Thread and fabric for insect screens

A technology of weaving nets and yarns, which can be used in insect control, textiles, fabrics, etc., and can solve problems such as lack of durability and affect the perception of observers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

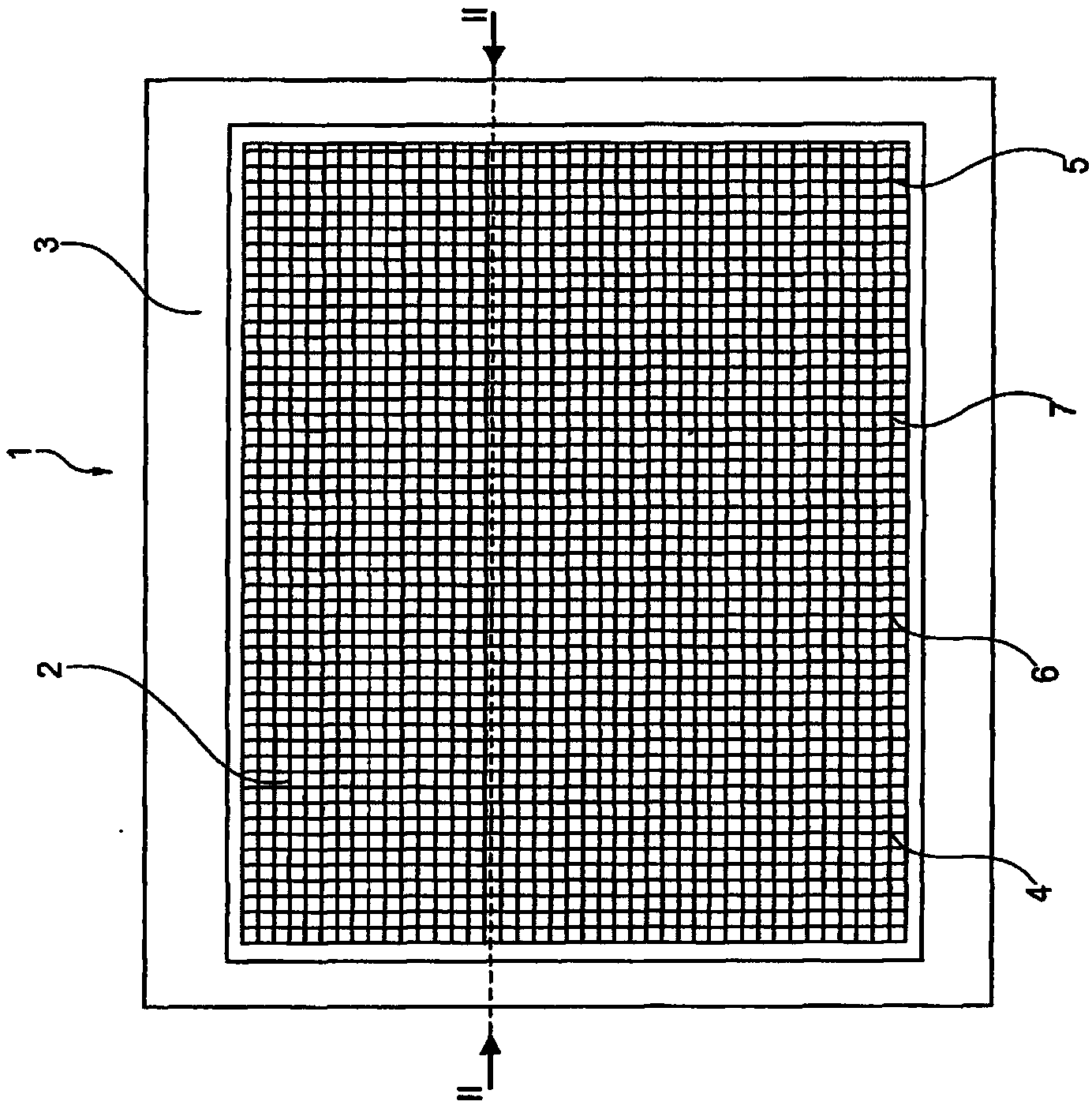

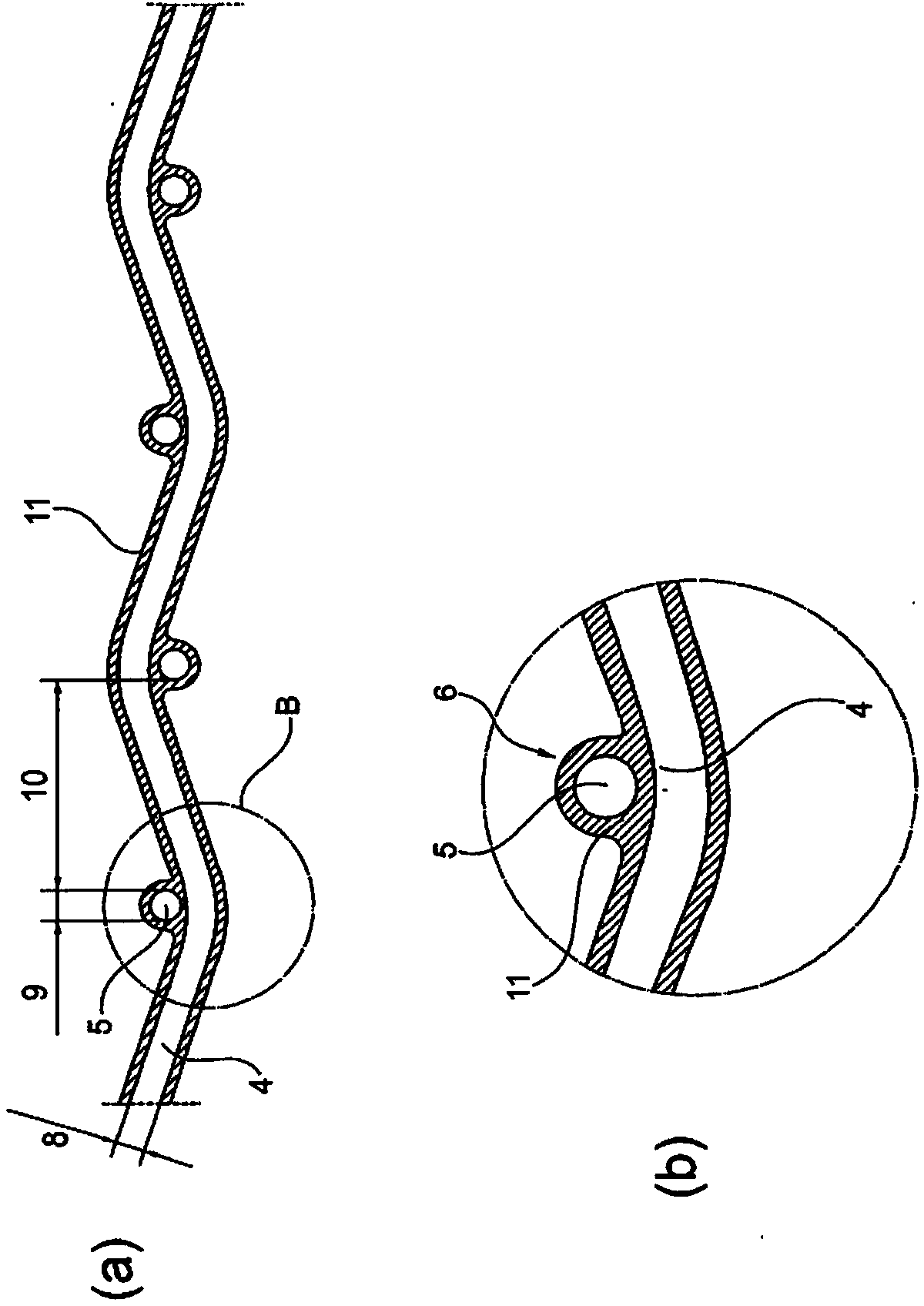

[0032] figure 1 The insect screen 1 according to the present invention is schematically shown. The insect screen 1 essentially consists of a woven fabric 2 according to the invention, which is embedded in a frame 3 in a manner not described in detail but known. Weave Web 2 by in figure 1 Warp yarns 4 running vertically in the center and weft yarns 5 running perpendicular to warp yarns 4 are formed. The terms warp thread 4 and weft thread 5 are known to refer to the production flow of weaving. However, within the scope of the invention, for example during the production of the web 2, it is not important which thread is the warp thread 4 or the weft thread 5. The warp yarns 4 and the weft yarns 5 form a knot 6 at each point of intersection. exist figure 1 In this way, the woven netting 2 according to the invention obtains a woven structure with mesh openings 7 . Warp 4 and Weft 5 are bicomponent yarns Including yarn core and cladding 11. In the particularly preferred em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com