High-effective organic waste gas recovery processing method and complete equipment

A technology for recycling and treating organic waste gas, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as high construction cost, substandard tail gas, and poor safety, and achieve strong safety, increased recovery efficiency, and self-control high level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

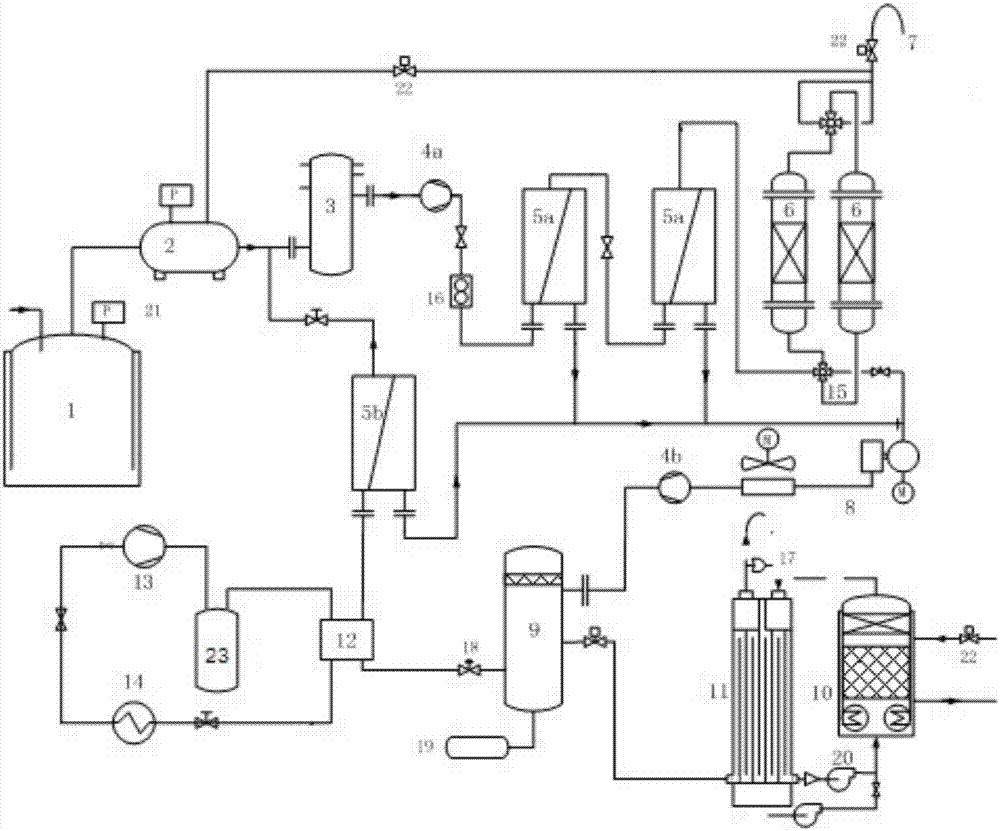

Method used

Image

Examples

Embodiment 1

[0100] The application results of the recovery and treatment process of the organic waste gas discharged from the catalytic gasoline tank on the vaulted top of the oil storage tank area. The main composition of the organic waste gas (volume fraction) is nitrogen, and the concentration of volatile organic compounds (VOCs) is about 150,000 to 300,000 mg / m 3 between. The design capacity of the device is 40m 3 / h, the maximum concentration of rated air intake is 200000mg / m 3 , the pressure on the retentate side of the first-stage membrane is 0.2Mpa, the pressure on the retentate side of the second-stage membrane is 0.38Mpa, the pressure of the compression and condensation process in the device is 0.4MPa, the temperature is 2°C, the vacuum degree of the permeate side is not lower than -0.09Mpa, and the low-temperature catalytic process starts The initial temperature ranges from 260°C to 340°C. The intake flow rate during the operation of the device, the concentration of non-metha...

Embodiment 2

[0104] The effect of the method and the device on the recovery and treatment of the organic waste gas discharged from the breathing valve of the floating roof sewage tank in the intermediate tank area in the refinery. Its organic waste gas composition (volume fraction) is mainly nitrogen accounting for about 80% to 88% of the volume fraction, and volatile organic compounds (VOCs) accounting for between 12% and 20% of the volume fraction. The hydrocarbons in VOCs are mainly light hydrocarbons, including methane, ethane, ethylene, propane, propylene, isobutane, n-butane, n-butene, isobutene, trans-butene, and carbon 5. In addition, the exhaust gas also contains a small amount of hydrogen sulfide and oxygen. The design capacity of the device is 40m 3 / h, rated intake air maximum concentration 300000mg / m 3 Or the volume fraction is 20% (v / v), the pressure on the retentate side of the primary membrane is 0.2Mpa, the pressure on the retentate side of the secondary membrane is 0.38...

Embodiment 3

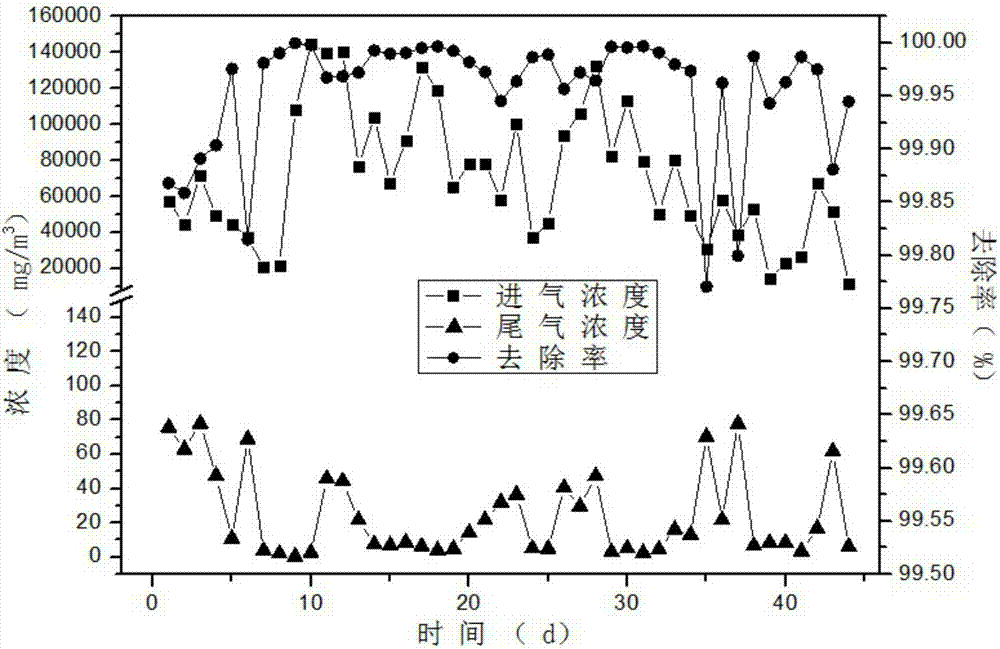

[0109] For the treatment of the waste gas from the catalyst production workshop, the VOCs concentration of the emission is theoretically estimated first. The VOCs in the waste gas mainly come from the raw materials hexane and toluene used in the production process. Due to the limitation of the process conditions in the production process, some toluene and hexane will be consumed During the production process, it is discharged into the atmosphere along with the equipment operation along with nitrogen. The concentration of hexane and non-methane total hydrocarbons in the system intake fluctuates greatly, most of which are at 20,000 mg / m 3 to 140000mg / m 3 Among them, the hydrocarbons in VOCs mainly include n-hexane and toluene. The design capacity of the device is 50m 3 / h, the maximum concentration of intake air should not exceed 350000mg / m 3 , the pressure on the retentate side of the primary membrane is 0.2Mpa, the pressure on the retentate side of the secondary membrane is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com