Cathode arc target cooling device

A cathodic arc target and cooling device technology, applied in the field of heat dissipation equipment, can solve the problems of large quantity restriction, troublesome replacement of target materials, affecting production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

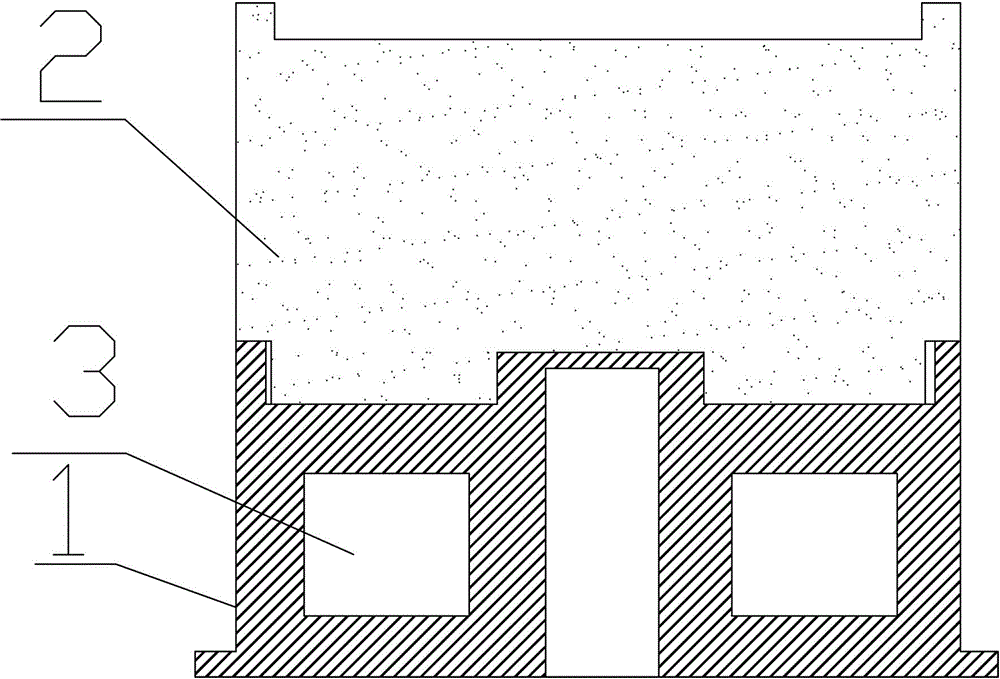

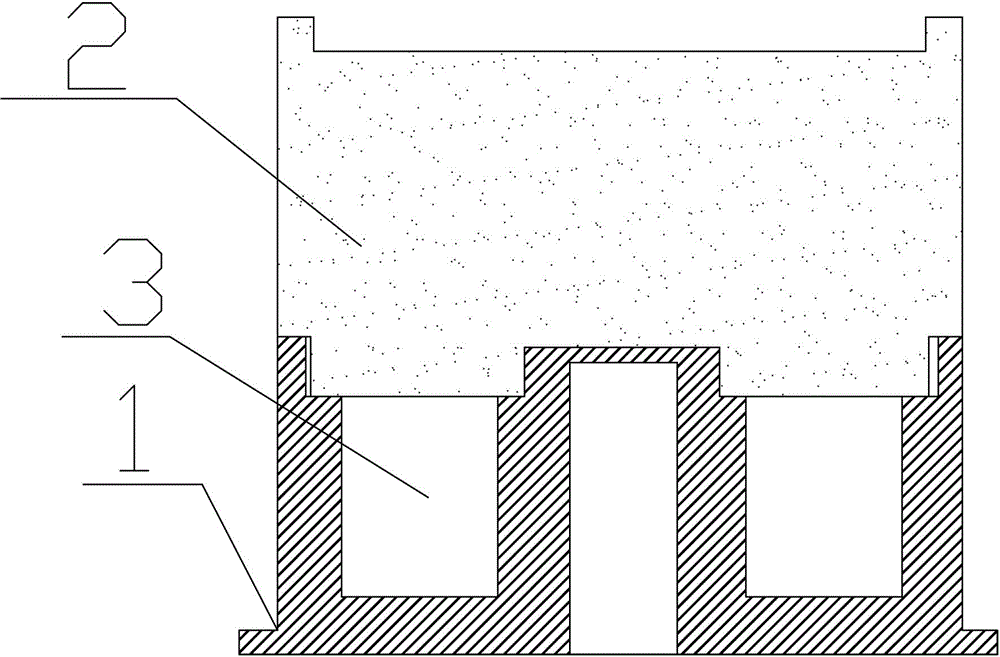

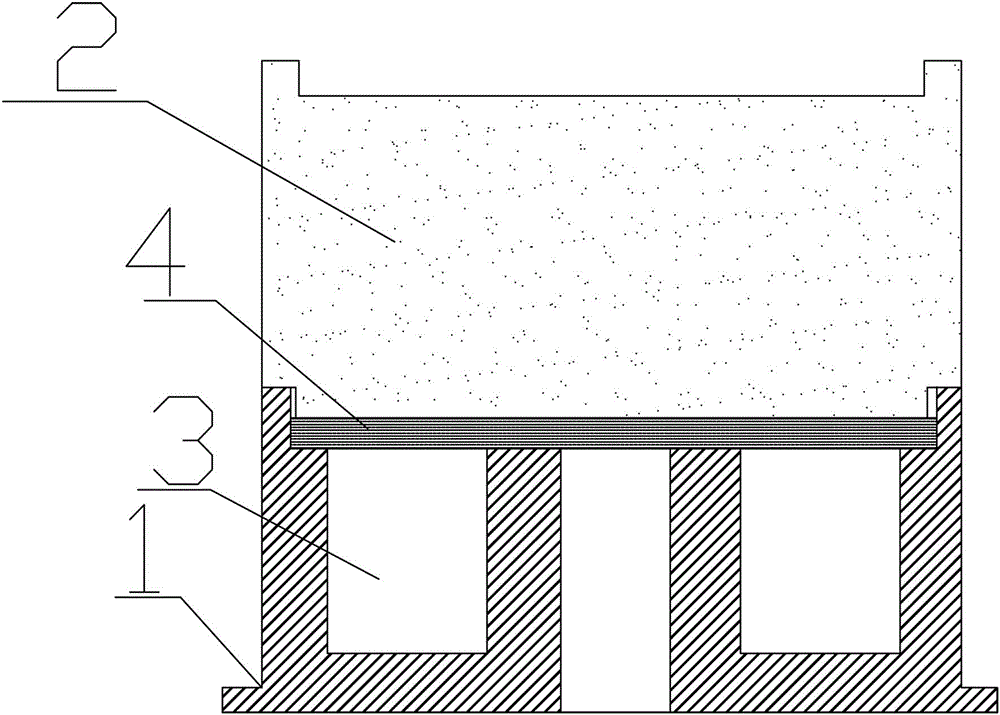

[0021] Such as image 3 Among them, a cathode arc target cooling device includes a target base 1, a target material 2, and two side-by-side cooling water channels 3 arranged inside the target base 1, the target material 2 is embedded on the surface of the target base 1, and the thickness of the copper plate 4 is 0.5 -2mm;

[0022] The target material 2 and the cooling channel 3 are separated by a copper plate 4. The copper plate 4 makes the cooling channel 3 and the target material 2 belong to different independent spaces. The strength temperature-resistant glue bonds the edge of the copper plate 4 on the top of the target base 2 ( image 3 , Figure 4 The middle is glued on the step of the target base 2) or the edge of the copper plate 4 is fixed in the target base 2 by one-time casting method, and the target material 2 is in contact with the copper plate 4;

[0023] Such as Figure 4 , when the liquid (cooling water) passes through the cooling channel 3, the copper plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com