Flexible printed circuit board steel disc reinforcing hot-pressing making process

A flexible circuit board, flexible circuit technology, applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of easy falling off or misalignment of steel sheets, easy melting, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] 1. Steel lamination fixture

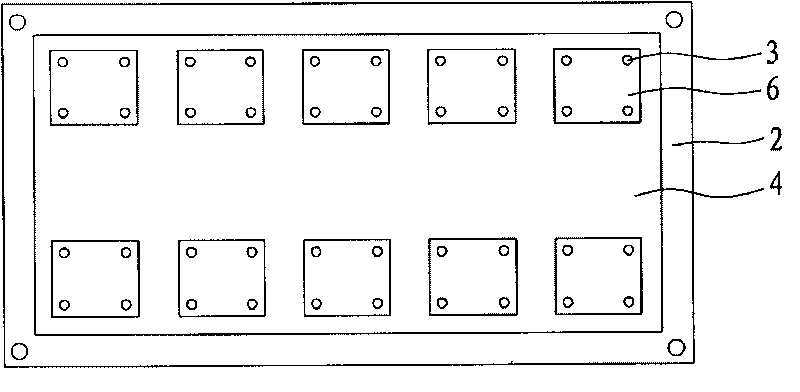

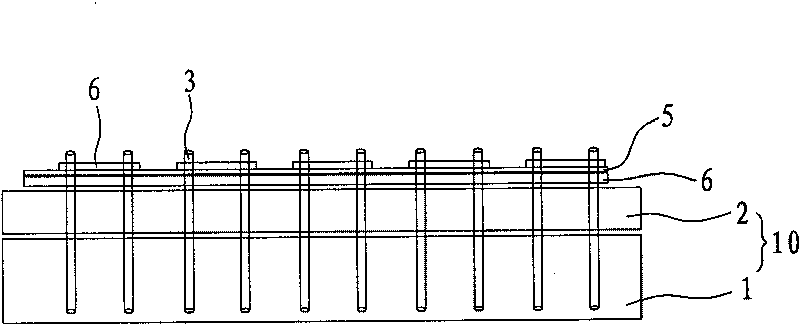

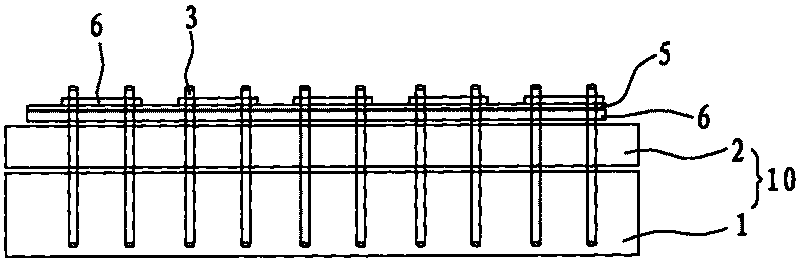

[0014] like figure 1 , figure 2 As shown, the steel lamination jig 10 used in the present invention includes a first base plate 1 , a second base plate 2 and a plurality of positioning pins 3 . The second substrate 2 is pasted on the top surface of the first substrate 1, and the same end of the first substrate 1 and the second substrate 2 are fixed with single-sided adhesive tape or other materials to bond them together. A plurality of positioning pins 3 pass through the relief holes on the second substrate 2 and are sleeved in the positioning holes on the first substrate 1 , and the penetration end surfaces of the positioning pins 3 are flush with the bottom surface of the first substrate 1 .

[0015] 2. Process

[0016] The present invention is a kind of flexible circuit board steel sheet reinforced hot pressing production process, which comprises the following steps:

[0017] (1) steel sheet 6 drilling: drill a positioning hole on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com