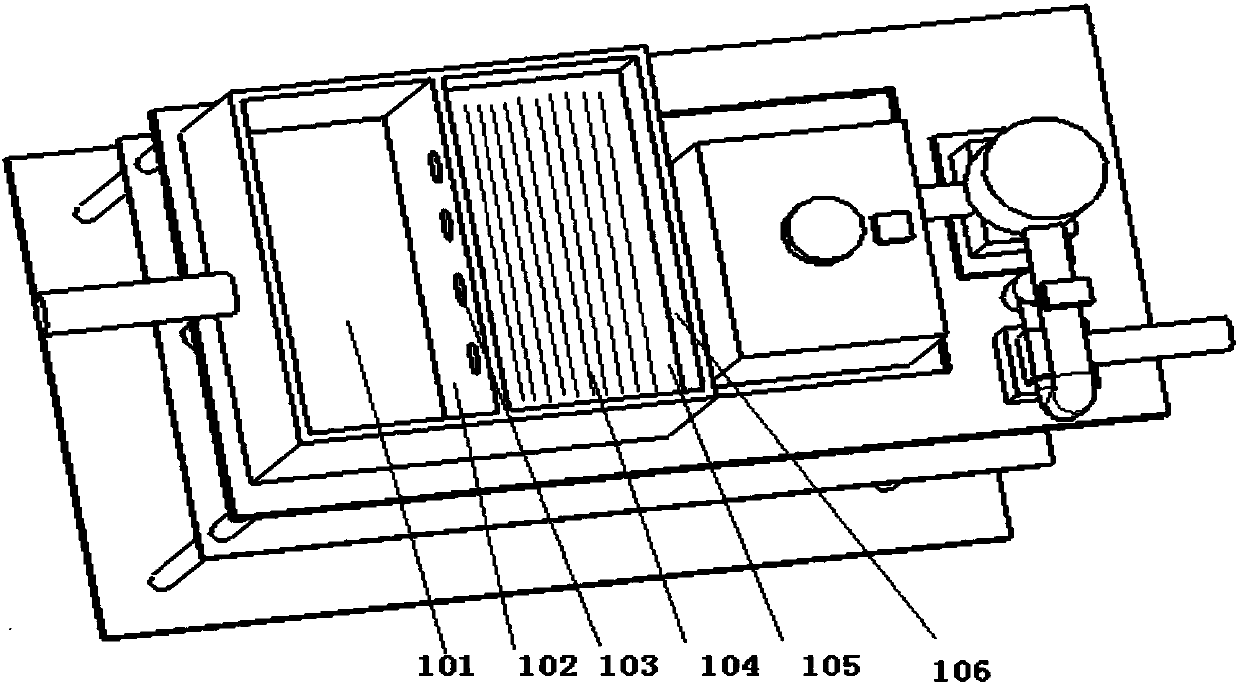

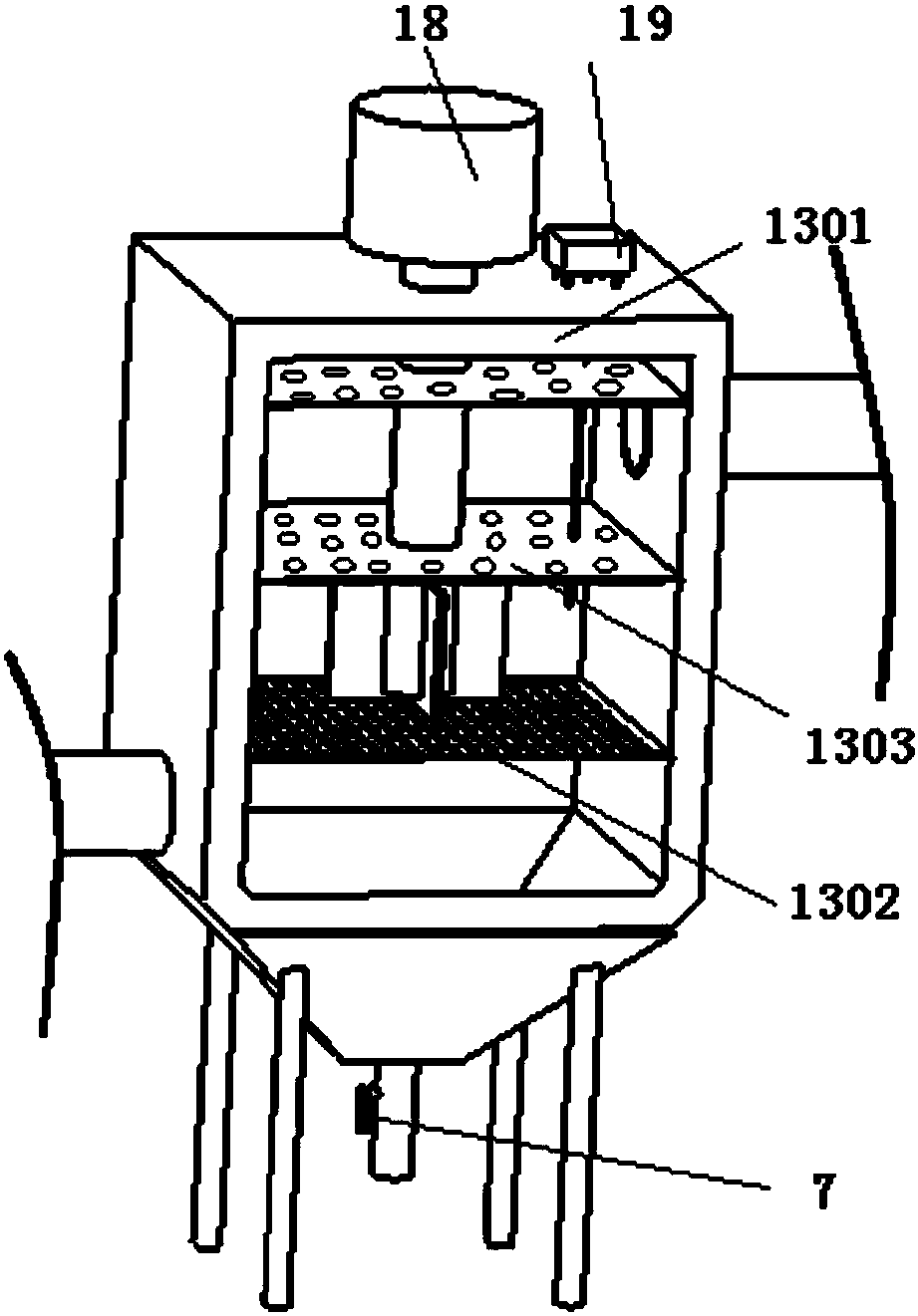

Continuous multistage grinding and dispersing machine for graphene preparation

ActiveCN110694740AImprove efficiencyImprove grinding qualityCocoaGrain treatmentsGear wheelElectric machinery

The invention relates to a continuous multistage grinding and dispersing machine for graphene preparation. The grinding and dispersing machine comprises a shell, a primary grinding mechanism, a secondary grinding mechanism and a material conveying mechanism, wherein the upper end of the inner part of the shell is provided with the primary grinding mechanism, the lower end of the inner part of theshell is provided with the secondary grinding mechanism, the material conveying mechanism is arranged between the primary grinding mechanism and the secondary grinding mechanism, through holes are uniformly formed in the outer wall of the shell in the circumferential direction of the shell, the primary grinding mechanism comprises a primary motor, a rotating grinding disc, a fixed grinding disc, aconnecting ring and a guide ring, the secondary grinding mechanism comprises an upper grinding disc, a lower grinding disc, a driven gear, a driving gear and a driving motor, the material conveying mechanism comprises a material containing tray, a screening branched chain, a material conveying pipe and a material guiding ring. According to the grinding and dispersing machine, the graphene is ground in a multi-stage grinding mode, and the sizes of graphene which meet the standard and do not meet the standard can be separated in advance before the subsequent grinding stage, so that the purposeof improving the subsequent grinding efficiency and the grinding quality is achieved.

Owner:上海焱丰科技有限公司

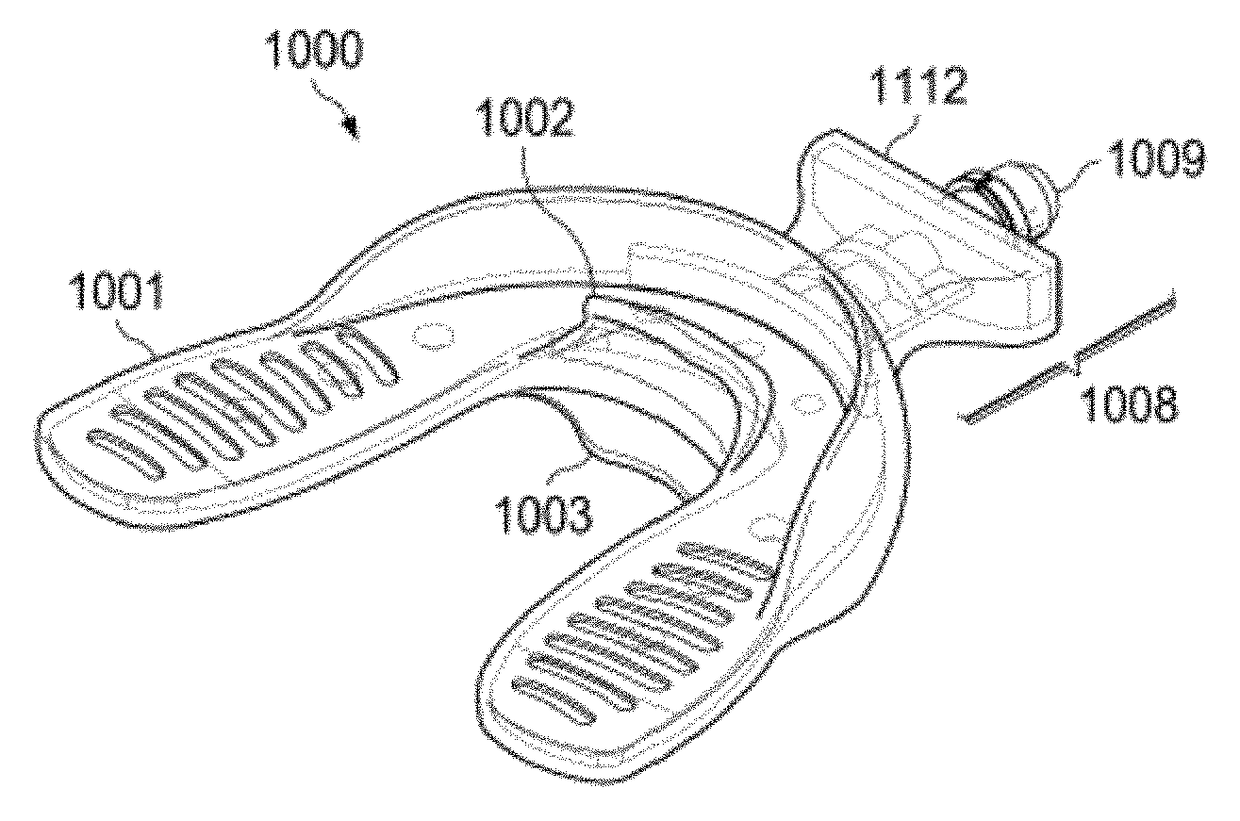

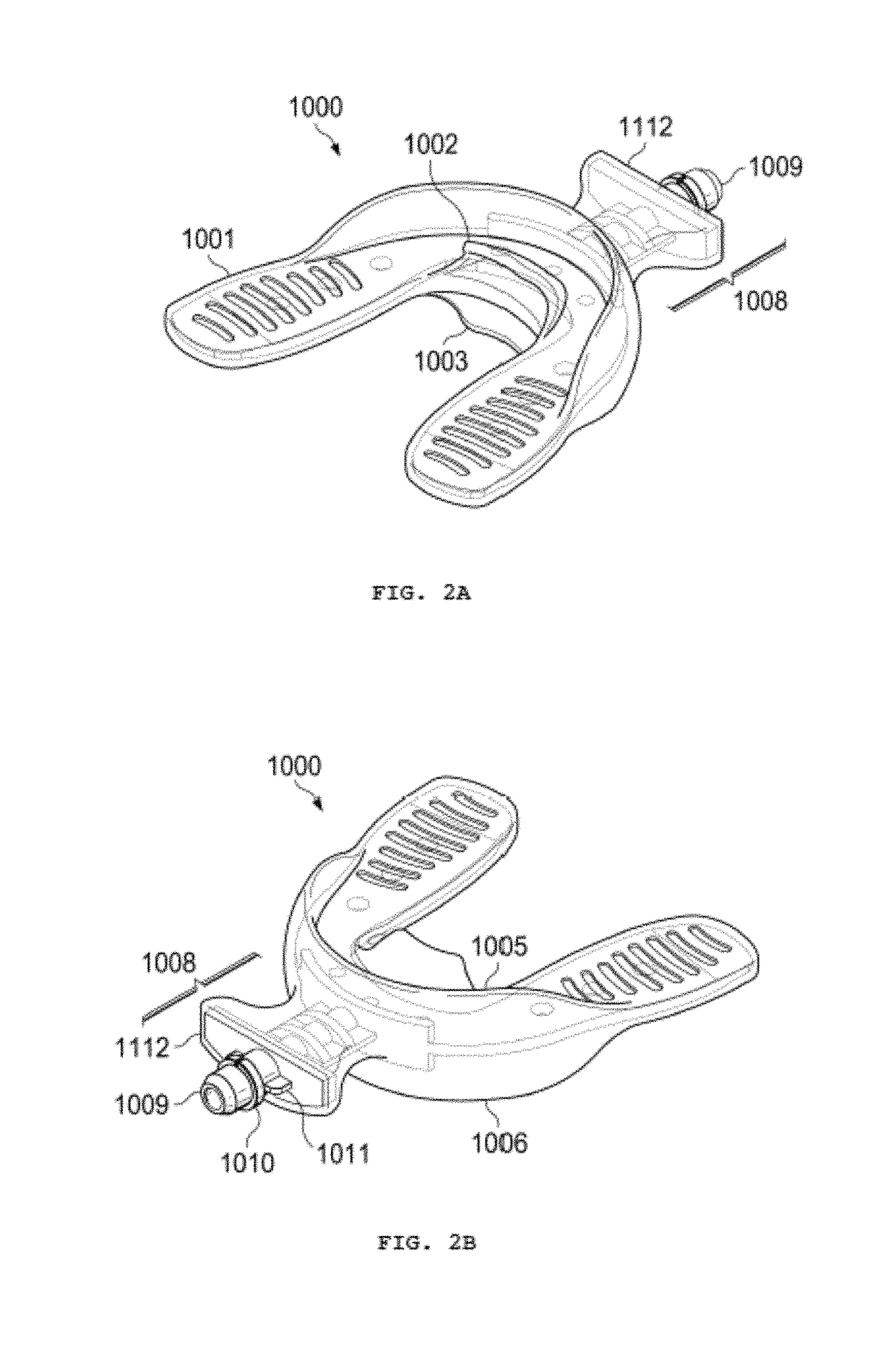

Night time orthodontics

ActiveUS10111729B1Increase bone remodelingSpeed tooth movementOthrodonticsSurgeryDiagnostic Radiology ModalityDecortication procedure

Night time use of removable orthodontic appliances coupled with night time use of accelerated orthodontic treatment modalities is provided. Accelerated orthodontic treatment modalities include micropulse vibrations, ultrasound vibrations, photobiomodulation, IR light, low-level laser therapy, pulsed EM fields, static magnetic fields, resonance vibrations, indirect electric current, direct electric current, pharmacological accelerators, surgical accelerators, decortication, osteoperforation, alveocentesis, and piezocision.

Owner:ADVANCED ORTHODONTICS & EDUCATION ASSOC LLC

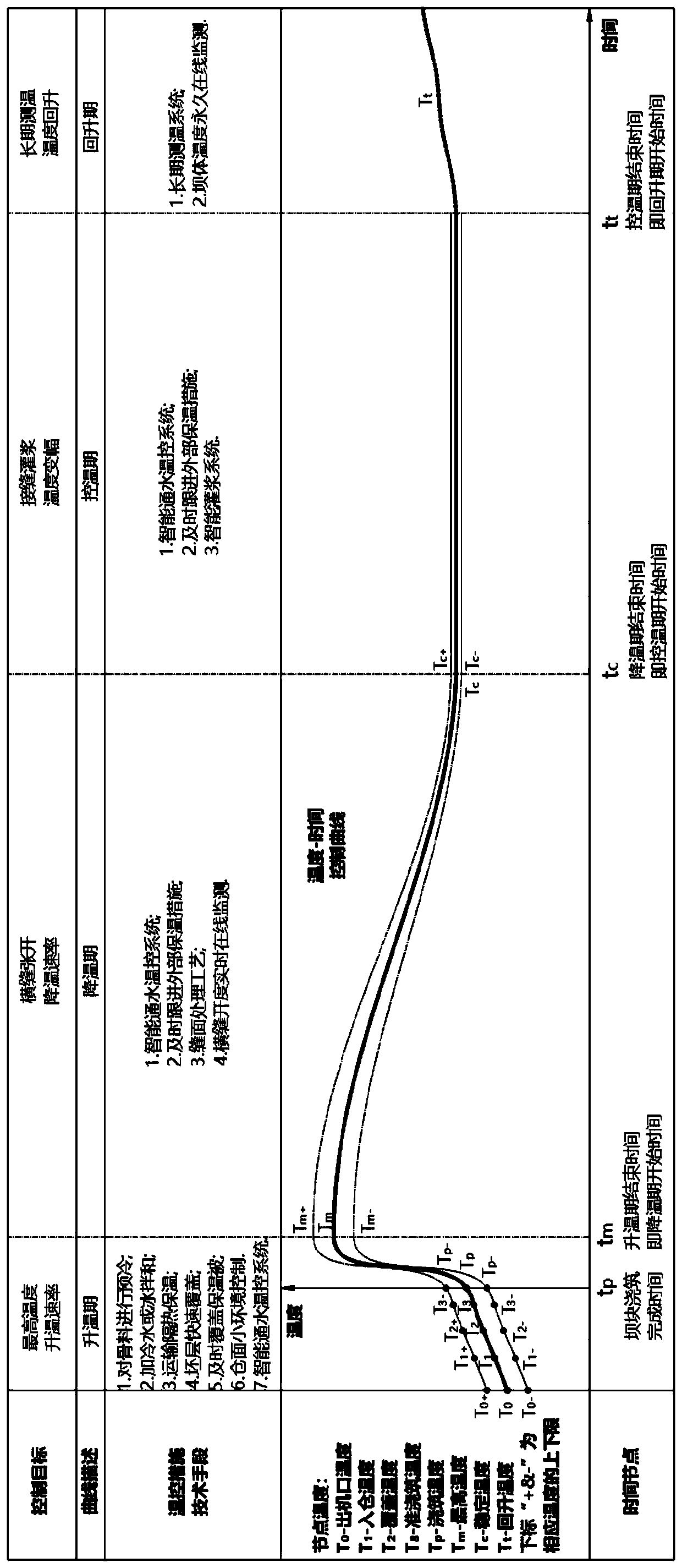

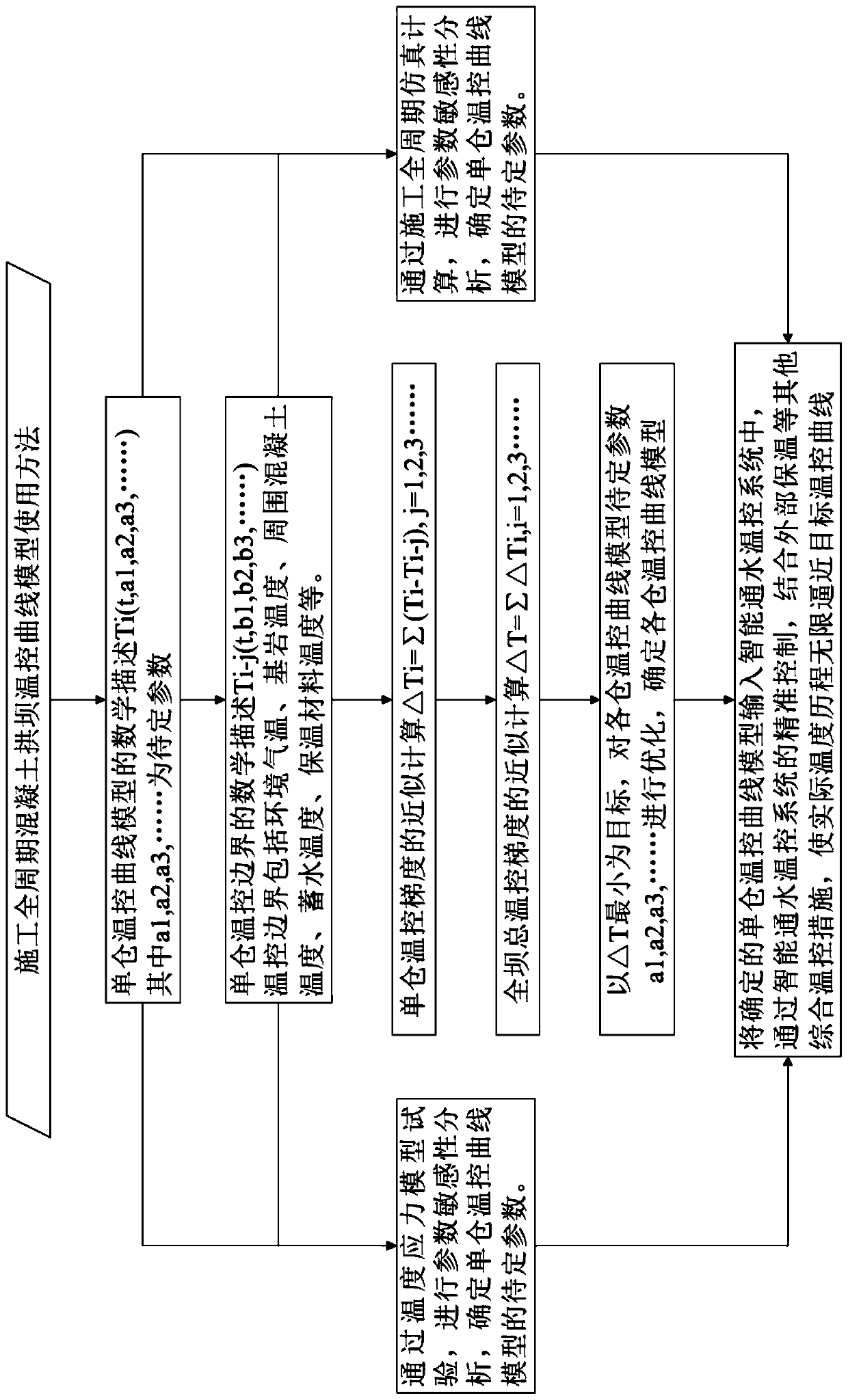

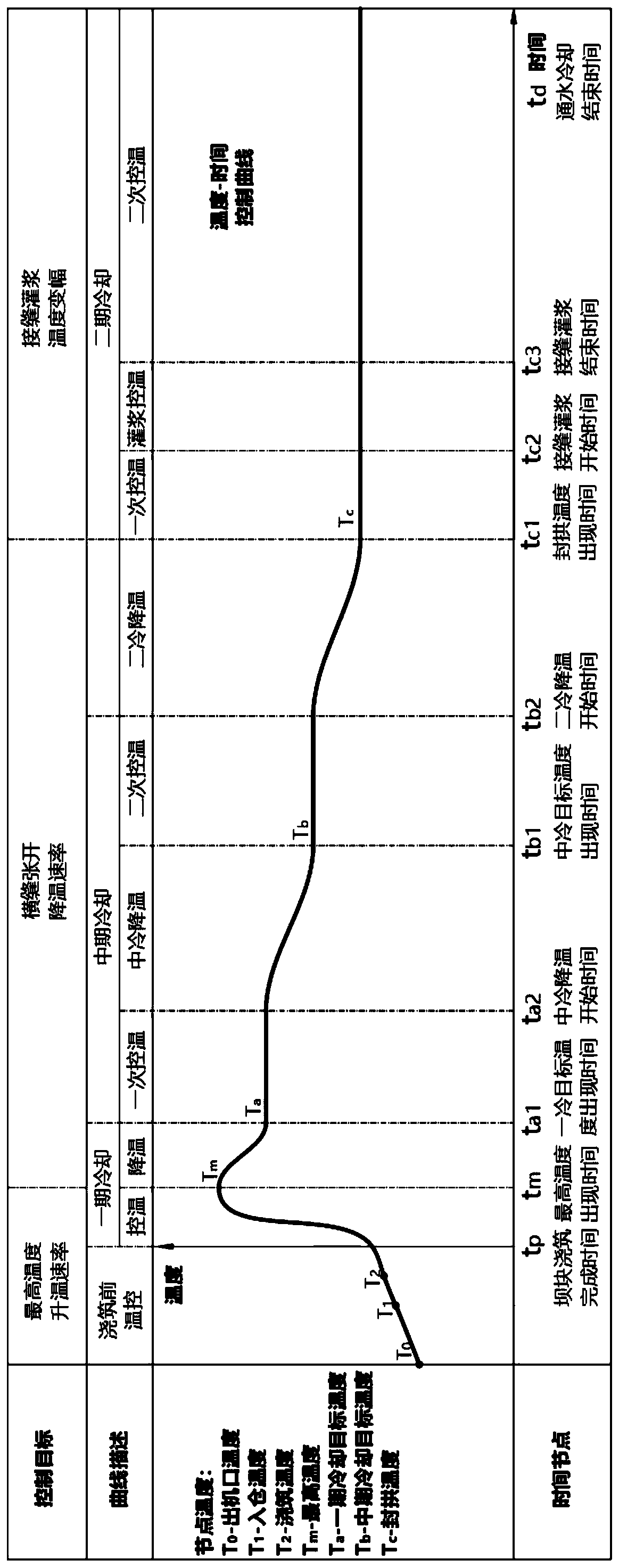

Construction full-period concrete arch dam temperature control curve model

ActiveCN111046457AMake sure the groutGuaranteed continuityGeometric CADDesign optimisation/simulationTemperature controlStructural engineering

The invention discloses a construction full-period concrete arch dam temperature control curve model. The concrete arch dam temperature control curve model comprises four continuous stages, wherein the four stages are respectively (1) a heating period, from a machine outlet of the concrete mixing plant to the highest temperature after warehousing and pouring; (2) a cooling period, from the highesttemperature to the arch sealing temperature designed by the arch dam, wherein a whole-course continuous smooth cooling scheme is adopted in the period; (3) a temperature control period, from reachingthe sealing temperature to the end of the heat exchange; and (4) a rising period, from the end of water passing heat exchange to the completion of overall construction of the arch dam, wherein a mainmonitoring index is temperature rising. The construction full-period concrete arch dam temperature control curve model provided by the invention is applied to construction of large-volume medium andlow-heat concrete arch dams; and in combination with an intelligent water passing temperature control system, the highest temperature of the concrete arch dam in the whole construction period can be controlled, the temperature control process is adjustable, temperature control measures can be optimized, the space-time temperature gradient of concrete is effectively reduced, and the cracking risk of a dam is reduced.

Owner:TSINGHUA UNIV +1

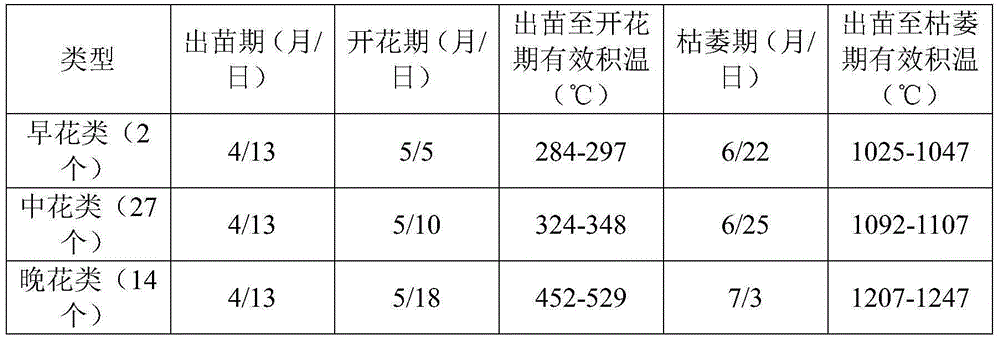

Method for producing bulb and controlling florescence by utilizing effective accumulated temperature in tulip growing period

InactiveCN105075578AExtend photosynthesis timeImproved bulb qualityPlant cultivationCultivating equipmentsPhacusPhases of clinical research

The invention discloses a method for producing bulb and controlling florescence by utilizing effective accumulated temperature in tulip growing period, wherein the method for producing bulb by utilizing effective accumulated temperature in tulip growing period comprises the steps of determining the effective accumulated temperature at the tulip growing period; selecting a low temperature semi-arid climate type area that has an average temperature of 12-16 DEG C and a dryness fraction of 2-3 in July as the production base on the basis of determining the effective accumulated temperature at the tulip growing period; planting the tulip to control the tulip stem and leaf coverage between 95-100%; and covering the organic matter 3-5cm thick. After grasping the effective accumulated temperature at the growing period of the cultivar and the set temperature when planting, namely the temperature of tulip at growing period, calculate the accurate blossom date by the following formula: N=K / (T-C).

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS +1

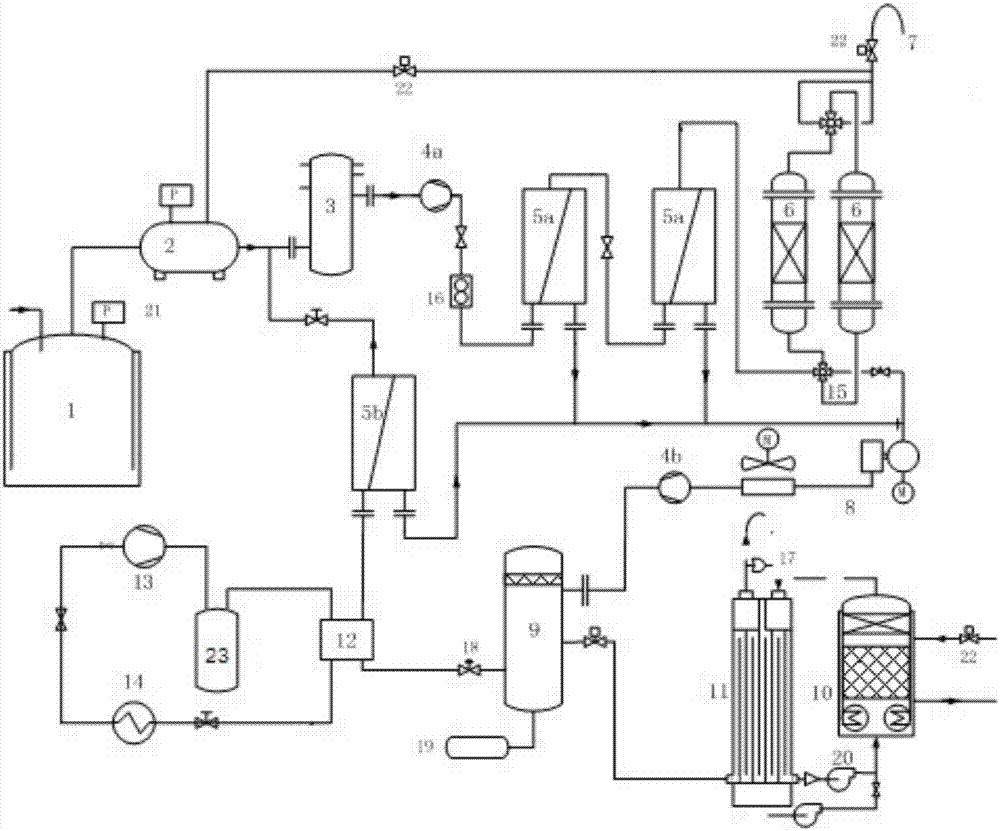

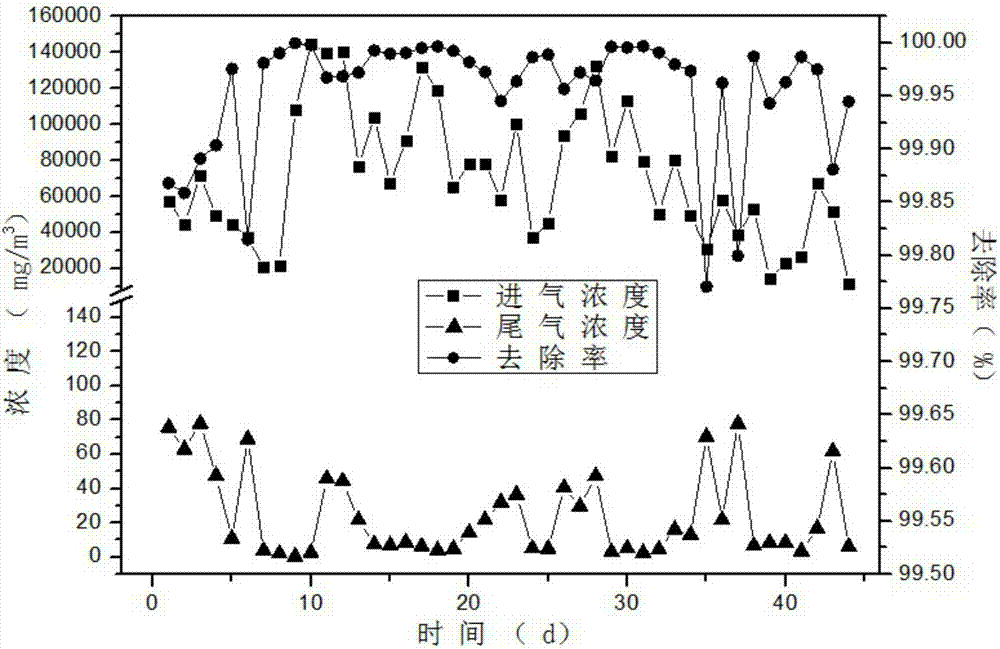

High-effective organic waste gas recovery processing method and complete equipment

ActiveCN107413173AHigh recovery rateHigh explosion-proof gradeGas treatmentDispersed particle separationHigh concentrationBuffer tank

The invention relates to a high-effective organic waste gas recovery processing method and complete equipment. The complete equipment includes: an organic waste gas collection apparatus, a gas storage tank, a buffer tank, a primary membrane unit, an active carbon adsorption unit, a vacuum pump, a gas-liquid separation tank, a compression condensing unit, a secondary membrane unit, a low temperature catalytic oxidizing reactor, and a tubular heat exchanger. Through the two-stage membrane as a core technology, advantages that a membrane process is high in efficient, is continuous, has high recover rate and high safety and is suitable for high-concentration organic waste gas are achieved, thus recovering the recoverable components in the waste gas; in addition, with the low temperature catalytic oxidization technology, an advantage of deep processing thereof is achieved, so that a problem of accumulation of light-hydrocarbon substances is overcome. The processing method and complete equipment not only high-effectively recover valuable organic substances, but also can perform deep processing to the organic waste gas with satisfaction of strict requirements on safety production in petrochemical enterprises. Through the deep processing to the organic waste gas, discharged organic waste gas can reach national emission standards.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rearing method for correcting dysplasia of laying hens at growing period

InactiveCN101822236AImprove uniformityImprove compliance rateAnimal feeding stuffAnimal scienceMortality rate

The invention discloses a rearing method for correcting dysplasia of laying hens at a growing period, which deeply studies how to correct the dysplasia of body types of the laying hens caused by rearing deficiency during brooding through compensation feed at the growing period of the laying hens aged 7 to 18 weeks, and further allows the actual body type development index of the laying hens at the end of the growing period to reach the target body type development index as much as possible, and lays the foundation for the laying hens to achieve high yield. Compared with the conventional rearing method, the method has the advantages that: the rates of reaching to the standards of the body weight and the shank length of pullets aged 19 weeks respectively increase by 11.3% and 8.7%, and the uniformity of hen populations increases by 9.2%; the egg production increases by 8.7%, and the mortality rate reduces by 5.7% at the laying period; and the hen raising efficiency increases by 17.6%.

Owner:NORTHWEST A & F UNIV

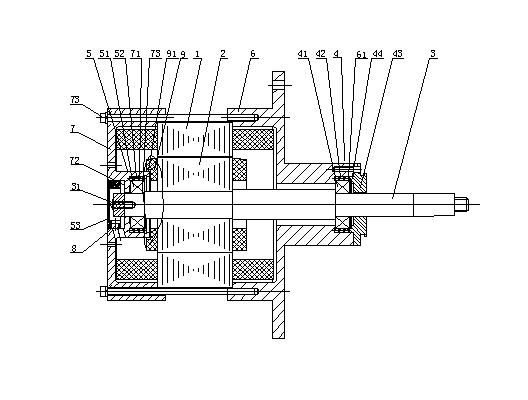

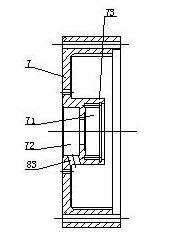

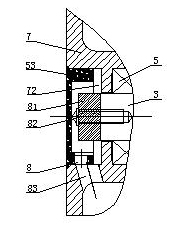

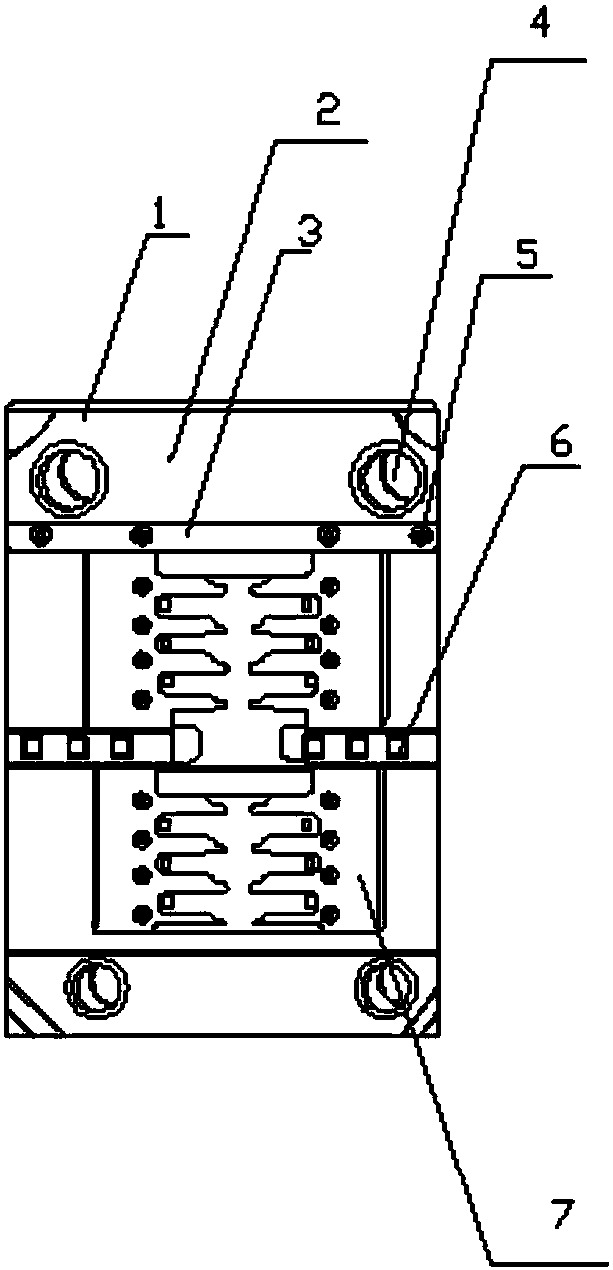

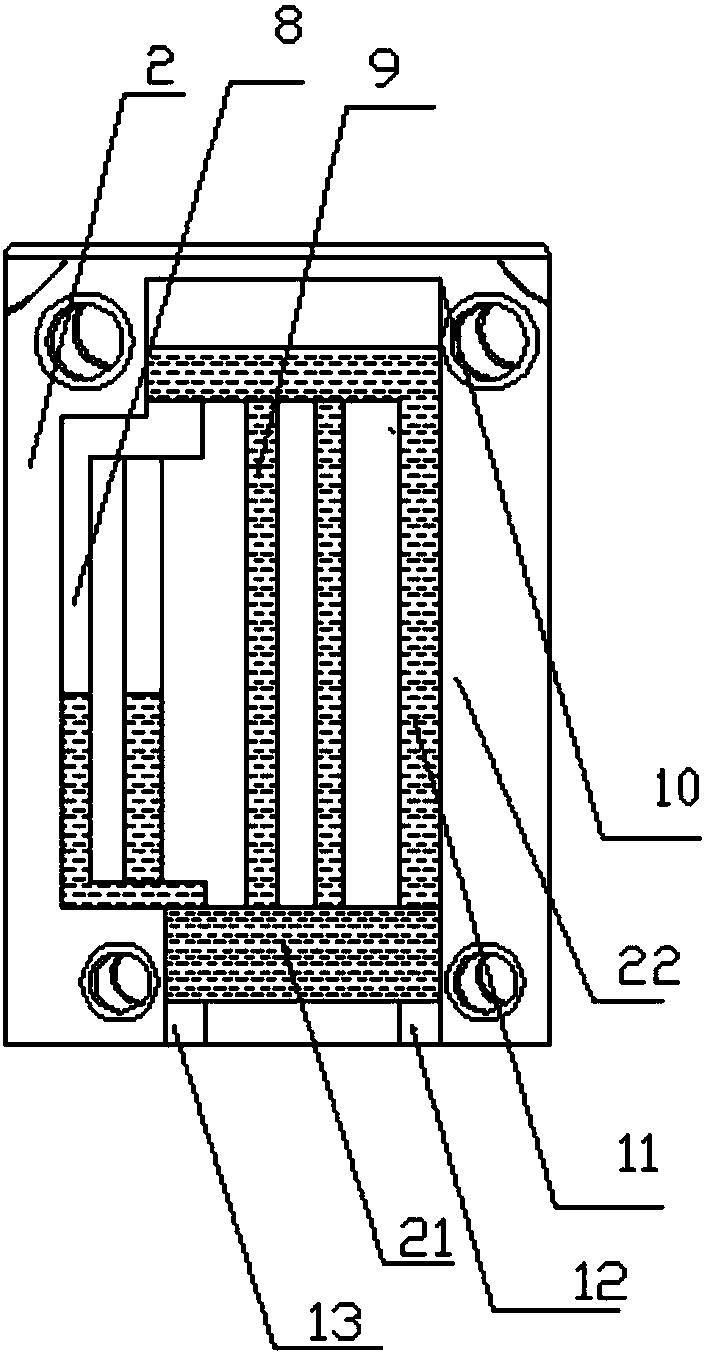

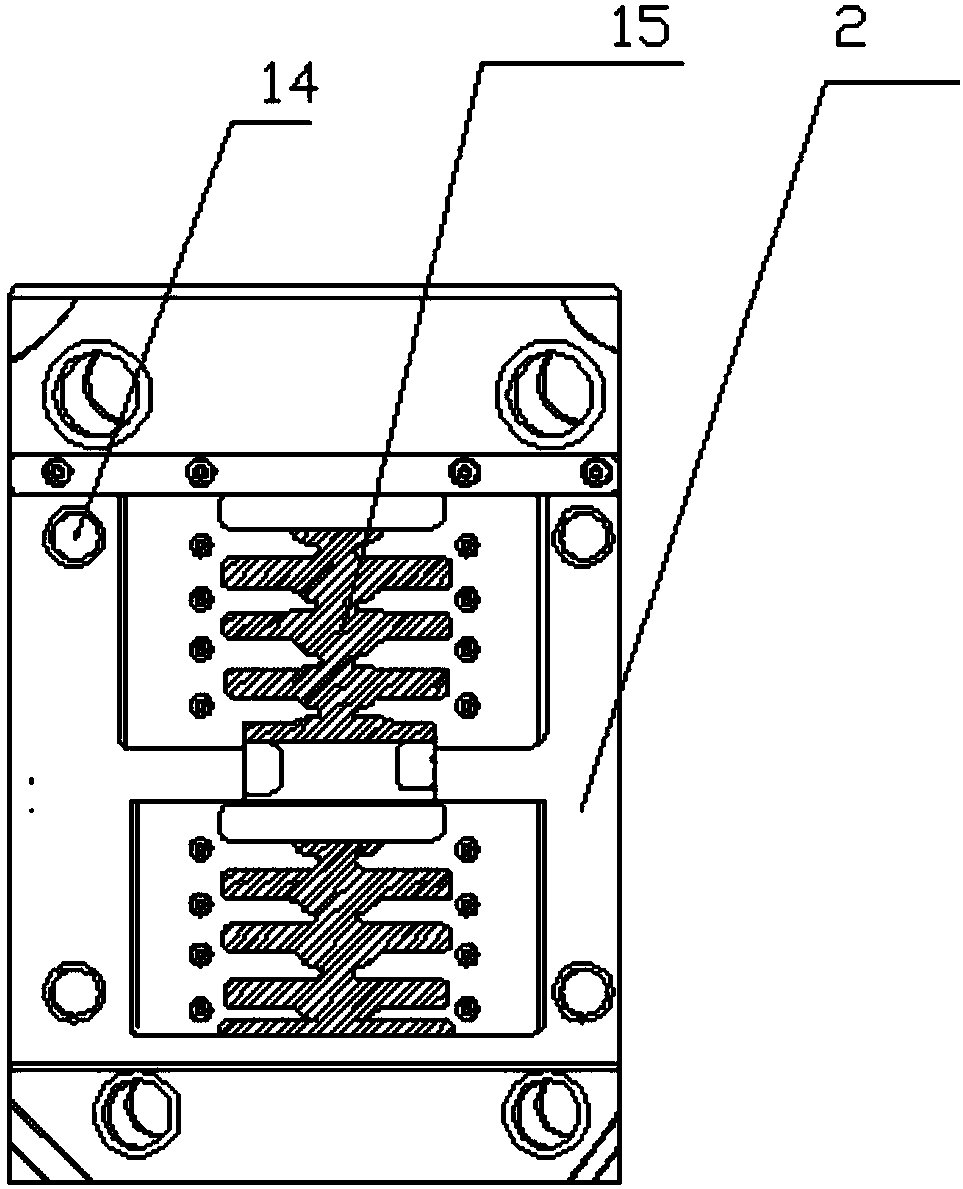

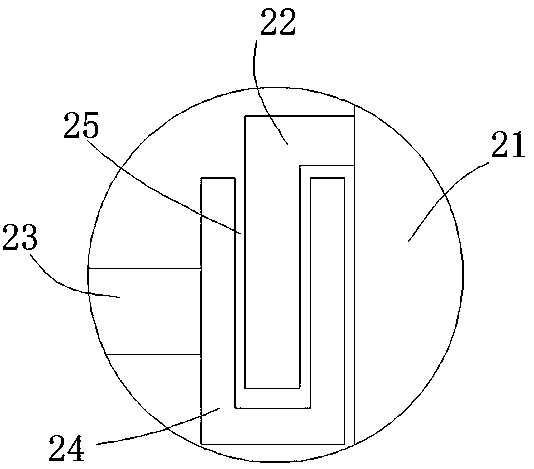

Bearing buffer unit for motor

InactiveCN102097884AIncreased resistance to cushioningImprove compliance rateSupports/enclosures/casingsMechanical engineeringStator

The invention provides a bearing buffer unit for a motor, comprising motor spindles, wherein the motor spindles pass through the centers of a stator core and a rotor core, and are respectively fixed in the upper end cap and the lower end cap of a motor by an upper bearing device and a lower bearing device; the upper bearing device comprises upper end cap bearings which are fixed at the spindles; the upper end cap bearings are arranged in a concave platform of the upper end cap of the motor; the upper end cap bearings in the concave platform are respectively provided with an upper bearing elastic element in a radial direction; each upper bearing elastic element is provided with an upper sealing cover plate in an axial direction; the lower bearing device comprises lower end cap bearings which are fixed at the spindles; the lower end cap bearings are arranged in an inner concave platform of the lower end cap of the motor; each lower end cap bearing in the inner concave platform is provided with a lower bearing elastic element in a radial direction; and lower sealing cover plates are arranged in an outer concave platform of the lower end cap of the motor. The above technical scheme isused to overcome the defects that bearings for an existing motor are easily extruded mutually and damaged at the joints of the spindles and the end caps due to high-speed running, heat emission, parking, cooling, deformation and the like, the tail ends of the spindles of the motor are exposed and the like. The bearing buffer unit is used for controlling motors in different freezing operating rooms.

Owner:胡磊

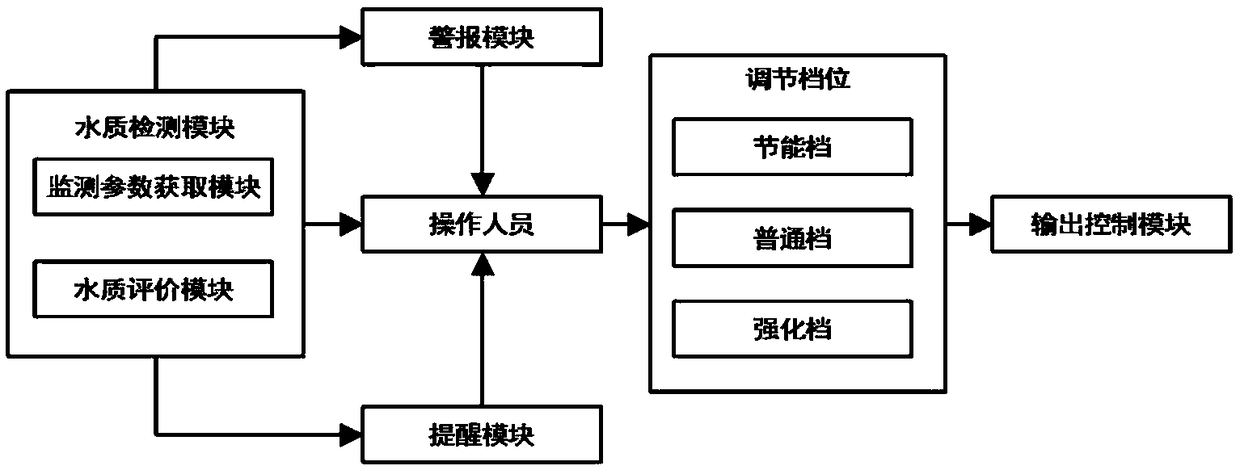

Intelligent sewage treatment adjusting system based on simple control

ActiveCN109133209AReduce learning costsSave energyWater treatment parameter controlTesting waterWater treatment systemWater quality

The invention relates to the technical field of sewage treatment systems, in particular to an intelligent sewage treatment adjusting system based on simple control. The system comprises an adjusting gear, a water quality detection module and an output control module, the water quality detection module is used for detecting various monitoring parameters of sewage to be treated and acquiring water quality conditions of the sewage to be treated according to various detected monitoring parameters, the adjusting gear includes an energy-saving gear, a common gear and a reinforcement gear, the outputcontrol module controls a reactor to work in a low-power state after the energy-saving gear is started, the output control module controls the reactor to work in a standard-power state after the common gear is started, and the output control module controls the reactor to work in a high-power state after the reinforcement gear is started. According to the intelligent sewage treatment adjusting system based on simple control, energy can be saved, unnecessary energy loss is avoided, treatment efficiency is improved, standard reaching rate is increased, control complexity is reduced, and the learning cost of operators is reduced.

Owner:CHONGQING TECH & BUSINESS UNIV

Plastic pipe extrusion equipment heat-exchange circulatory system and application method thereof

The invention relates to plastic pipe production equipment, especially to a plastic pipe extrusion equipment heat-exchange circulatory system and an application method thereof. The plastic pipe extrusion equipment heat-exchange circulatory system comprises a single-screw plastic extruder and a plastic extrusion mold body. An input end of the single-screw plastic extruder is connected to a drying machine charging barrel. An auxiliary heating cylinder and an auxiliary blower fan are connected on the drying machine charging barrel. A suction fan is arranged at the plastic extrusion mold body. A heat-exchange air-suction pipe is arranged at the axis of the plastic extrusion mold body. The heat-exchange air-suction pipe is connected to the suction fan through a front air-suction pipe. An output end of the suction fan is communicated with the drying machine charging barrel through a hot air induction-pipe, which is provided with a thermal insulation device for thermal insulation of the hot air induction-pipe. According to the system, residual heat during extrusion of plastic can be recovered and utilized, energy consumption during drying of plastic can be reduced, and utilization rate of heat can be raised.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

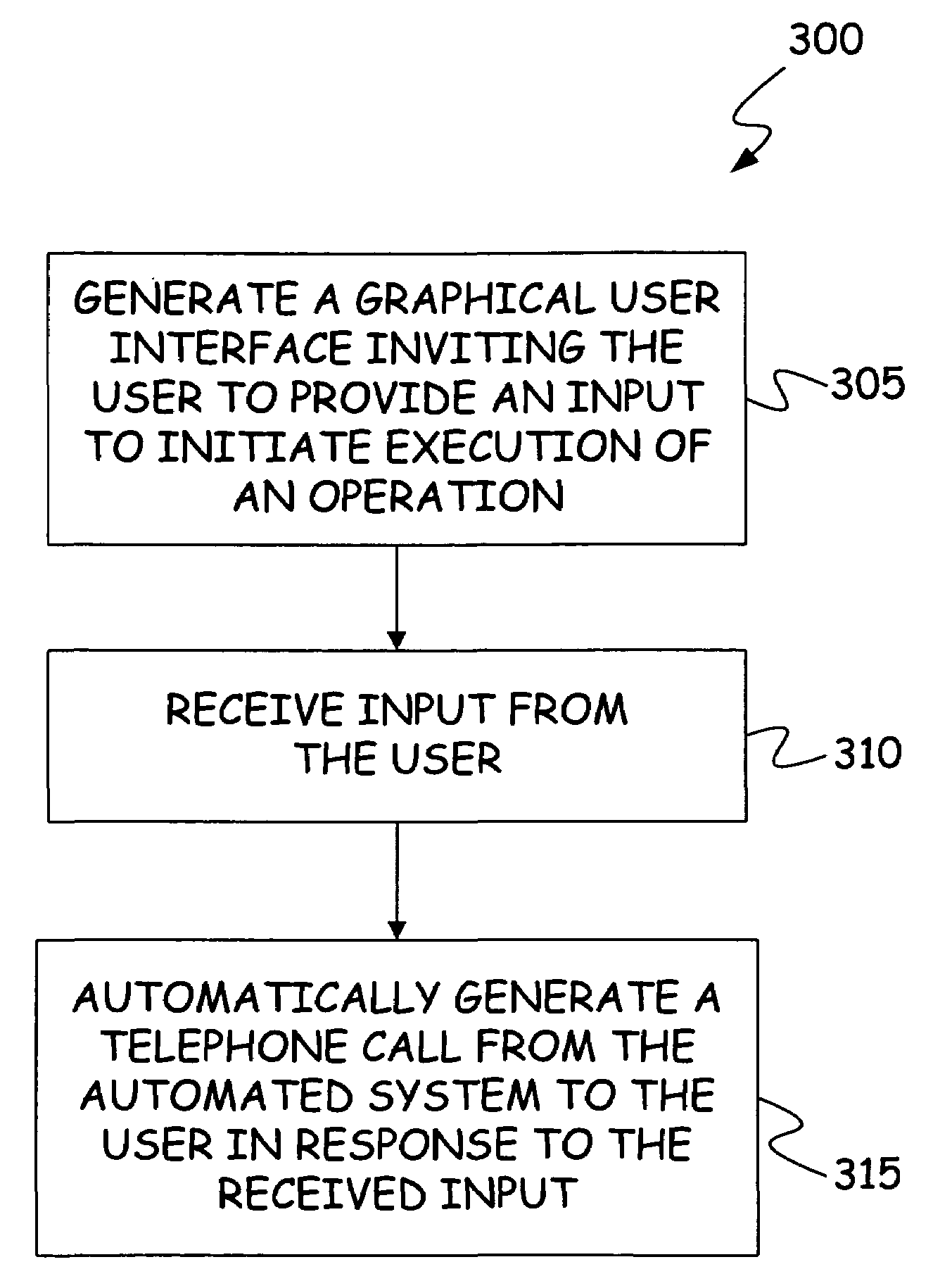

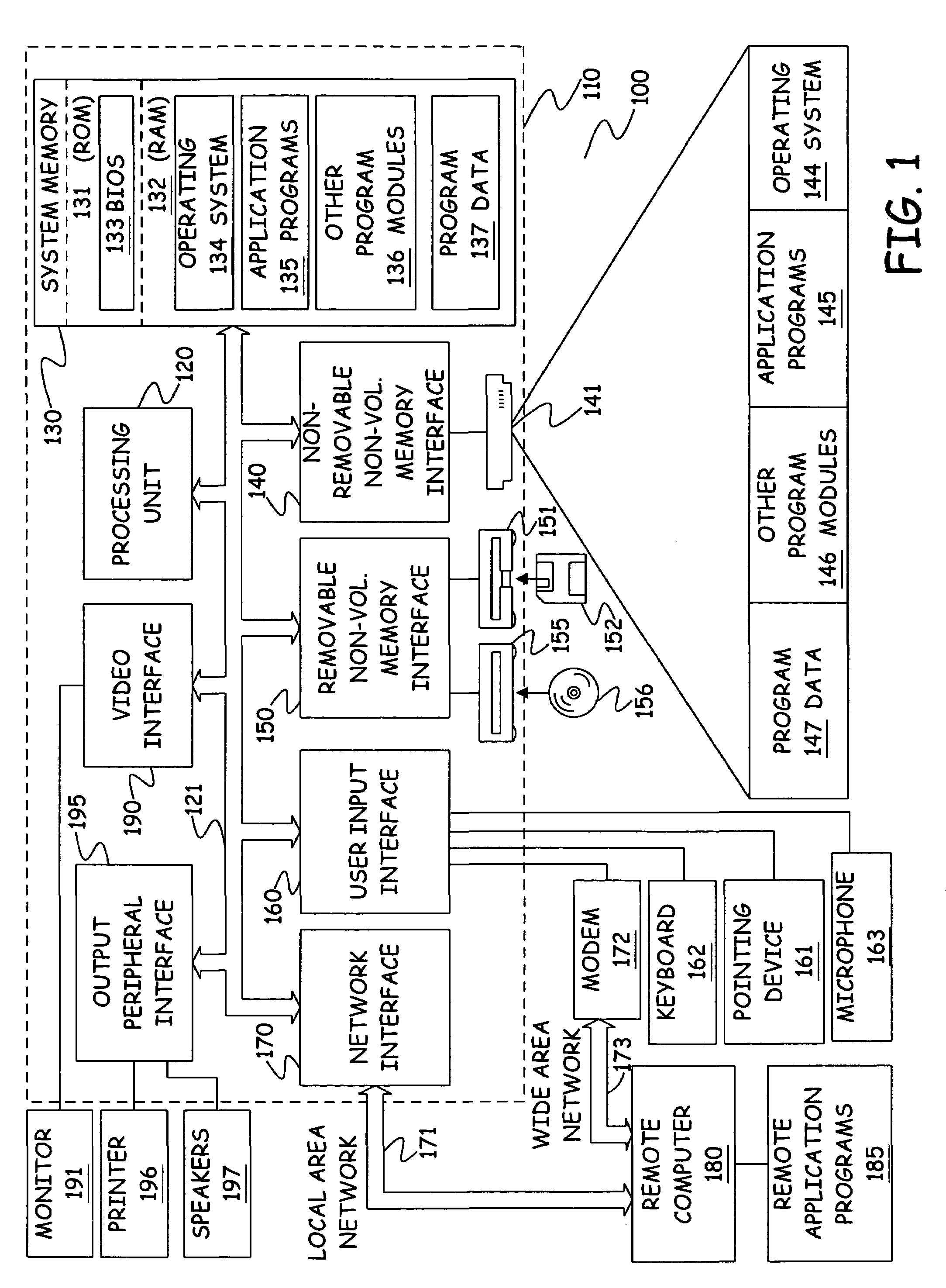

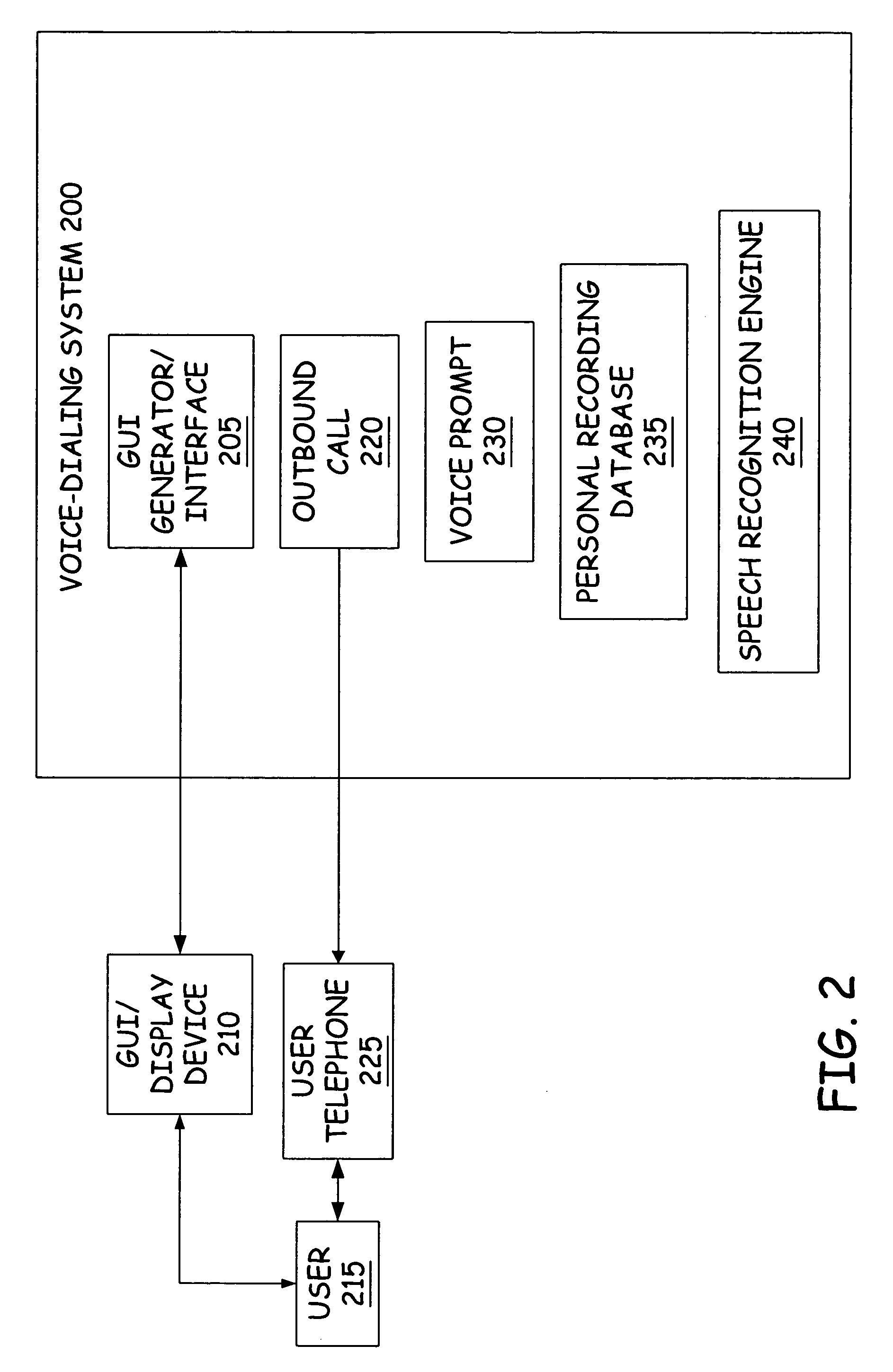

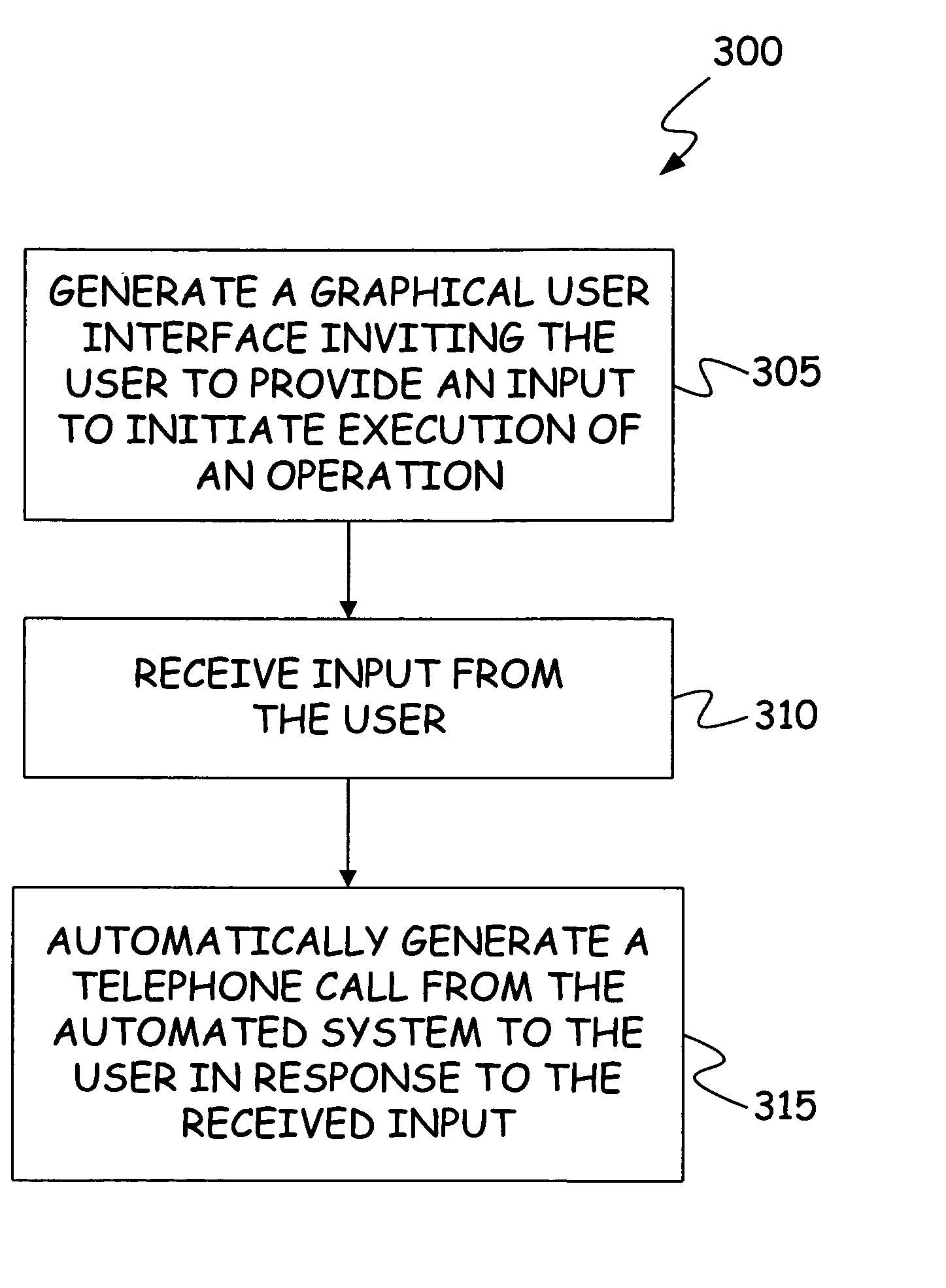

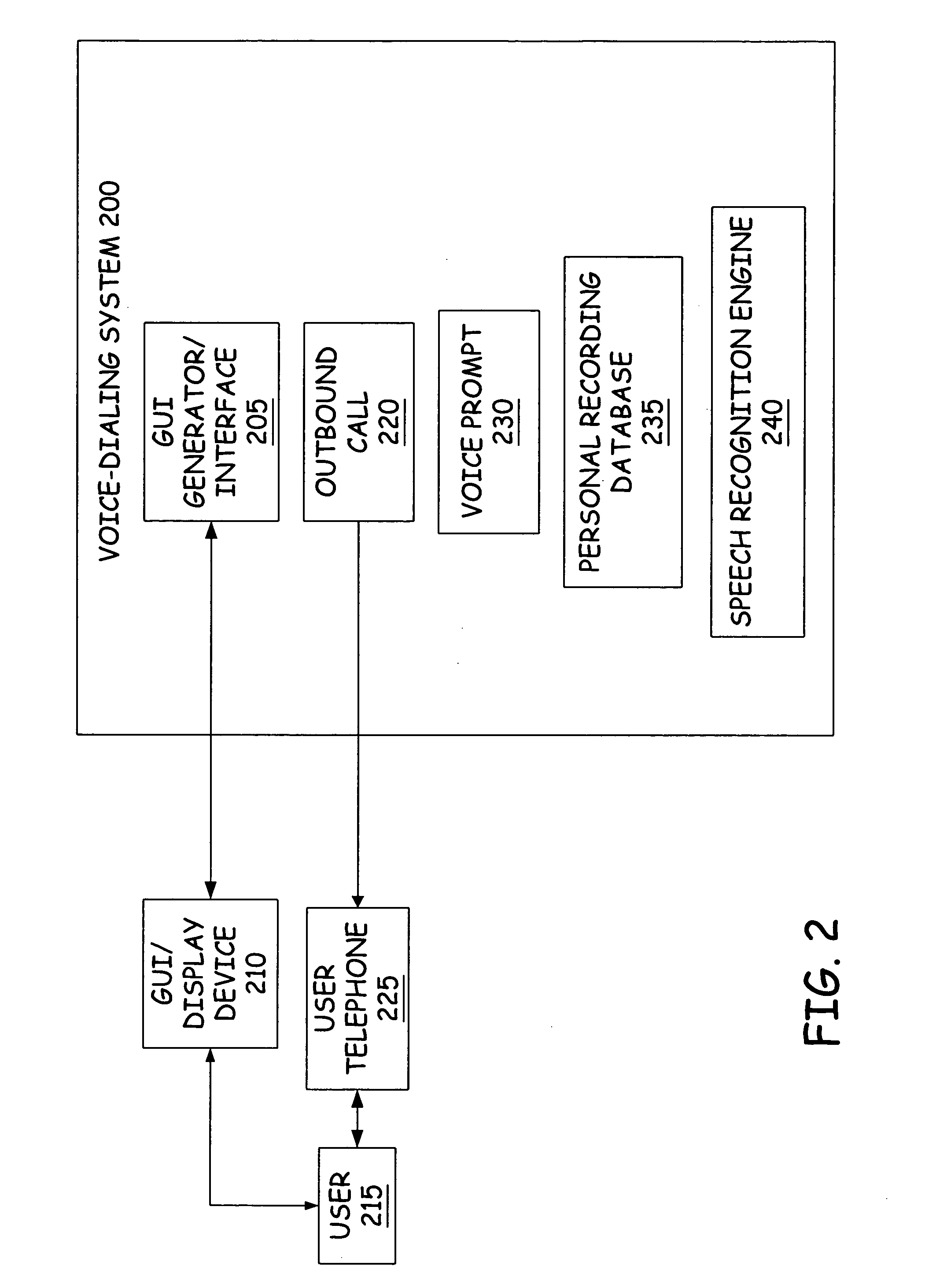

Method and apparatus for soliciting personal voice recordings for a voice-dialing system

InactiveUS7133501B2Improve compliance rateEnhanced interactionSpecial service for subscribersAutomatic call-answering/message-recording/conversation-recordingGraphicsGraphical user interface

A method of facilitating interaction between a user and an automated system is provided. The method includes generating a graphical user interface on a display, with the graphical user interface inviting the user to provide an input to initiate execution of an operation. Upon receipt of an input from the user, a telephone call is automatically generated or initiated from the automated system to the user. The automated system can then prompt the user as required to execute the operation.

Owner:MICROSOFT TECH LICENSING LLC

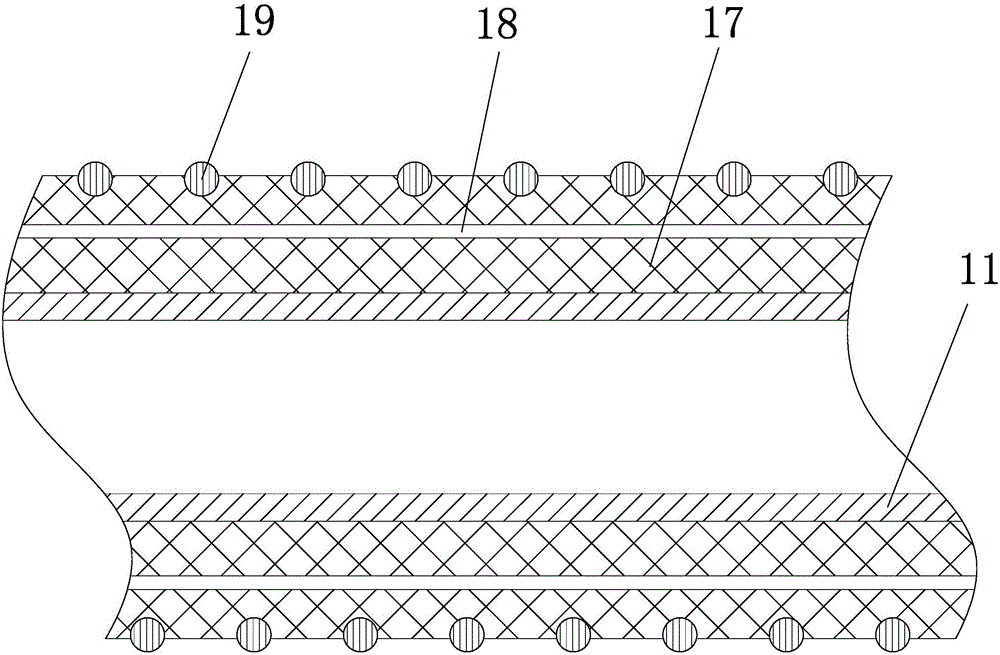

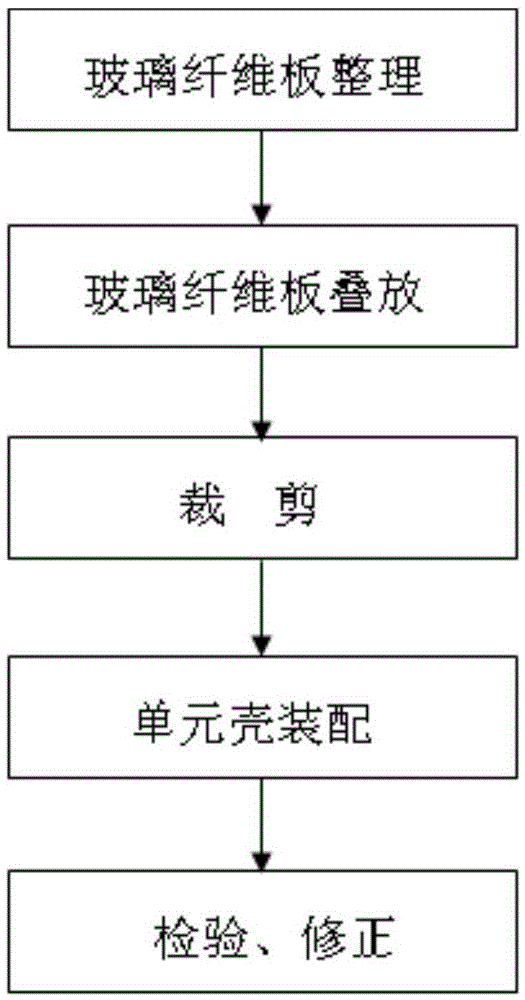

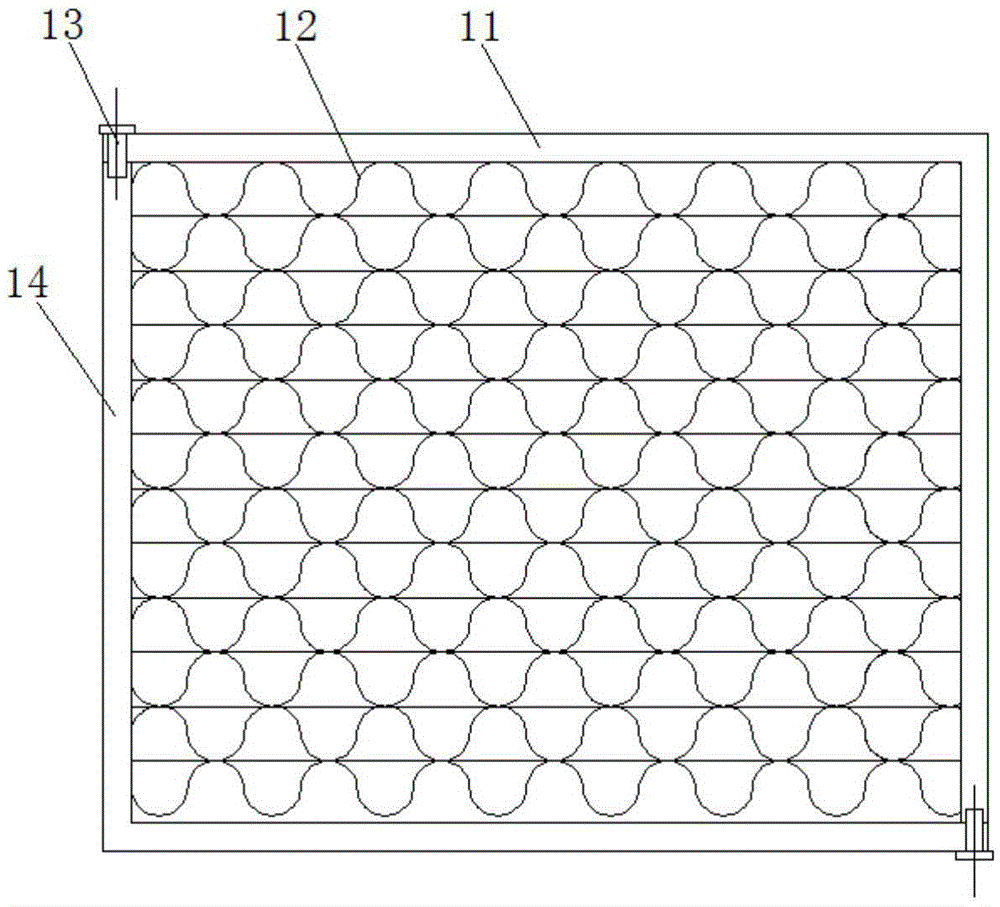

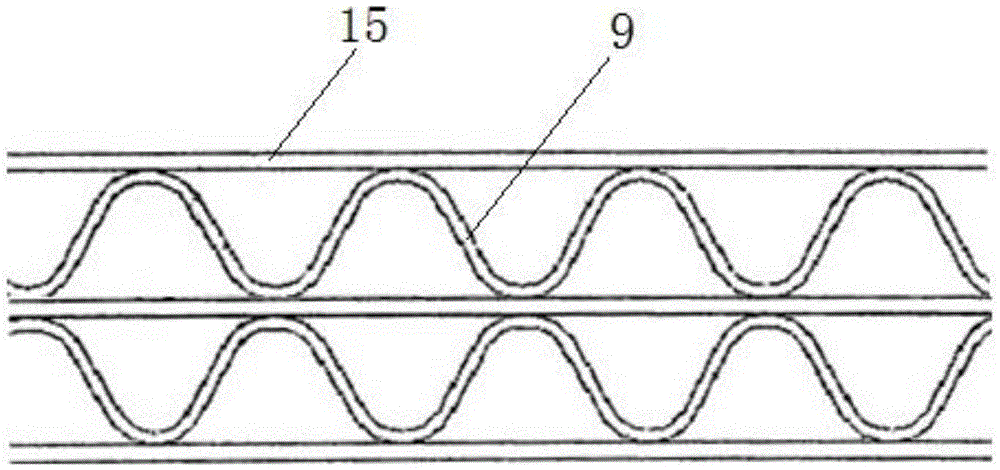

Corrugated plate type denitration catalyst unit assembling platform and assembling method

ActiveCN105597536AReduce fatigueImprove operational flexibilityDispersed particle separationFiberGlass fiber

The invention discloses a corrugated plate type denitration catalyst unit assembling platform and assembling method. The assembling method comprises steps as follows: arrangement, stacking, cutting, assembling and self-inspection processes, glass fiber corrugated plates meeting the quality requirements are arranged through plate screening, a glass fiber corrugated plate with upward wave crests, a glass fiber panel and a glass fiber corrugated plate with upward wave troughs are stacked repeatedly, catalyst unit casings are mounted after cutting and fastened through rivets, the stacking method of the glass fiber corrugated plates of corrugated plate type denitration catalyst testing units for detection is similar to unit assembly, after the testing units are assembled, the testing units are put in corrugated plate type denitration catalyst units, and the glass fiber corrugated plates and testing blocks are closely attached. 90% or more of corrugated plate type denitration catalyst units assembled with the assembling method meet the design requirements, and the production quality of denitration catalysts of enterprises is guaranteed.

Owner:QIYUAN XIAN DAE YOUNG ENVIRONMENTAL PROTECTION TECH CO LTD

Metal mold production technology capable of conveniently quickening cooling setting

The invention provides a metal mold production process which is convenient for accelerating cooling and shaping, and relates to the field of mold equipment. The metal mould, the mold body includes an upper mold and a lower mold, both ends of the lower mold are provided with fixing holes, the bottom of the lower mold is provided with a fixing plate, one end of the fixing plate is provided with a fixing bar, and the fixing bar is provided with a fixing screw , the fixed plate is provided with the first heat dissipation rib, the top of the lower mold is provided with an inner cavity, both sides of the inner cavity are provided with small fixing holes, the inside of the lower mold is provided with a cooling device, and one end of the cooling device is provided with a liquid inlet hole and a liquid outlet hole, the other end of the cooling device is provided with a gas-liquid separation chamber, and one end of the liquid inlet hole and the liquid outlet hole is provided with a liquid storage chamber. The metal mold is externally connected to the condenser through the liquid outlet hole and the liquid inlet hole, the cooling liquid enters the liquid storage cavity, and the cooling liquid is circulated in the liquid return pipe and the condensation pipe in the lower mold by the rising pipe, so as to accelerate the cooling of the mold The purpose is to facilitate the rapid shaping of the mold and to speed up the work efficiency.

Owner:屠雪丰

Method and apparatus for soliciting personal voice recordings for a voice-dialing system

InactiveUS20060062381A1Improve compliance rateEnhanced interactionInterconnection arrangementsSpecial service for subscribersGraphicsGraphical user interface

A method of facilitating interaction between a user and an automated system is provided. The method includes generating a graphical user interface on a display, with the graphical user interface inviting the user to provide an input to initiate execution of an operation. Upon receipt of an input from the user, a telephone call is automatically generated or initiated from the automated system to the user. The automated system can then prompt the user as required to execute the operation.

Owner:MICROSOFT TECH LICENSING LLC

Grinding device for metal powder processing

The invention discloses a grinding device for metal powder processing. The device comprises a box body; one side of the top of the box body communicates with a feeding funnel; a mounting plate is arranged in the middle of the top of the box body; a servo motor is mounted on the upper surface of the mounting plate; limiting columns are welded around the lower surface of the mounting plate; guide columns are arranged at the bottoms of the limiting columns; the bottoms of the limiting columns are in sliding connection with the guide columns; and the bottoms of the guide columns are welded on theupper surface of the box body. According to the device, a stepping motor drives a driving shaft to rotate, the driving shaft drives a cam to rotate, the cam rotates to enable a clamping block to slideon the surface of the cam, the clamping block moves to enable the limiting columns to slide in the guide columns, so that the height of the mounting plate can be changed, the height of the mounting plate changes to drive the positions of the servo motor, a rotating shaft and a grinding block to change, the position of the grinding block can be conveniently adjusted, the distance between the bottom of the grinding block and the bottom of a grinding plate can be changed, and the grinding is facilitated.

Owner:安徽哈特三维科技有限公司

Novel filtering device for sewage treatment equipment

PendingCN108017184AEfficient removalEfficient separationTreatment involving filtrationMultistage water/sewage treatmentFiltrationWastewater

The invention provides a novel filtering device for sewage treatment equipment. The novel filtering device comprises a first filtering device and a second filtering device connected by a pipeline. Thefirst filtering device comprises a first shell, and a first stirrer and an alkali adding tank are arranged above the first housing. A first filter net is also arranged in the first shell, and the first filter net is in the shape of a square shell. The second filtering device includes a second shell. A second stirrer and an acid adding box are installed above the second shell. A second filter netand a third filter net are parallelly arranged in the second shell. Through the multi-layered filtration structure of the novel filtering device, oil pollution and heavy metal ions in acidic wastewater can be effectively removed, the purification effect is better, and the industrial wastewater can be recycled and reused.

Owner:天津瑞祥千弘科技发展有限公司

Method for determining total output of hydrogen sulfide in oil well

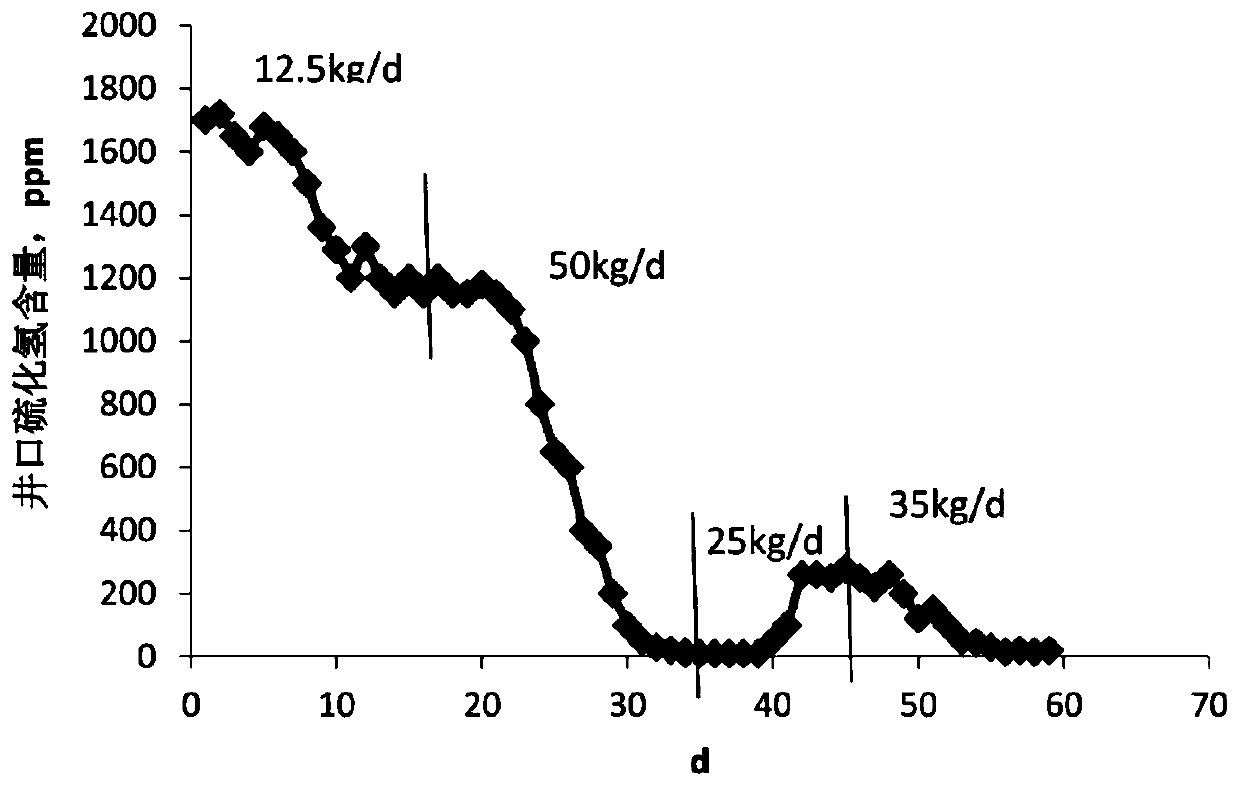

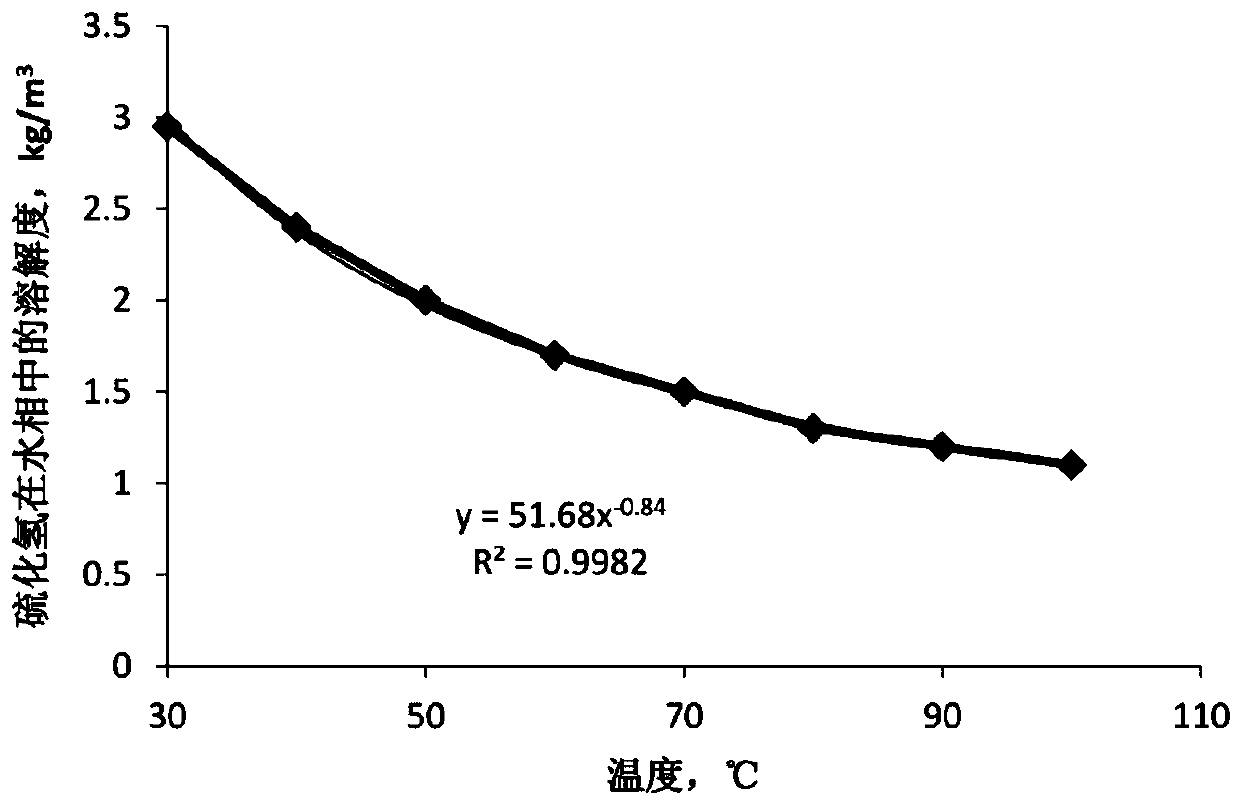

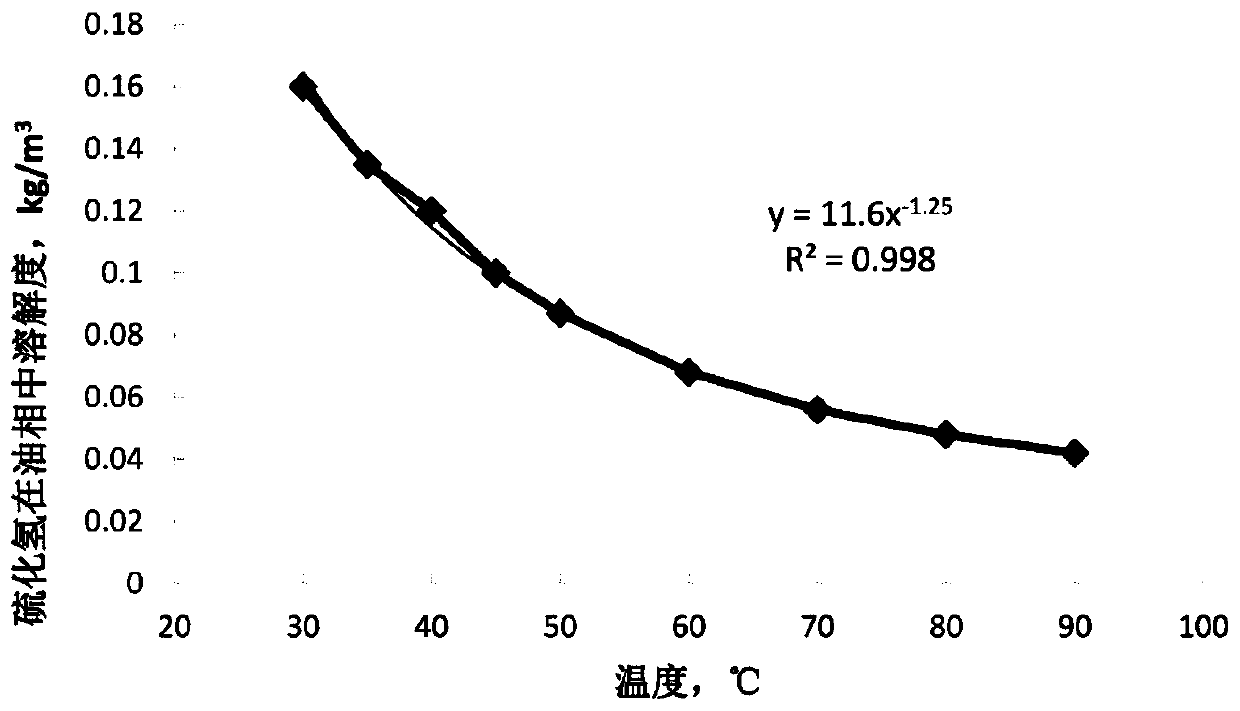

InactiveCN110596318AAccurately reflectShorten the compliance cycleMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsGas phaseOil phase

The invention belongs to the technical field of safety production and environmental protection, and particularly relates to a method for determining total output of hydrogen sulfide in an oil well, and the method specifically comprises the following steps of determining the content of gas phase hydrogen sulfide in the test oil well; determining the content of aqueous phase hydrogen sulfide in thetest oil well; determining the content of hydrogen sulfide in the oil phase; determining the output of the gas phase hydrogen sulfide; determining the output of the aqueous phase hydrogen sulfide; determining the output of the oil phase hydrogen sulfide; and determining the total output of hydrogen sulfide in the test oil well. The method provided by the invention, by not only considering gas phase hydrogen sulfide, but also considering aqueous phase and oil phase hydrogen sulfide, more accurately reflects the actual situation of the total amount of hydrogen sulfide in the oil well to providea reliable basis for the source treatment of hydrogen sulfide of the oil well, shortens the treatment cycle of hydrogen sulfide compliance by more than 60% and increases the compliance rate of hydrogen sulfide dosing treatment in the oil well to reduce hidden safety hazards, and effectively reduces the amount of dosing to save the cost of dosing by 30%.

Owner:CHINA PETROLEUM & CHEM CORP +1

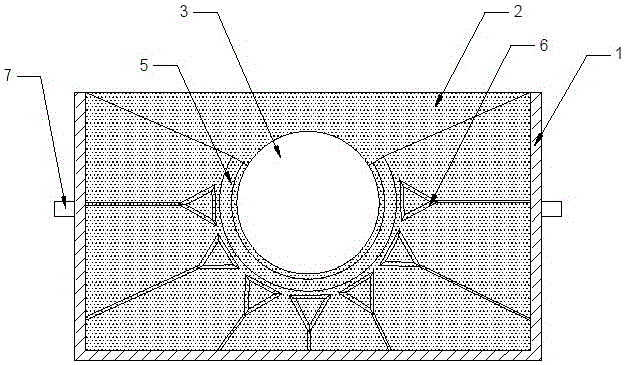

Lost-foam casting device

ActiveCN106363132AIntegrity guaranteedImprove compliance rateFoundry mouldsFoundry coresEngineeringLost-foam casting

The invention discloses a lost-foam casting device which comprises a box body and a foam model, wherein molding sand is arranged in the box body; the foam model is arranged inside the molding sand; the foam model comprises a body and a rope groove; the box body is further equipped with a flexible packing layer matched with the rope groove; a plurality of groups of expanding blocks which are pre-heated to expand are arranged in the molding sand; each group of expanding blocks is opposite to the filling layer; and a supporting rod is arranged between each group of expanding blocks and the box body. According to the scheme adopted by the invention, the lost-foam casting device mainly solves the problem that the rate of reaching the standards of cast pieces is low due to the fact that fit degree between the molding sand the foam model is not high.

Owner:沛县东方铸造有限公司

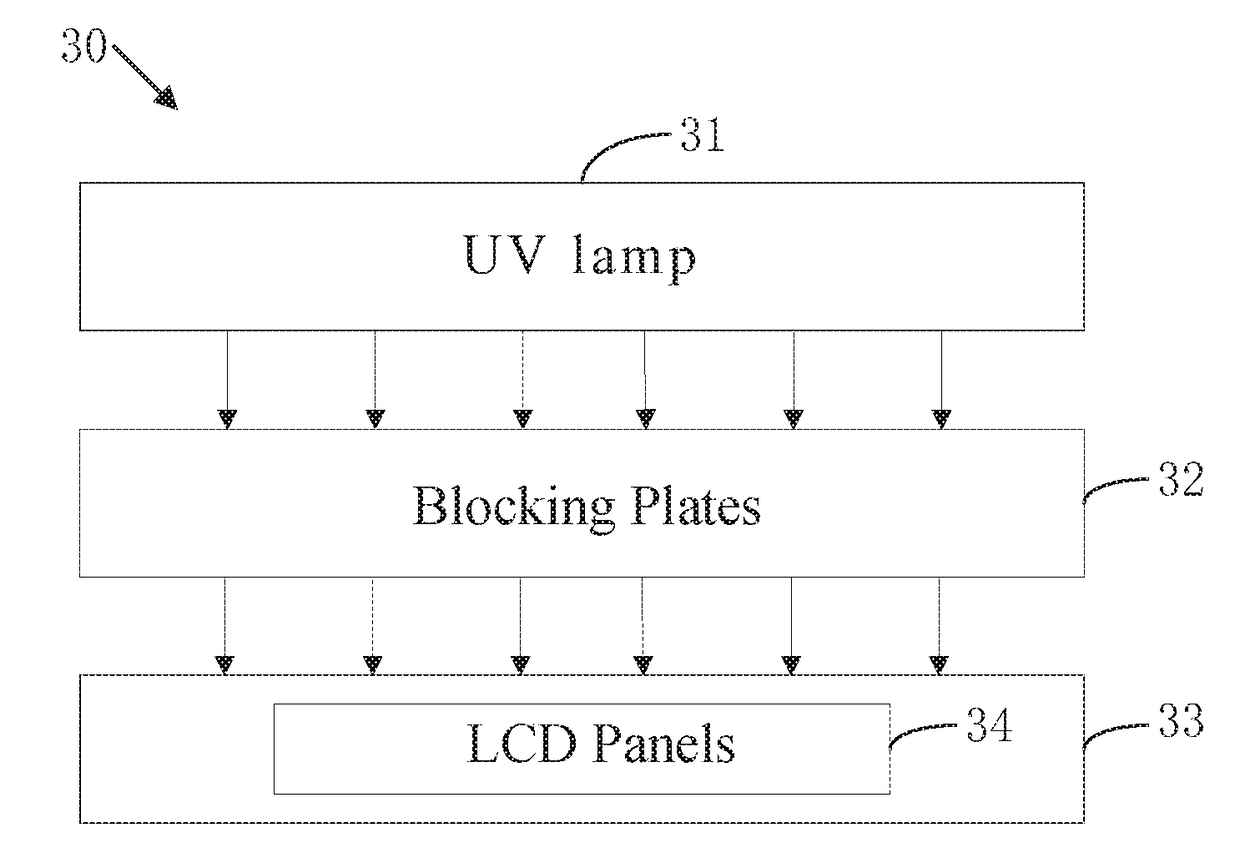

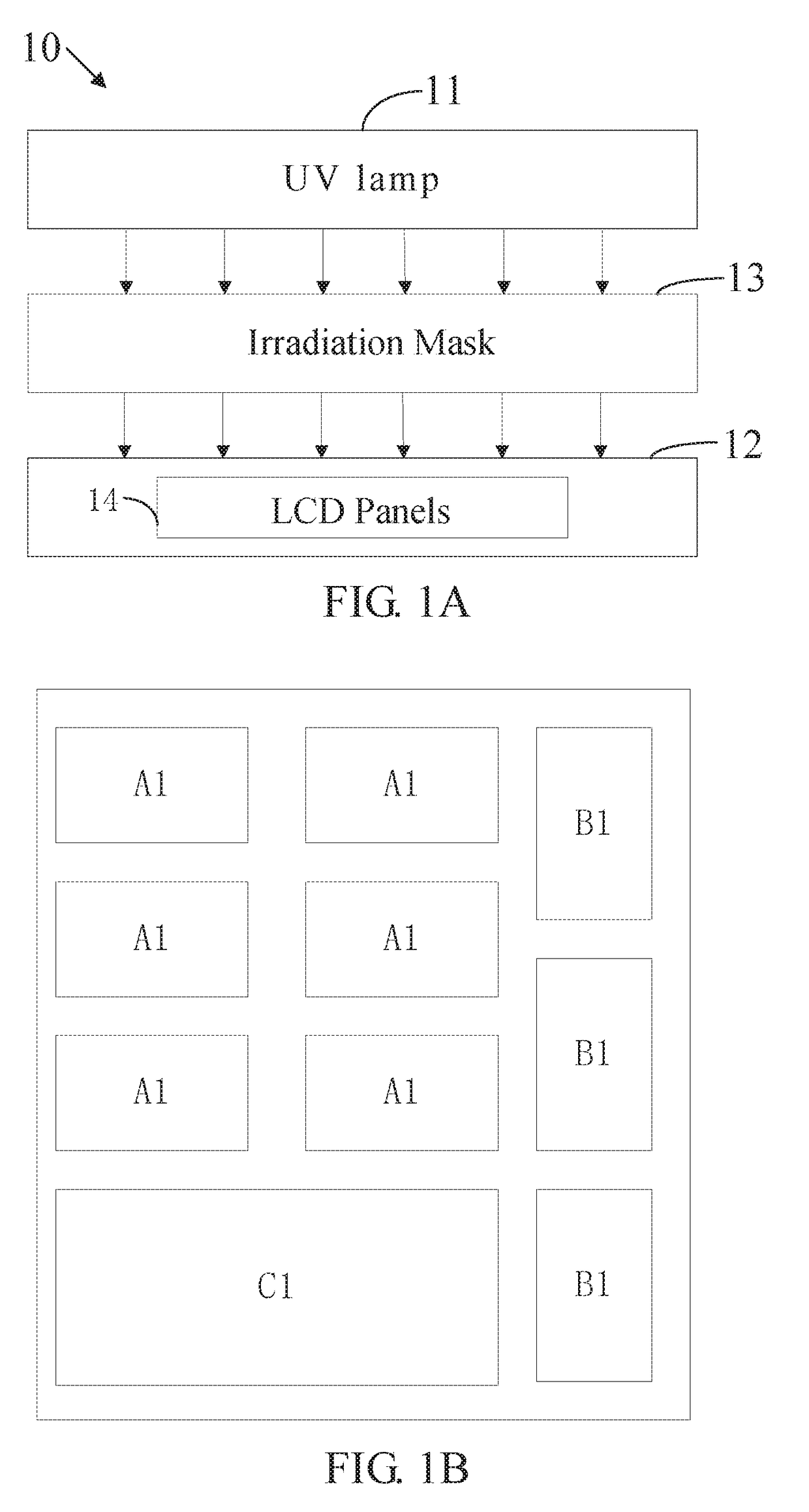

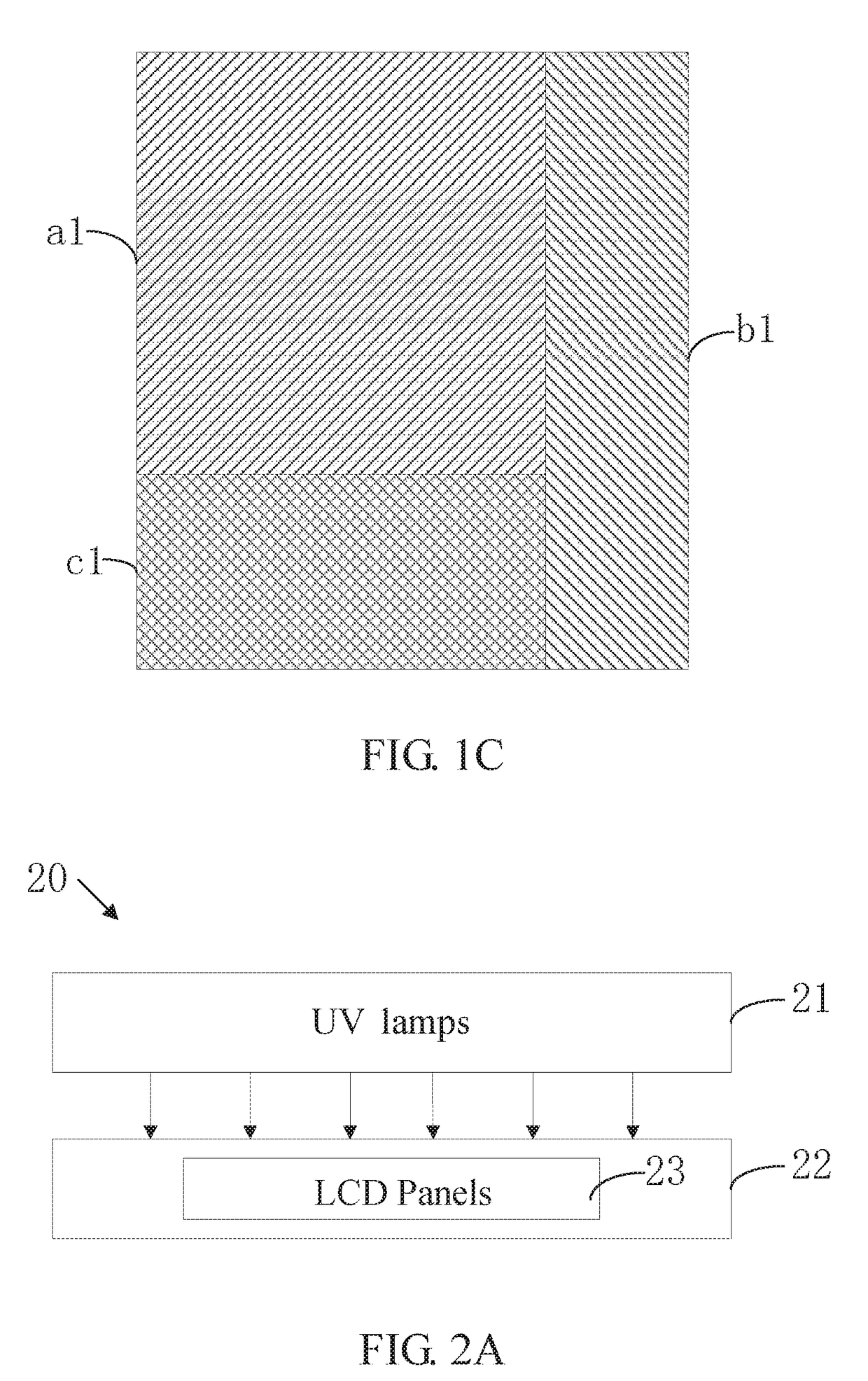

Optical alignment device for liquid crystal display panels

ActiveUS20170307913A1Improve compliance rateLow compliance rateNon-linear opticsUltravioletEngineering

An optical alignment device for a plurality of liquid crystal display panels is disclosed, and has a panel carrying stage, a UV lamp, and a plurality of irradiation masks. The panel carrying stage is used for placing the liquid crystal display panels, the UV lamp is used for applying a UV irradiation to the liquid crystal display panels on the panel carrying stage so that liquid crystals in each of the liquid crystal display panels have pretilt angles, and the irradiation masks are disposed between the UV lamp and the liquid crystal display panels for changing an irradiation intensity of the UV irradiation on the crystal display panels.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

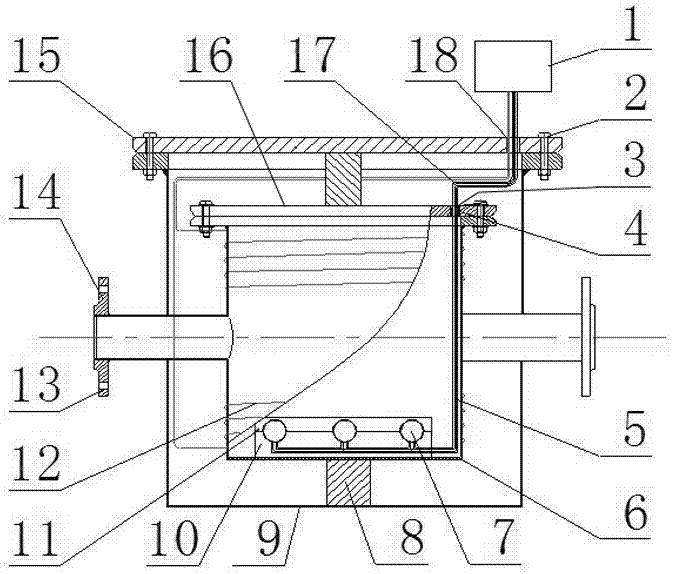

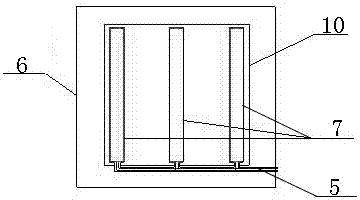

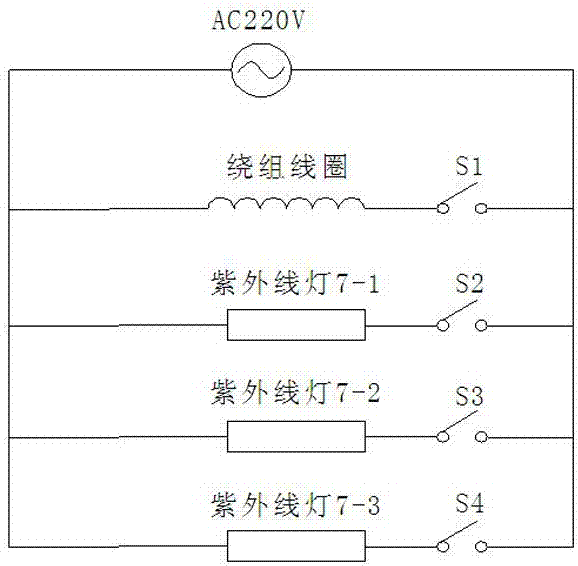

UV sterilizing device under alternating magnetic field environment

InactiveCN106946323ANo secondary pollutionImprove compliance rateWaste water treatment from quariesWater/sewage treatment by irradiationUltravioletWater quality

A UV sterilizing device under an alternating magnetic field environment comprises an outer cylinder, an inner cylinder, winding coils, and an alternating power supply. A UV lamp is arranged in the inner cylinder. The UV lamp is fixed on the bottom of the inner cylinder through a lamp holder. The upper part of the inner cylinder is provided with an inner cylinder flange cover. The winding coils are winded around the outer surface of the inner cylinder. The inner cylinder is arranged in the outer cylinder. The upper part of the outer cylinder is provided with an outer cylinder flange cover. The upper part of the outer cylinder flange cover is provided with the alternating power supply. The alternating power supply is connected to the UV lamp and the winding coils. The bottom center and top center of the outer cylinder are both provided with a cylindrical support. Pipelines on two sides of the inner cylinder are welded on the lateral surface of the outer cylinder. Two ends of the pipeline that connects the inner cylinder are provided with a connection flange and a bolt hole. The UV sterilizing device is more economic, safer, and more stable, does not have any side effect, and does not generate secondary pollution to the environment. The winding coils are directly winded around the inner cylinder, the installation is convenient and quick, the sterilization efficiency is high and can reach more than 99%, and the qualified rate of water quality of reinjection water is greatly increased.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com