Patents

Literature

119results about How to "Simple operability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

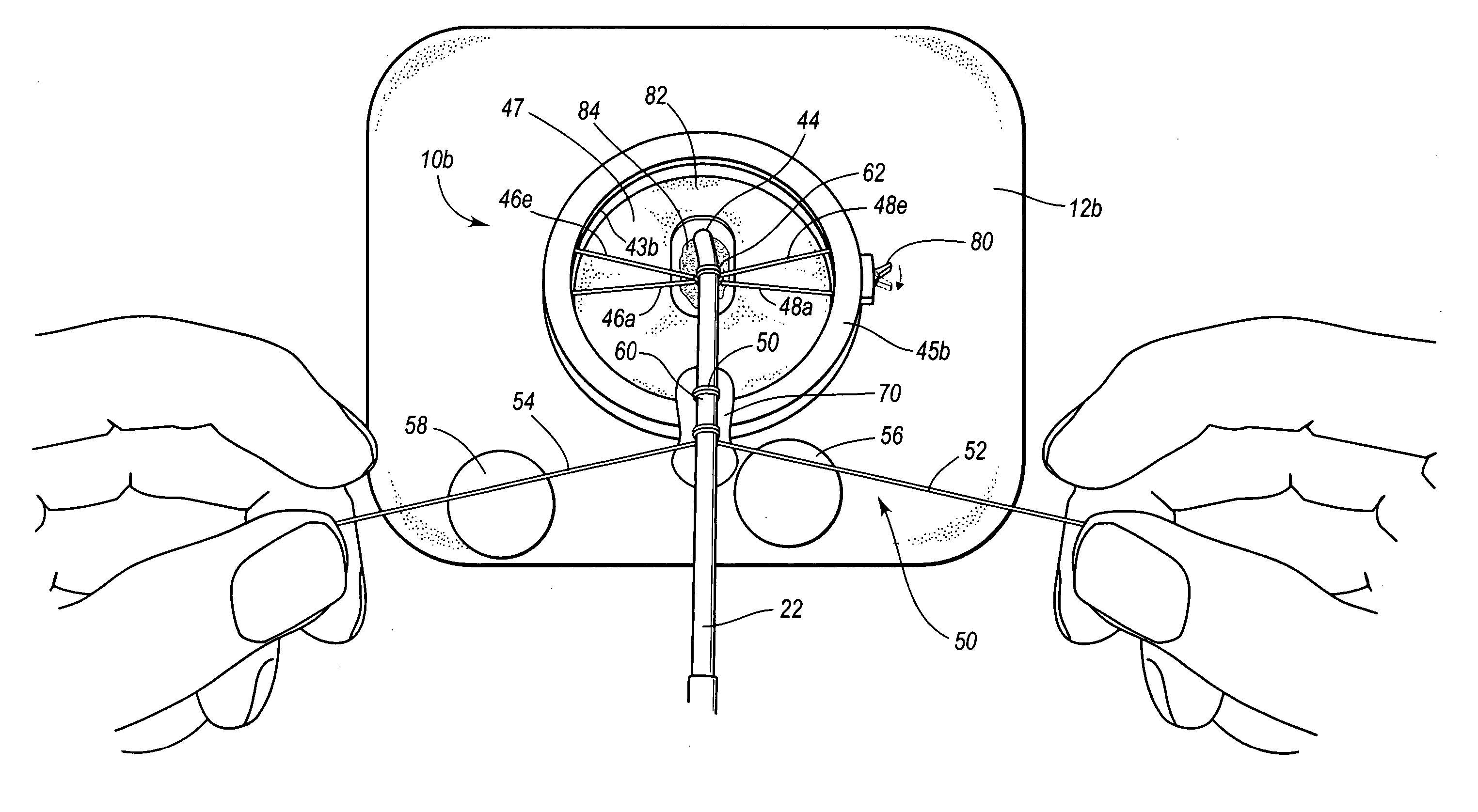

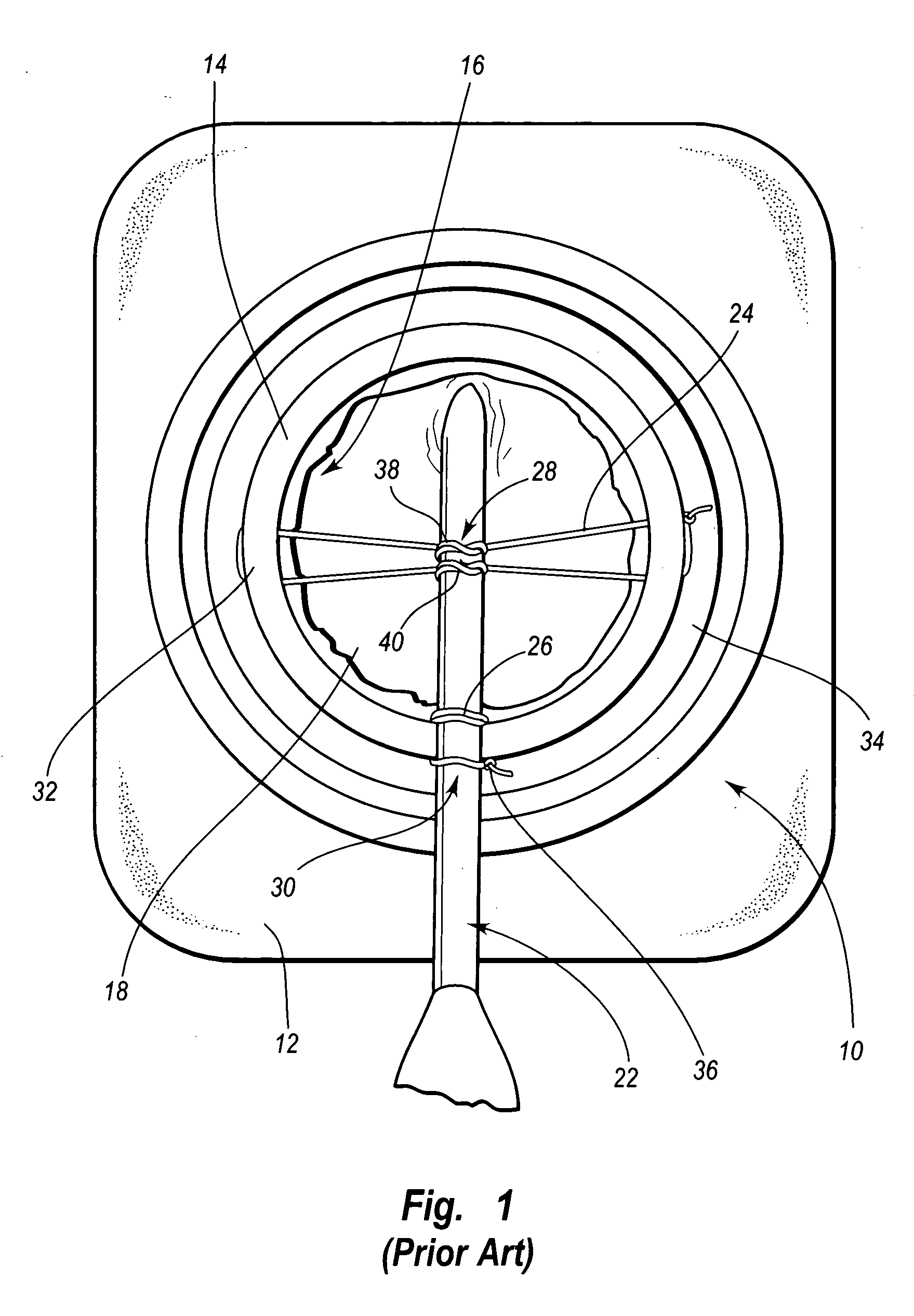

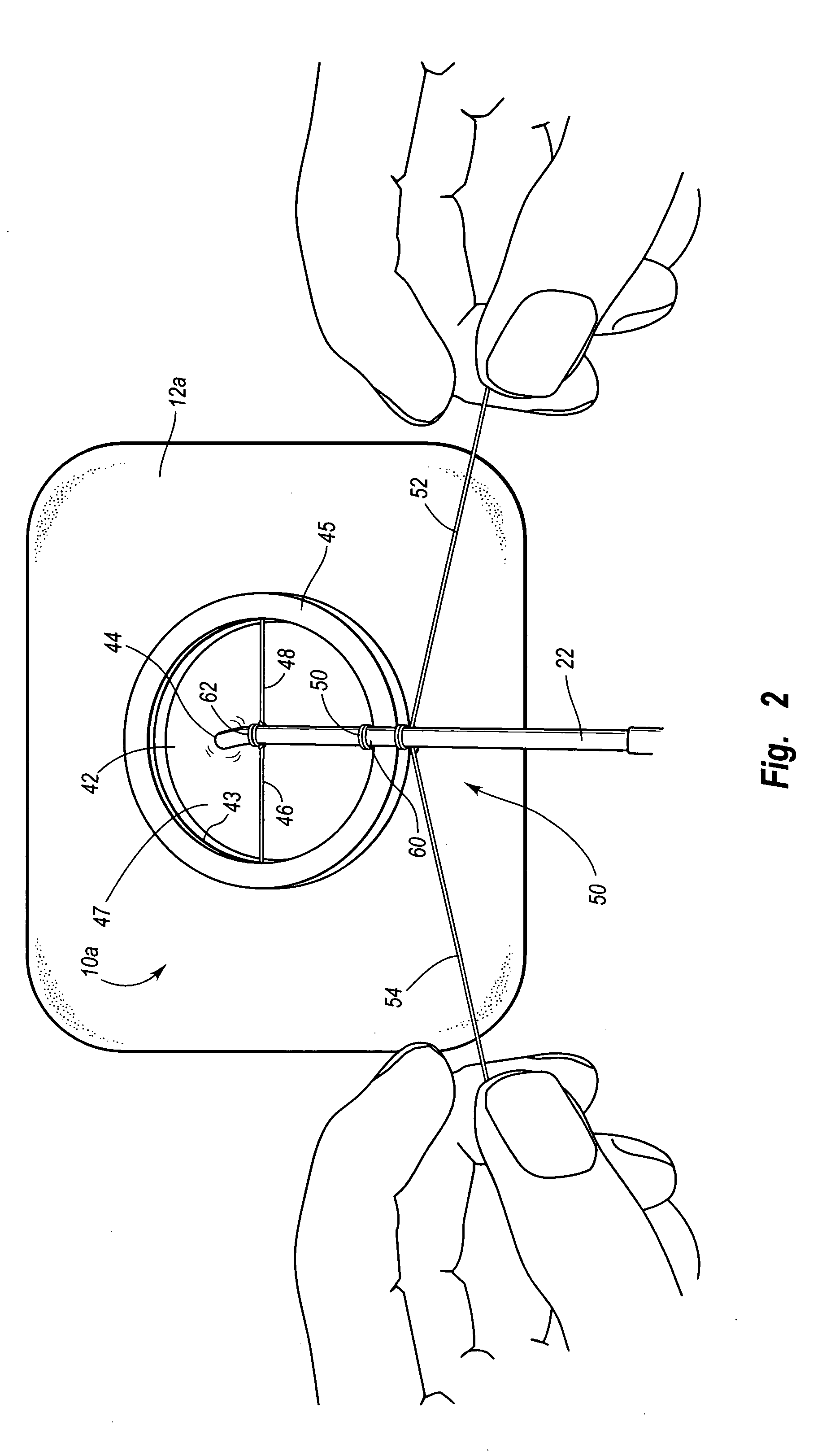

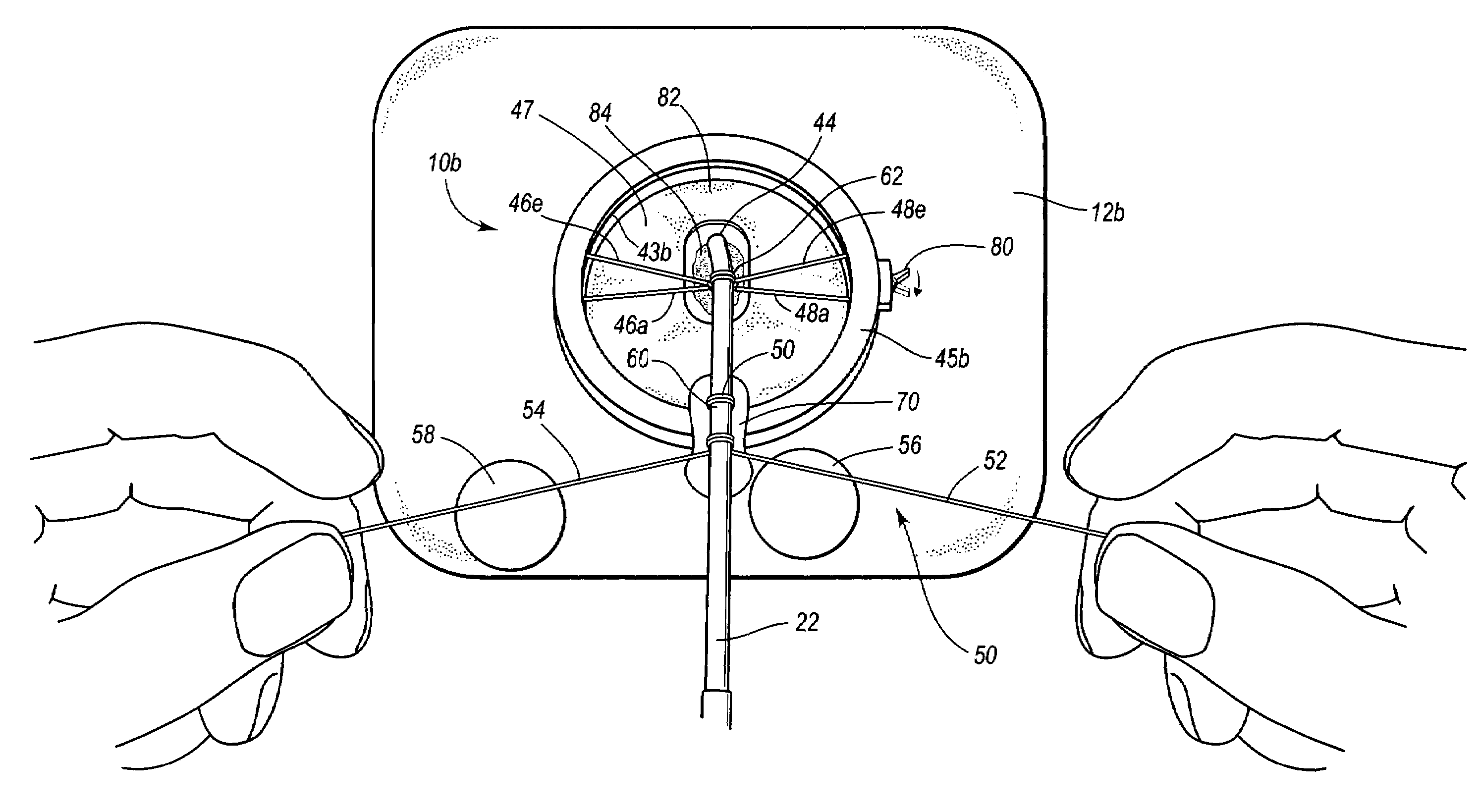

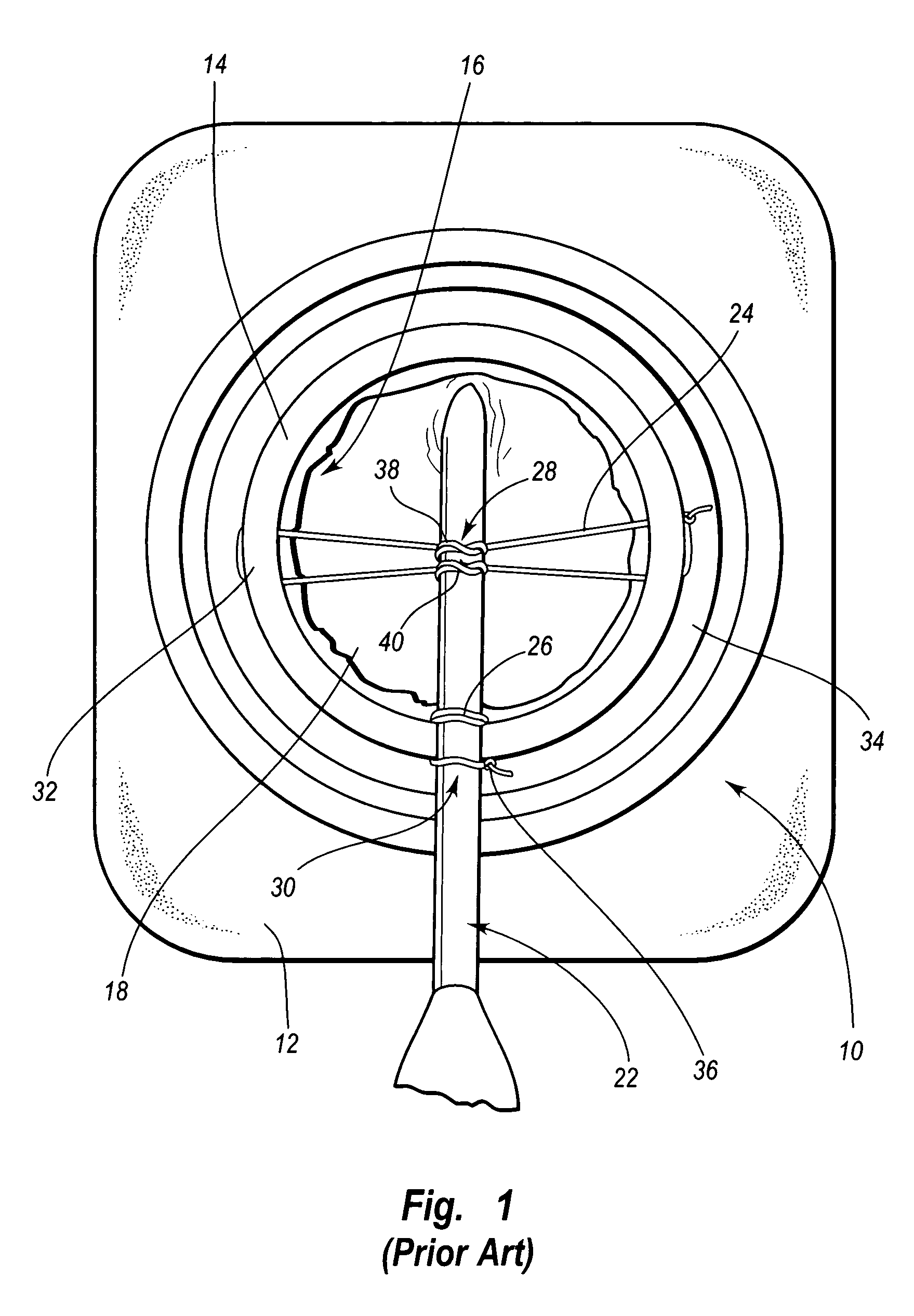

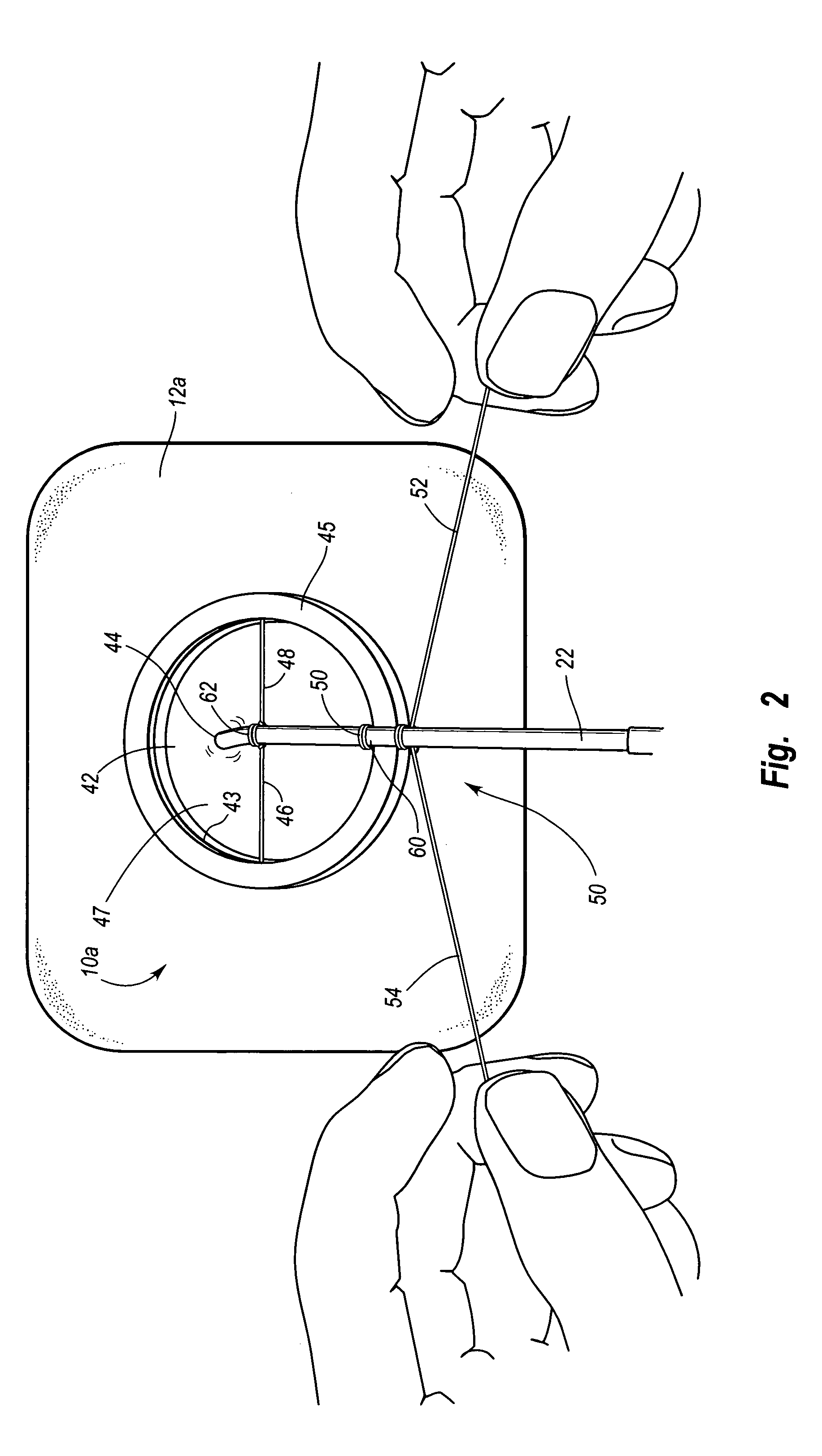

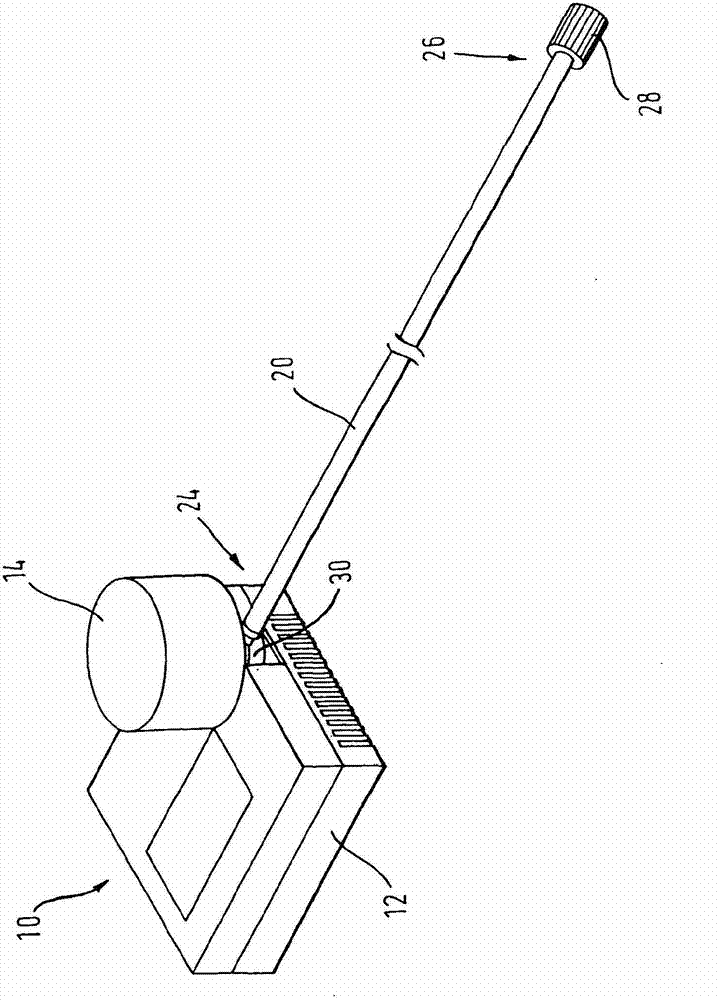

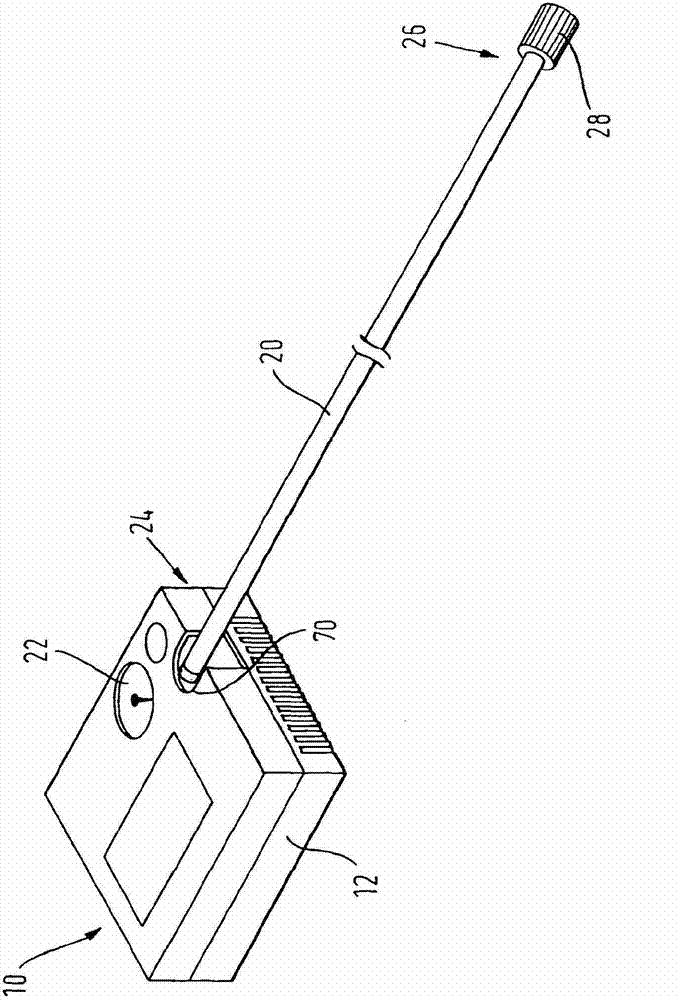

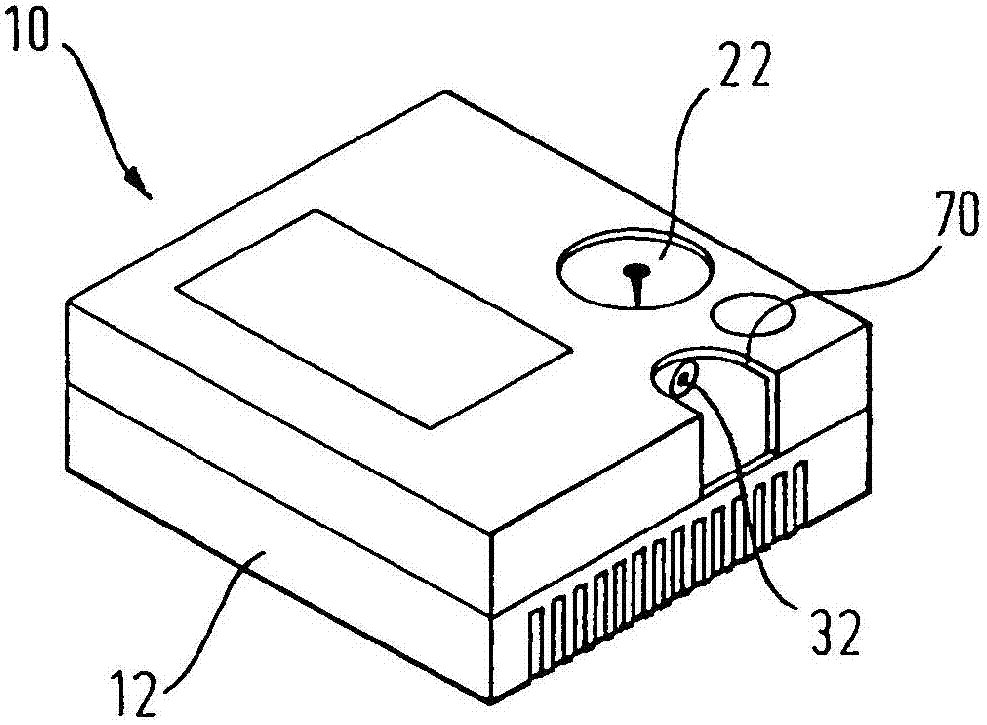

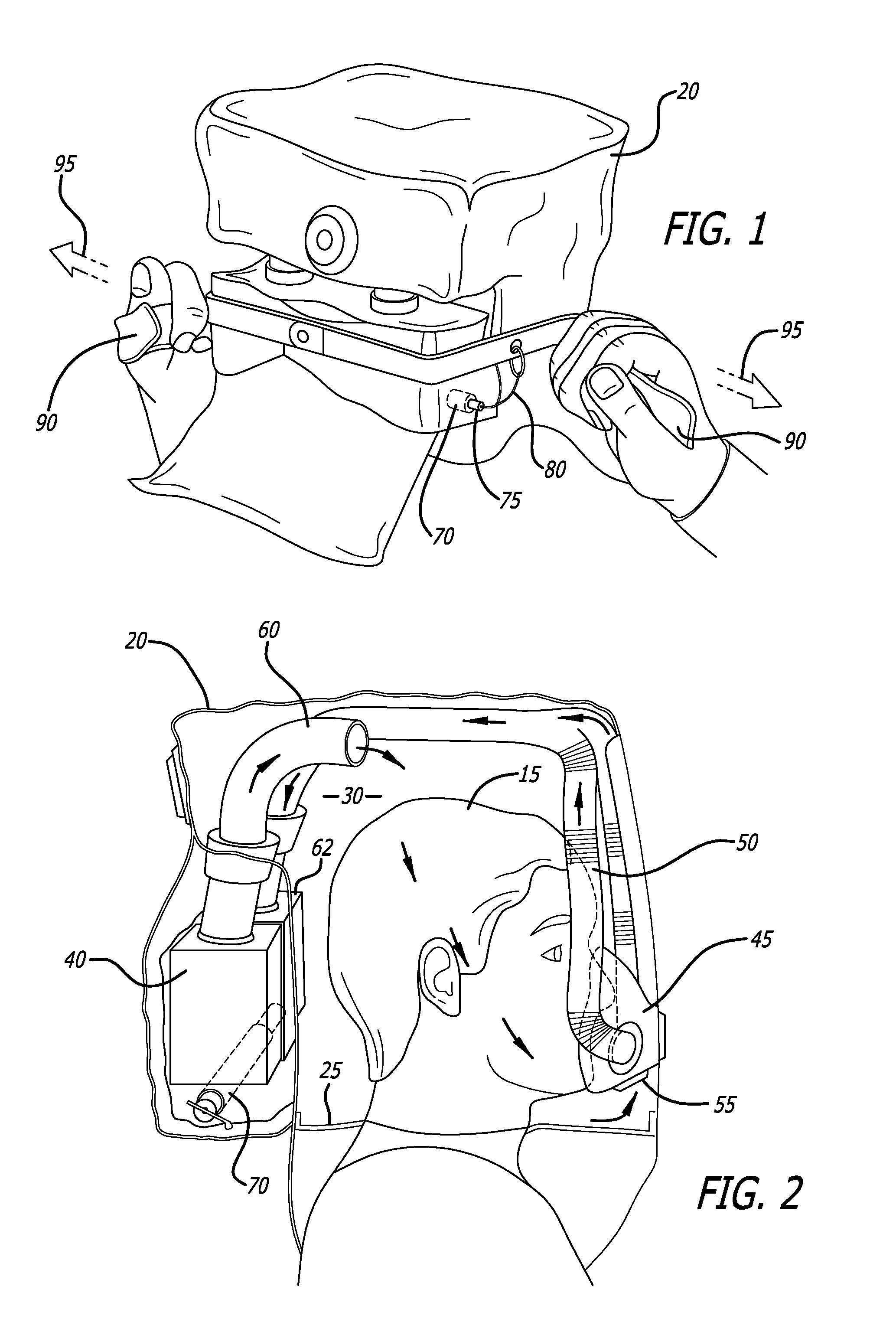

Self-suturing anchor device for a catheter

ActiveUS20060095008A1Automatic and quick and efficient securementShorten the lengthSuture equipmentsSurgical furnitureSuture anchorsCatheter device

A self-suturing anchor device includes a base having a securement mechanism. The securement mechanism includes one or more resilient pockets in which are placed a plurality of looped sutures. The securement mechanism and looped sutures facilitate automatic securement of a catheter relative to the self-suturing anchor device. In at least one embodiment, the looped sutures are also threaded through loops in another corresponding looped suture, such that each looped sutures slidably tighten in concert with one another. When at least a portion of the securement mechanism is moved, at least one of the plurality of looped sutures is tensioned and closes against a securement point on the catheter. A catheter can be secured in a self-suturing anchor device in a quick and efficient manner with minimal effort.

Owner:MERIT MEDICAL SYST INC

Self-suturing anchor device for a catheter

ActiveUS7520869B2Automatic and quick and efficient securementShorten the lengthSuture equipmentsSurgical furnitureSuture anchorsCatheter

A self-suturing anchor device includes a base having a securement mechanism. The securement mechanism includes one or more resilient pockets in which are placed a plurality of looped sutures. The securement mechanism and looped sutures facilitate automatic securement of a catheter relative to the self-suturing anchor device. In at least one embodiment, the looped sutures are also threaded through loops in another corresponding looped suture, such that each looped sutures slidably tighten in concert with one another. When at least a portion of the securement mechanism is moved, at least one of the plurality of looped sutures is tensioned and closes against a securement point on the catheter. A catheter can be secured in a self-suturing anchor device in a quick and efficient manner with minimal effort.

Owner:MERIT MEDICAL SYST INC

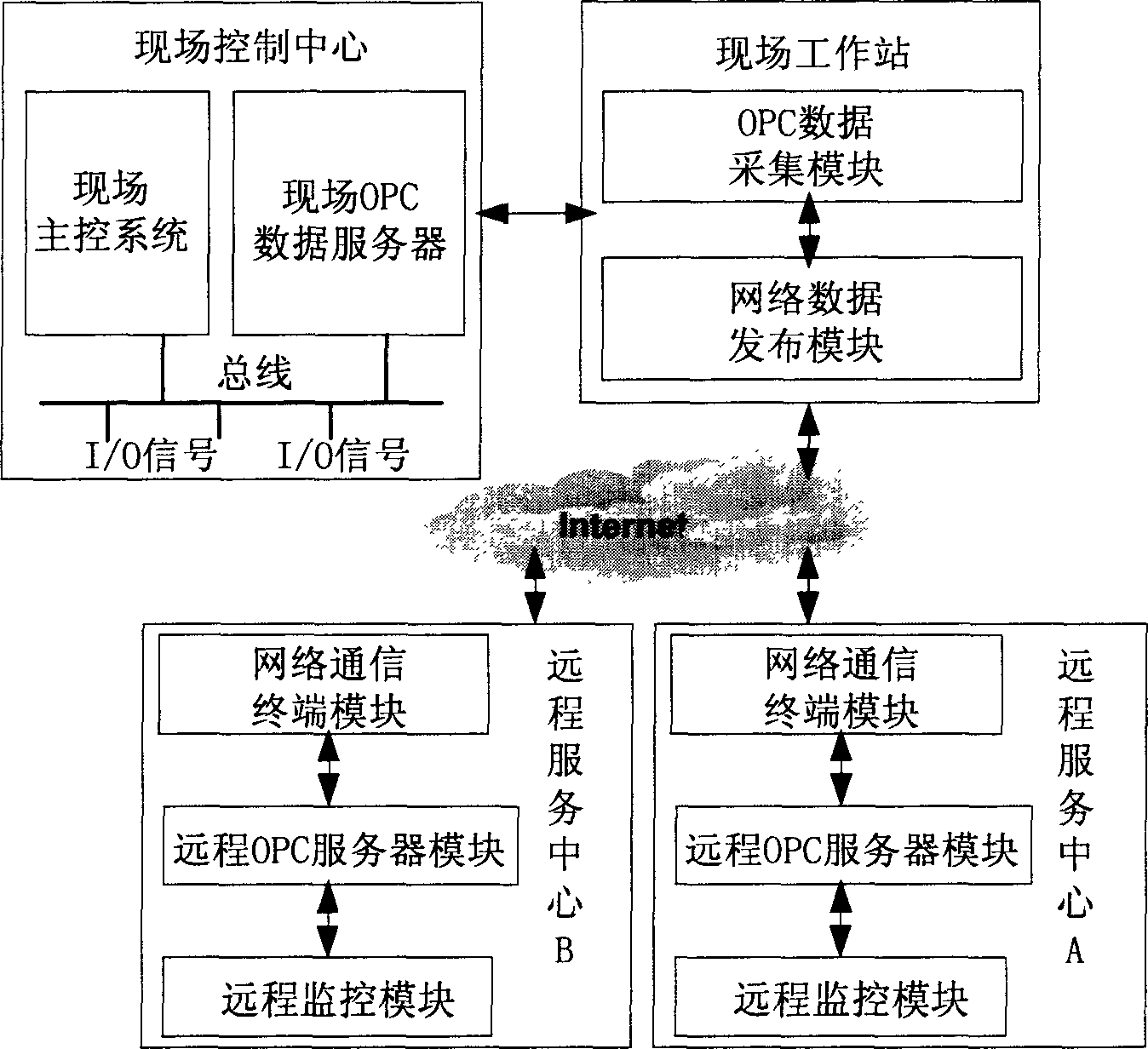

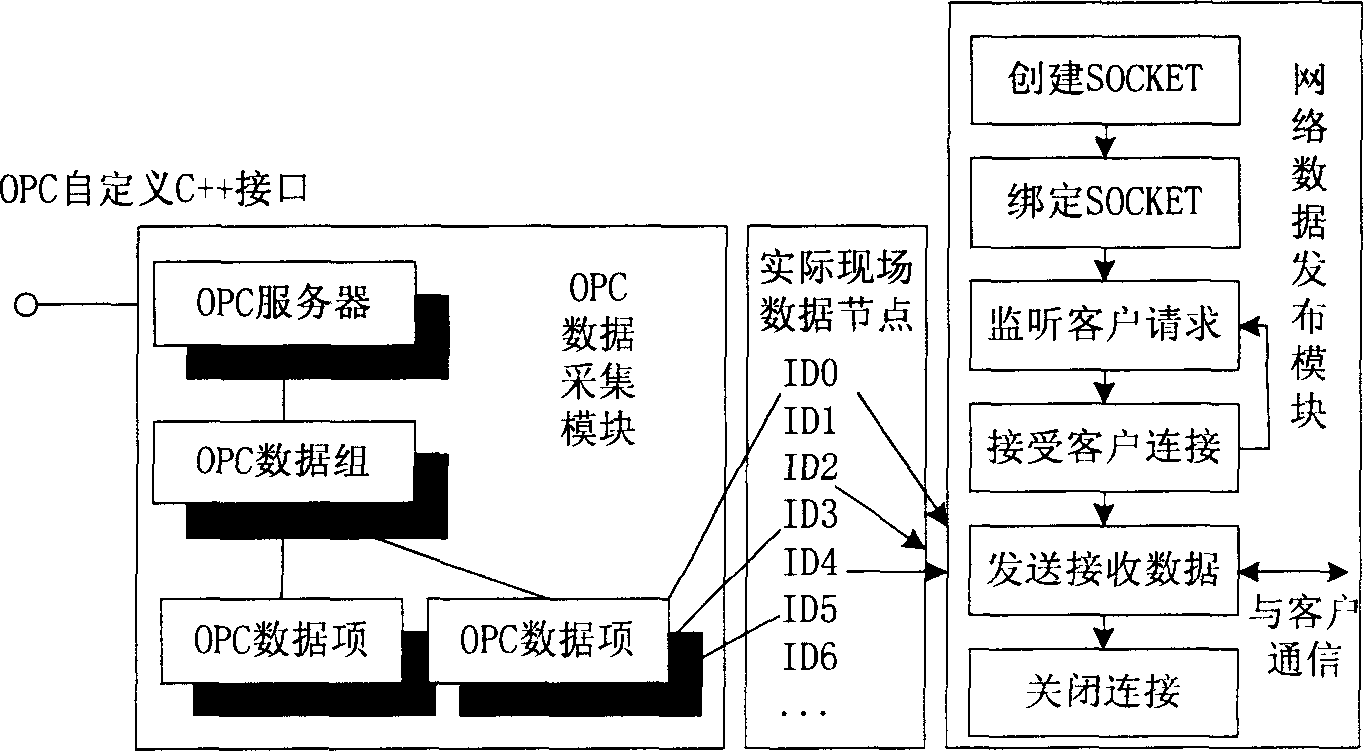

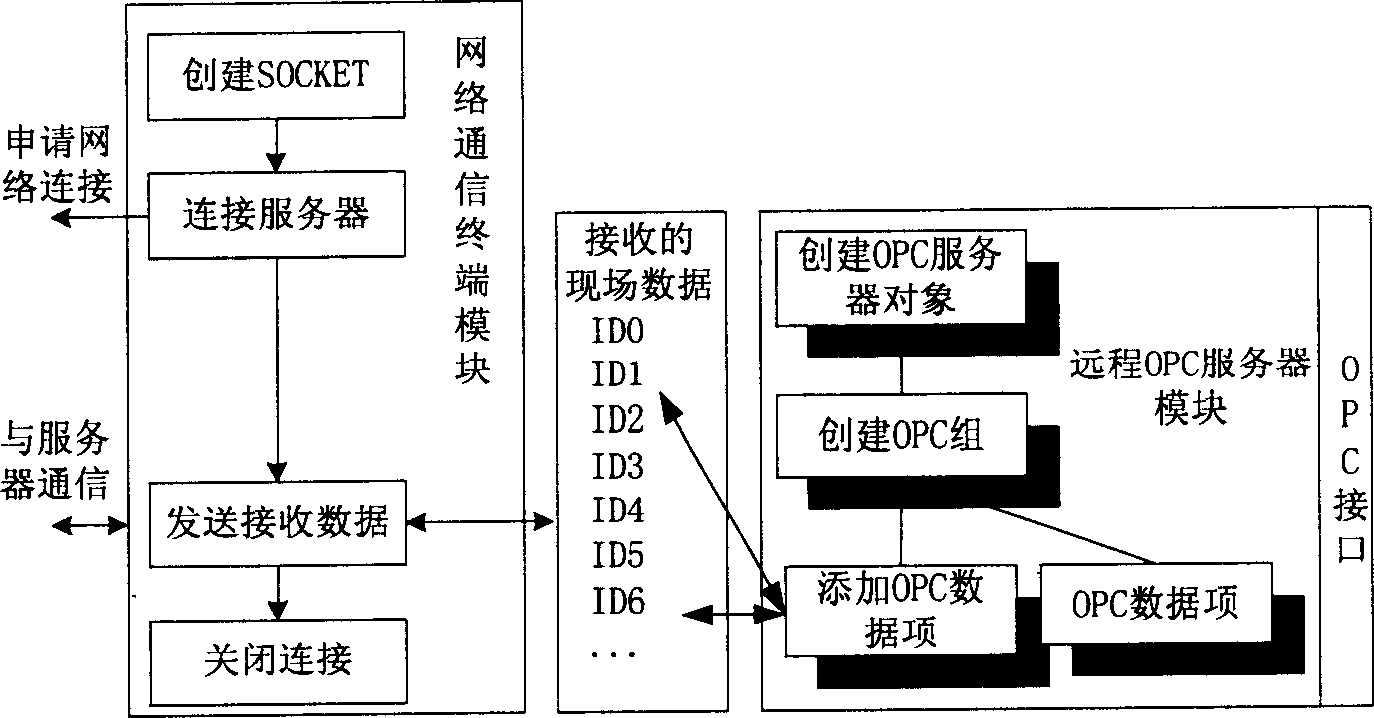

System accorded with OPC standard for monitoring remote configuration

InactiveCN1798141ATroubleshoot Remote TroubleshootingSolve problemsData switching networksTotal factory controlRemote controlData acquisition

The system includes a field working station and a remote service center. The field working station runs the OPC data collection module and the network data releasing module conforming to TCP / IP protocol by using the OPC data collection and network data releasing application program, and is connected to the field control center through OPC interface. The remote service center runs the network terminal module conforming to TCP / IP protocol, the remote OPC server module and the remote control module supporting OPC interface by using network terminal application program and the remote OPC service application program. The network communication terminal module receives the field data released by the network data releasing module, and then releases the received data to the remote OPC service module by which the data is transmitted to the remote monitoring module.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Composite edible fungi polysaccharides and preparation method thereof

ActiveCN102093598AHigh anticancer activityImprove immunityMetabolism disorderDigestive systemVacuum dryingGanoderma lucidum

The invention relates to composite edible fungi polysaccharides and a preparation method thereof. The preparation method comprises the following steps: selecting fruiting bodies of Lentinus edodes, Auricularia aurlcula, Ganoderma lucidum and Grifola frondosa as raw materials; weighing at a ratio of (1:2):(2:1), mixing, pulverizing, adding distilled water, homogeneously mixing, and sequentially performing microwave extraction and condensation reflux extraction; separating residues and liquid; adding residues into distilled water, and sequentially performing microwave extraction and condensation reflux extraction for 1-2 times; mixing extractive solutions, carrying out vacuum concentrating until the volume of the extractive solution is 1 / 3-1 / 4 of the original volume; and precipitating with alcohols, vacuum drying, and pulverizing to obtain composite edible fungi polysaccharides. The composite edible fungi polysaccharides provided by the invention have good physiological activity and complete efficacy, and has the functions of resisting viruses, reducing blood lipid, regulating immune system, resisting platelet aggregation, resisting tumor, protecting liver, resisting gene mutation and resisting acquired immunodeficiency syndrome (AIDS) and the like. The preparation method of the composite edible fungi polysaccharides has the advantages of high yield of polysaccharides, reasonable process, and high operability.

Owner:山东海普盾生物科技有限公司

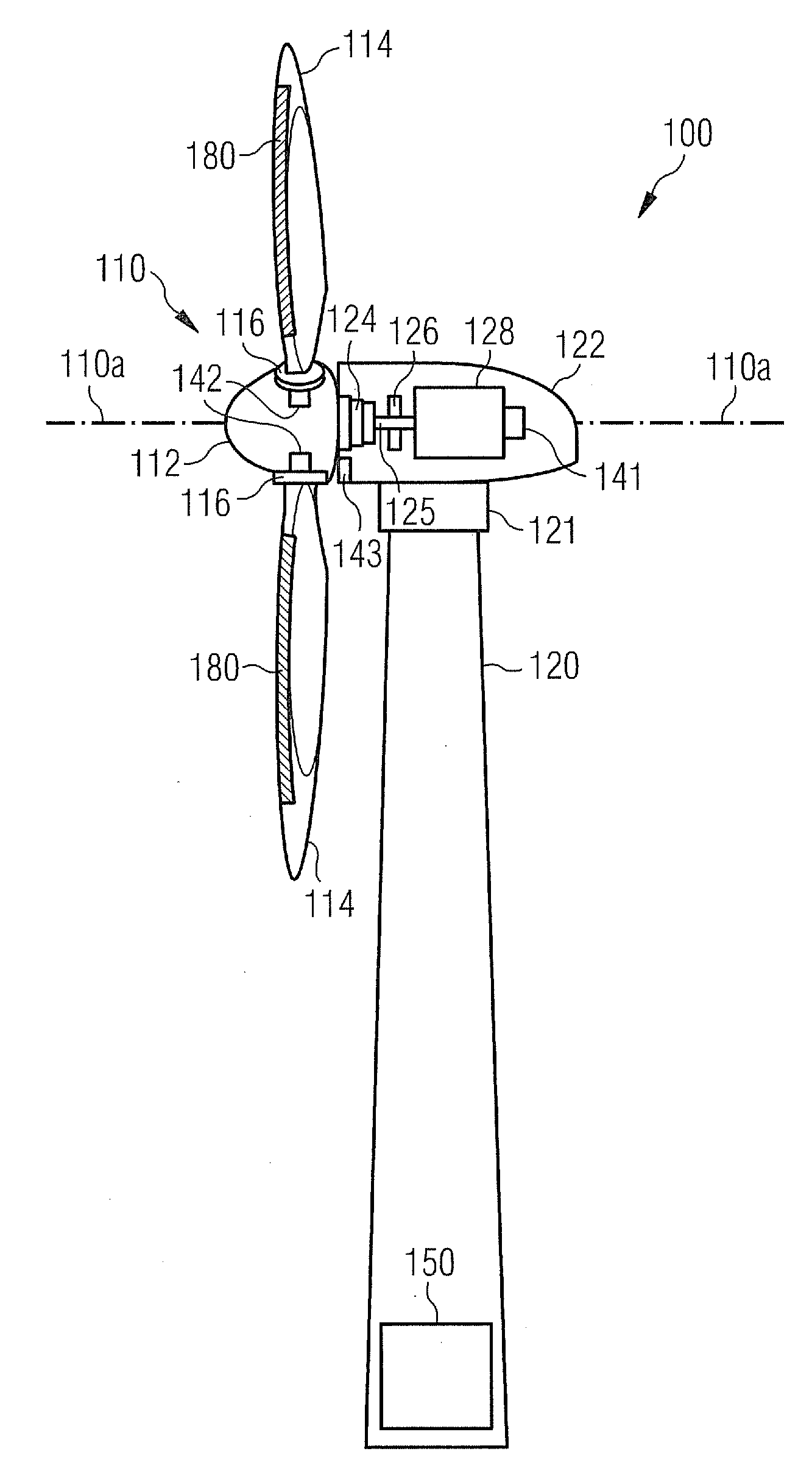

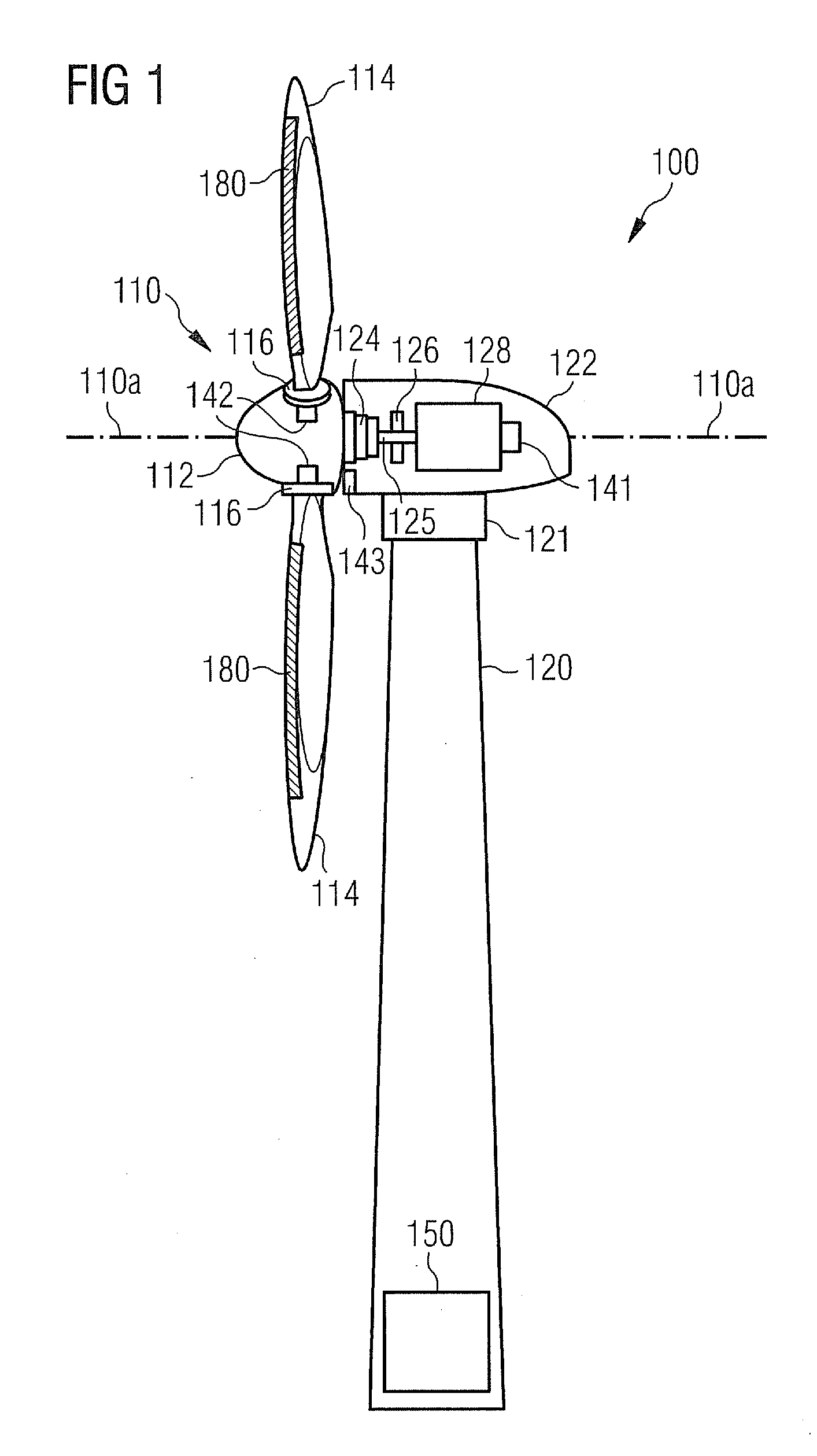

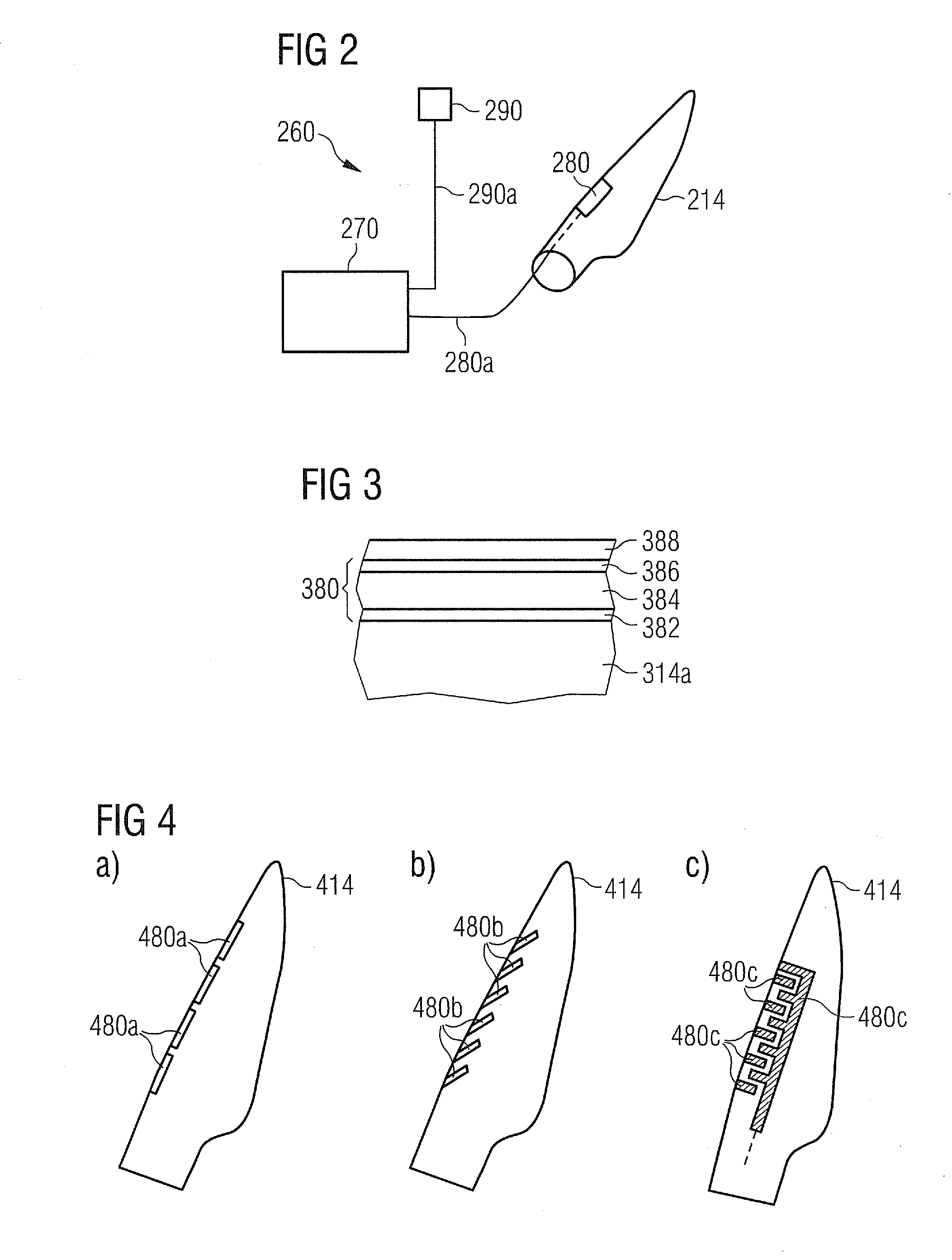

De-icing and/or Anti-icing of a wind turbine component by vibrating a piezoelectric material

A system for de-icing and / or for avoiding an icing of a component of a wind turbine is provided. The system includes a vibrator. The vibrator includes a piezoelectric material and which is adapted to be mounted to at least to a portion of the component, and an electric generator, which is adapted to supply an electric signal to the vibrator, wherein the electric signal causes the vibrator to vibrate and to transfer vibrational energy to at least a surface portion of the component. A corresponding method for de-icing and / or for avoiding an icing of a component of a wind turbine is also provided.

Owner:SIEMENS AG

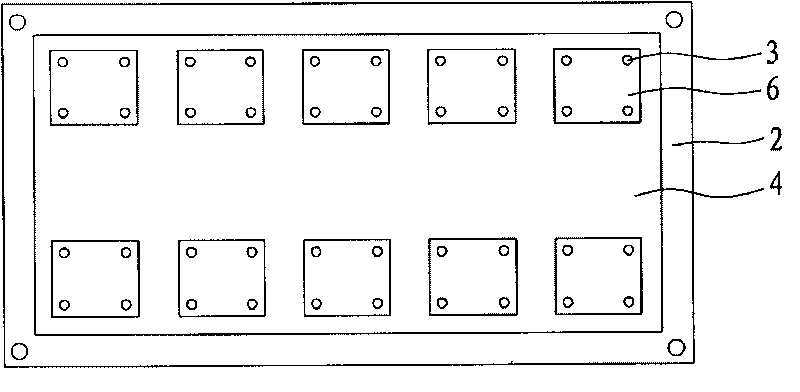

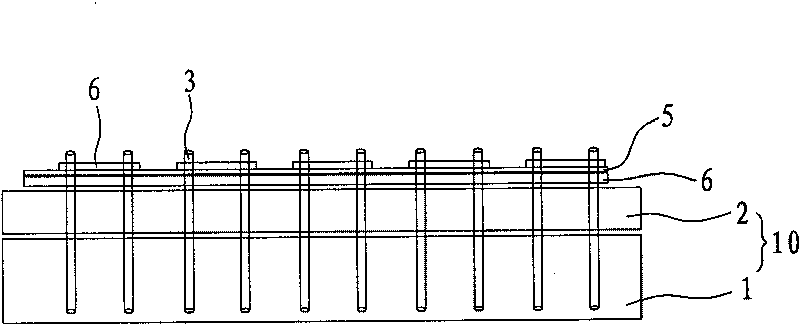

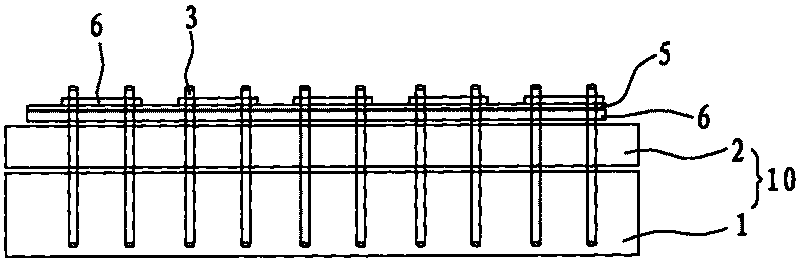

Flexible printed circuit board steel disc reinforcing hot-pressing making process

InactiveCN101720169ANot easy to fall offPromote sheddingPrinted circuit manufactureFlexible circuitsPrinted circuit board

The invention discloses a flexible printed circuit board steel disc reinforcing hot-pressing making process, including that pure glue is firstly adhered on the steel disc reinforcing position of the flexible printed circuit board and then steel disc is adhered, lamination curing is carried out to complete steel disc reinforcing, and the steel disc is fixed by steel disc adhesion jig. The invention adopts electric iron to preheat the steel disc firstly, so that certain stickiness is kept between the steel disc and the flexible printed circuit board and the steel disc can not drop in the process that the flexible printed circuit board is taken out and transferred; and the pure glue used for adhering the flexible printed circuit board and reinforcing the steel disc in steel disc hot-pressing process is thermosetting glue, namely glue system capable of being molten and cohered under heating condition and can be cured after curing at certain temperature for a while, so that the steel disc is firmly adhered on the flexible printed circuit board and can not drop in post making processes. The invention has simple making process and strong feasibility, can thoroughly avoid steel disc dropping and deviation problems and has wide applicability and higher production efficiency.

Owner:XIAMEN HONGXIN ELECTRON TECH

Apparatus for the introduction of air and/or sealant into a tire

An apparatus for the introduction of air and / or sealant into a tire includes a container for the sealant which has an inlet and an outlet, wherein the outlet can be connected to the inlet end of a hose whose outlet end can be connected to the tire to be filled and includes a pressure generation means which can be selectively connected to the inlet of the container or to the inlet end of a hose whose outlet end can be connected to the tire to be filled. The same hose is provided for the connection between the pressure generation means and the tire to be filled, on the one hand, and between the outlet of the container and the tire to be filled, on the other hand, with respective couplings being provided at the pressure generation means, at the inlet of the container and at the outlet of the container as well as at the inlet end of the hose which selectively enable the inlet end of the hose to be connected directly to the pressure generation means or the inlet of the container to be connected to the pressure generation means and the inlet end of the hose to be connected to the outlet of the container.

Owner:SUMITOMO RUBBER IND LTD

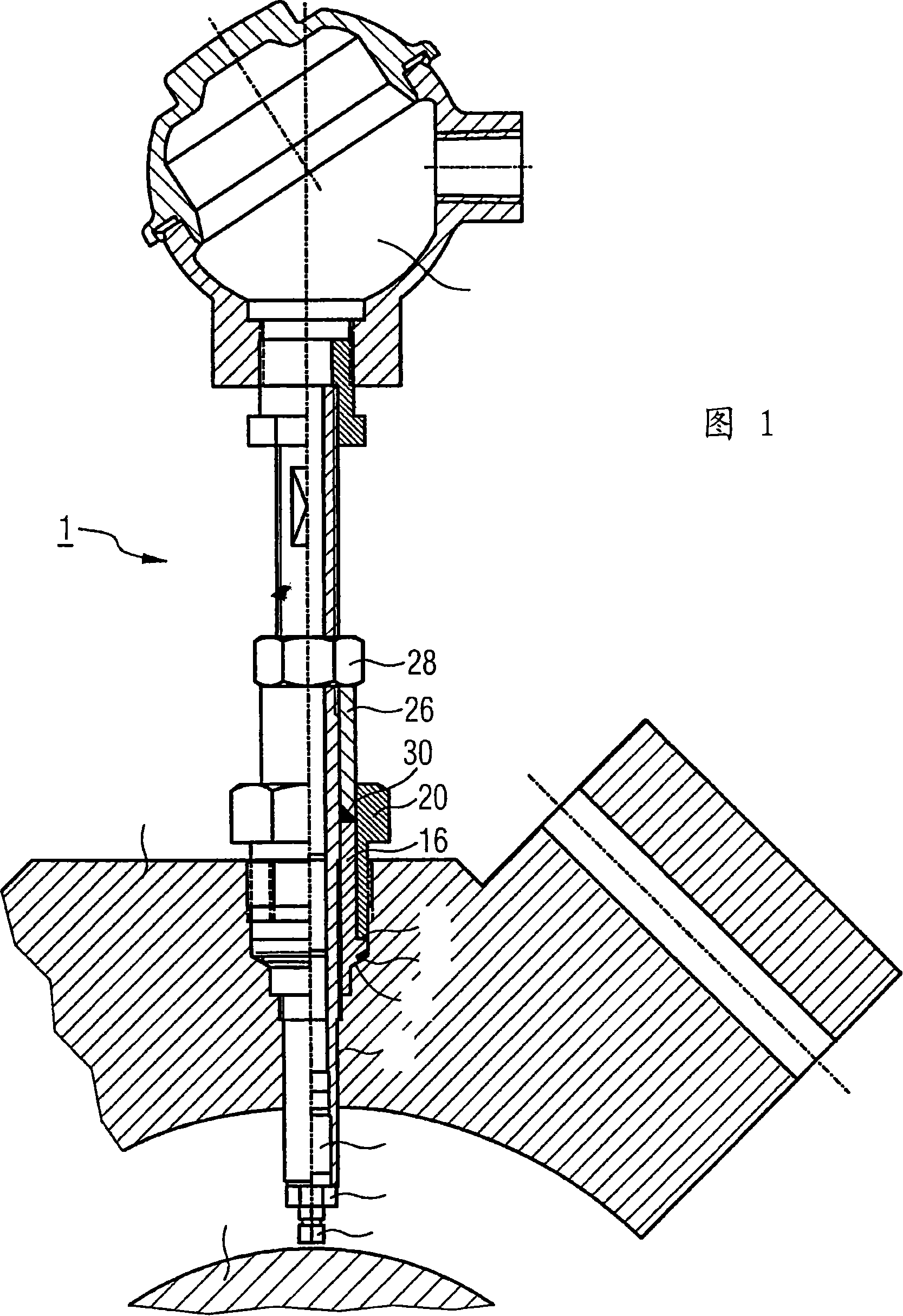

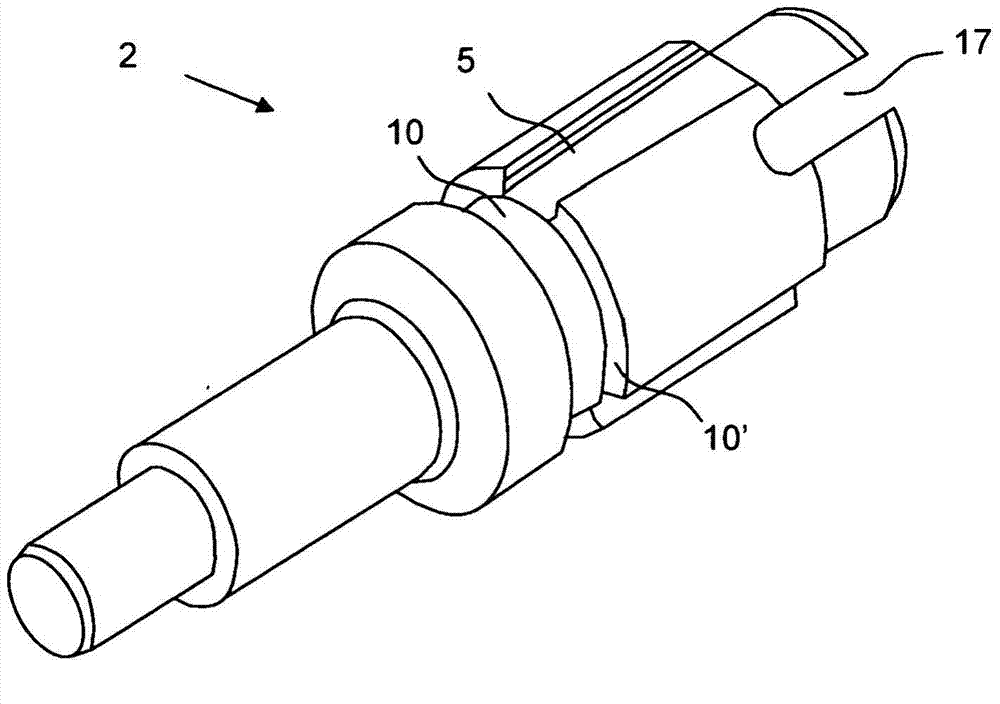

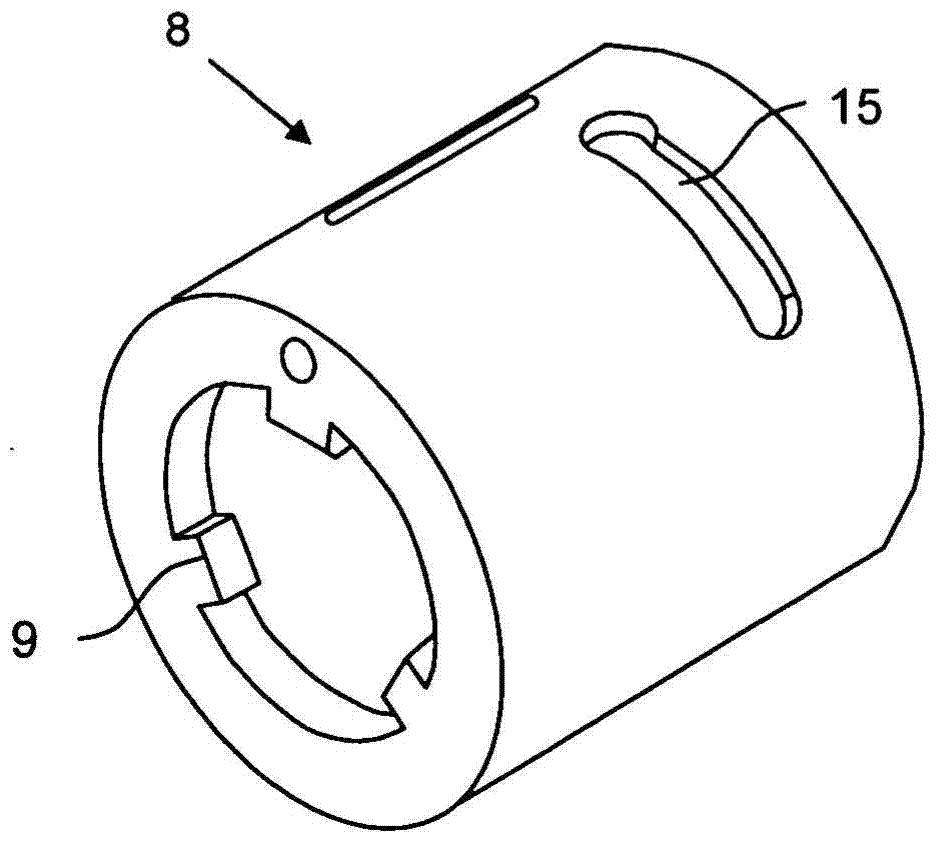

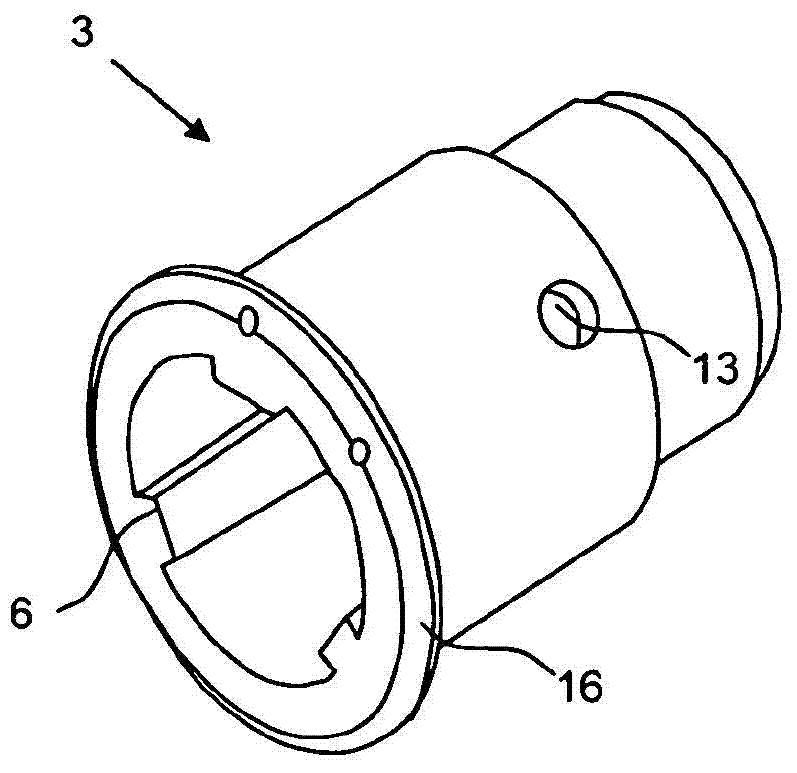

Probe holder system, message for fixing a probe holder system and method for adjusting a probe

InactiveCN101091104APrecise positioningReproduce original spacingMeasurement apparatus componentsBiomedical engineering

A probe holder system (1) for fixing a probe (2) to a housing (4), wherein it is possible to provide a simple structure and position the probe (2) as accurately and easily as possible in relation to a measuring object. According to the invention, a housing bushing (16) provided with an inner thread and a carrier rod (8) for the probe (2), which can screwed into the threaded bushing (16), are provided. The threaded bushing can be placed in a reference position in an associated recess (10) of the housing wall and can be arrested by means of a locking element.

Owner:SIEMENS AG

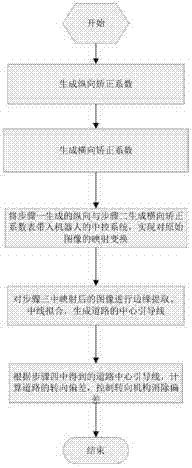

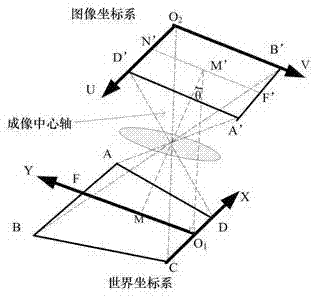

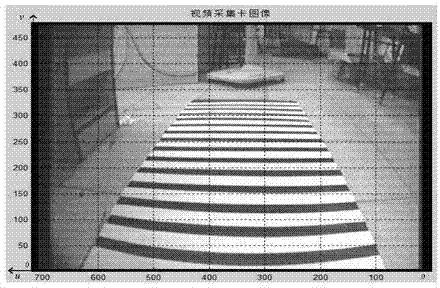

Monocular vision robot rapid tracking method based on road correction

InactiveCN104123535AFast real-time correctionRemove distortion effectsImage analysisCharacter and pattern recognitionControl mannerSimulation

The invention discloses a monocular vision robot rapid tracking method based on road correction, and belongs to the field of monocular vision robot path recognition. The basic idea of the method comprises building a correction mapping table for an original road image in longitudinal and transverse directions so as to achieve correction on the road image of a monocular vision robot; and on the above basis, automatic tracking travel of the robot is achieved by adopting a deviation control manner. On the above basis, the robot travels by tracking the road, physical information such as actual road curvature and curvature can be accurately obtained, and influence of road image distortion on control and operation of the robot is reduced.

Owner:BEIJING UNION UNIVERSITY

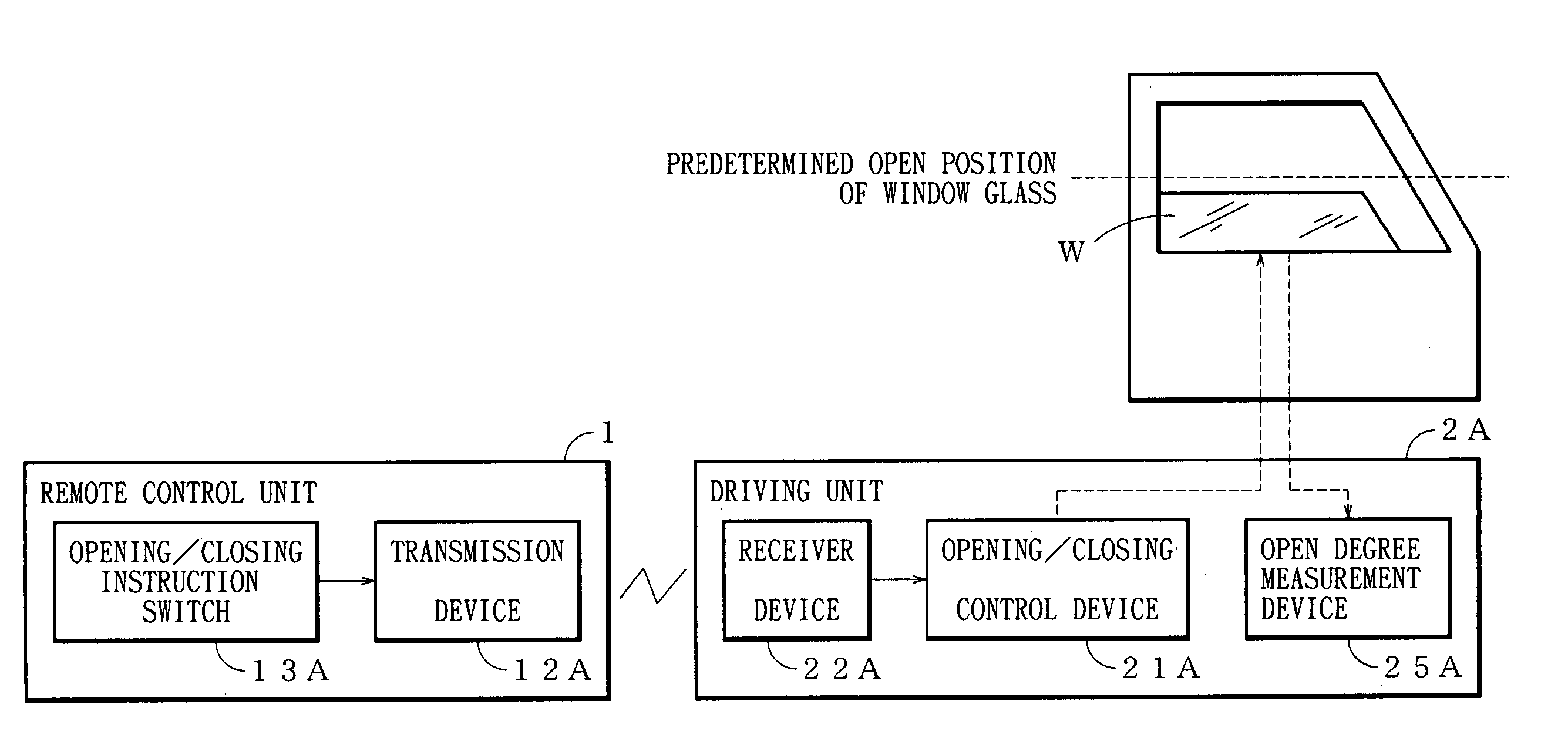

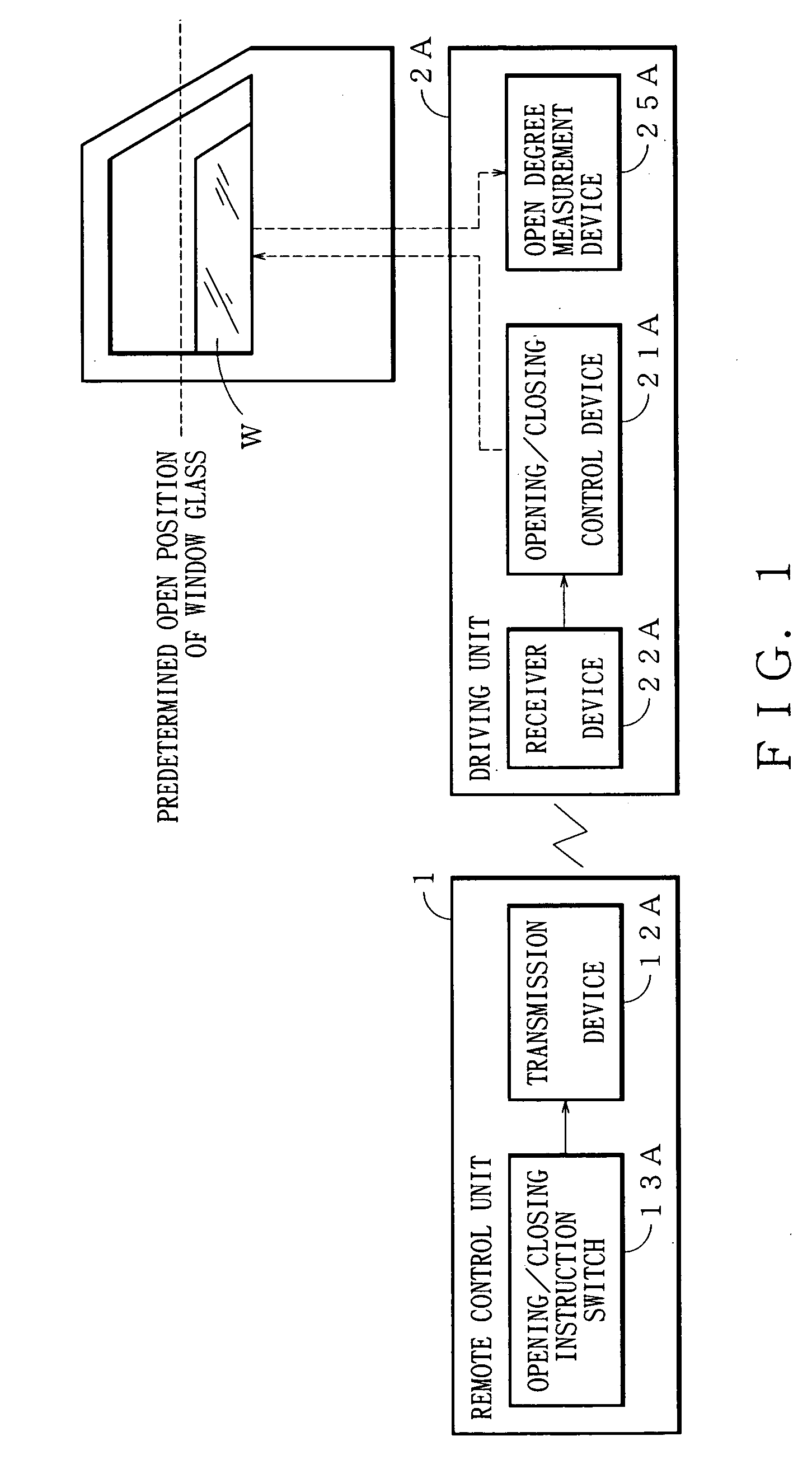

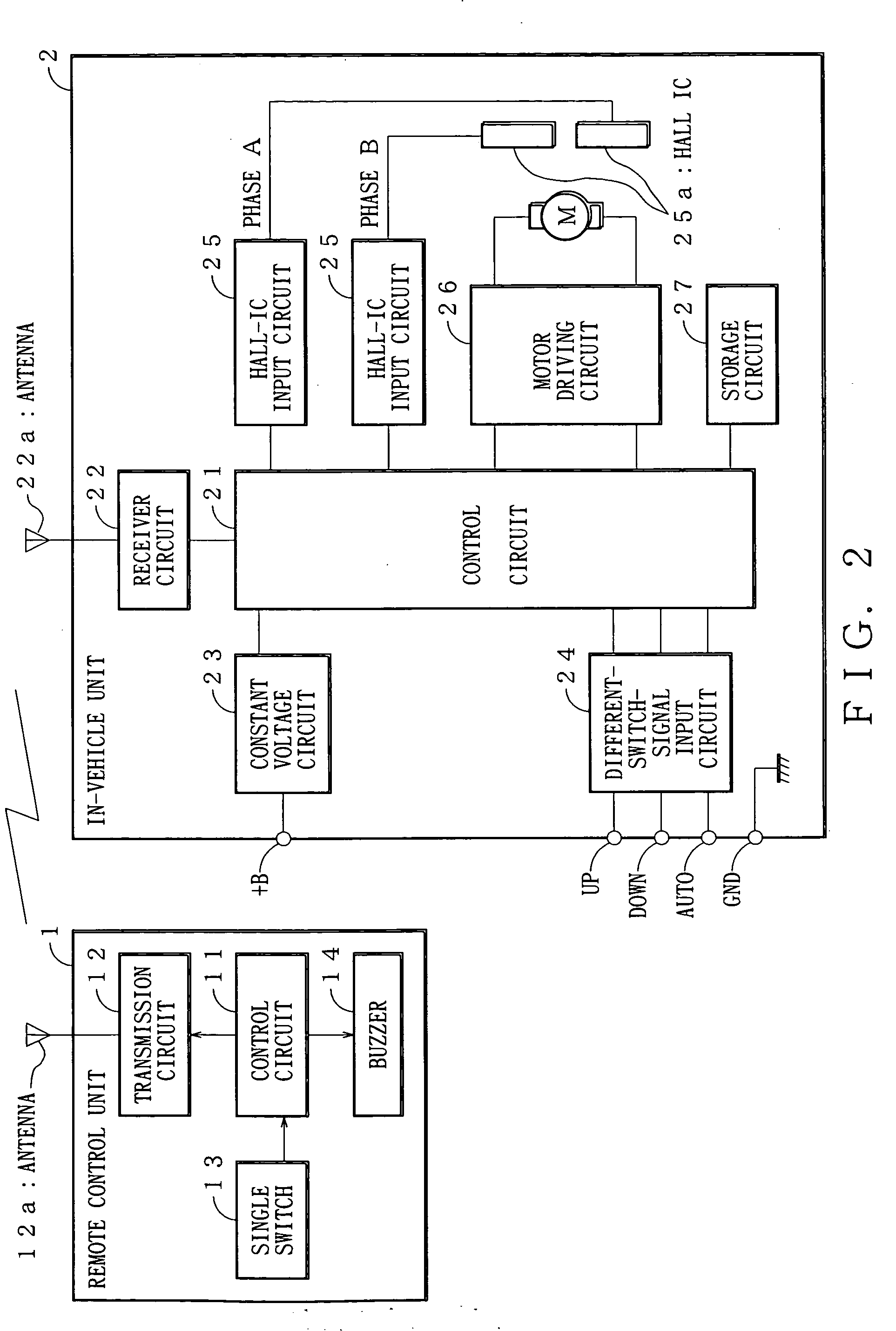

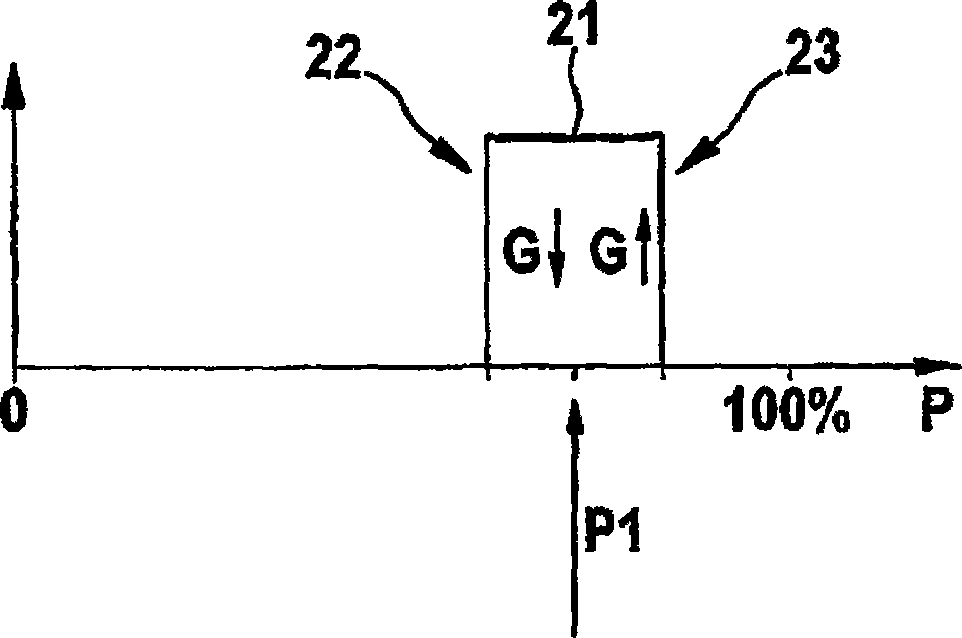

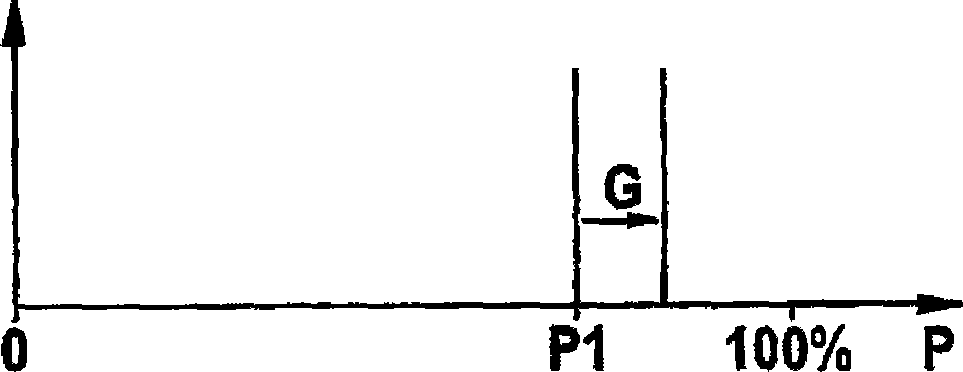

Power window system

ActiveUS20060038519A1Simple operabilityAvoid pinchingWindowsDC motor speed/torque controlMeasurement deviceEngineering

The power window system moves a window glass in opening and closing directions in response to operation of an opening and closing instruction switch. The power window system includes a measurement device for obtaining an open degree of the window glass and a control device for controlling movement of the window glass in response to operation of the switch. The control device moves the window glass in the closing direction when an open degree obtained by the measurement device is not less than a predetermined degree and in the opening direction when the open degree is less than the predetermined degree.

Owner:YAZAKI CORP

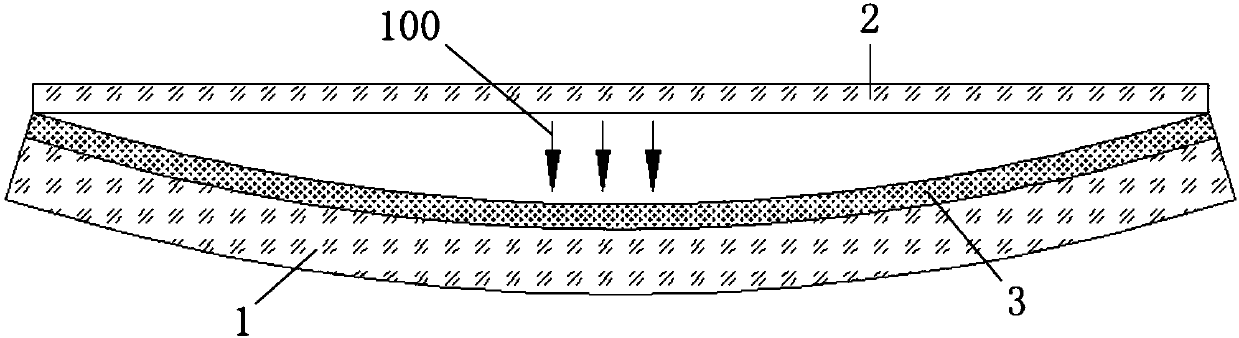

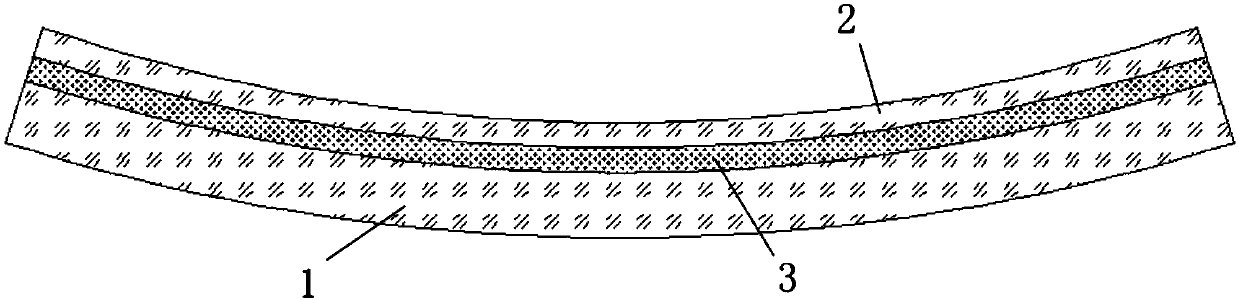

Ultrathin laminated glass and production method thereof

ActiveCN108032595AGuarantee the safety of useGuaranteed Optical QualityLamination ancillary operationsLaminationManufacturing cost reductionOptical property

The invention relates to the technical field of laminated glass, in particular to ultrathin laminated glass used on vehicles, and provides the ultrathin laminated glass and a production method thereof. The production method includes: preparing a first glass substrate and a second glass substrate; heating and bending the first glass substrate to obtain a first bent glass plate; chemically toughening the second glass substrate to obtain a second straight glass plate; adhering the first bent glass plate, the second straight glass plate and at least one intermediate membrane piece to obtain the ultrathin laminated glass. Bending formation of the second straight glass plate which is thin is not needed, the forming process is simplified, and operability, convenience and continuity in subsequentproduction are determined, the laminated glass is thinned, mechanical and optical properties can meet requirements, and use safety and optical quality of the ultrathin laminated glass are guaranteed.

Owner:FUYAO GLASS IND GROUP CO LTD

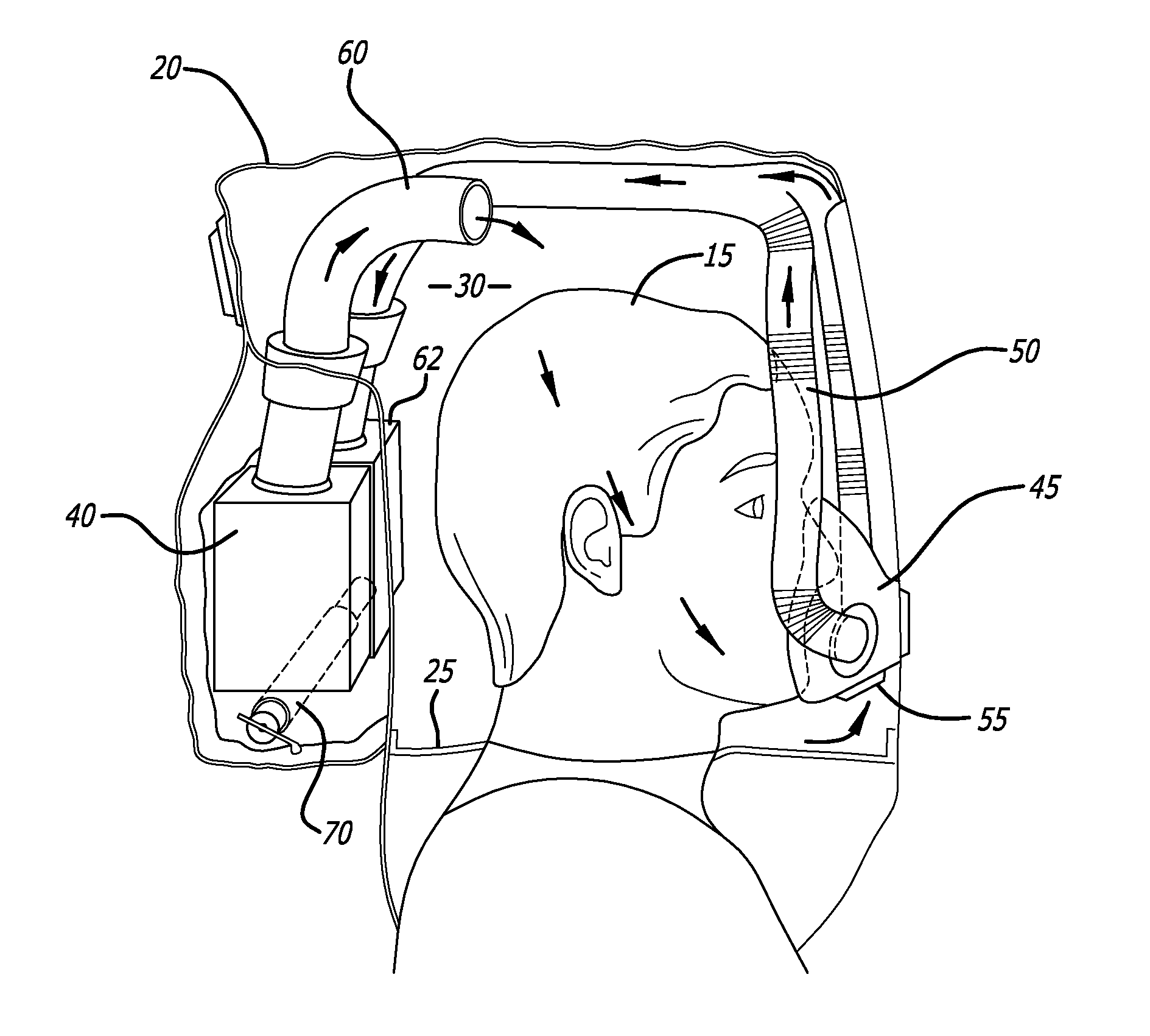

Aircraft crew member protective breathing apparatus

ActiveUS20140014099A1Simple operabilitySimple indicator of operabilityChemical protectionHeat protectionAirplaneCarbon dioxide

A self-contained breathing device for use in fighting fires comprising a hood for covering a wearer's head, a membrane for sealing the hood to create a breathing chamber inside the hood, and a source of oxygen disposed inside the hood. The source of oxygen is connected to the user by a conduit inside of the hood, and another conduit directs user-exhaled carbon dioxide to the source of oxygen. The breathing device includes a visual indicator inside of the hood that reacts to the presence of a gas within the hood and providing visual feedback to the user based on a quantity of said gas present in the hood.

Owner:BE AEROSPACE INCORPORATED

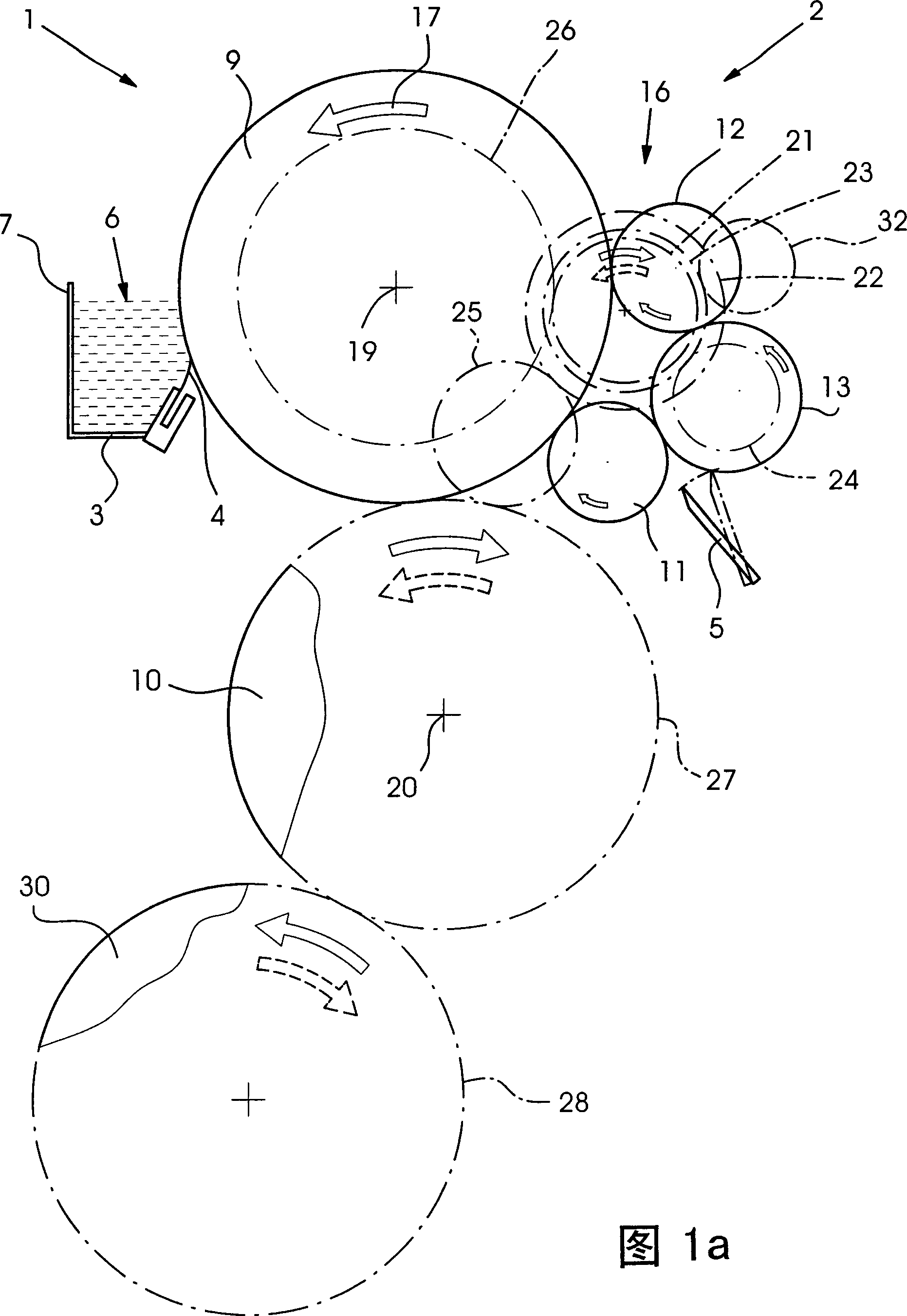

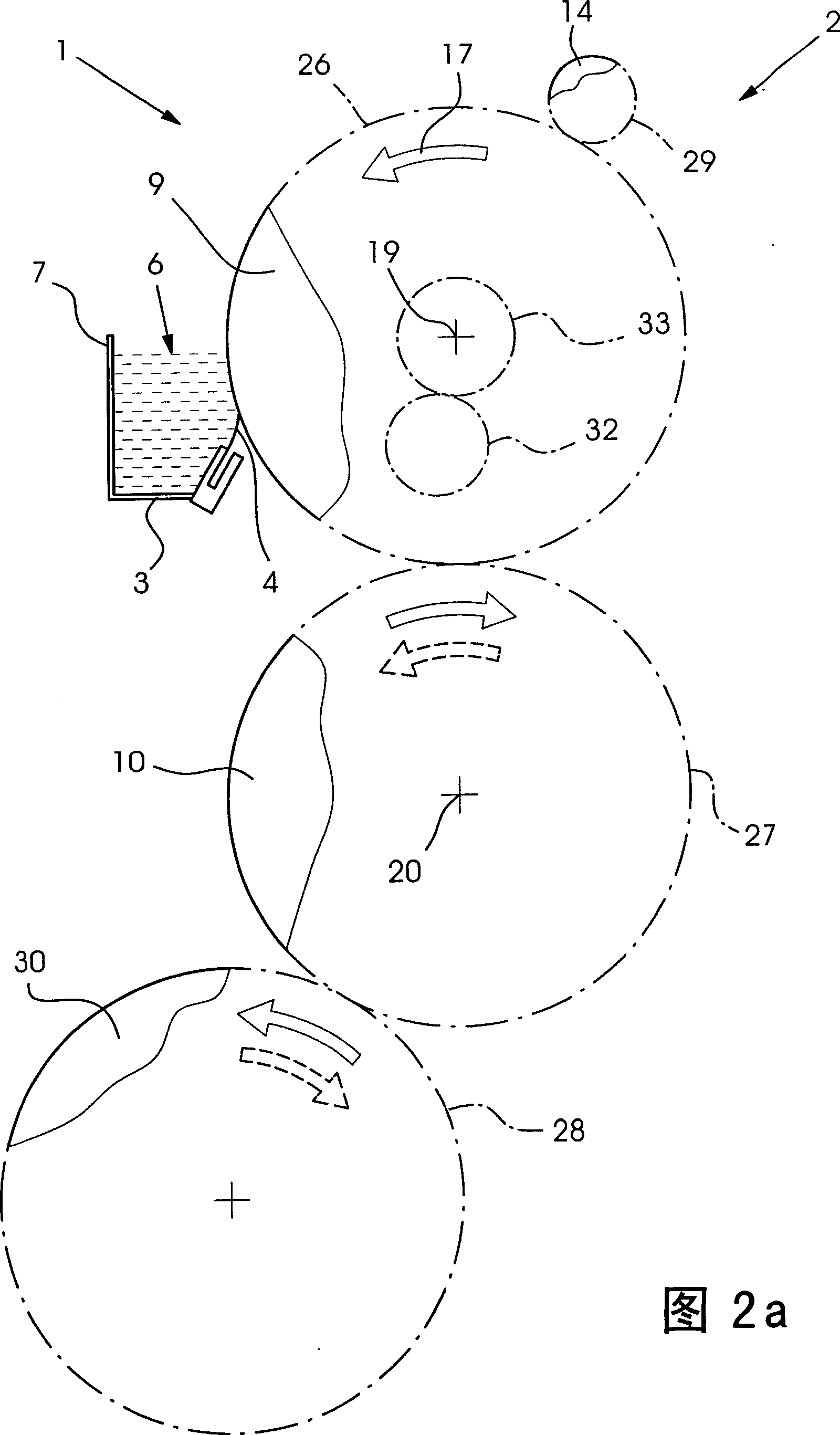

Printing press and method for operating the same

A method for operating a printing press having a printing form cylinder and a screen roller, includes rotating the printing form cylinder in a first direction of rotation and rotating the screen roller at the same time, during a continuous printing operation. The printing form cylinder is rotated in a second direction of rotation and the screen roller is kept at a rotational standstill at the same time, during an interruption in the printing operation. A printing press for carrying out the method has a clutch, preferably a freewheeling clutch, integrated into an anilox inking unit having the screen roller, in such a way that the clutch stops the rotation of the screen roller during reverse running of the printing press.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

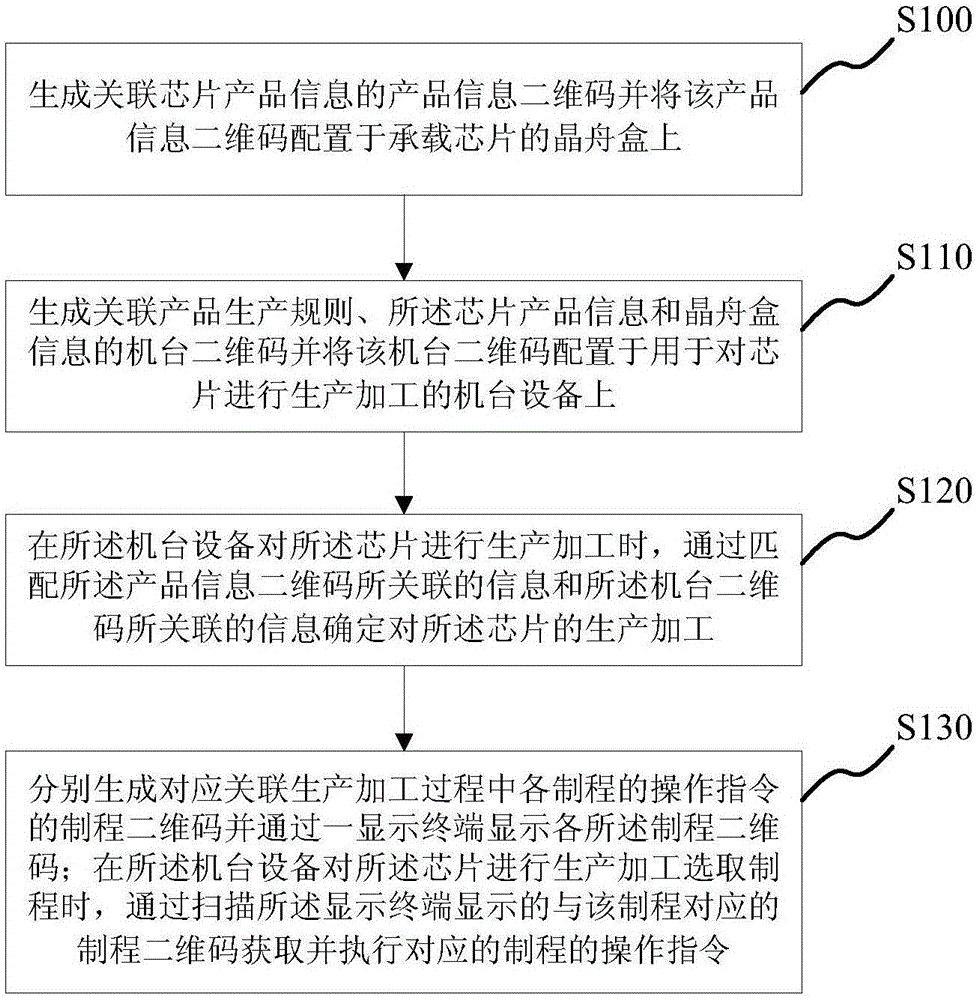

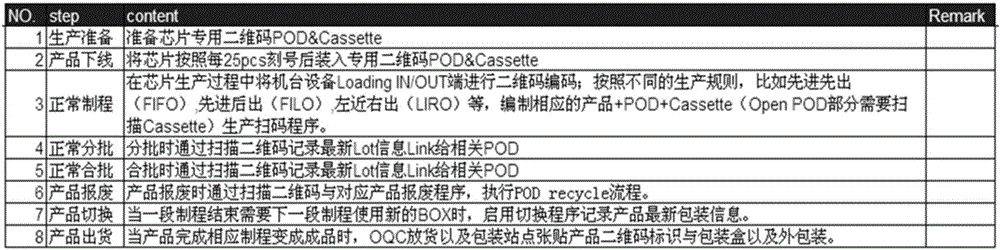

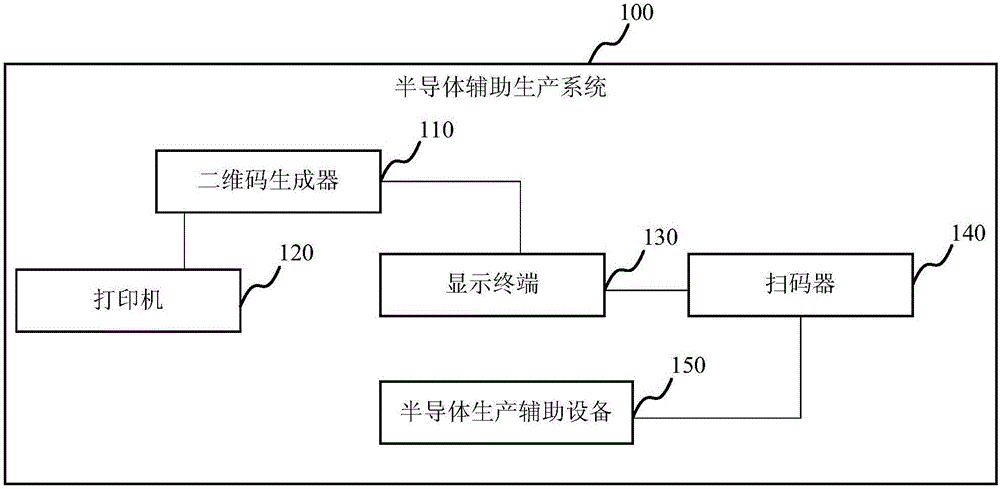

Semiconductor auxiliary production method and system

ActiveCN107527077AImprove integritySimple operabilityCo-operative working arrangementsMachining processManufacturing engineering

The present invention provides a semiconductor auxiliary production method and system. The method includes the following steps that: product information two-dimensional codes associated with chip product information are generated and are configured on a boat box for carrying chips; machine two-dimensional codes associated with product production rules, the chip product information and boat box information are generated, and the machine two-dimensional codes are configured on machine equipment; when the chips are produced and processed on the machine equipment, the production and processing of the chips are determined through matching the information associated with the product information two-dimensional codes and the information associated with the machine two-dimensional codes; the manufacture procedure two-dimensional codes of operation instructions of manufacture procedures in corresponding associated protection and processing processes are generated, and are displayed through a display terminal; and when the machine equipment selects manufacture procedures for producing and processing the chips, the operation instructions of the corresponding manufacture procedures are obtained and executed through scanning the manufacture procedure two-dimensional codes which are corresponding to the manufacture procedures and displayed by the display terminal. With the semiconductor auxiliary production method and system of the invention adopted, manual operation is simplified, and the production efficiency of manufacturing enterprises can be improved.

Owner:CHINA RESOURCES MICROELECTRONICS (CHONGQING) CO LTD

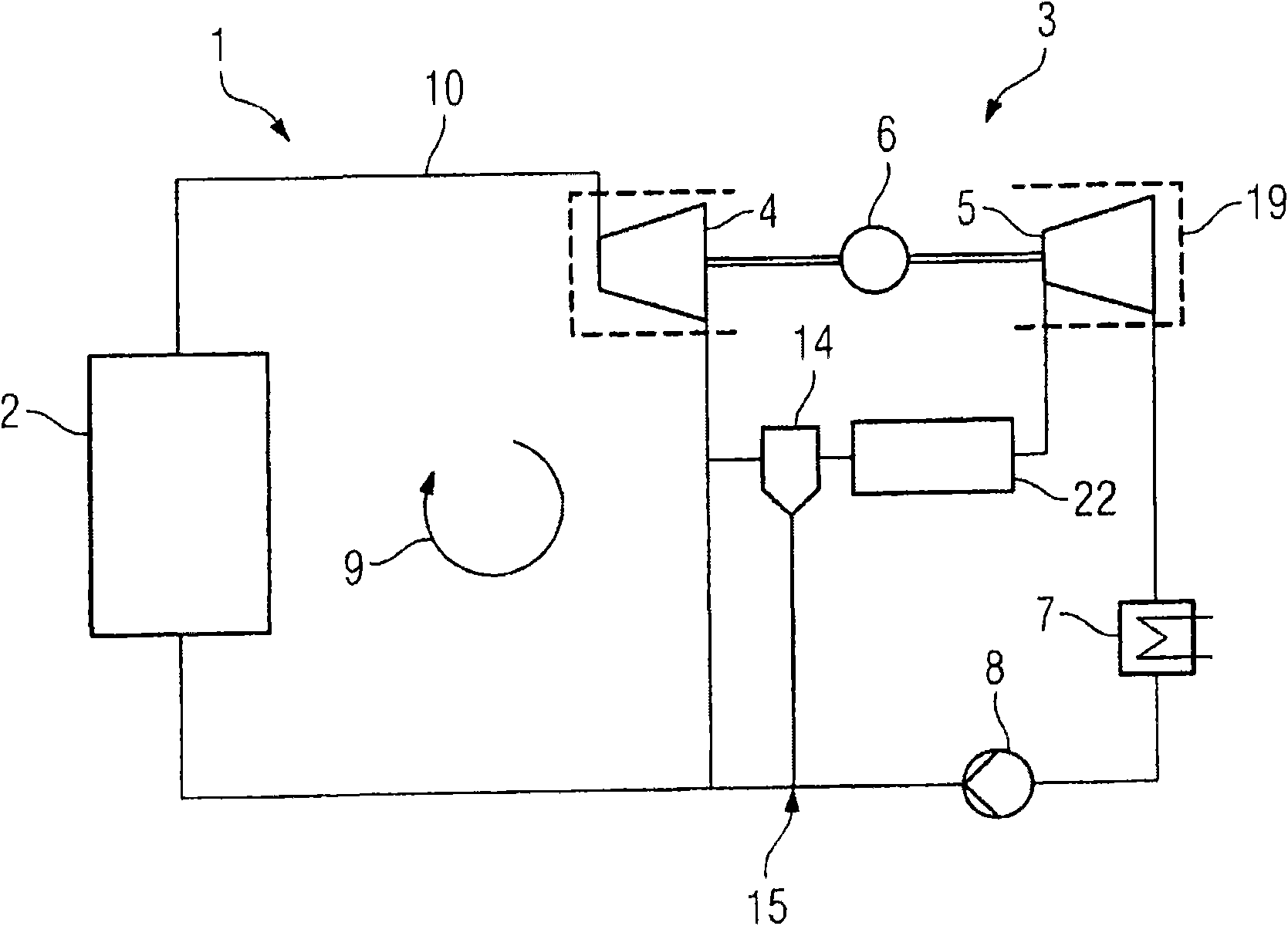

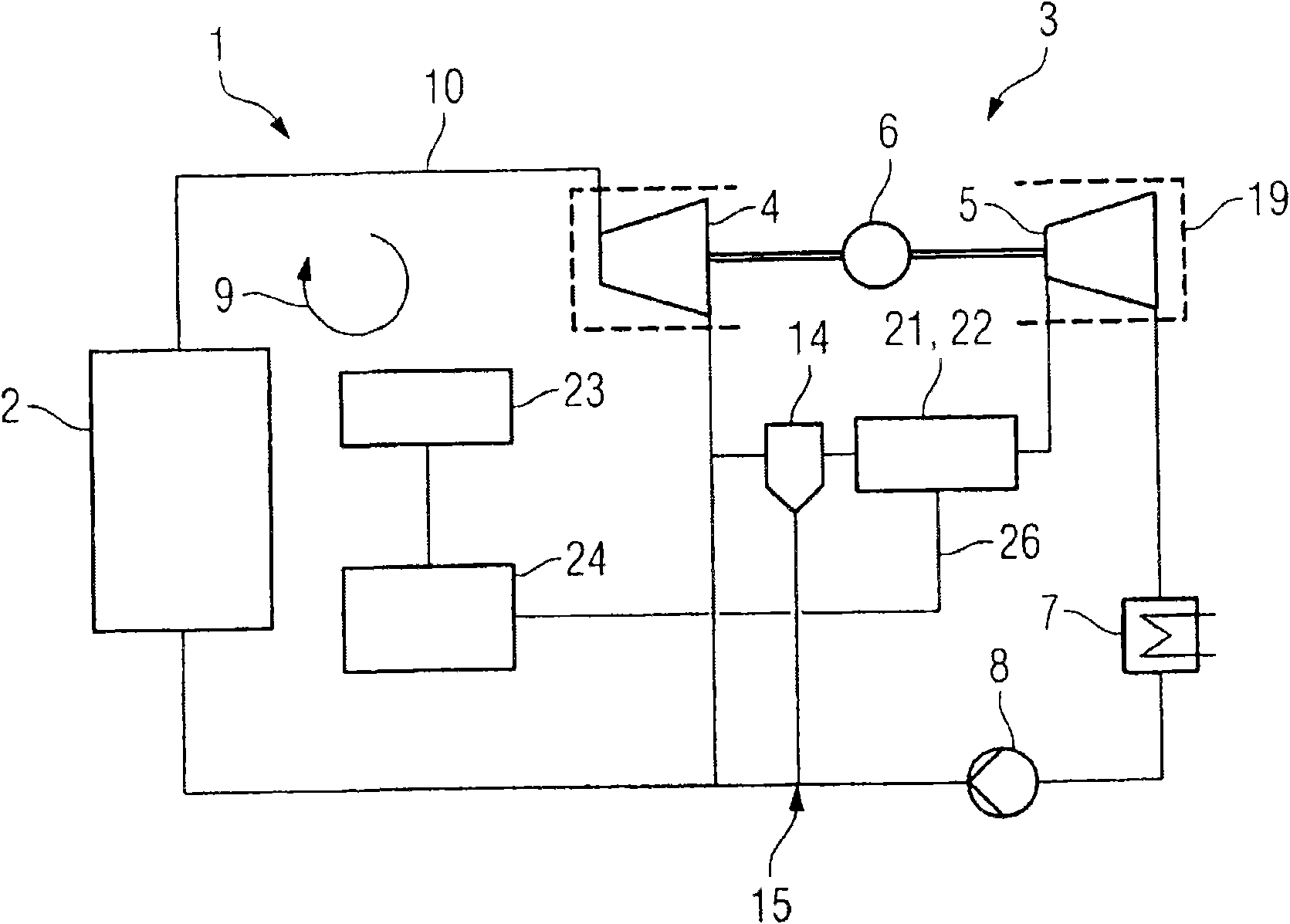

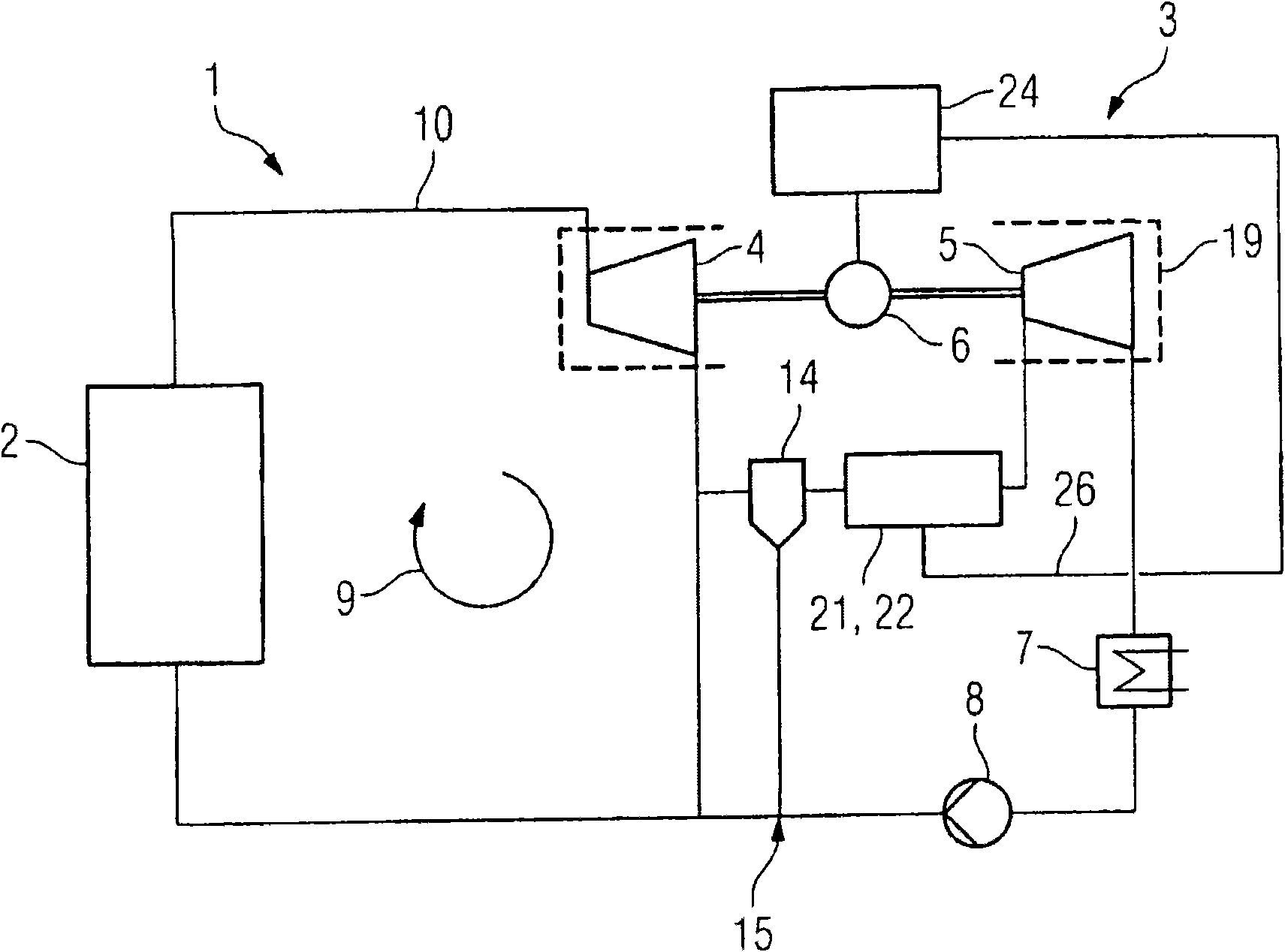

Method and device for fired intermediate overheating during direct solar vapourisation in a solar thermal power station

The invention relates to a solar thermal power station (1) comprising a work fluid circuit (9), a solar steam generator based on direct vapourisation and a steam turbine (3) for releasing the work fluid for technical work. The solar steam generator and the steam turbine (3) are mounted in the work fluid circuit (9). The solar thermal power station comprises an additional firing system (22) for intermediate heating of the work fluid. The invention also relates to a method for operating said type of installation.

Owner:SIEMENS AG

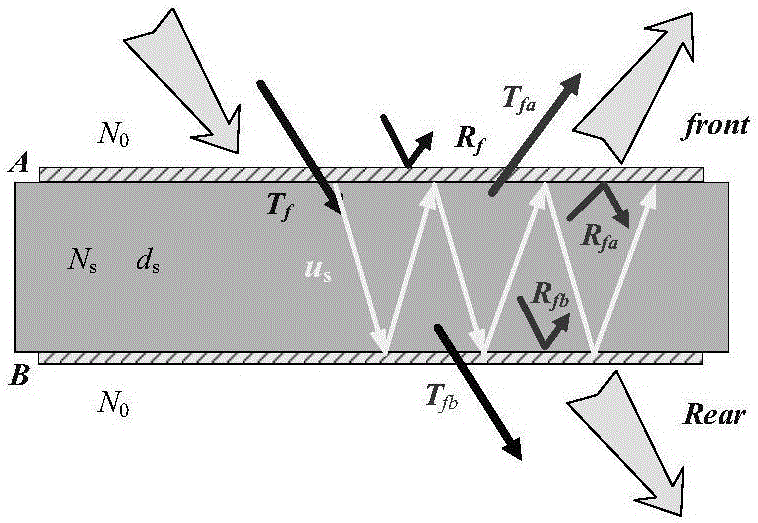

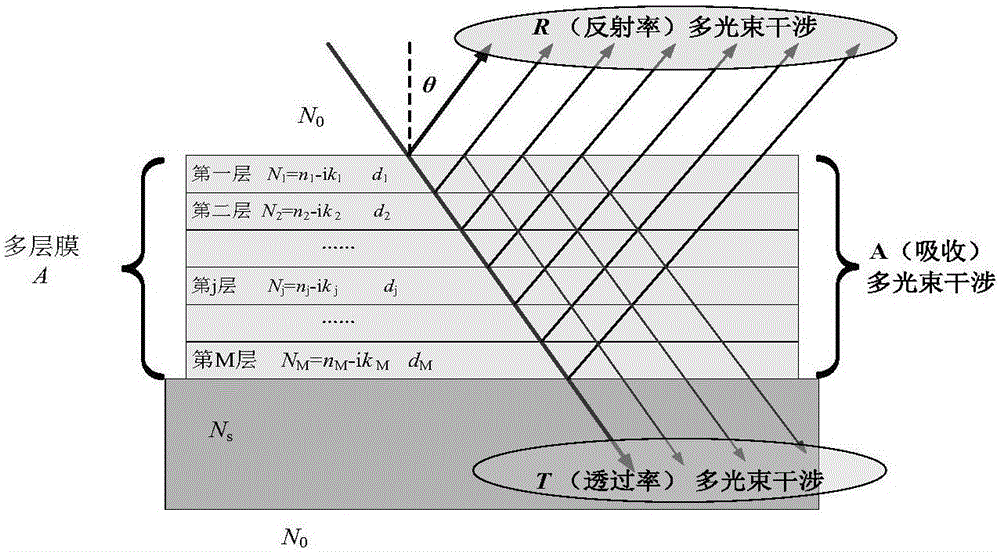

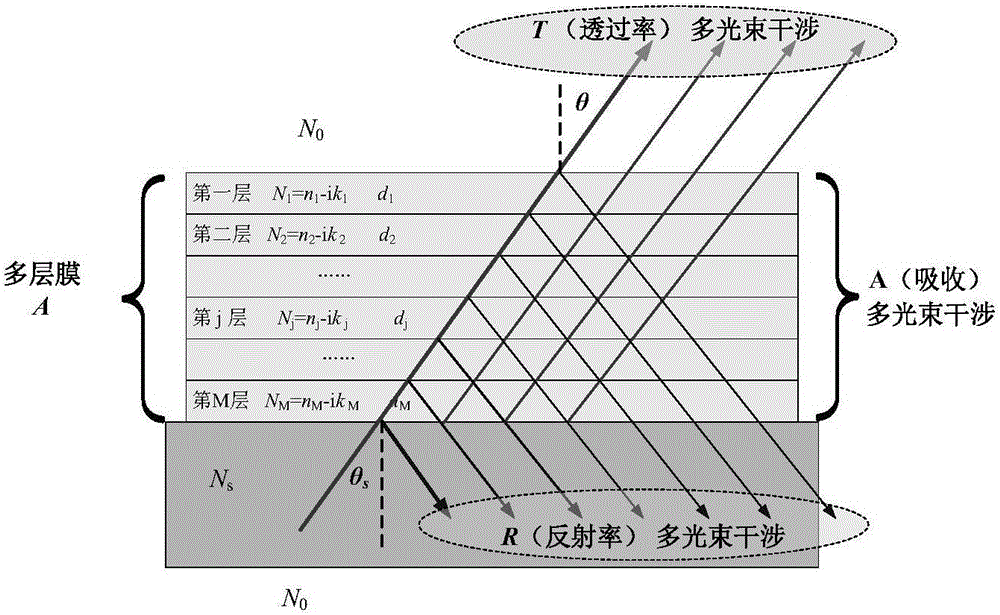

Method for calculating spectrum thermal radiance of multilayer optical film

ActiveCN106644087ASimple operabilityAvoid complex structure designRadiation pyrometryMeasuring instrumentRadiance

The invention belongs to the field of spectrum thermal radiance representation, and specifically relates to a method for calculating the spectrum thermal radiance of a multilayer optical film. The method is simple and feasible. For a determined multilayer film-substrate-multilayer film system structure, the method can completely express the spectrum directional radiance, directional radiance, spectrum radiance and integral spatial radiance of an optical multilayer film with only one need to determine the thermo-optical coefficients of a substrate and a film material. The method can avoid the tedious operation of direct measurement and a complex structure design of a measuring instrument, and has a certain scientific and application value.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

Battery and method for regulating a battery voltage using switch-on probabilities

ActiveCN103972956AReduce lossReduce communication costsCharge equalisation circuitElectric devicesEngineeringControl circuit

A method for regulating a battery voltage of a battery having a plurality of battery cells configured to be selectively bridged and connected to a battery string includes regulating the battery voltage to a desired nominal voltage by alternately driving the battery cells. The method is characterized by transmitting a value for a nominal switch-on probability to one or more driving circuits of the battery cells, with the result that the one or more battery cells are each switched with an allocated switch-on probability. In addition, the invention also discloses a battery equipped with a regulating electronic device used for executing the method.

Owner:ROBERT BOSCH GMBH +1

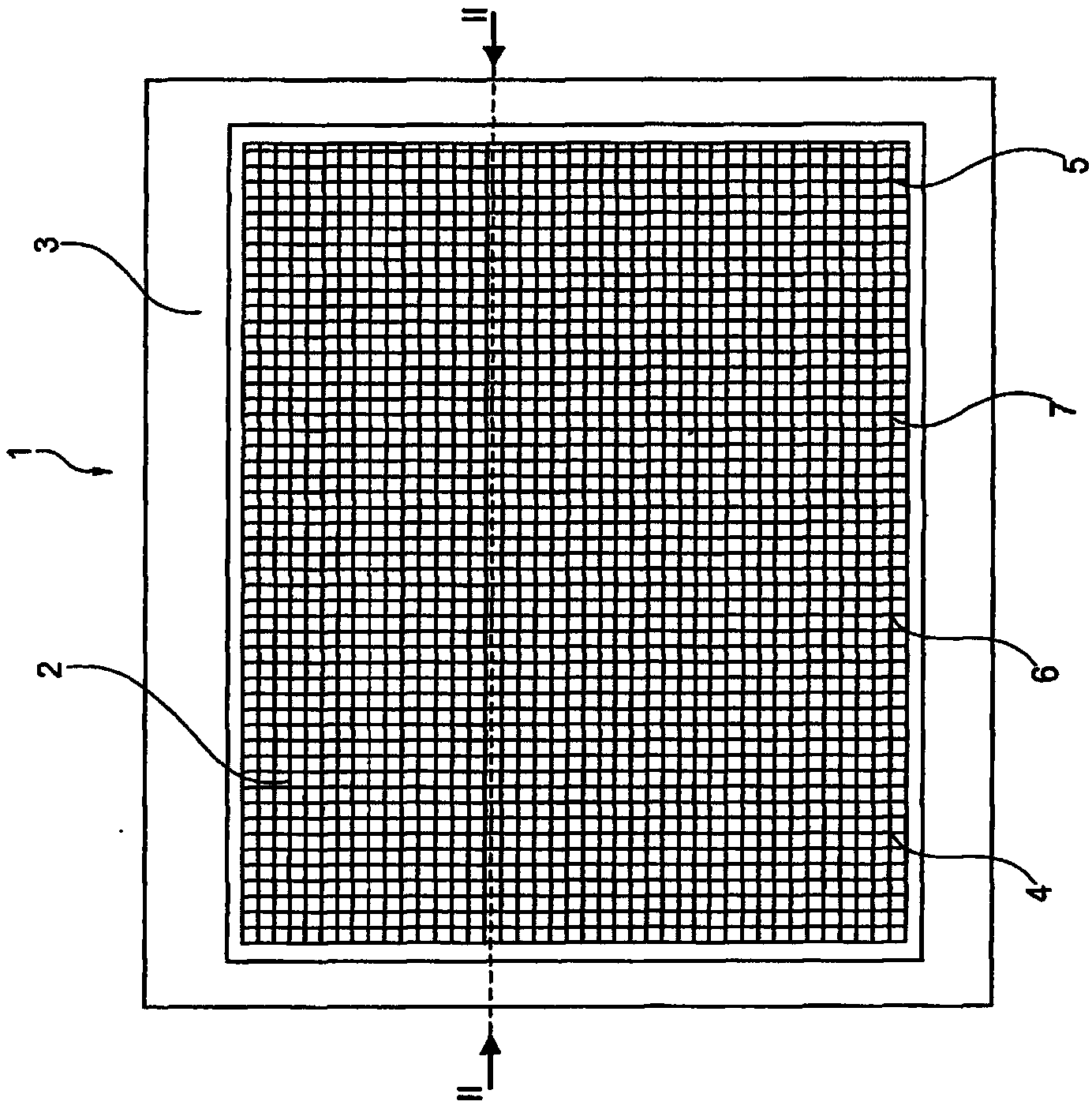

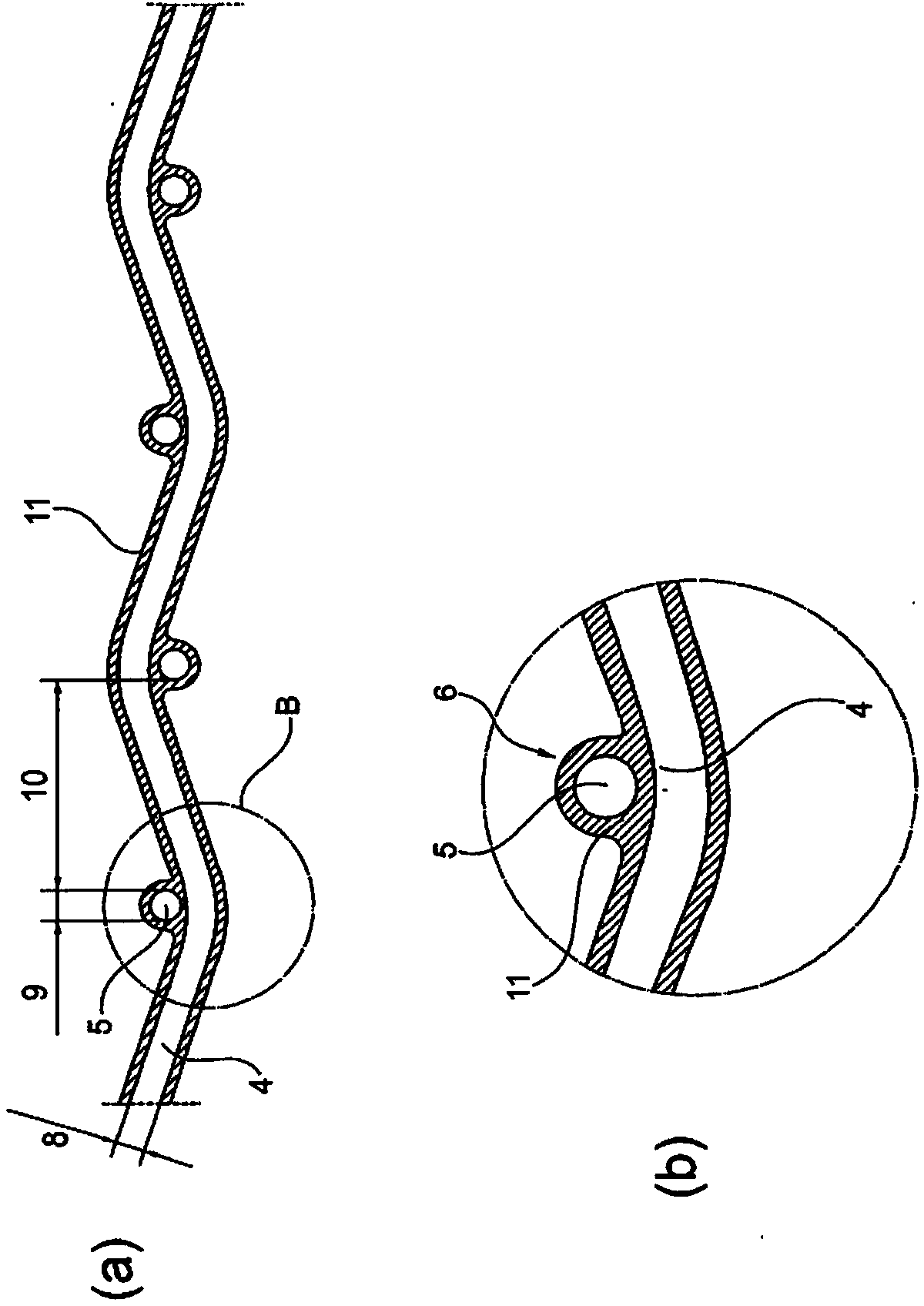

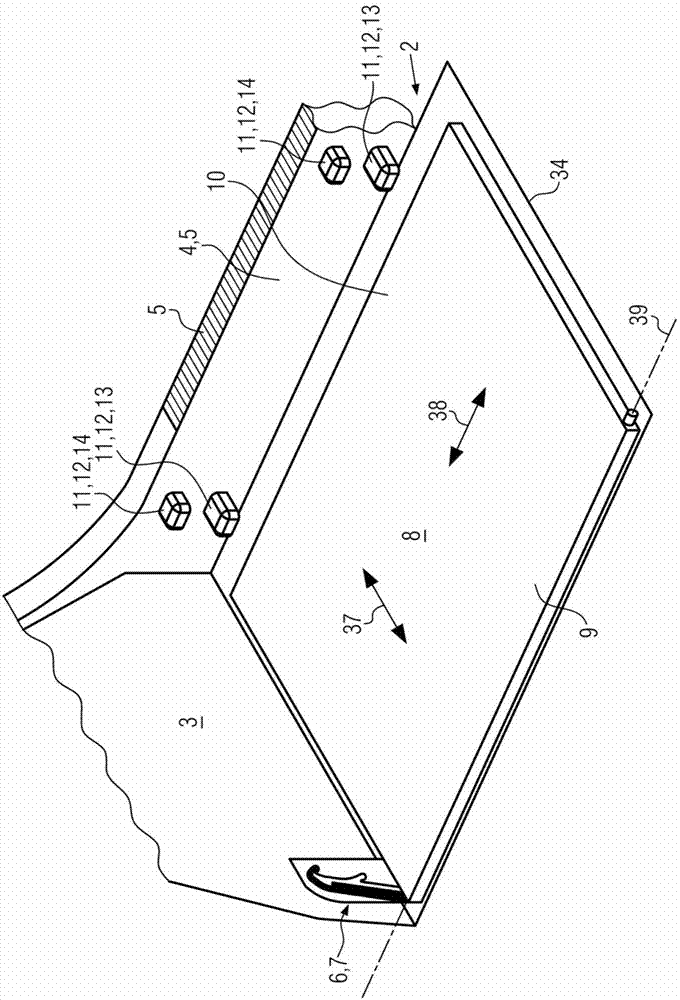

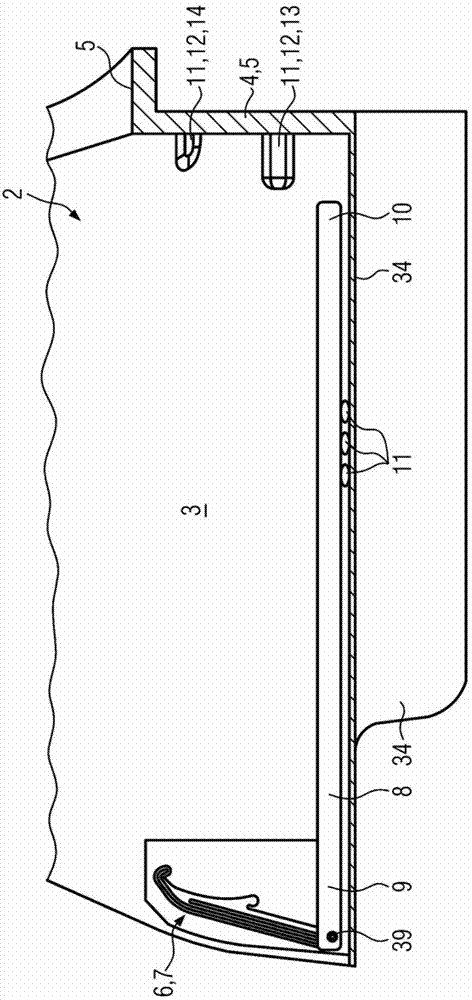

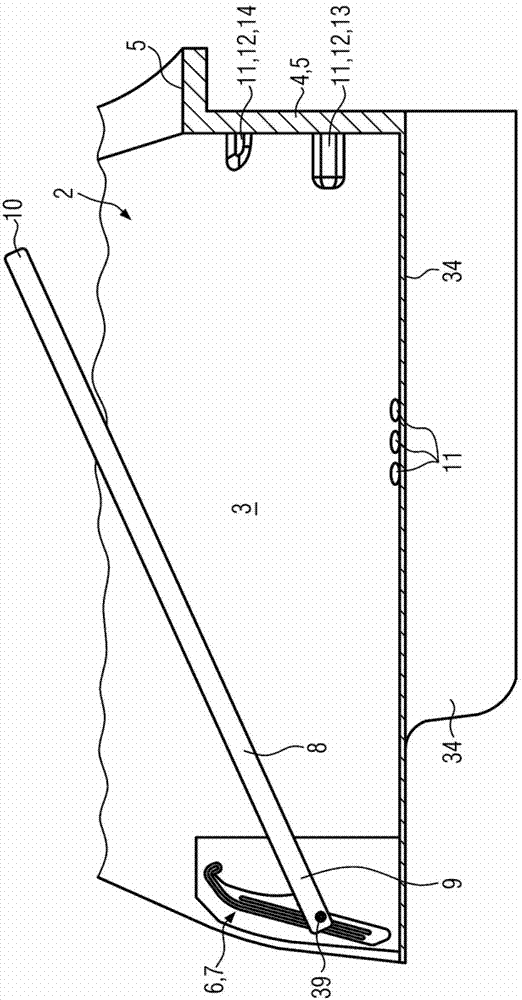

Thread and fabric for insect screens

InactiveCN104136666AAvoid tearingRealize industrial productionInsect protectionConjugated synthetic polymer artificial filamentsEngineeringMelting point

The invention relates to a thread (4, 5) for producing fabrics (2) for insect screens (1), comprising a core which has a coating (11) that comprises a heat-activatable adhesive in order to bond to itself or to other threads of the fabric (2), said core having a higher melting point than the adhesive; to a fabric (2) for insect screens (1) with a mesh (7) web structure, comprising warp threads (4) and weft threads (5) which are connected to one another by means of adhesive at node points (6); to an insect screen (1) comprising a frame (3) and a fabric (2) which is stretched by means of the frame (3); and to a method for producing fabrics (2) for insect screens (1), having the steps of a) providing threads (4, 5) as warp threads (4) and weft threads (5), b) weaving a fabric (2) using the warp threads (4) and weft threads (5), and c) heating the fabric (2) to a temperature which is higher than the melting point of the adhesive and lower than the melting point of the core in order to produce bonds between the warp threads (4) and the weft threads (5) at the thread node points (6). The aim of the invention is to provide such a thread which can be processed into an transparent fabric (2) for insect screens (1) in a particularly efficient manner. This is achieved in that the coating (11) comprises hydrophobic repellents.

Owner:TRITTEC +1

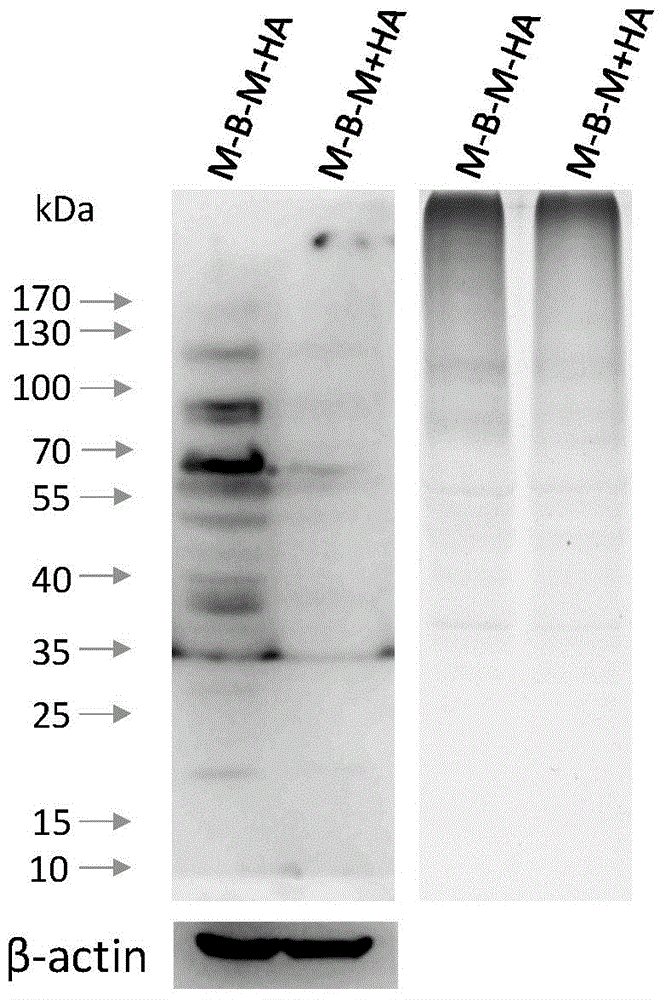

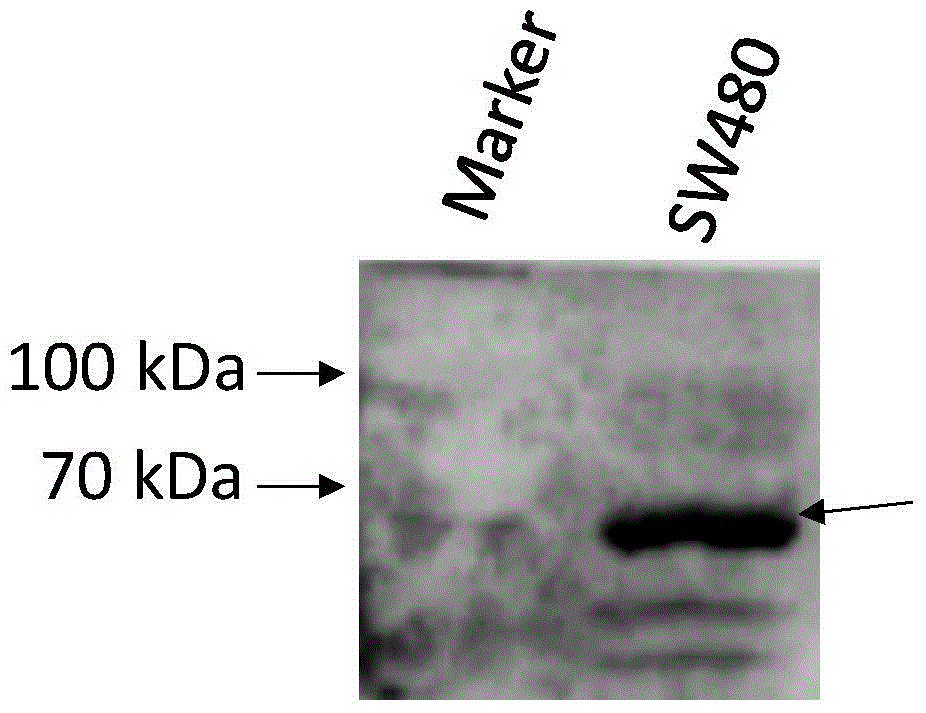

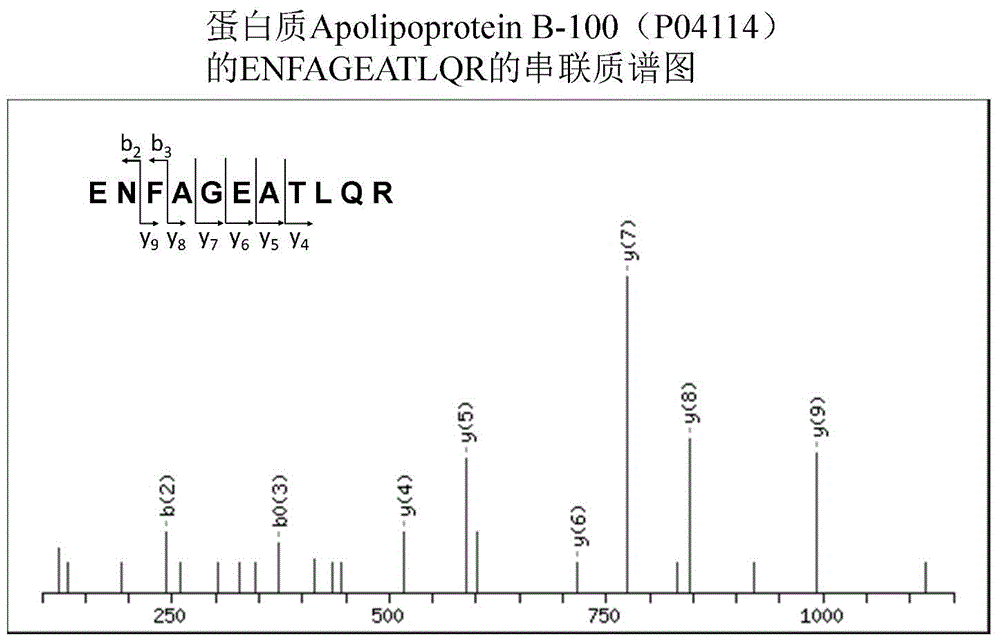

Test method of palmitoylated modified protein based on specific antibody

InactiveCN106153941AHigh specificityStrong specificityMaterial analysis by electric/magnetic meansBiological testingFalse positive rateProtein protein

The invention belongs to the field of biochemical analysis and relates to a high-throughput test method of palmitoylated modified protein in complex biological samples based on prepared protein palmitoylated modified generic antibody serum and utilizing the same. The method includes: adopting a palmitoylated modified peptide segment as an antigen to prepare high-specificity palmitoylated modified generic antibody serum; utilizing the specific antibody serum to test protein palmitoylated modifying state. Compared with existing throughput analysis methods, the test method has the advantage of high specificity, is low in false positive rate, can directly indicate palmitoylated modified protein, can be used for samples of various sources, can identify palmitoylated modified protein in the biological samples in a high-throughput manner and is simple, convenient and easy to operate. The method provides an effective means for high-throughput testing of protein palmitoylated modifying in the biological samples.

Owner:FUDAN UNIV

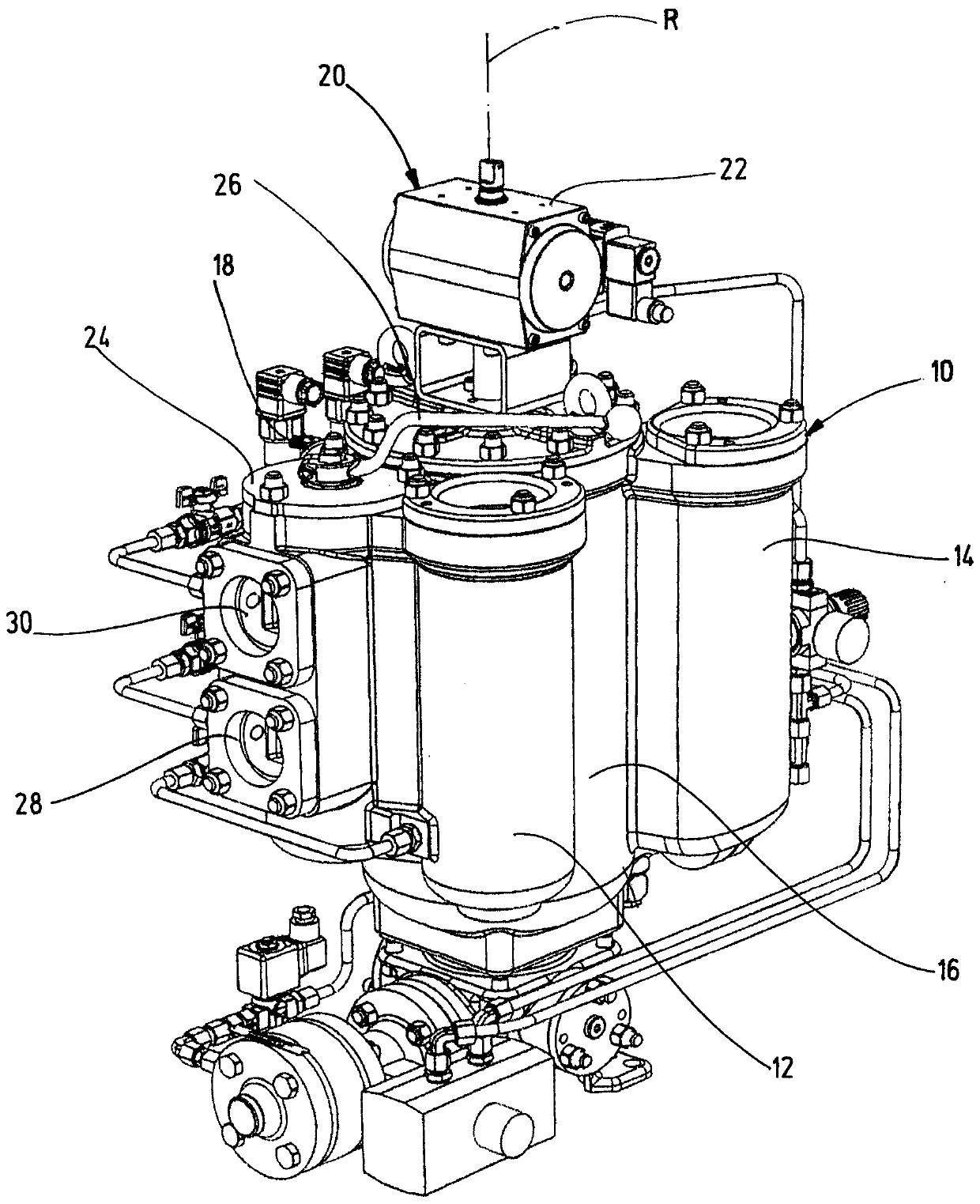

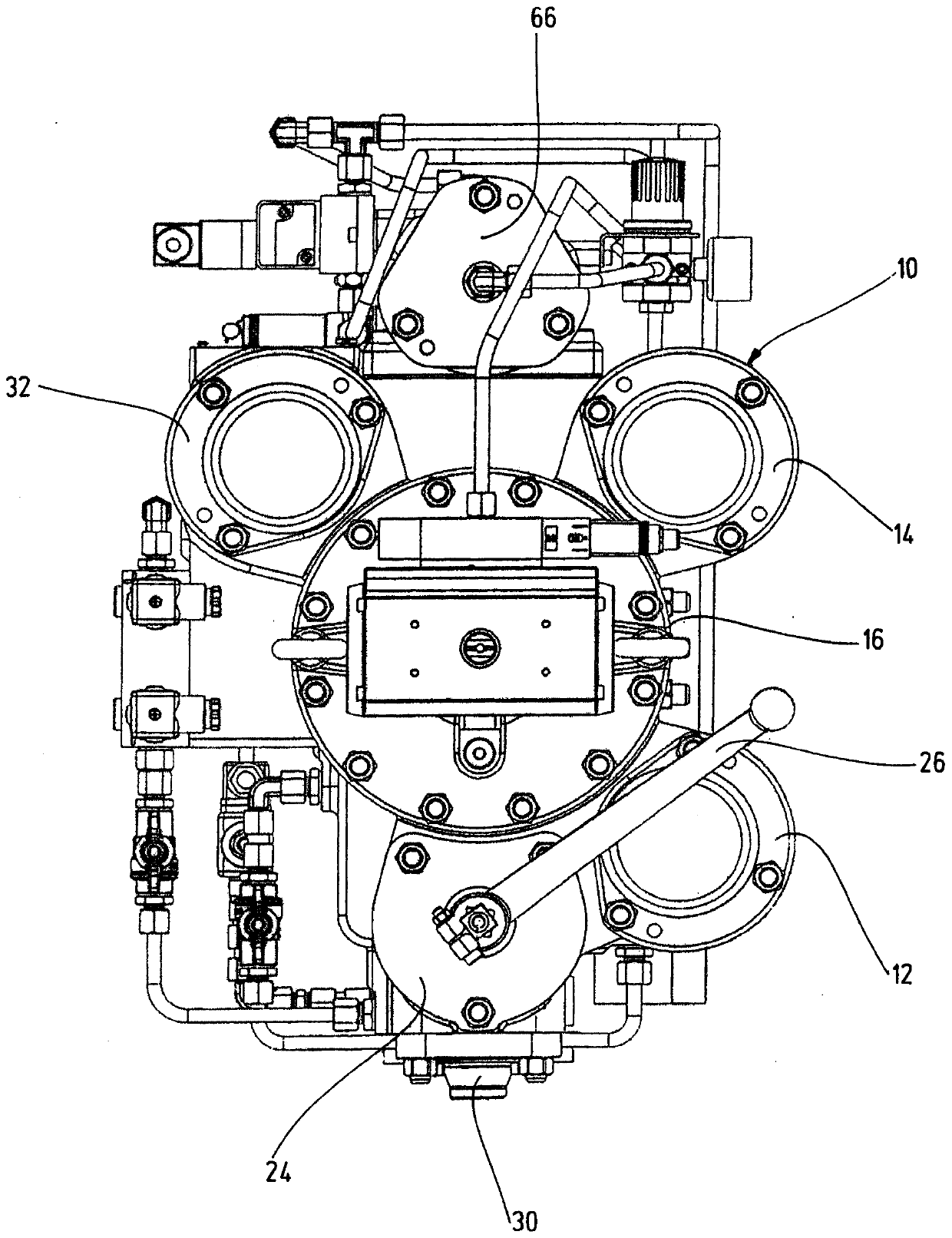

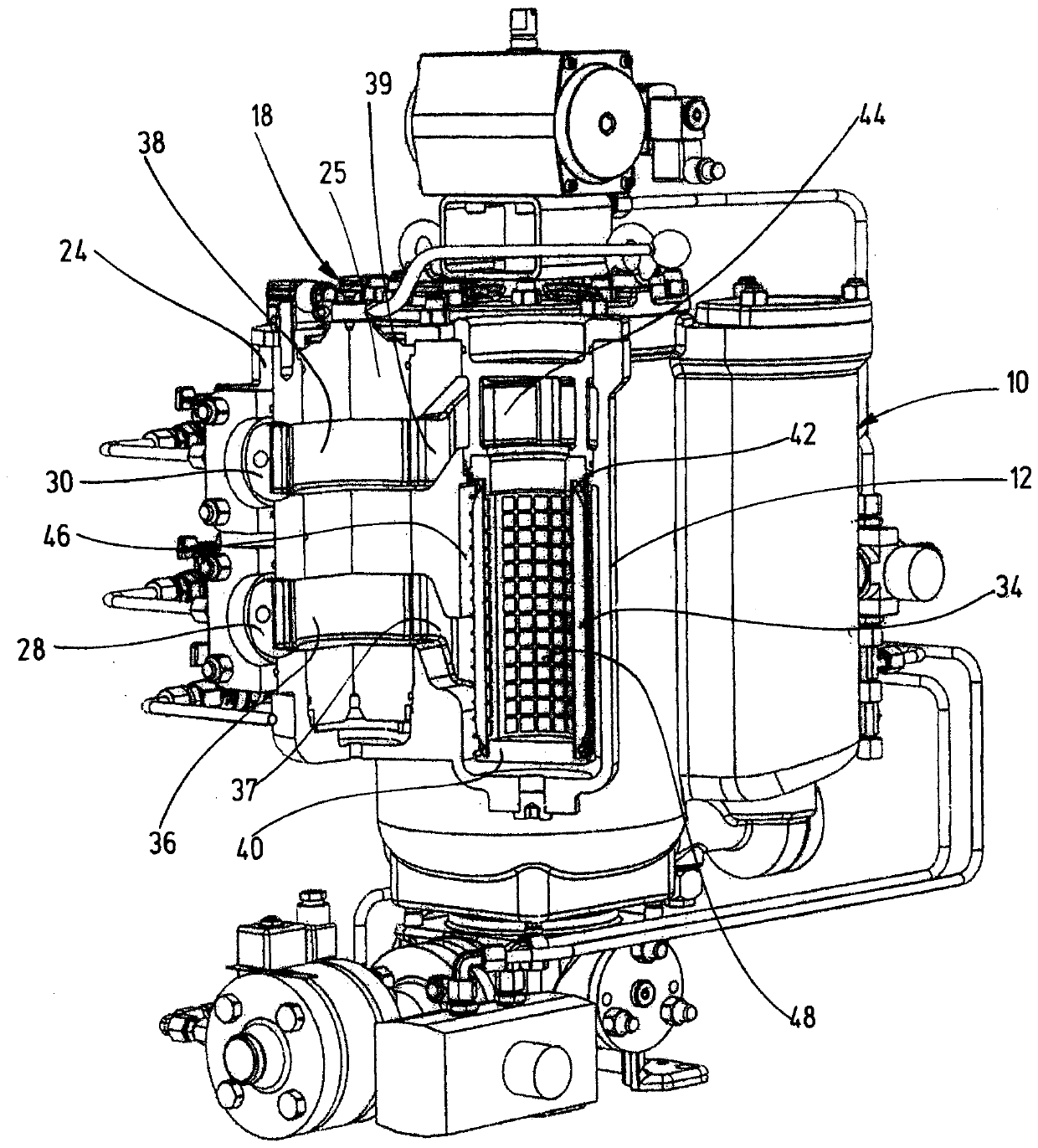

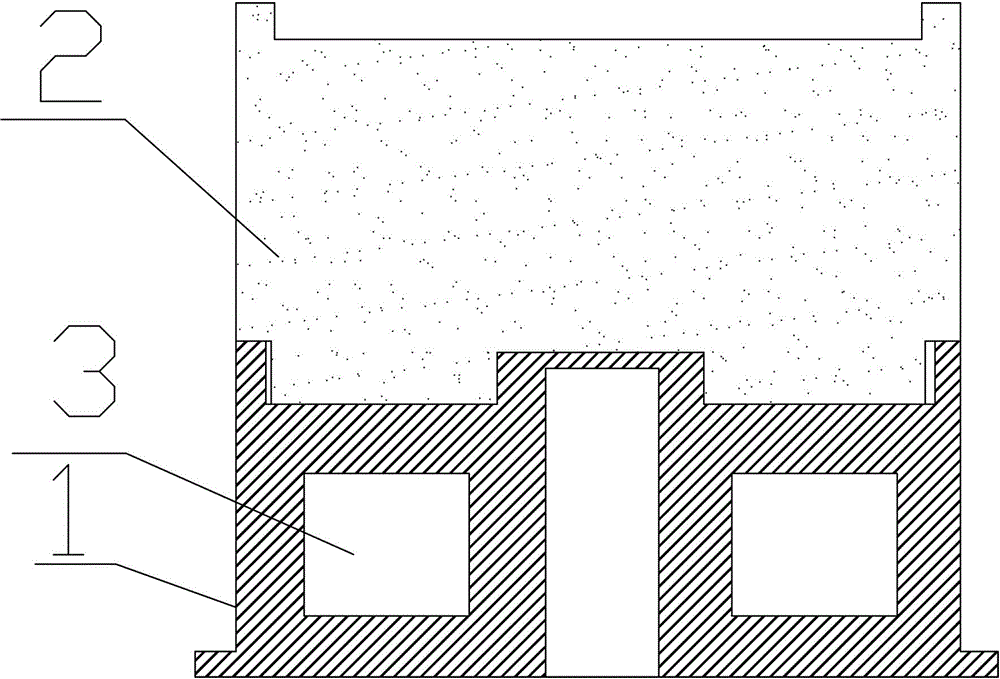

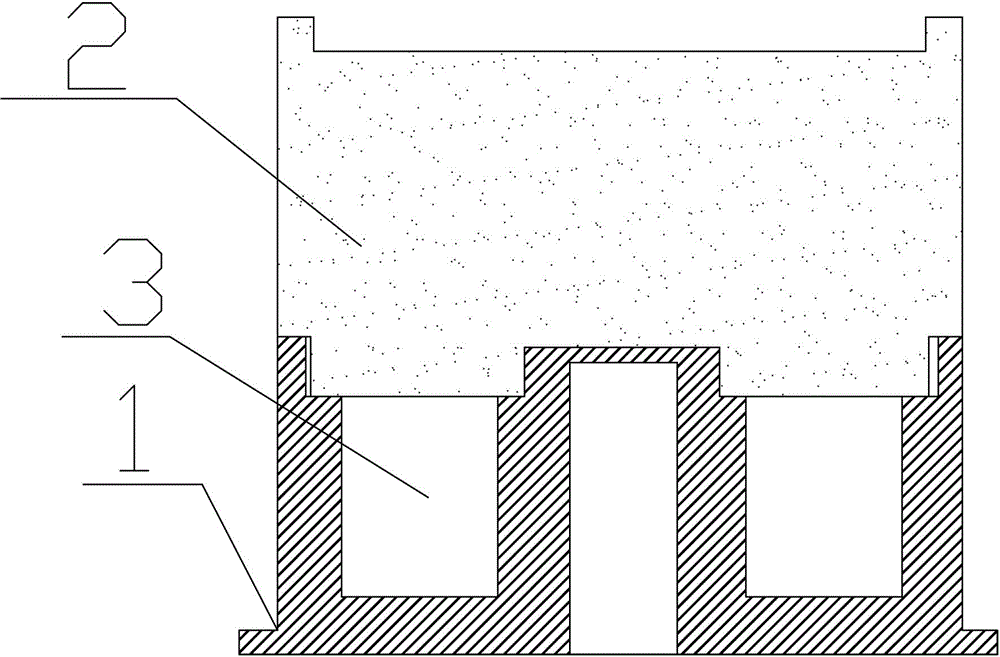

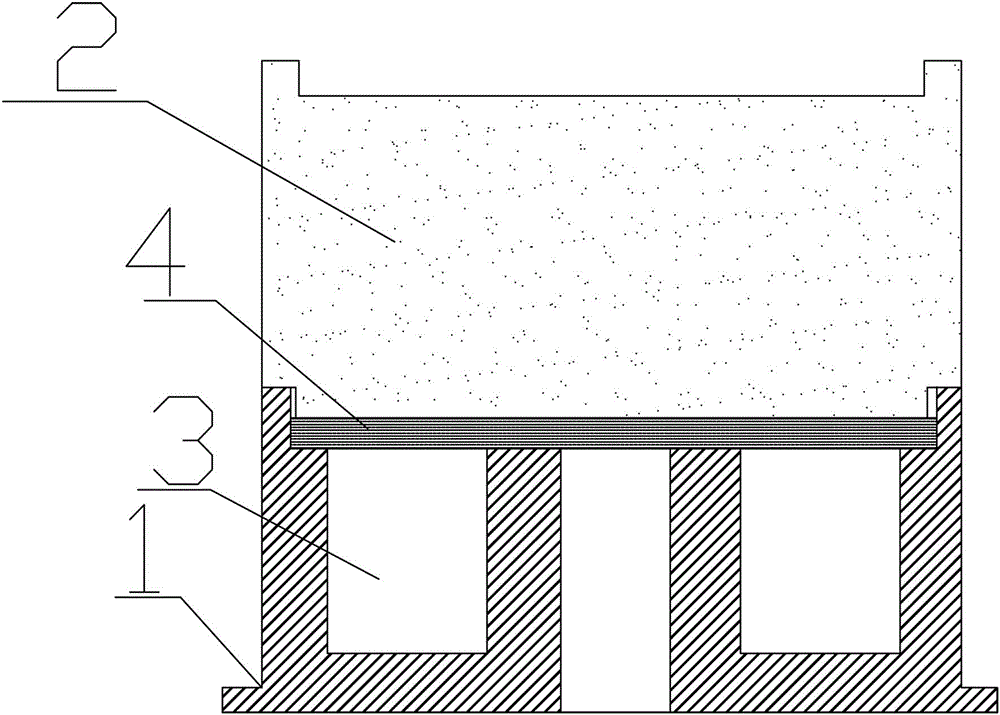

Filter apparatus

ActiveCN111263657ASimple operabilitySimple structure costsMembrane filtersStationary filtering element filtersEnvironmental engineeringMechanical engineering

The invention relates to a filter apparatus for cleaning particulate contaminants out of a fluid flow, having a plurality of filter elements (34, 60), which, received in filter chambers (12, 14, 32) as a component of a common filter housing (10), group about a backwash device (20), which, in order to receive a backwash volume, has a piston accumulator (56), in the accumulator housing (64) of whicha piston (57) is guided in a longitudinally movable manner, said piston, actuated by a pressure medium, forwarding the backwash volume stored in the accumulator housing (64) to at least one filter element (60), which is to be backwashed for cleaning thereof, via a backwash device (20), which also undertakes removal of the backwash volume from the filter apparatus, characterized in that a specificfilter element, as a bypass filter element (34), which is selected from the plurality of filter elements (34, 60), solely undertakes the particle cleaning after actuating a changeover device (18), and the other filter elements (60) are excluded from said cleaning.

Owner:HYDAC PROCESS TECH

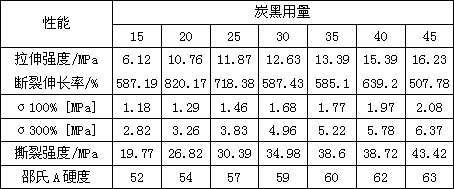

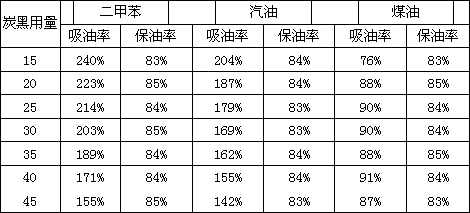

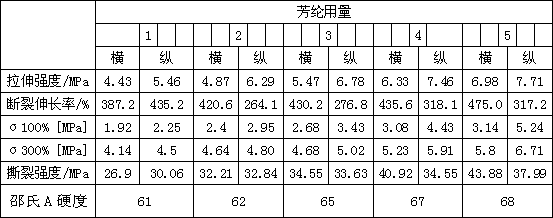

Preparation method for oil-absorbing swelling rubber

The invention discloses a preparation method for oil-absorbing swelling rubber. The oil-absorbing swelling rubber is characterized by being prepared from the following components in parts by weight: 100 parts of butadiene styrene rubber, 20-50 parts of carbon black, 20-50 parts of oil-absorptive resin and 1-5 parts of aramid fiber, wherein the oil-absorptive resin is prepared by copolymerizing butyl acrylate (BA), methyl methacrylate (MMA), styrene and a coupling reagent; vulcanization additives are added in the preparation process; and the vulcanization additives include zinc oxide, stearic acid, anti-aging agent, sulfur and accelerants TT, DM, M, D and CZ. According to the invention, the monomers are synthesized into the oil-absorptive resin and then the oil-absorptive resin is mixed with butadiene styrene rubber and aramid fiber so as to acquire a novel oil-absorbing swelling rubber, so that the oil-absorbing property is promoted under the condition that the material strength is notreduced, the oil-absorbing swelling rubber is low in cost and has excellent performances and the industrial large-scale production can be realized.

Owner:贵阳柯四达金属结构有限公司

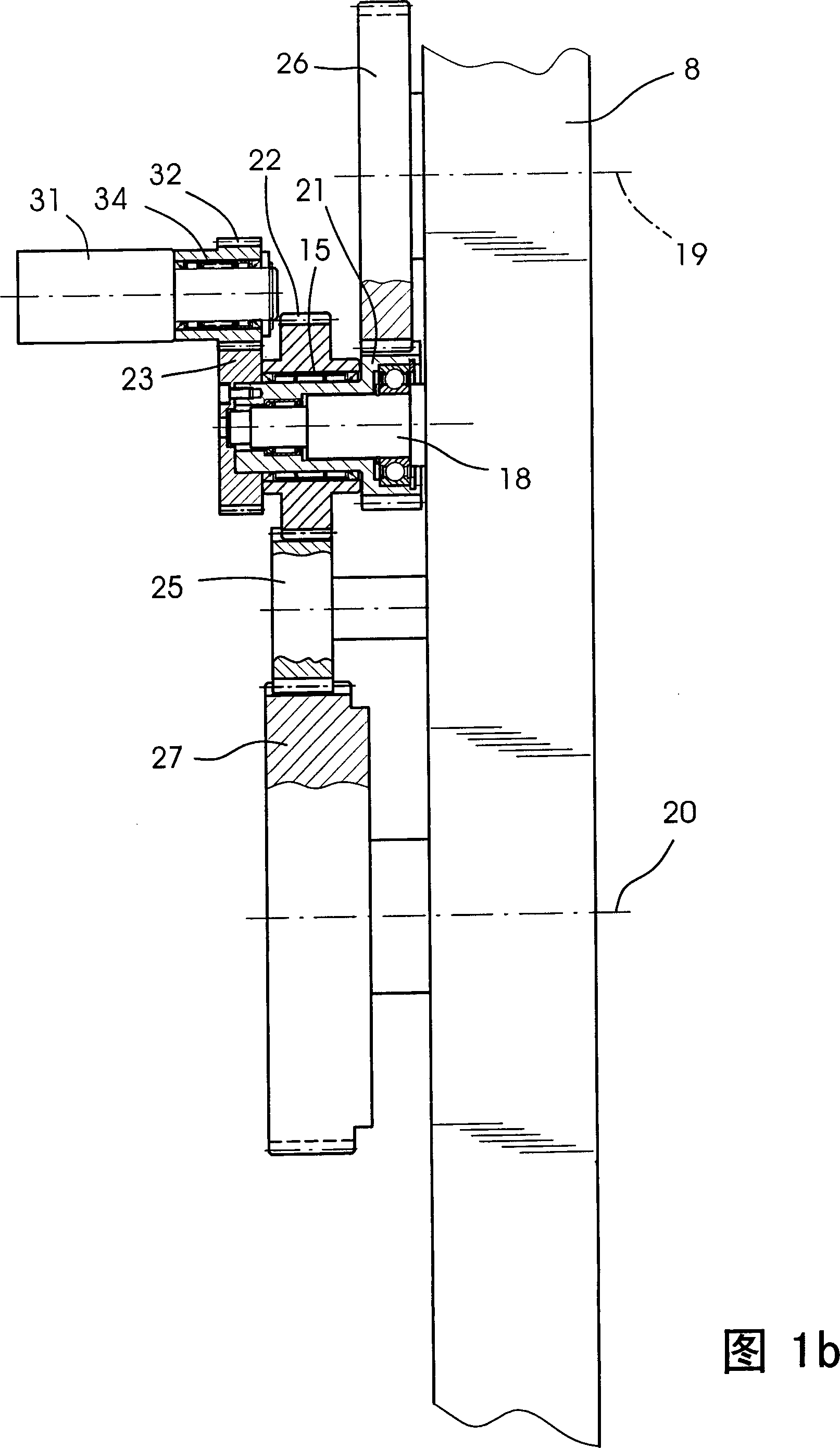

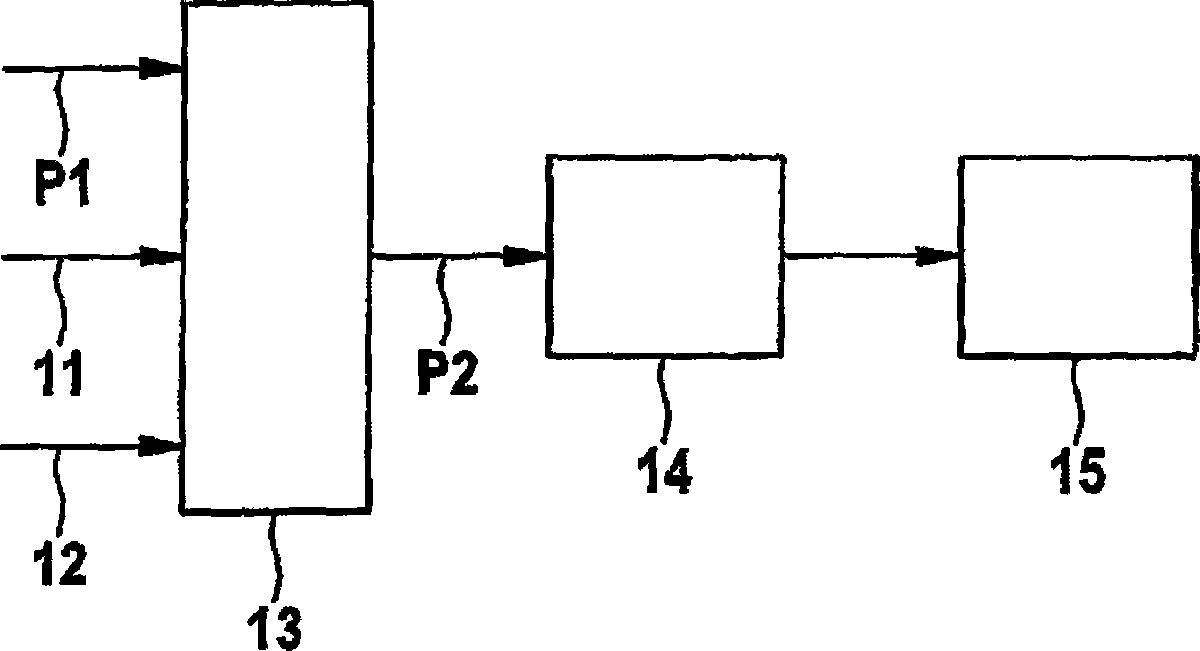

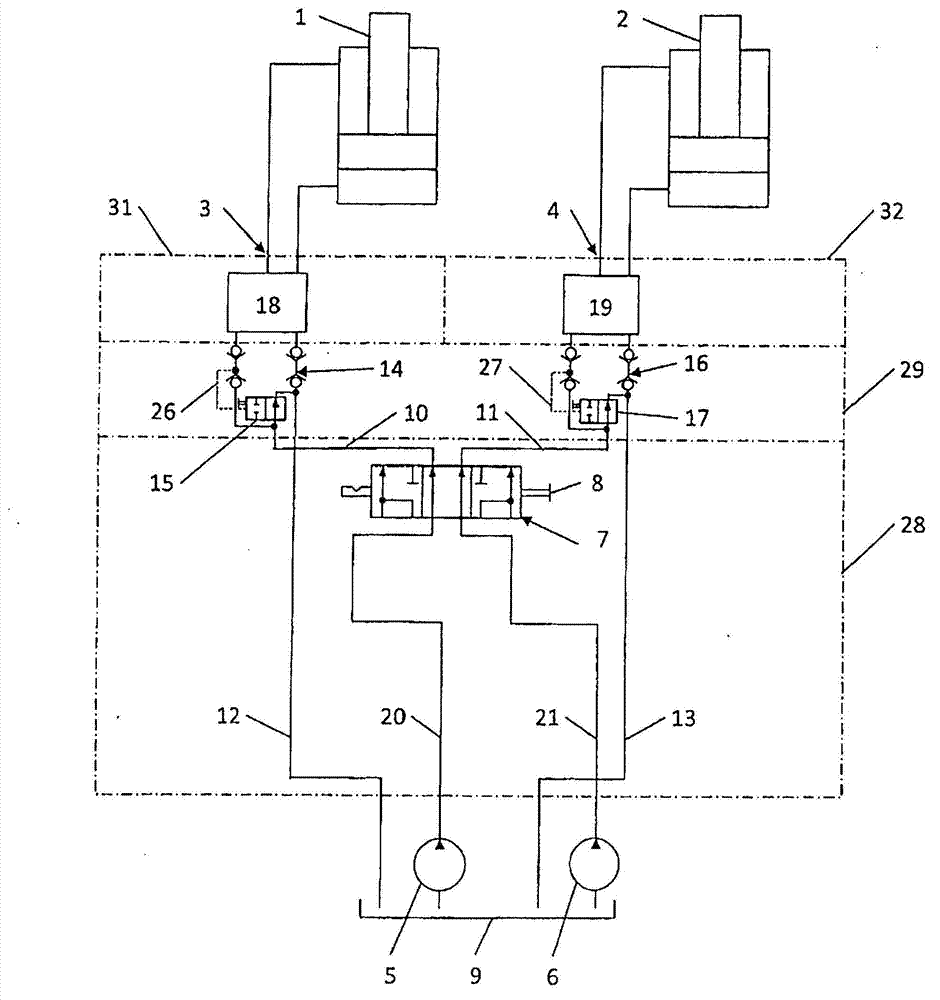

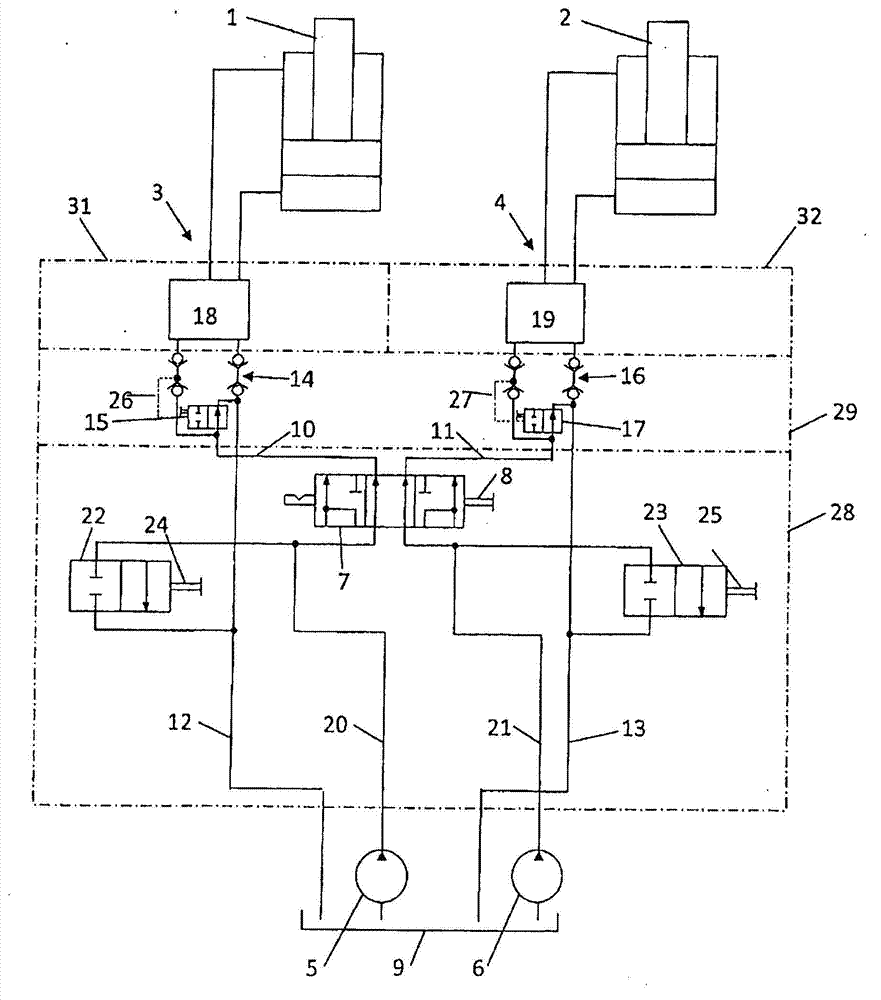

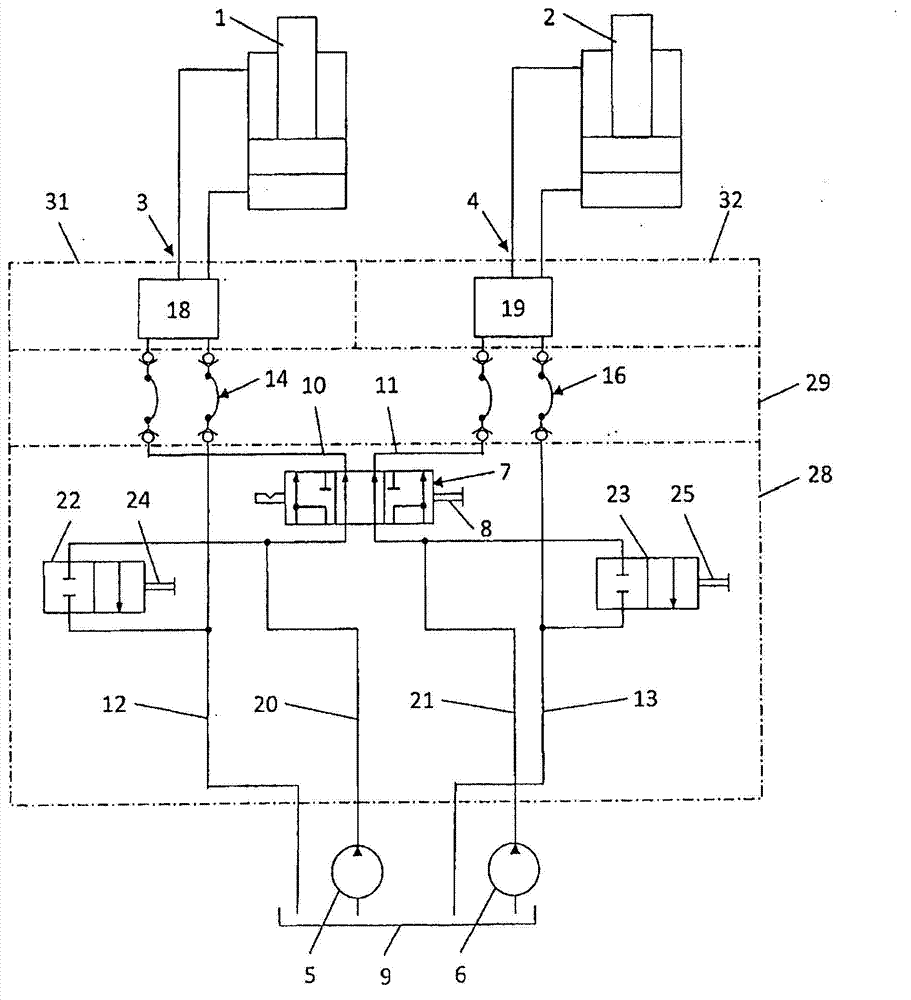

Control apparatus for a first tool and a second tool

ActiveCN103119306ASimple structureReduce structural costsServomotorsServometer circuitsUsabilityControl valves

The invention relates to a control apparatus for a first and a second tool (1, 2) operated by means of a pressure medium, in particular hydraulic oil, comprising a first supply circuit (3) for the first tool (1) and a second supply circuit (4) for the second tool (2). The control apparatus is or at least can be connected to a first pressure line (20) and to a second pressure line (21) of a control device to be operated in particular manually, by means of which control device the flow rate at the first tool (1) and at the second tool (2) can be changed.; In order to improve the usability and to simplify the design, a novel control device is proposed, which is characterized in that a control valve (7) is provided jointly for the first and second supply circuits (3, 4) as the control device, the control valve (7) has three switching positions, namely: (a) the flow rate from the first pressure line (20) is available only to the first tool (1) and the flow rate from the second pressure line (21) is available only to the second tool (2), (b) the flow rate from the first and second pressure lines (20, 21) is available preferably to the first tool (1), (c) the flow rate from the first and second pressure lines (20, 21) is available preferably to the second tool (2).

Owner:LUKAS HYDRAULIK

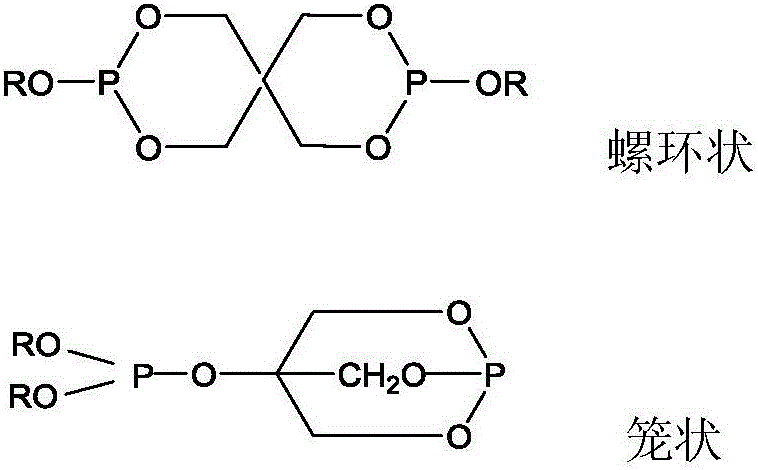

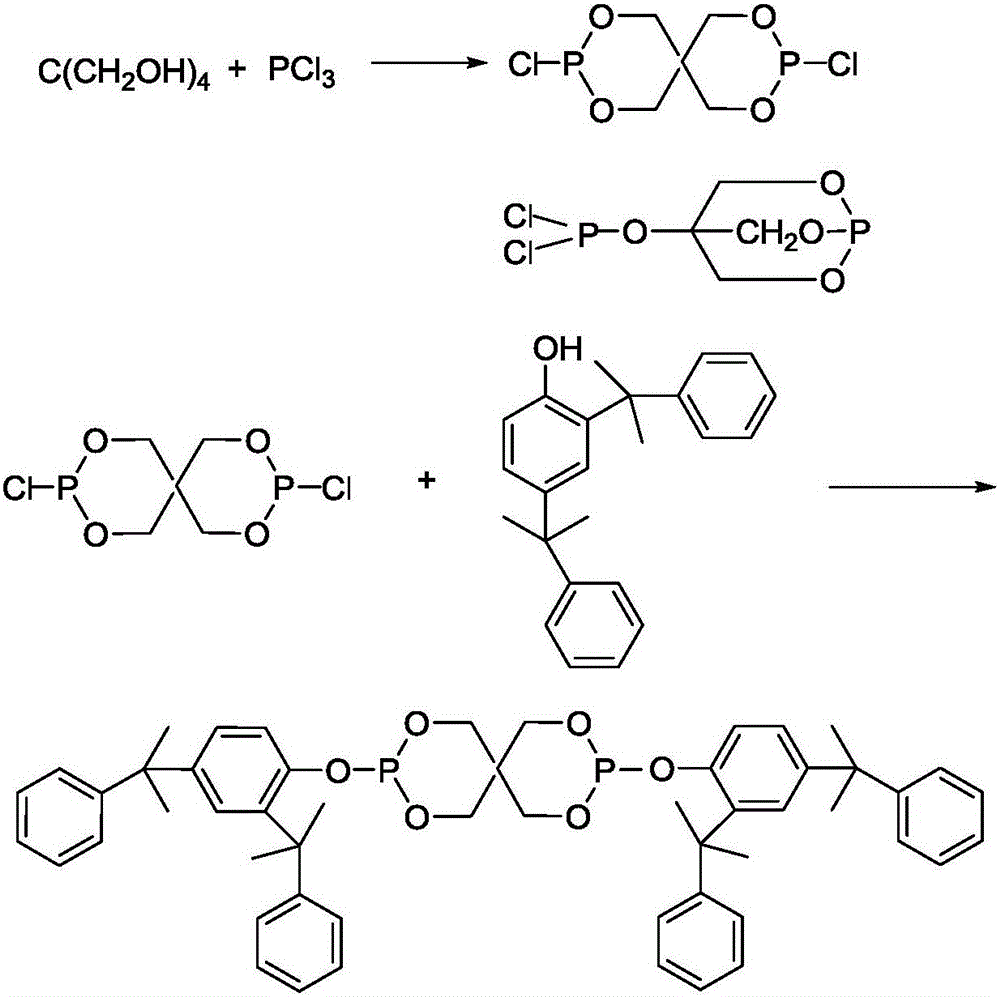

Preparation method of bis(2,4-dicumylphenyl)pentaerythritol diphosphite antioxidant

ActiveCN106588991AReduce consumptionHigh selectivityGroup 5/15 element organic compoundsPentaerythritolAntioxidant

The invention relates to a preparation method of a bis(2,4-dicumylphenyl)pentaerythritol diphosphite antioxidant. The preparation method comprises the steps of dropwise adding phosphorus trichloride at a nitrogen environment in an existing system of pentaerythritol, a catalyst and a solvent so as to obtain dichlone pentaerythritol diphosphite reaction liquid, adding 2,4-dicumylphenol, heating to 130-140 DEG C in the presence of nitrogen to react, carrying out reduced pressure backflow reaction to obtain a reactant, adding organic amine to neutralize and regulate the reactant to be alkaline, continuing to carry out esterification reaction until reaction mediums are still alkaline, cooling, and filtering, so as to obtain bis(2,4-dicumylphenyl)pentaerythritol diphosphite. By controlling the reaction process, high-selectivity and high-yield bis(2,4-dicumylphenyl)pentaerythritol diphosphite with a spiral structure is obtained, the yield of the product is higher than 92%, the recovery rates of generated side effects and an unreacted raw material, namely 2,4-dicumylphenol are higher than 90%, the consumption of the raw materials is reduced, and the simple and feasible operability is realized.

Owner:RIANLON +2

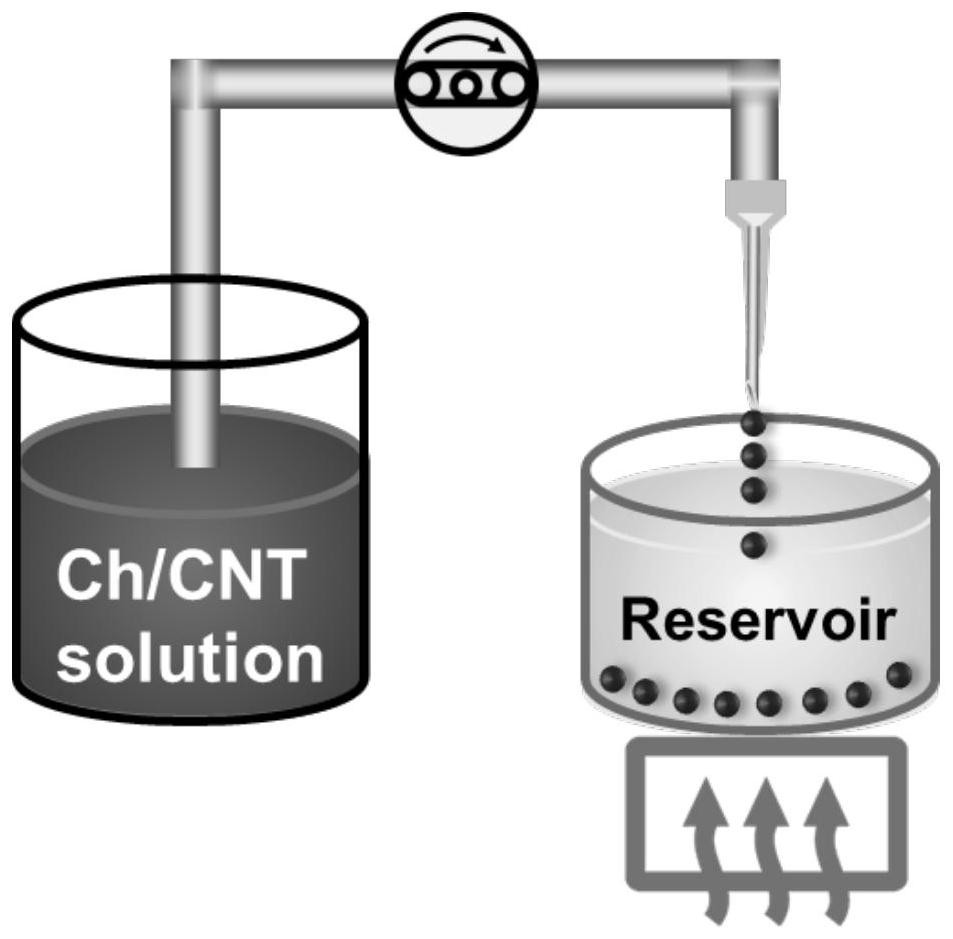

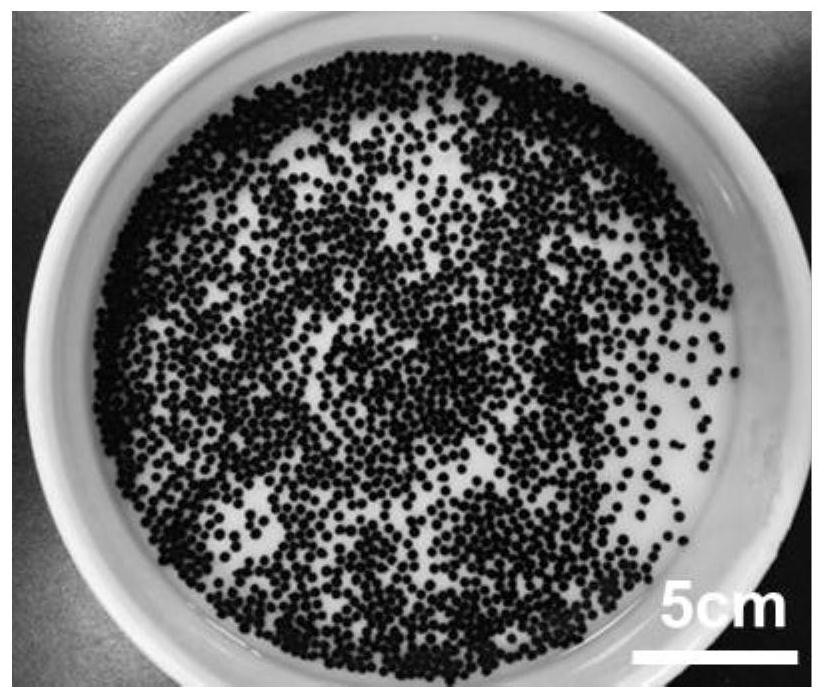

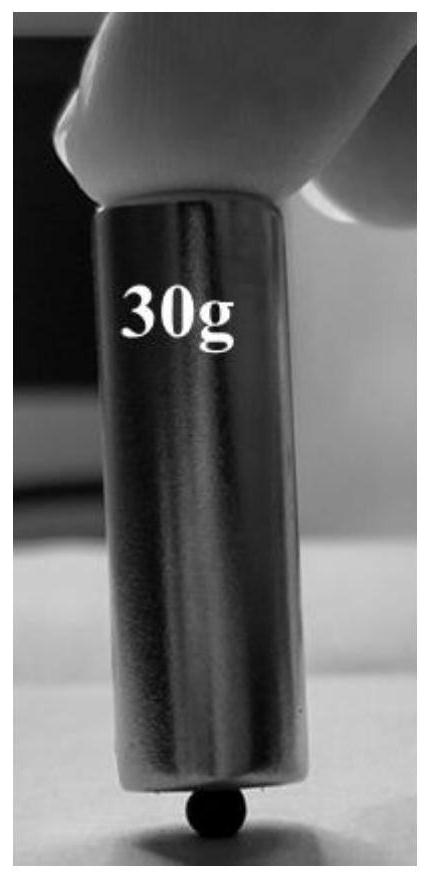

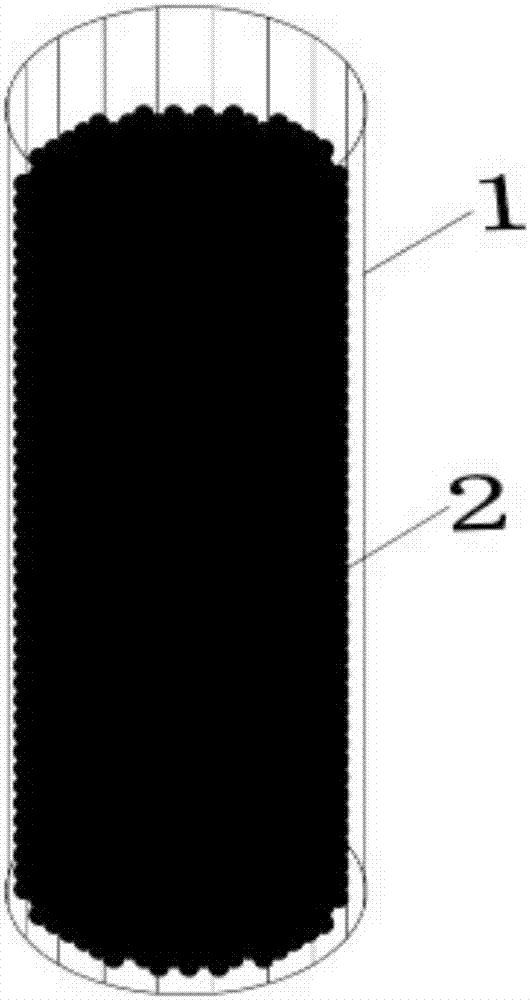

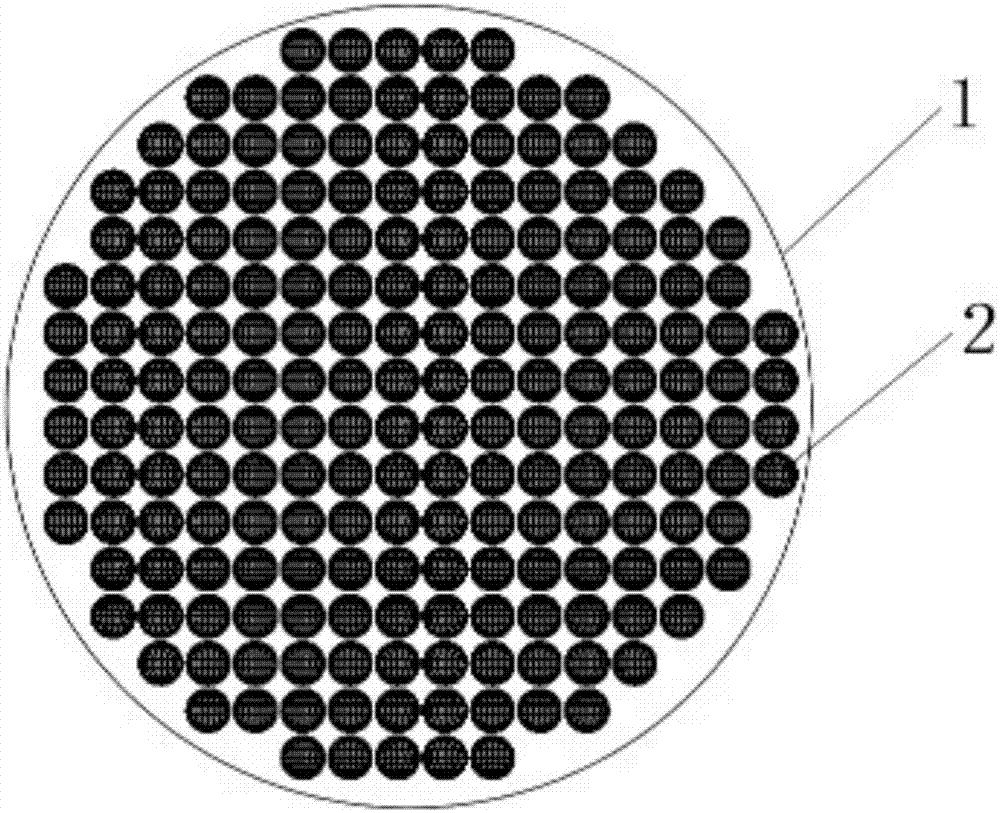

Whole blood perfusion adsorbent as well as preparation method and application thereof

ActiveCN112871139AImprove adsorption capacityReduce the amount of adsorptionOther blood circulation devicesOther chemical processesMicrospherePerfusion

The invention belongs to the field of natural polymer biomedical materials, and particularly relates to a whole blood perfusion adsorbent as well as a preparation method and application thereof; the adsorbent is large-size nanofiber porous network microspheres compounded by natural polymer nanofibers, an inorganic functional filler, an organic functional filler and / or an organic coating material, wherein the inorganic functional filler and the organic functional filler are wrapped in the natural polymer nanofiber microspheres, and the organic coating material coats the surfaces of the natural polymer nanofiber microspheres. The whole blood perfusion adsorbent has a microsphere size suitable for whole blood perfusion, has good blood compatibility, has a nanofiber porous network structure, is an inorganic and organic functional material capable of specifically adsorbing toxins, can be designed for specific toxins, and is high in adsorption efficiency, high in selectivity and easy to popularize and apply.

Owner:WUHAN UNIV

Cathode arc target cooling device

InactiveCN104947045ASmall granularityImprove cooling effectVacuum evaporation coatingSputtering coatingWater channelCooling effect

The invention discloses a cathode arc target cooling device which comprises target bases, targets and a plurality of cooling water channels formed inside the target bases, wherein the targets are embedded in the surfaces of the target bases and are isolated from the cooling water channels by using copper plates; the copper plates divide the cooling water channels and the targets into different independent spaces; the targets contact the copper plates; when a liquid flows through the water cooling channels, the copper plates protrude out towards the targets under the pressure of the liquid. The cathode arc target cooling device has the advantages that as good conductivity of copper pieces is adopted to conduct heat, and meanwhile the targets are isolated from the cooling water channels by using the copper pieces, the equipment is good in cooling effect, and in addition, vacuum equipment and production efficiency are not affected.

Owner:YICHANG HOUHUANG VACUUM TECH

Motor vehicle with height adjusting device for loading floor

A motor vehicle includes, but is not limited to a loading floor, a height adjusting device for the loading floor with a guide, on which the loading floor is mounted pivotably on a front end portion about a pivot axis and movably for a movement with a component in vertical direction and the loading floor with the guide can be mounted in at least two different height positions, at least two support elements formed in a different vertical orientation for supporting a rear end portion of the loading floor in the at least two different height positions. The guide includes, but is not limited to a first guideway for moving the front end portion towards the top and a second guideway for moving the front end portion towards the bottom and the first and second guideway are formed spatially separated on the guide.

Owner:GM GLOBAL TECH OPERATIONS LLC

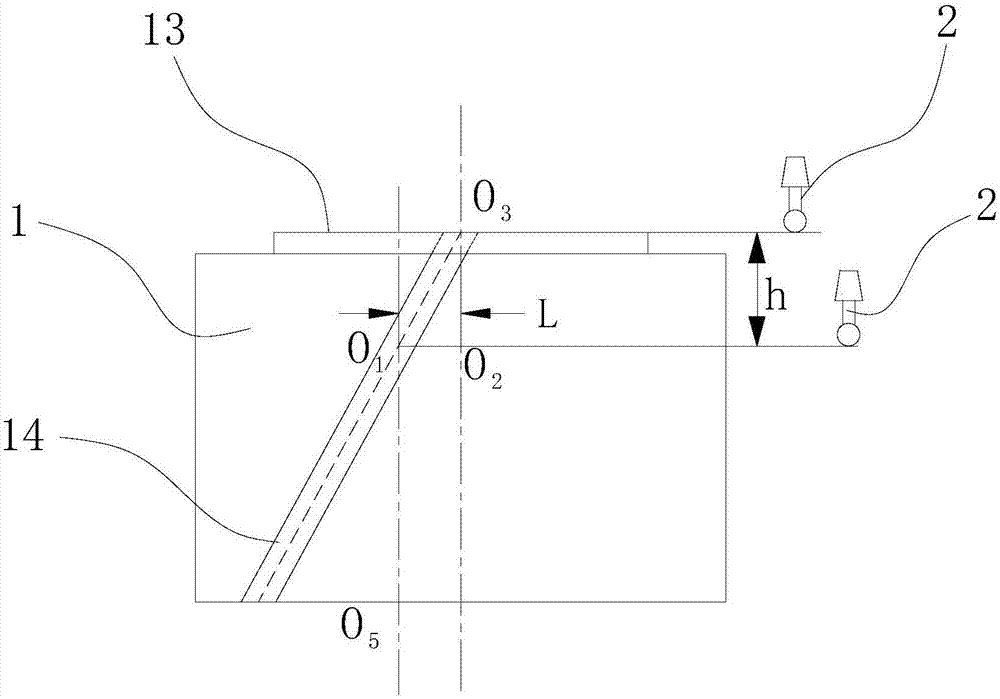

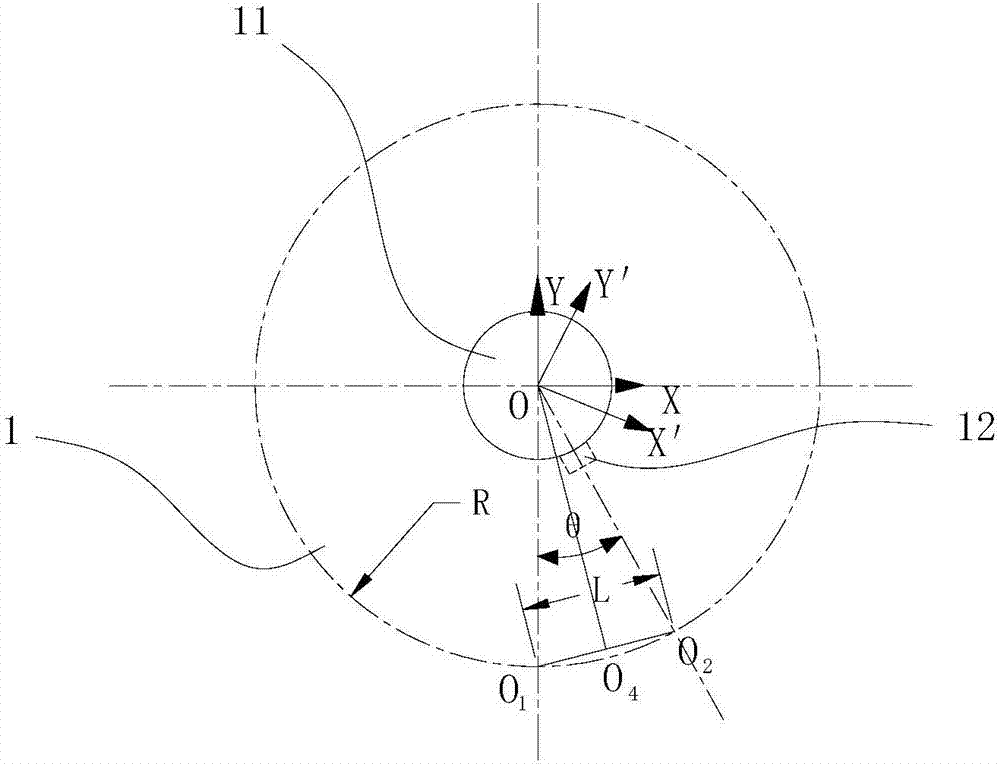

Method for controlling symmetry of machining keyway and center of tooth or tooth space

ActiveCN107357261AGuaranteed relative to positionSolve processing problems with high precisionProgramme controlComputer controlRectangular coordinatesEngineering

The invention discloses a method for controlling the symmetry of a machining keyway and the center of a tooth or a tooth space, through which the cost is reduced, the product quality is improved, and the work efficiency is improved. The method includes following steps: 1) selecting a cross section of a single helical gear, marking the center O1 of the tooth space or the tooth on the cross section, and establishing a rectangular coordinate system XOY on a base plane by regarding a connecting line of the O1 and the center O of the cross section as a Y axis, wherein the height from the cross section to the base plane is h; 2) calculating L, wherein L=h*tan[beta], and beta is an inclination angle of the tooth space or the tooth of the single helical gear; 3) calculating a rotation angle theta, wherein theta=2*(theta / 2)=2*arcsin((L / 2) / R); 4) rotating the XOY rectangular coordinate system for the theta angle, and re-establishing an X'OY' rectangular coordinate system; and 5) milling the keyway by regarding the X'OY' rectangular coordinate system as the datum. By employing the method for controlling the symmetry of the machining keyway and the center of the tooth or the tooth space, the operation is simple, the labor intensity of workers is reduced, the work efficiency is improved by multiple times, and the quality and the precision can be guaranteed.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

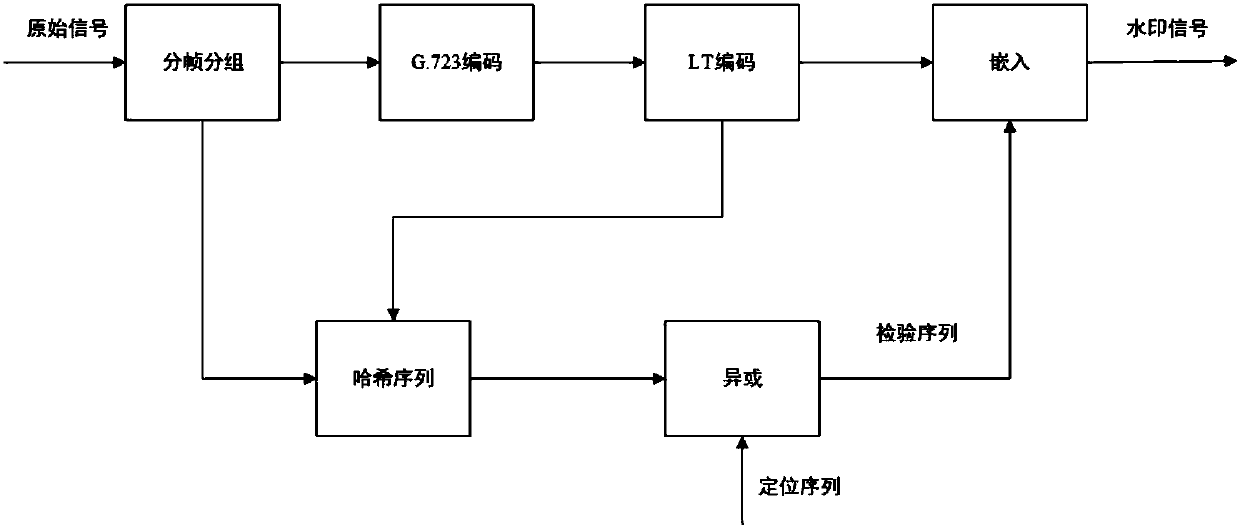

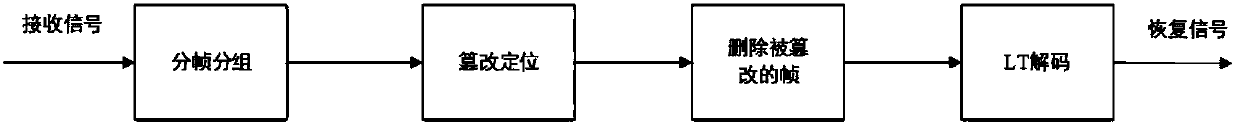

Fountain code based fragile watermark self-restoration algorithm

The invention discloses a fountain code based fragile watermark self-restoration algorithm. The algorithm includes a watermark embedding process comprising framing original voice signals, performing compression and encoding on each frame of data, performing random ranking on all the frames, performing frame grouping, performing fountain encoding on compression information of each frame group, generating reference value information and storing the reference value information and check information into a least significant bit; and a signal data restoration process comprising performing framing and frame grouping on received signals, extracting the reference value information and the check information in the least significant bit of each frame, positioning a tampered position according to thecheck information and restoring the whole original voice signals according to the reference value information of frames that are not tampered. According to the invention, by utilizing characteristicsof being codeless and suitable for channel deletion of fountain codes, watermark technology and fountain code technology are combined together. Pre-estimation of the range of a destruction rate is not needed and good universality is achieved.

Owner:TIANJIN UNIV

Sludge-based micro-pore framework capturing mesh wall and method for repairing heavy-metal pollution of underground water

ActiveCN106975435ARealize waste utilizationImprove reduction efficiencyOther chemical processesWater contaminantsSludgeEngineering

The invention relates to a sludge-based micro-pore framework capturing mesh wall and a method for repairing heavy-metal pollution of underground water and belongs to the technical field of environmental engineering. The invention aims at providing the sludge-based micro-pore framework capturing mesh wall which takes modified sludge as a foundation and the method for repairing the heavy-metal pollution of the underground water, which can be used for carrying out targeting reduction and adsorption aiming at a target on heavy-metal pollutants in the underground water. The sludge-based micro-pore framework capturing mesh wall provided by the invention is characterized in that a capturing mesh wall is composed of a plurality of stereoscopic capturing modules; each stereoscopic capturing module is formed by a core region and a membrane wall through compounding, wherein each core region is a sludge-based micro-pore framework hard ball carrying nano Fe (0) and each membrane wall is a sludge-coal pitch carbonized membrane; the sludge-based micro-pore framework hard balls carrying the nano Fe (0) are filled into the sludge-coal pitch carbonized membranes to form the cylindrical stereoscopic capturing module.

Owner:山西青舟环境科技有限公司

Steering spindle arrangement

ActiveCN103717475ALoose prohibitionRealize no tighteningYielding couplingCouplings for rigid shaftsEngineeringControl theory

The invention relates to a steering arrangement (1) which has a steering spindle with a steering spindle connection (2) that is connected to a fork head (4) of a steering coupling via an intermediate piece (3). The steering spindle connection (2) and the hub-shaped intermediate piece (3) are designed as plug partners at ends that face each other by means of at least one groove and spring guiding element pair (5, 6) which is oriented in a longitudinally axial manner and which provides a positive guide that transmits a torque. This is achieved in that a first guiding element (5, 6) of the guiding element pair (5, 6) is arranged on the steering spindle connection (2), and a second guiding element (5, 6) of the guiding element pair (5, 6) is arranged on the intermediate piece (3). A clamping device which clamps the plug partners against each other in a plugged position, is provided

Owner:梅赛德斯-奔驰集团股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com