Patents

Literature

83results about How to "Realize waste utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite combining silica thermal repairing material and preparation method thereof

The invention discloses a composite bonded silicious hot repair material, which belongs to the technical field of refractory materials. The repair material comprises the following compositions in percentage by weight: 45 to 55 percent of silicious clinker aggregate, 8 to 12 percent of silicious clinker powder, 20 to 30 percent of natural silica powder, 8 to 12 percent of complex binder, 3 to 5 percent of plasticizer, and 1 to 1.5 percent of dispersant. The silicious clinker aggregate and the silicious clinker powder are waste main crown silica bricks (SiO2 is more than or equal to 95 percent) and fused quartz tubes or fused quartz wedges (SiO2 is more than or equal to 98 percent), SiO2 is more than or equal to 96 percent in natural silica, the complex binder is formed by compounding an SiO2 ceramic bond and a phosphorous acid (phosphate) chemical bond, the plasticizer is white clay or bentonite, and the dispersant is silica fume. The repair material is processed according to the particle size. The invention can satisfy various conditions proposed by hot repair of a kiln to the repair material, can also realize the aims of saving energy sources and increasing the service life of the kiln, and can also be used for filling or building positions which are not suitable for silica brick masonry during the cold repair at the same time.

Owner:山西高科耐火材料股份有限公司

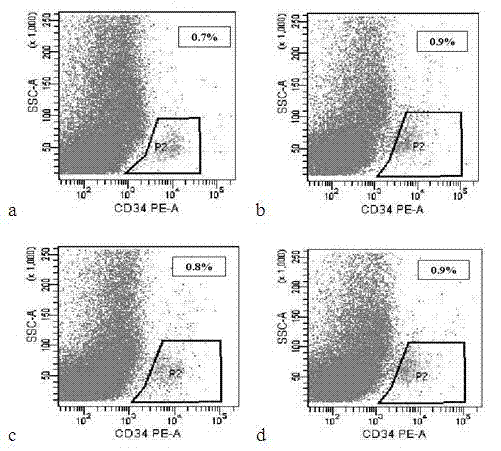

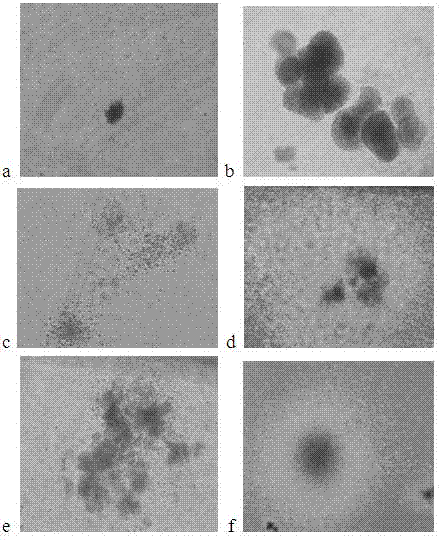

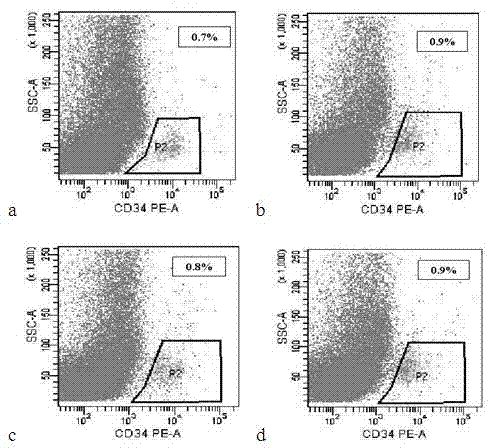

Freezing storage liquid for freezing and storing mononuclear cells

InactiveCN102301992AFreezing is safe and effectiveHigh recovery rateDead animal preservationBlood plasmaCell

The invention relates to freezing storage liquid for freezing and storing mononuclear cells and a preparation method for the freezing storage liquid, and belongs to the technical field of biology. The freezing storage liquid for freezing and storing the mononuclear cells comprises blood plasma and dimethyl sulfoxide. The freezing storage liquid is mainly applied to the freezing storage of the mononuclear cells, and has the advantages of good freezing storage effect and cost conservation.

Owner:SHENZHEN BEIKE BIOTECH

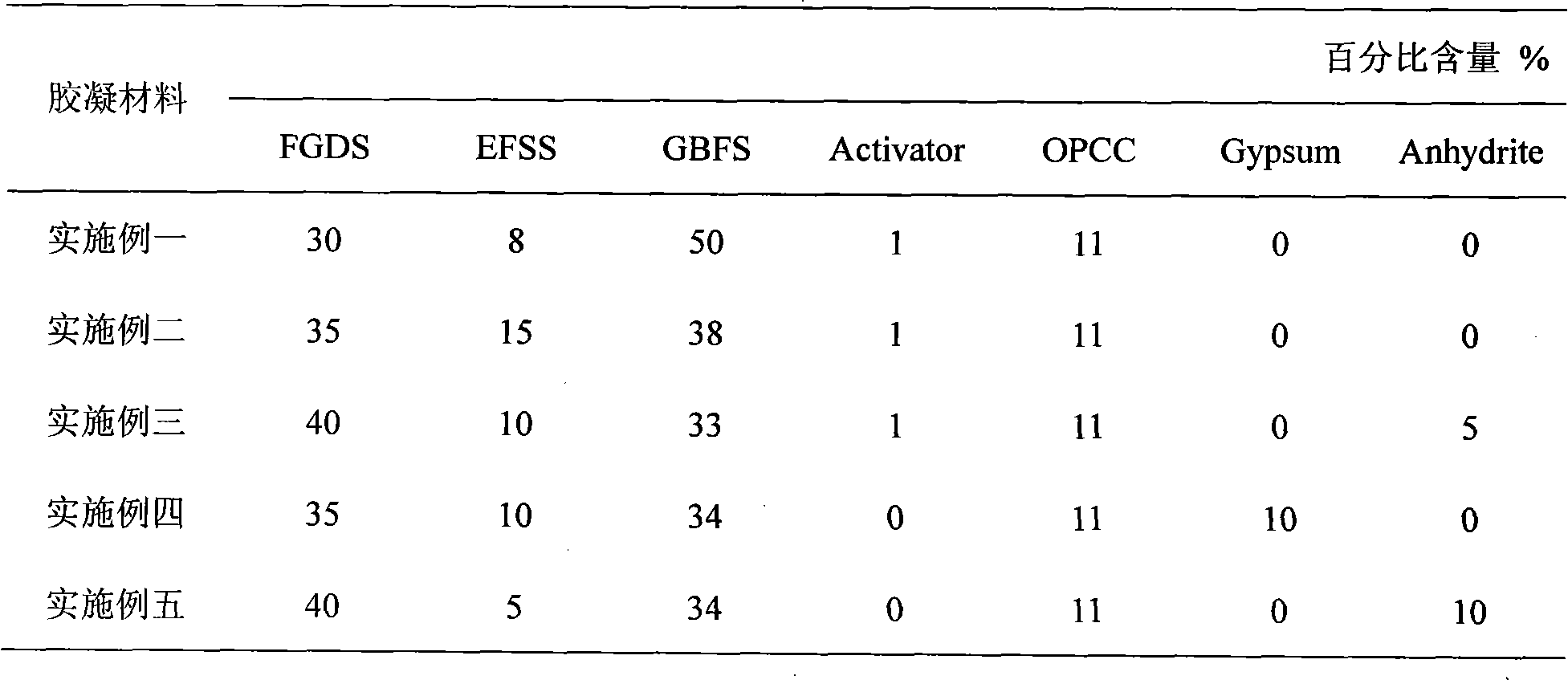

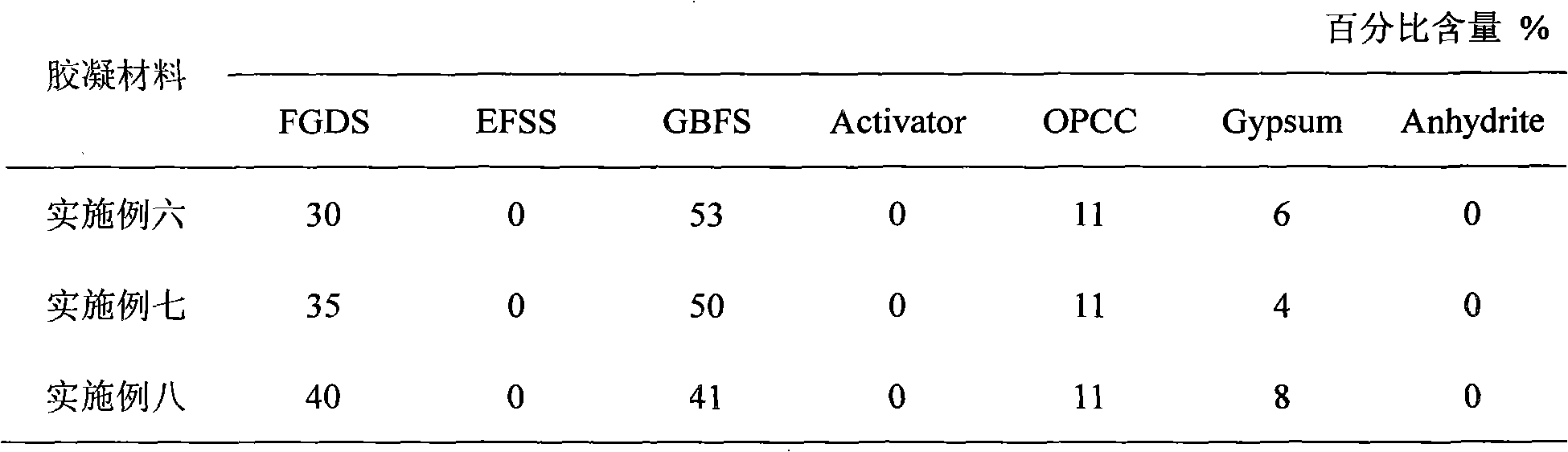

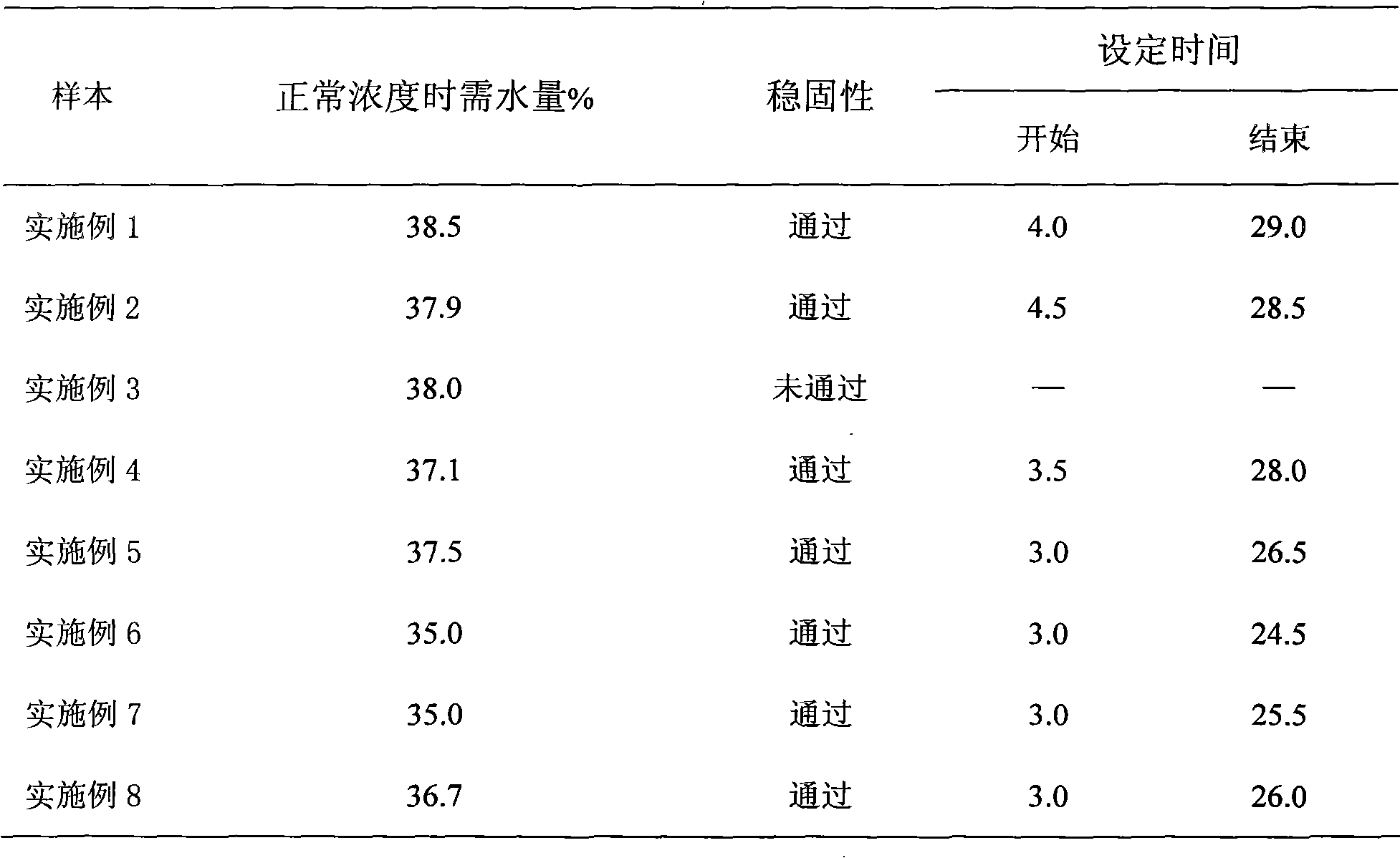

Silt curing agent and preparation method thereof

InactiveCN102060428ARealize waste utilizationReduce pollutionSludge treatment by de-watering/drying/thickeningSlagContinuous operation

The invention discloses a silt curing agent and a preparation method thereof. The using amount of the curing agent can be saved and continuous operation is realized simultaneously. The silt curing agent comprises the following components of: 5 to 15 percent of electric furnace steel slag (EFSS), 5 to 15 percent of blast furnace cinder (OPCC), 20 to 45 percent of granulated blast furnace slag (GBFS), 20 to 45 percent of flue gas desulfurization slag (FGDS) and 4 to 16 percent of activator. The preparation method comprises the following steps of: (1) mixing the components and drying in a heating furnace for 3 to 6 hours; and (2) grinding in a grinder in which a backmixing device is arranged, and feeding partial curing agent into a feeding port and mixing with newly added components through the backmixing device. The curing agent can be used for building road base soil or curing silt produced by dredging rivers, lakes, dredged canals to prepare civil materials. The invention has the advantages that: the curing agent is good in curing effect and favorable for environment friendliness, the using amount is saved and the continuous operation can be realized.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

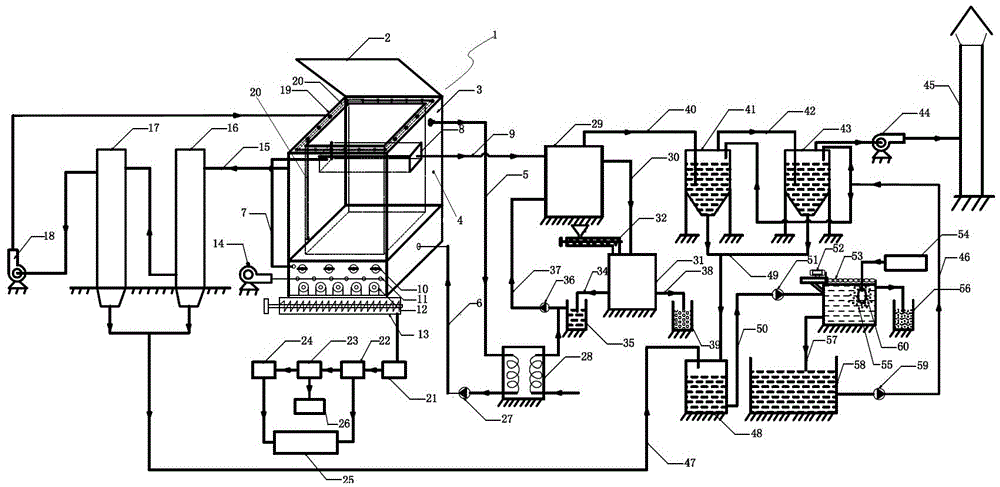

Multifunctional solid waste treatment device and solid waste treatment method thereof

ActiveCN105546548AReduce energy wasteRealize waste utilizationSludge treatment by de-watering/drying/thickeningIncinerator apparatusTarWaste treatment

The invention discloses a multifunctional solid waste treatment device. The multifunctional solid waste treatment device comprises a pyrolysis gasifier. The pyrolysis gasifier comprises a gasifier body and a smoke drying box. A combustible gas storage box is arranged on the top of the gasifier body and communicated with the bottom of the gasifier body. A combustible gas delivery pipe is arranged on the upper portion of the gasifier body and connected with a condensation device, and the condensation device is connected with the combustible gas storage box. A smoke internal delivery pipe is arranged on the lower portion of the gasifier body, the smoke drying box is connected with a waste heat boiler connected with a smoke washing system, and the waste heat boiler is connected with a sludge drying device. The smoke washing system is connected with a sewage pool and a chimney, and the condensation device is connected with the sewage pool. The sewage pool is connected with a tar-water separation system capable of separating tar and water. The invention further provides a solid waste treatment method. By means of the device and the method, solid waste can be completely treated, combustion is complete, smoke is exhausted after reaching the standard, and meanwhile sludge treatment capacity is achieved.

Owner:深鹏环保工程有限公司

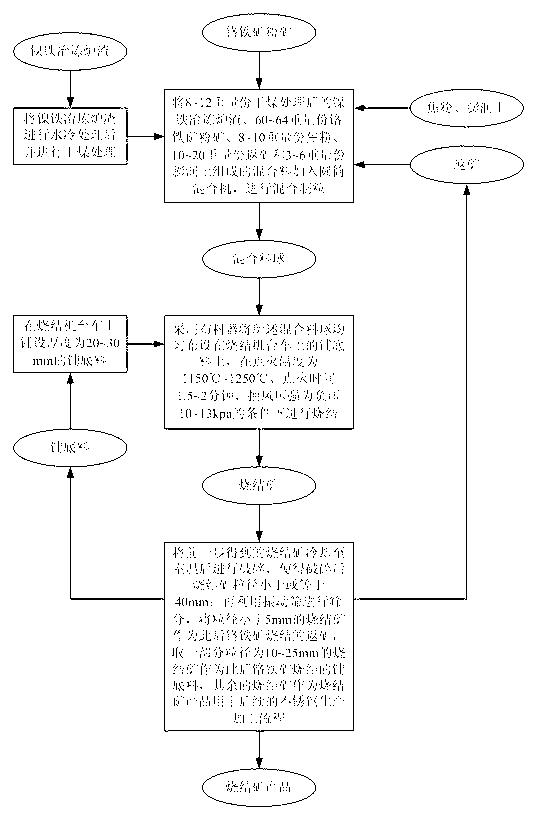

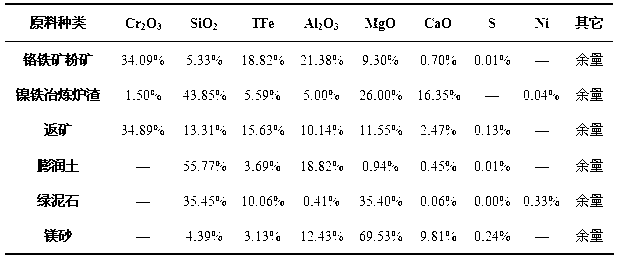

Method for sintering chromite powder recycled based on ferronickel smelting furnace slag

The invention provides a method for sintering chromite powder recycled based on ferronickel smelting furnace slag. According to the method, the chromite powder is added with the ferronickel smelting furnace slag and then is granulated and sintered, so that the sintering temperature of the chromite can be reduced, the liquid phase amount is increased, the carbon proportion can be decreased, the yield and the strength of the sintered ore are improved, the difficult chromite powder sintering problem is solved, the energy consumption for the production is reduced simultaneously, an expensive solvent is unnecessary, and the obtained sintered product is a nickel-chromium-iron alloy which can be directly applied to the stainless steel production and does not increase a subsequent smelting slag discharge process of the stainless steel production. Compared with the chromite sintering process in the prior art, the method has the advantages that the coke proportion is low, the sintering temperature is low, the quality of the sintered ore is high, the ferronickel smelting furnace slag is effectively recycled and the production cost is low, the waste utilization in the nickel alloy production process is realized, the total cost of the stainless steel production is reduced, the economic benefit of enterprises is increased, and the energy conservation and emission reduction pressure of the enterprises is relieved.

Owner:CHONGQING UNIV

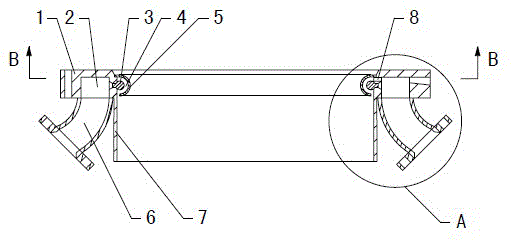

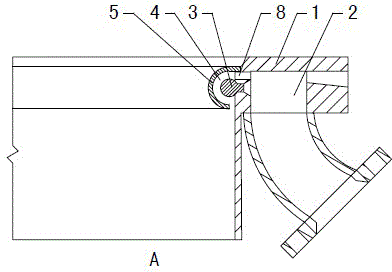

Method for repairing chilling ring of gasifier

The invention relates to a technique of repairing a chilling ring of a waste coal water slurry gasifier. The method for repairing the chilling ring of the gasifier comprises the steps that an original outer ring tube is cut down from the inner ring of a cavity base; lathe turning is carried out on a water outlet of a water distribution hole on the inner ring of the cavity base, impurities on the lathe turning surface are removed by abrasive blasting, a thickness removed by the lathe turning is made up by spray welding, and a new water distribution hole is drilled in the inner ring of the cavity base; impurities on washed parts of the outer surface of a water distribution inner ring are removed by the abrasive blasting, and an original size of the water distribution inner ring is recovered through processing and polishing after the spray welding; and a new outer ring tube is fabricated, the outer ring tube is cut into at least three sections which are butt jointed and positioned and fixed to the inner ring of the cavity base, and the outer ring tube is welded on the inner ring of the cavity base. The waste chilling ring is repaired, so an expensive fee for replacing a new chilling ring is saved, production cost of an enterprise is saved, and waste reutilization is realized.

Owner:CHINA PETROLEUM & CHEM CORP

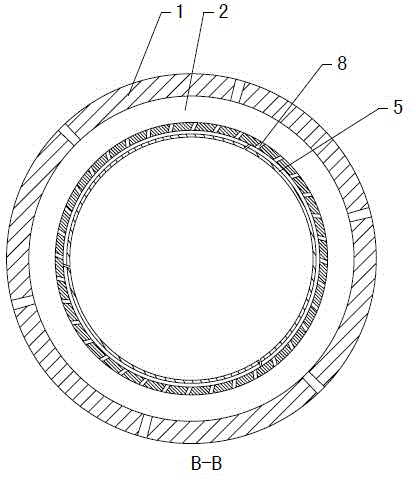

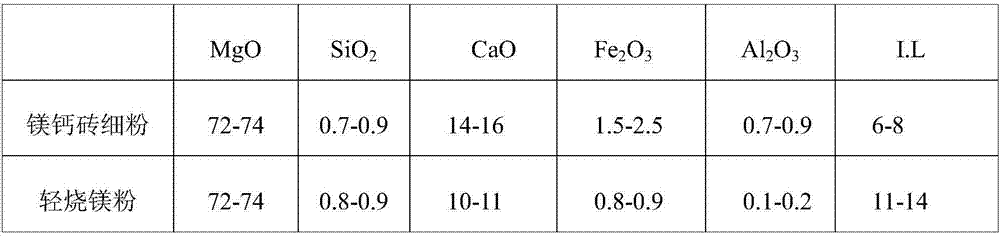

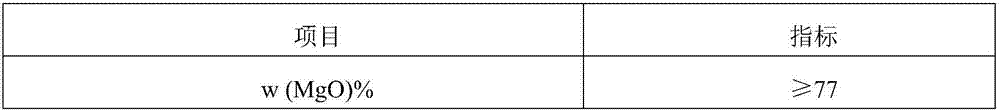

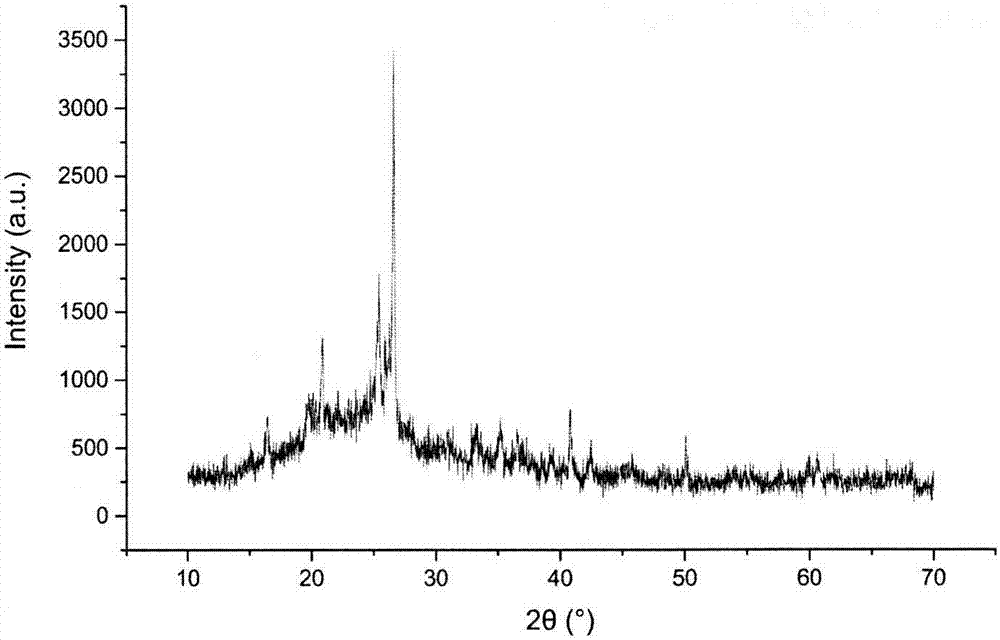

MgO-CaO-Fe2O3 series electric furnace ramming material prepared from fine magnesia-calcium brick powder

InactiveCN107266100ASimple preparation processRealize waste utilizationTitanium dioxideThermal shock

The invention provides a MgO-CaO-Fe2O3 series electric furnace ramming material prepared from fine magnesia-calcium brick powder. The MgO-CaO-Fe2O3 series electric furnace ramming material is prepared from, by weight, 95 or below parts of 0-0.078 mm fine magnesia-calcium brick powder, 50 or below parts of 0-0.078 mm light-burnt magnesia powder, 6 or below parts of iron red, 1-3 parts of MgO micro-powder, 1-5 parts of alpha-Al2O3 micro-powder, 0.5-5 parts of ceramic fibers and 1-1.5 parts of titanium oxide. The fine magnesia-calcium brick powder, the light-burnt magnesia powder and the iron red are adopted as main raw materials, the alpha-Al2O3 micro-powder, MgO, rare earth oxide-containing ceramic fibers and titanium dioxide are added as auxiliary materials, and the fine magnesia-calcium brick powder is used to substitute parts of the light-burnt magnesia powder in the briquetting process; and a preparation technology of the ramming material has the advantages of simplicity, realization of the waste utilization of magnesia-calcium bricks, and improvement of the thermal shock stability and the erosion resistance of the above product.

Owner:辽宁利尔镁质合成材料股份有限公司 +1

Method of resourcefully utilizing sludge containing manganese, aluminum, and iron in water treatment plant

InactiveCN106946434ARealize waste utilizationImplement resourcesSludge treatment by de-watering/drying/thickeningOther chemical processesSludgeSorbent

The invention discloses a method of resourcefully utilizing sludge containing manganese, aluminum, and iron in a water treatment plant. The method comprises the following steps: taking sludge containing manganese, aluminum, and iron in a water treatment plant as the raw material; dehydrating the sludge at first to obtain dry sludge; then adding fly ash obtained in a power plant and sulfuric acid in sequence to carry out an acidifying treatment to obtain an acidified material; then adding kaolin, utilizing sodium silicate to adjust the silicon / aluminum ratio of the silicified material to 1:1, allowing the system to stand still to carry out reactions for 7 days, drying the sludge in the air or baking the sludge to obtain a dry material; heating the dry material to a temperature of 400 to 500 DEG C, burning the dry material for one hour, and naturally cooling the dry material to obtain a material with an adsorbing performance. The wastes are fully utilized. Sludge, fly ash, and cheap kaolin are used to prepare an adsorbent, and the wastes are utilized and converted into resources. The obtained adsorbing material has good adsorption activity, can absorb organic substances, phosphor, and heavy metal ions, and can be directly used in the wastewater / sewage treatment field.

Owner:HEFEI WATER SUPPLY GRP CO LTD +1

Harbor construction sea reclaimed material utilizing silt and preparation method thereof

InactiveCN102617078ASolve the way outSave natural resourcesSolid waste managementNatural resourceUltimate tensile strength

The invention relates to a harbor construction sea reclaimed material utilizing silt, which is prepared by mixing gangue sand, the silt and cement. Water content of the silt is 60%-100%, and the weight ratio of the silt, the gangue sand and the cement is 1: 3-5: 0.04-0.06. A preparation method of the harbor construction sea reclaimed material utilizing silt is further disclosed. The material and the method achieve waste object utilization of the gangue sand and the silt. The material is high in strength, low in construction cost and capable of achieving quick solidification of silt and saving a large amount of natural resources. The material can be applied to projects such as sand quilt blowing filling, filtering guide layers, sand cushion layers and land area backfilling.

Owner:连云港港口工程设计研究院有限公司

Hippophae rhamnoides jam and preparation method thereof

The invention discloses hippophae rhamnoides jam and a preparation method thereof. The method comprises the following steps of (1) preparing hippophae rhamnoides juice; (2) preparing hippophae rhamnoides pericarp paste; (3) preparing concentrated juice: mixing cucumber juice, apple juice and the hippophae rhamnoides juice at the mass ratio of 1:(2-3):(10-15), and freezing and concentrating until the weight percent of a soluble solid is 30-38%; (4) sterilizing: evenly mixing the separated pulp, pectin, fibers and the hippophae rhamnoides pericarp paste, then conducting pasteurization to obtain a pulp material, and conducting high voltage pulsed electric field sterilization on the concentrated juice to obtain sterile concentrated juice; and (5) taking the following raw materials by weight: 50-70 parts of the sterile concentrated juice, 5-15 parts of the pulp material, 1-5 parts of a stabilizer, and 10-25 parts of a sweetening agent, and mixing the raw materials evenly to obtain the hippophae rhamnoides jam. The hippophae rhamnoides jam prepared through the method is low in loss of nutrients and flavor substances, and is tasty and refreshing.

Owner:新疆慧华沙棘生物科技有限公司

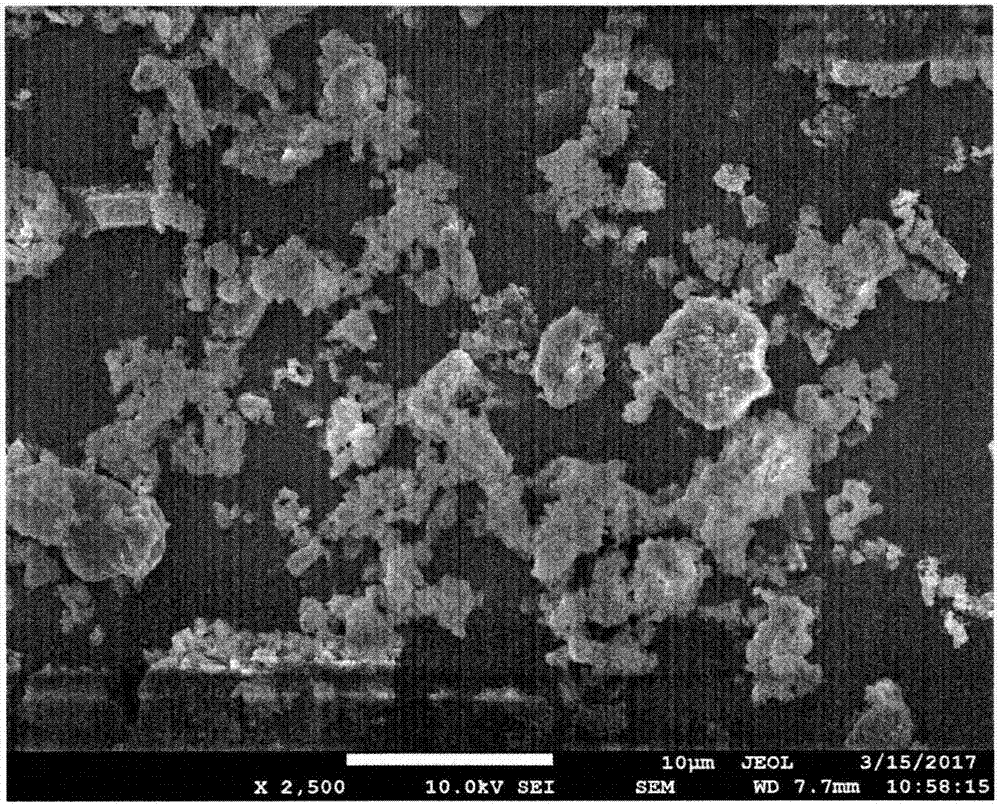

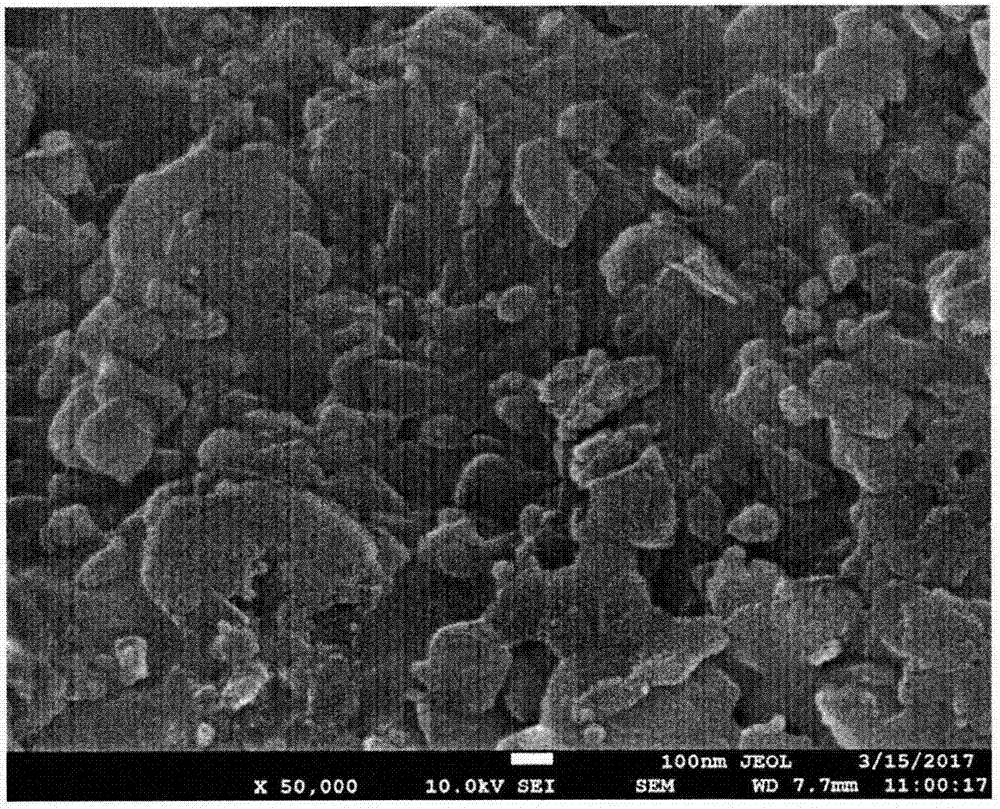

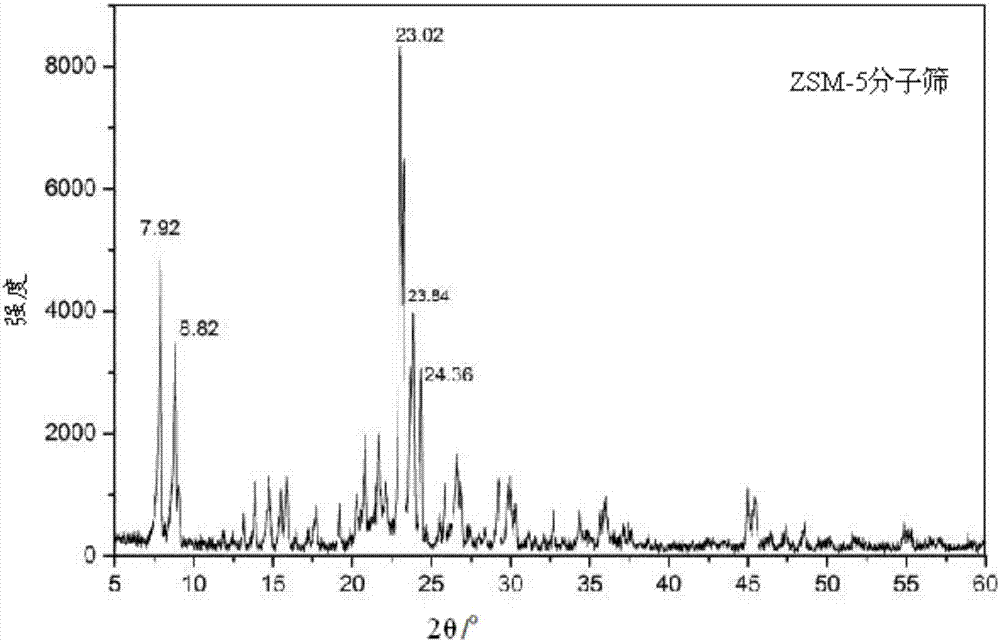

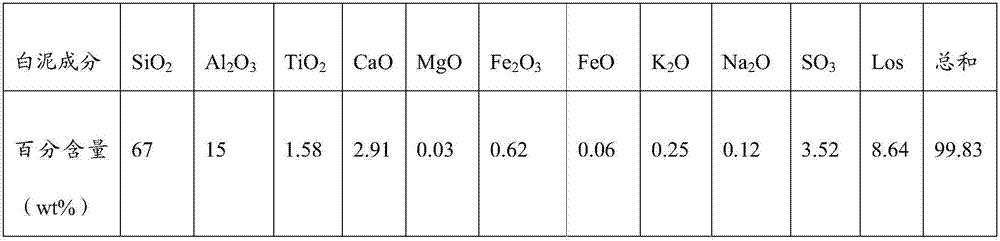

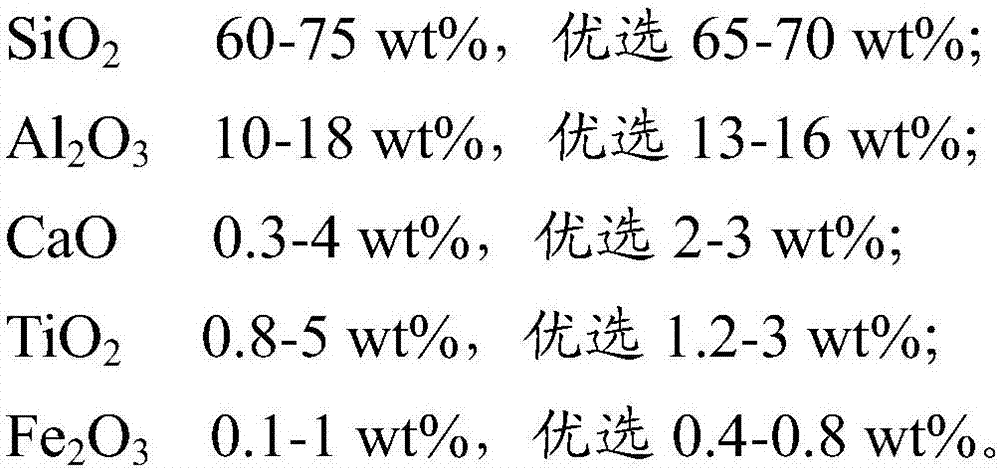

Method used for preparing ZSM-5 molecular sieve taking white mud as raw material, and ZSM-5 molecular sieve

ActiveCN107324357AReduce manufacturing costTake advantage ofMolecular sieve catalystsHydrocarbonsEconomic benefitsBiological activation

The invention provides a method used for preparing ZSM-5 molecular sieve taking white mud as a raw material, and the ZSM-5 molecular sieve prepared via the method. The method comprises following steps: 1, white mud and an activator are subjected to calcining activation so as to obtain a clinker, wherein the activator is sodium hydroxide or anhydrous sodium carbonate; 2, deionized water and a template agent are added into the clinker, and uniform stirring is carried out so as to obtain a silicon-aluminium gel; and 3, the silicon-aluminium gel obtained in step 2 is delivered into a crystallization kettle for crystallization so as to obtain the ZSM-5 molecular sieve. According to the method, white mud is taken as a raw material to prepare the ZSM-5 molecular sieve, full utilization of effective silicon and aluminium in white mud to prepare the ZSM-5 molecular sieve is realized, waste utilization of white mud is realized, the preparation cost of the ZSM-5 molecular sieve is reduced, it is beneficial for improvement of economic benefit and market competitiveness, the preparation method is simple, the obtained ZSM-5 molecular sieve is low in production cost, is high in economic benefit and market competitiveness.

Owner:CHINA SHENHUA ENERGY CO LTD +1

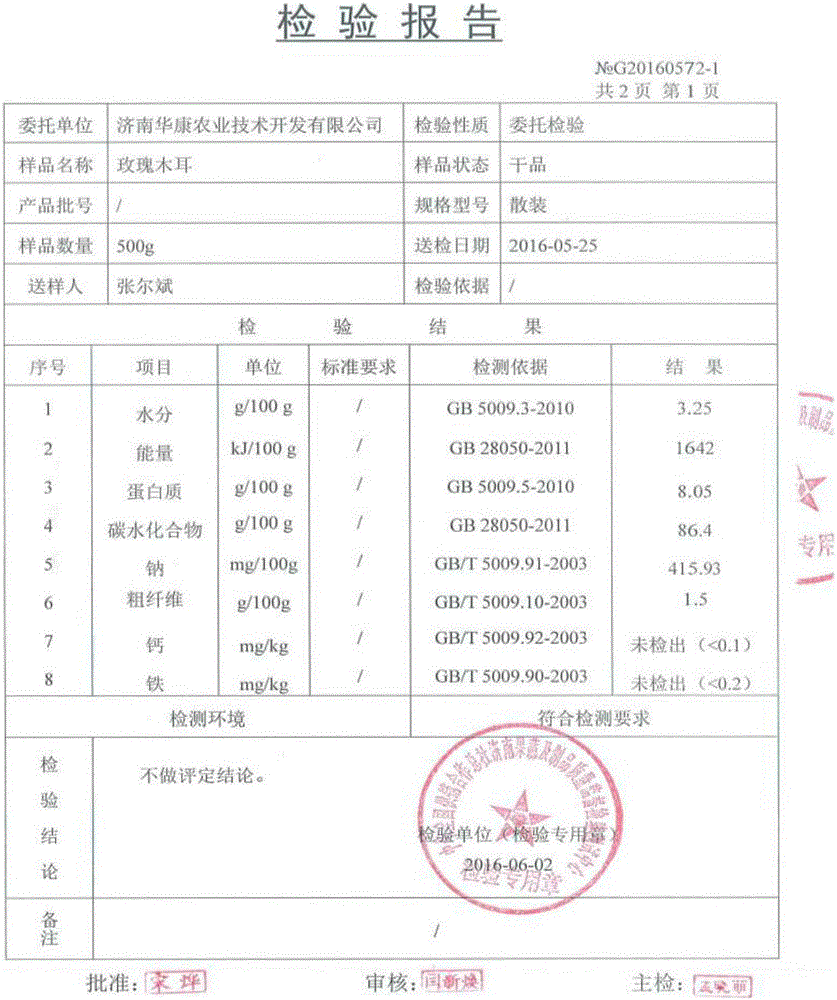

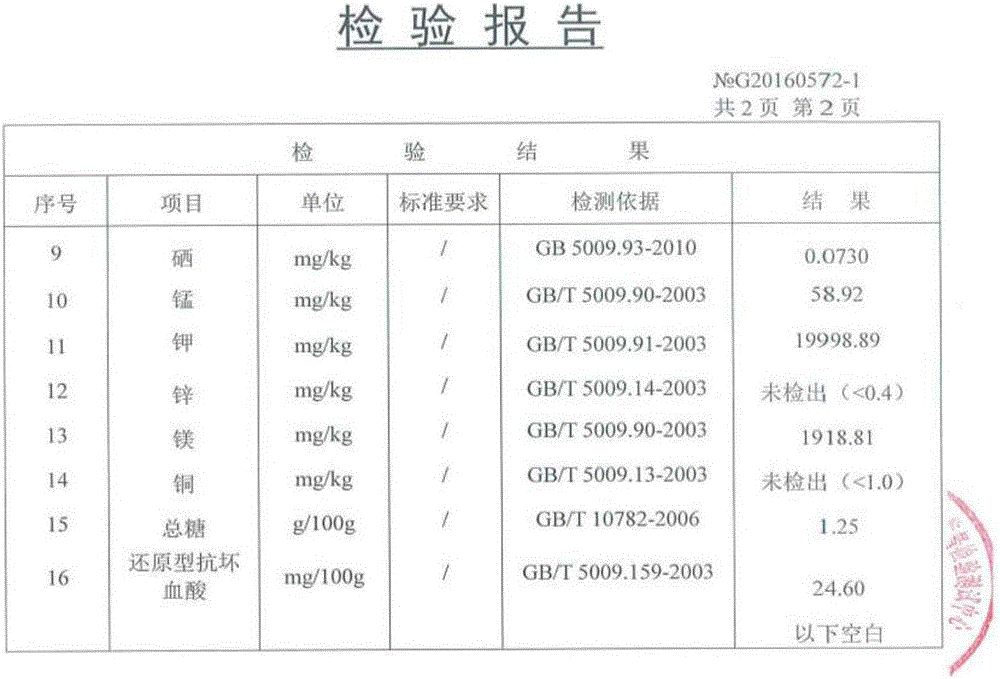

Rose-edible fungus cultivation material and method for cultivating rose-edible fungus

ActiveCN106171521AImprove immunityPreserve natural nutrientsCalcareous fertilisersBio-organic fraction processingSugarAqueous solution

The invention discloses a rose-edible fungus cultivation material and a method for cultivating the rose-edible fungus. A rose-edible fungus cultivation material comprises following material in proportion by weight: 45-55 parts of rose graft wood dust, 5-10 parts of rose flower residue, 25-35 parts of corncob particles, 5-10 parts of calcium-magnesium phosphate, 10-15 parts of wheat bran, 3-5 parts of soybean meal, 3-5 parts of white granulated sugar, 2-3 parts of land plaster, 65-70 parts of fresh rose flower cell sap water solution.

Owner:济南华康农业技术开发有限公司

Preparation method and application of natural plant dye solution of Phytolacca acinosa berries

InactiveCN102127309AIncrease the variety of dyeingRaise the gradeNatural dyesDyeing processChemistryWool

The invention provides a preparation method and application of a natural plant dye solution of Phytolacca acinosa berries. The preparation method comprises the following steps: cleaning Phytolacca acinosa berries, draining, and grinding to obtain Phytolacca acinosa berry pulp; adding water to the Phytolacca acinosa berry pulp (the weight ratio of the Phytolacca acinosa berry pulp to the water is 1:(3-6), immersing at normal temperature under sealed conditions for 1-2 hours, and leaching once or twice; and merging the leaching solutions, and filtering to obtain the natural plant dye solution of Phytolacca acinosa berries. The application method comprises the following steps: dyeing fabric by a chrome-free dyeing, pre-chrome dyeing, metachrome dyeing or after-chrome dyeing process, taking out the fabric, flushing with water and drying in the shade. The natural dye is extracted from the waste Phytolacca acinosa berries and used for dyeing the fabric, thereby recycling the waste Phytolacca acinosa berries, increasing the dyeing types of textiles and enhancing the grade of the textiles, and is especially suitable for dyeing silk fabric and wool fabric. The preparation method and dyeing technique of the natural plant dye solution are simple, and have very broad market prospects.

Owner:YANCHENG INST OF IND TECH +2

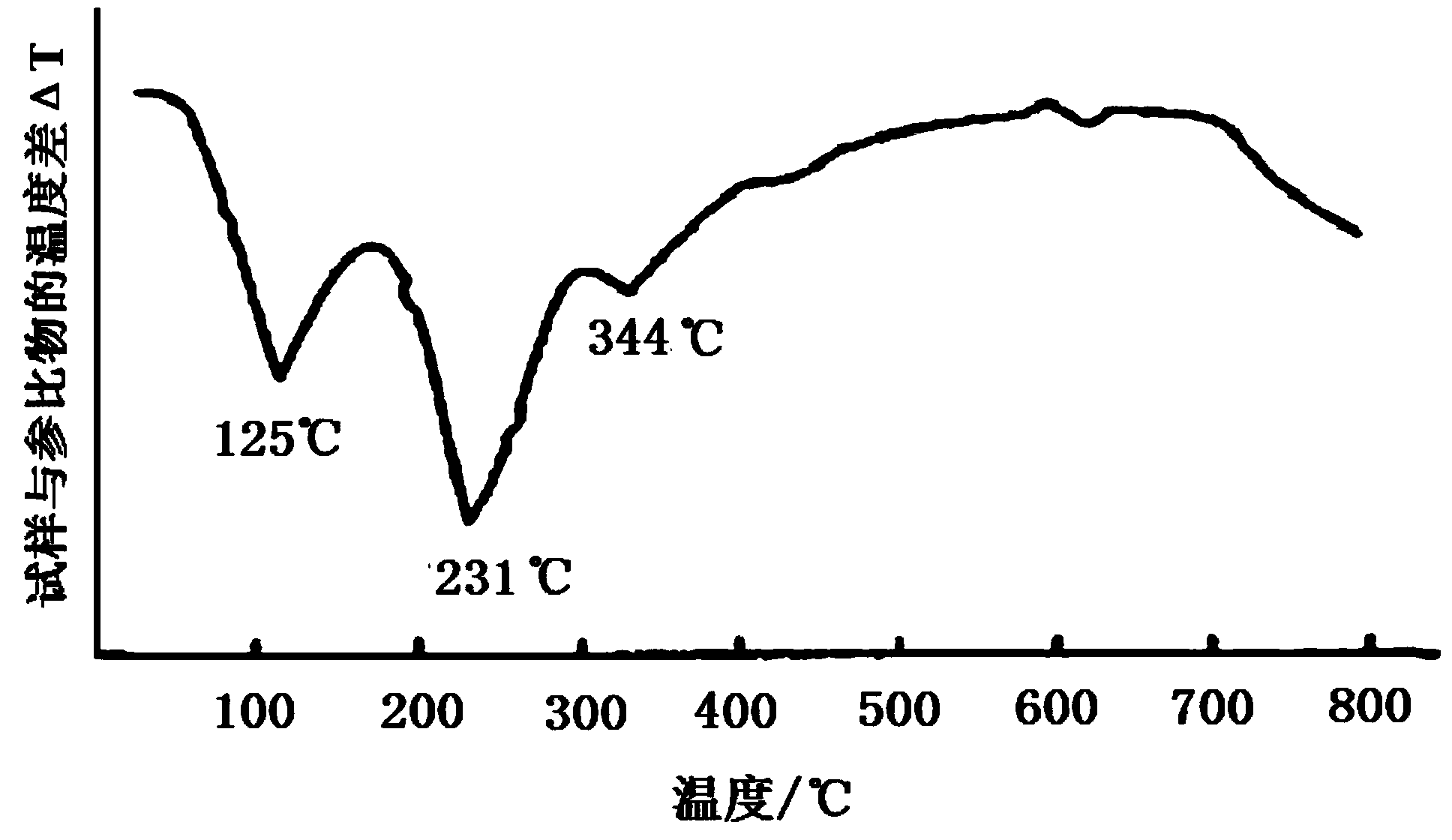

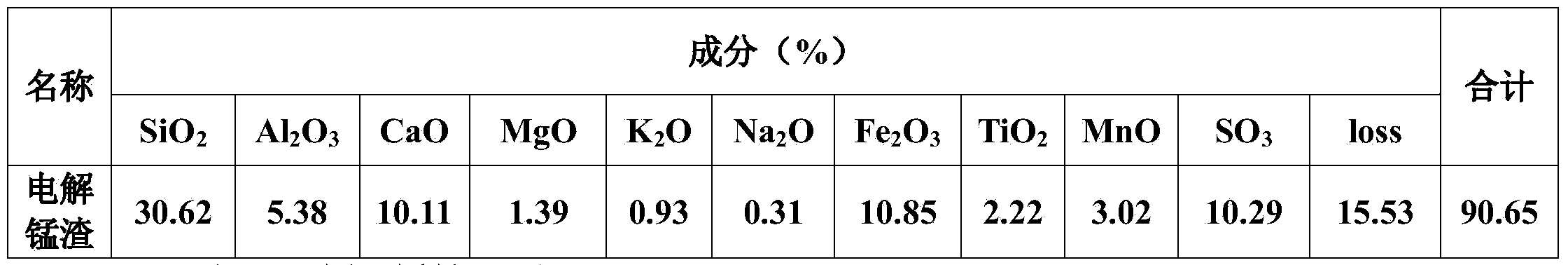

Method for preparing cement admixture by use of electrolytic manganese residue and product and application

InactiveCN104030583ARealize waste utilizationAchieve governanceCement productionElectrolysisPortland cement

The invention discloses a method for preparing a cement admixture by use of electrolytic manganese residue and a product and an application. The method comprises the following steps: breaking the electrolytic manganese residue into the particle size of 5-15mm; calcining the broken electrolytic manganese residue in a fluidized-bed furnace for 1-1.5 hours at 450-750 DEG C to obtain the cement admixture. The obtained cement admixture can be applied to the preparation of cement, namely that the cement is prepared by grinding 5-50% of cement admixture and 95-50% of Portland cement clinker by weight. Through the invention, waste utilization and comprehensive treatment of the electrolytic manganese residue can be realized.

Owner:贵州省工业固体废弃物综合利用(建材)工程技术研究中心

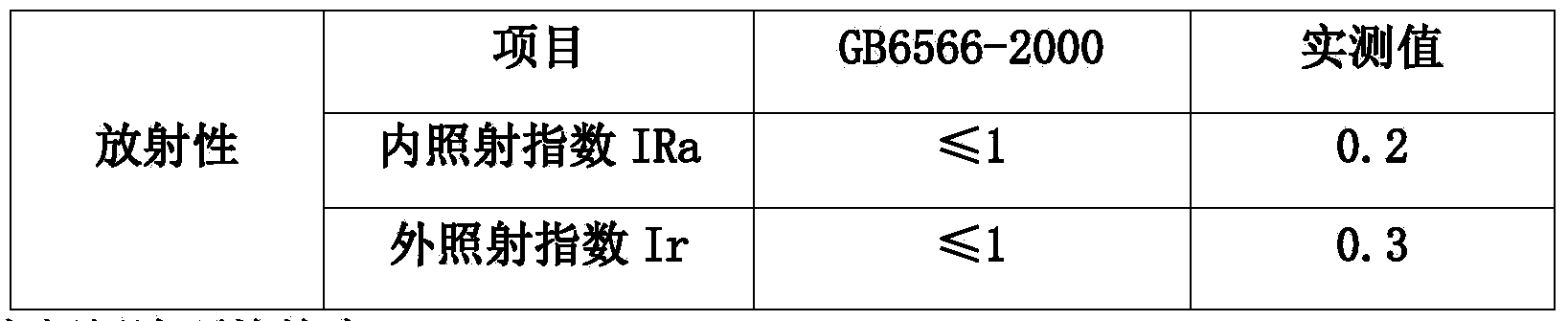

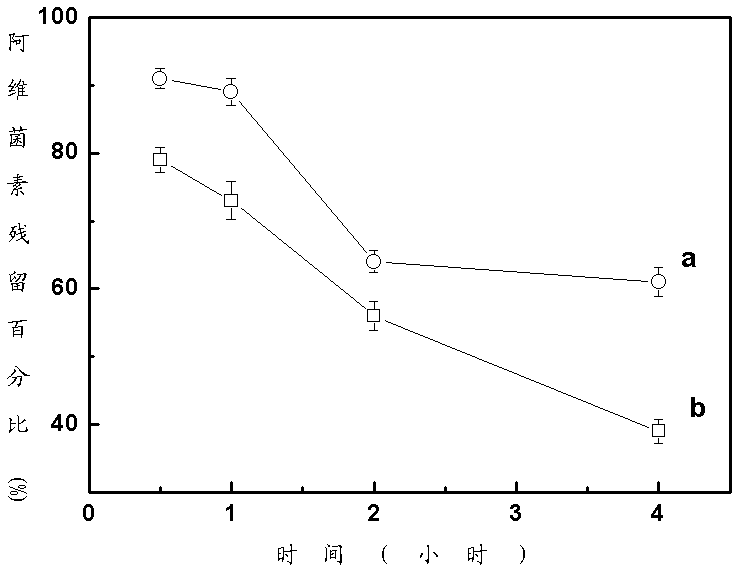

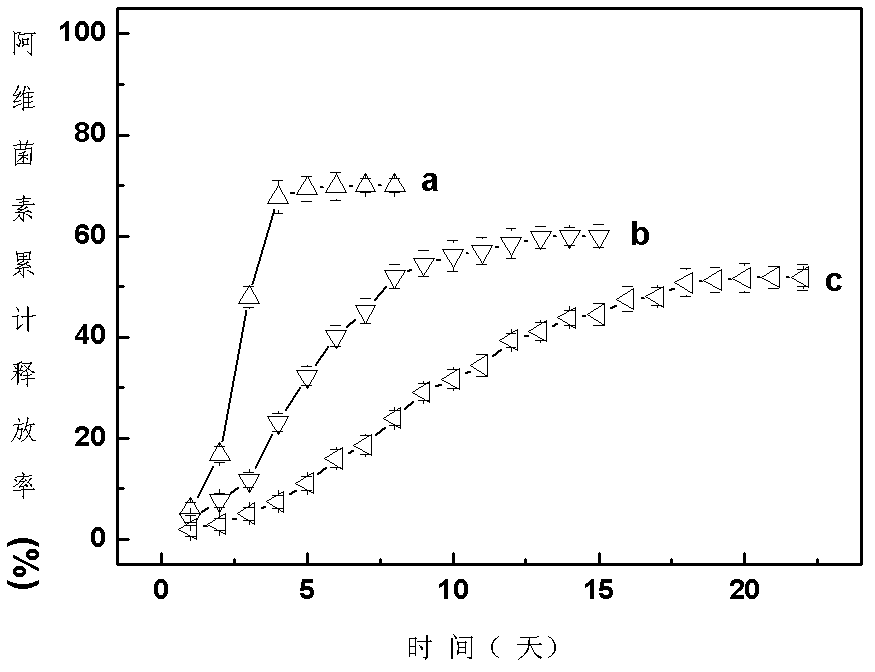

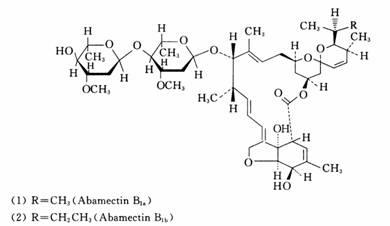

Abamectin-cyanobacteria anti-ultraviolet sustained-release microcapsule insecticide and preparation method thereof

ActiveCN102273447ALow toxicity to humans and animalsRealize waste utilizationBiocideAnimal repellantsAbamectinUltraviolet lights

The invention discloses an abamectin-cyanobacteria anti-ultraviolet sustained-release microcapsule insecticide and a preparation method thereof. In parts by weight, the components and contents thereof are: 0.5-50 parts of abamectin, 5 parts of blue-green algae powder -50 parts, surfactant 1-20 parts, easily degradable polymer 0.5-20 parts. The present invention utilizes blue-green algae as a pesticide carrier to adsorb abamectin, and relies on its own natural properties to delay the decomposition of abamectin due to ultraviolet light, and can be used as an organic fertilizer to increase production of crops to realize waste utilization of pollutants; secondly, using The degradable polymer is used as the coating agent, which is beneficial to environmental protection. Thirdly, the controlled release of abamectin is achieved by using the slow-release technology, which reduces the toxicity of abamectin to humans and animals.

Owner:SHANGHAI NORMAL UNIVERSITY

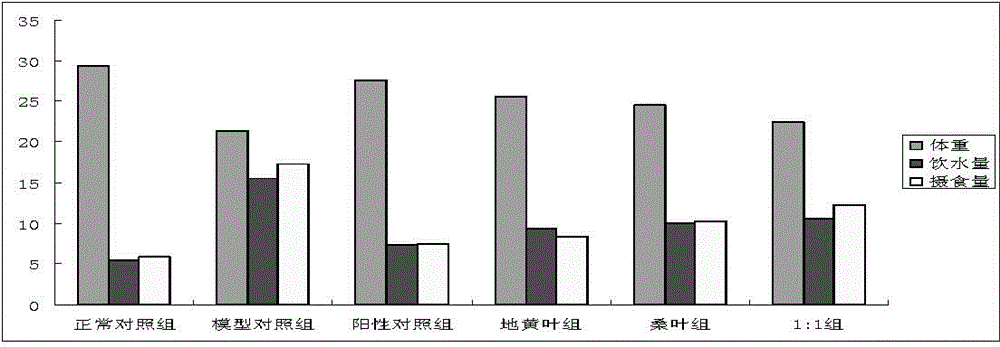

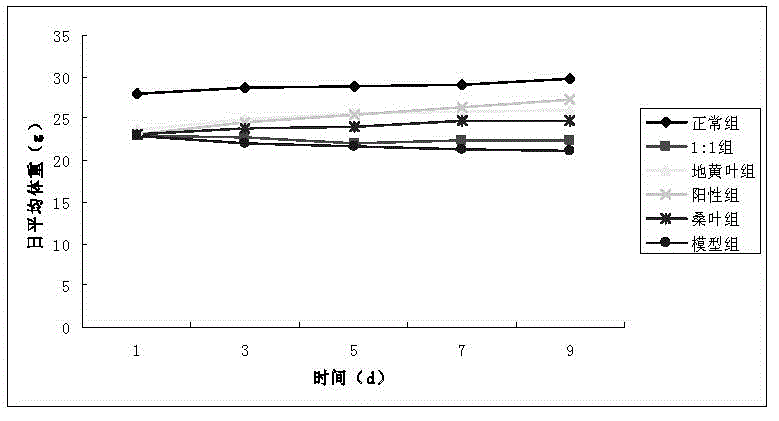

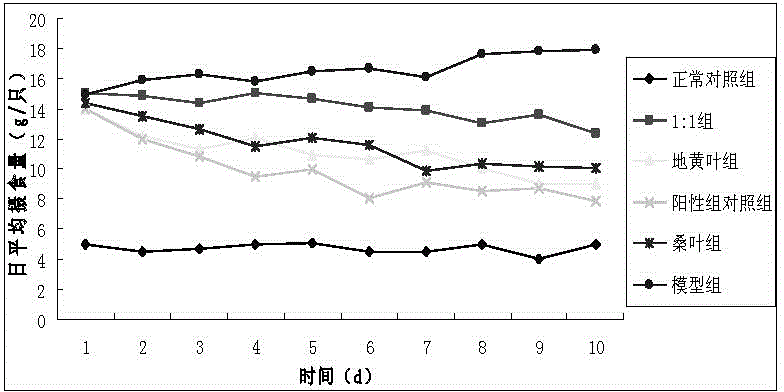

Application of radix rehmanniae leaf extract in preparation of blood glucose-reducing medicines

InactiveCN104666585ARealize developmentRealize waste utilizationMetabolism disorderPlant ingredientsBiotechnologyPharmaceutical drug

The invention relates to application of a radix rehmanniae leaf extract in preparation of blood glucose-reducing medicines and can effectively solve the problem of drug use for treatment of diabetics. The preparation method comprises the following steps: adding 10-12 times of water based on weight of radix rehmanniae leaves into the radix rehmanniae leaves to extract twice, 1-1.5 hours every time; combining extraction liquids twice; concentrating the extraction liquids at a reduced pressure to a concentration liquid containing 0.5-2 g / ml of crude drugs at 55 DEG C; adding 95% by mass of ethanol into the concentration liquid, wherein the alcohol concentration reaches 60-80%; leaving to stand for 24 hours; taking a supernate; concentrating the supernate at a reduced pressure to a concentration liquid containing1-4.5g / ml of crude drugs at 55 DEG C; then separating and purifying by using an H103 resin column; then, elutingwith 10-20% by mass of ethanol as an eluent; cololecting the eluant; concentrating the eluant at a reduced pressure; drying to obtain the extract. According to the invention, the raw materials are abundant, the preparation method is simple, easy to operate and stable and reliable, and the radix rehmanniae leaf extract in any quantity can be industrially produced. The radix rehmanniae leaf extract can be effectively utilized to prepare the blood glucose-reducing medicines, so that the radix rehmanniae leaves are comprehensively developed and wastes are utilized, and a novel path of preparing the blood glucose-reducing medicines is explored.

Owner:HENAN UNIV OF CHINESE MEDICINE

Low-energy-consumption sintering water seepage bricks and manufacturing method thereof

ActiveCN106747620AIncrease profitAvoid damageCeramic materials productionCeramicwareBrickHigh carbon

The invention belongs to the technical field of building materials, and specifically relates to water seepage bricks, in particular to a low-energy-consumption sintering water seepage brick using industrial waste residues as a main raw material and a manufacturing method of the low-energy-consumption sintering water seepage brick. The low-energy-consumption sintering water seepage brick comprises the following raw materials in parts by weight: 50-70 parts of blast furnace granulated slags, 20-50 parts of coal gangue, 2-5 parts of a solubilizer, 2-5 parts of a plastifier and 2-10 parts of a binder. According to the low-energy-consumption sintering water seepage brick disclosed by the invention, the blast furnace granulated slags and the coal gangue are compounded to prepare the sintering water seepage brick, so that the utilization rate of the blast furnace granulated slags can be effectively increased, the recycling clean high-value utilization of solid waste is realized, and the trash utilization and the sustainable development of resources are realized. According to the low-energy-consumption sintering water seepage brick disclosed by the invention, a granulate stacking method and a hole making agent method are united for use, and loose porous structure of the blast furnace granulated slags and high-carbon-content coal gangue can be used as a hole making agent, so that the intensity is guaranteed, besides, the opening communication hole rate can be increased as much as possible, the infiltrability is improved, and the water seepage brick with high permeability is manufactured.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

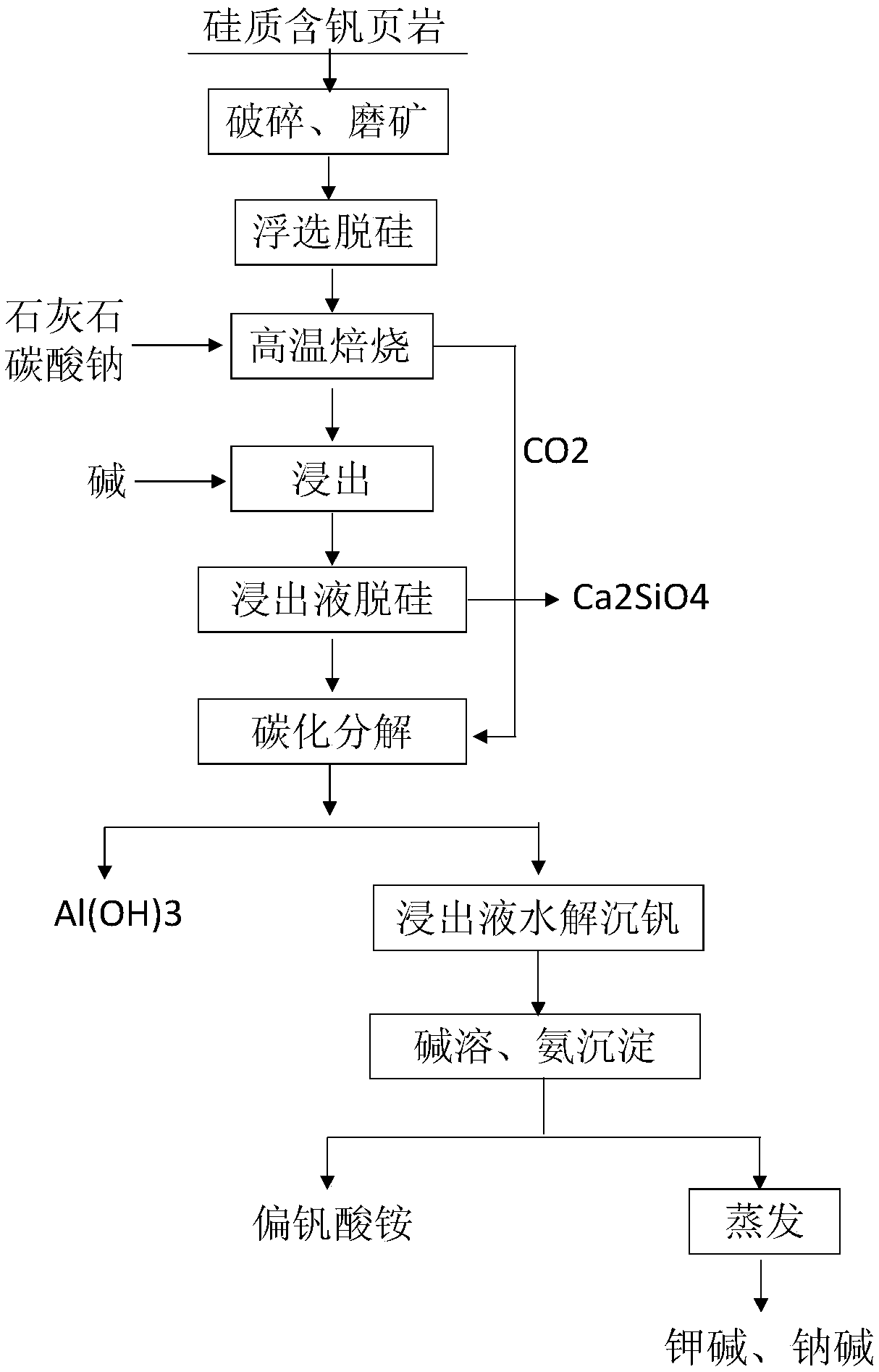

Beneficiation-metallurgy combination process with function of comprehensive recovery for vanadium, aluminum, potassium and silicon in vanadium-containing siliceous shale

ActiveCN107586947ARaise the gradeReduce manufacturing costAlkaline-earth metal silicatesProcess efficiency improvementCarbonizationPotassium

The invention relates to the field of beneficiation and metallurgy with a function of comprehensively recovering valuable components such as vanadium, aluminum, potassium and silicon from the vanadium-containing siliceous shale as a raw material. The process comprises steps as follows: the low-grade vanadium-containing siliceous shale is taken as the raw material, firstly, the vanadium-containingsiliceous shale is desiliconized with a flotation method, vanadium ore concentrate is uniformly mixed with excessive limestone and sodium carbonate, a mixture is subjected to high-temperature roastingin a rotary kiln, and products such as potassium aluminate, potassium ferrite, calcium metavanadate, calcium orthosilicate, carbon dioxide and the like are obtained; the sintered products are dissolved in a dilute alkaline solution, after a dissolution solution is desiliconized and purified, carbon dioxide gas produced by the rotary kiln is introduced into a closed container for carbonization reaction, Al(OH)3 precipitates are separated out, a dealumination solution is subjected to hydrolytic precipitation under the acidic condition, coarse vanadium is obtained and dissolved with alkali, ammonium chloride is added, ammonium metavanadate is obtained, a final solution is a potassium-rich and sodium-rich solution and evaporated step by step, and potash and soda are obtained. According to theinvention, the problem of environmental pollution produced by stockpiling of stone coal leaching residues is solved completely.

Owner:CENT SOUTH UNIV

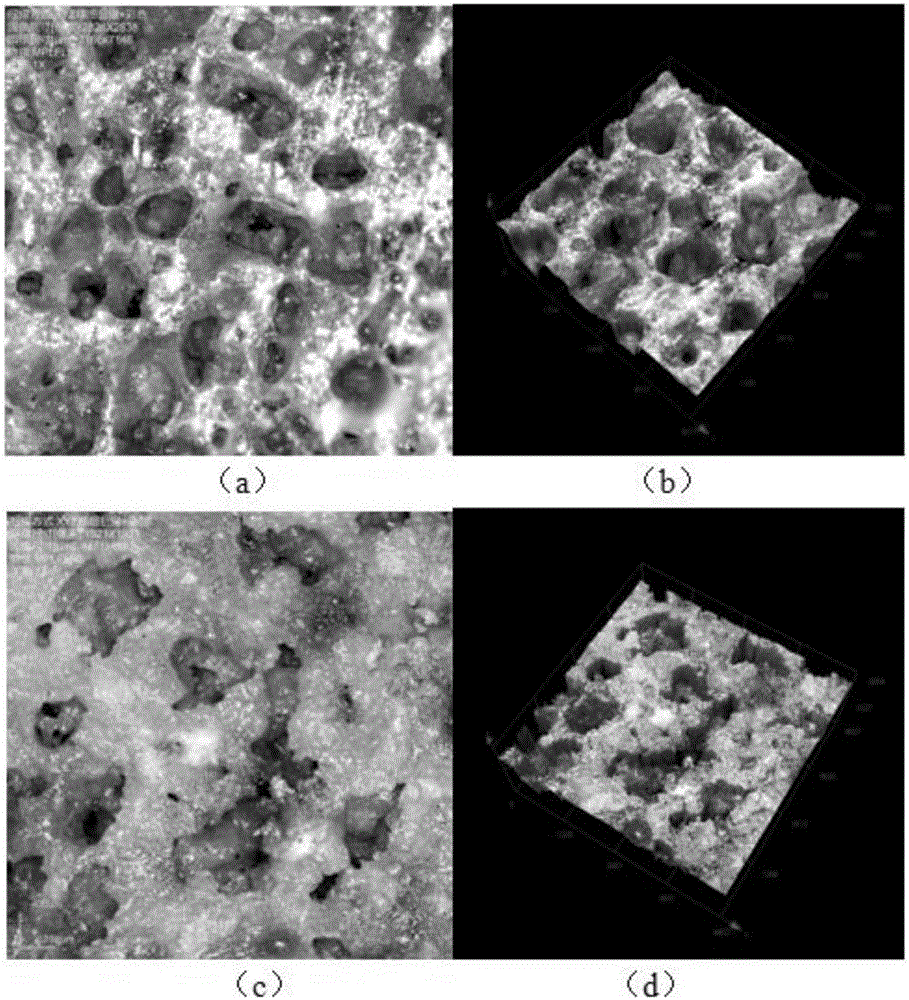

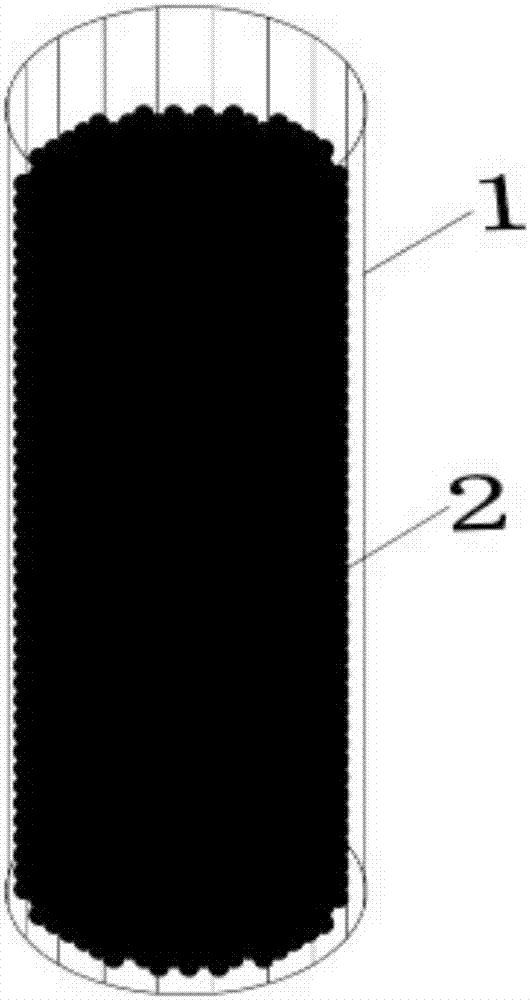

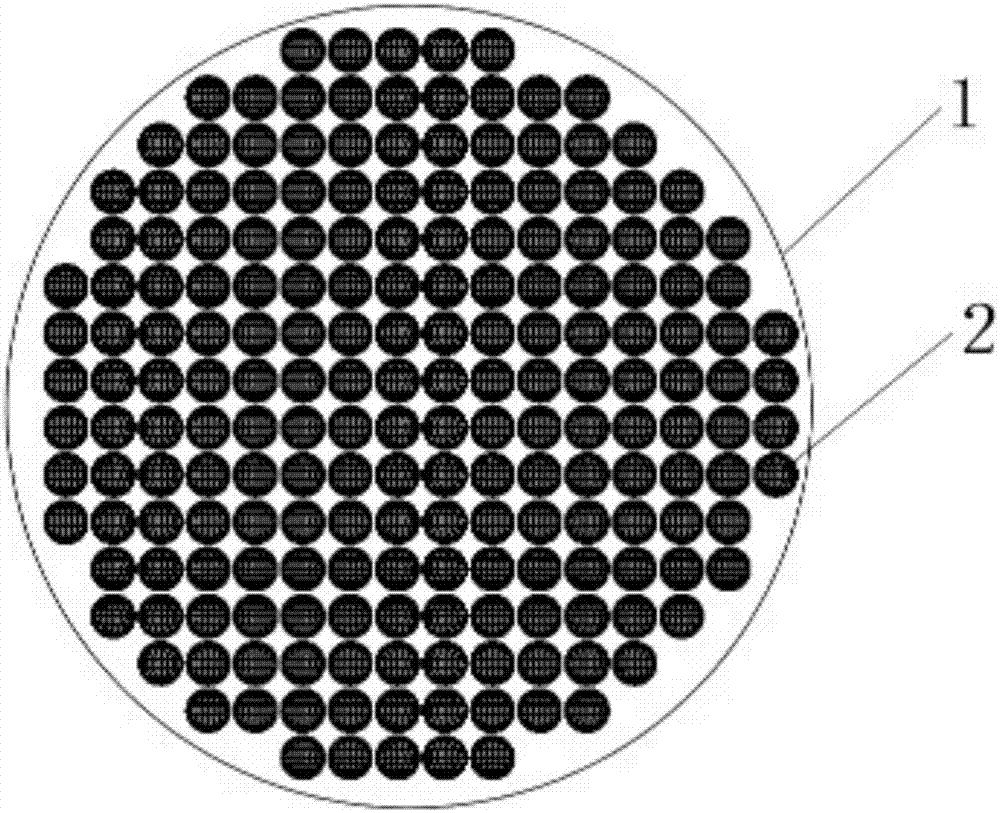

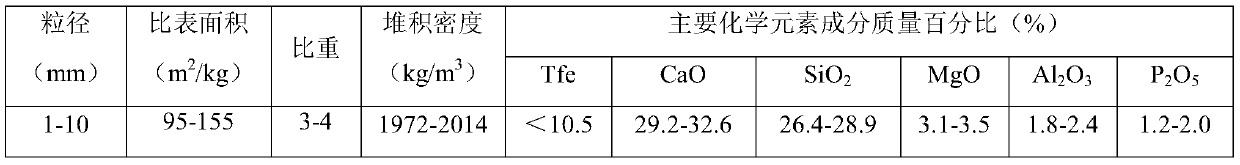

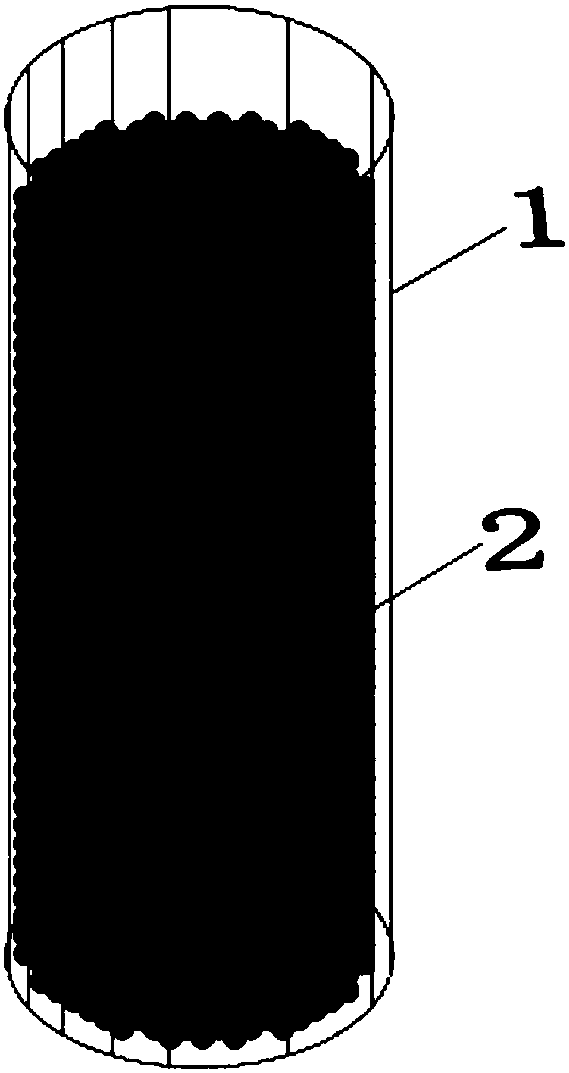

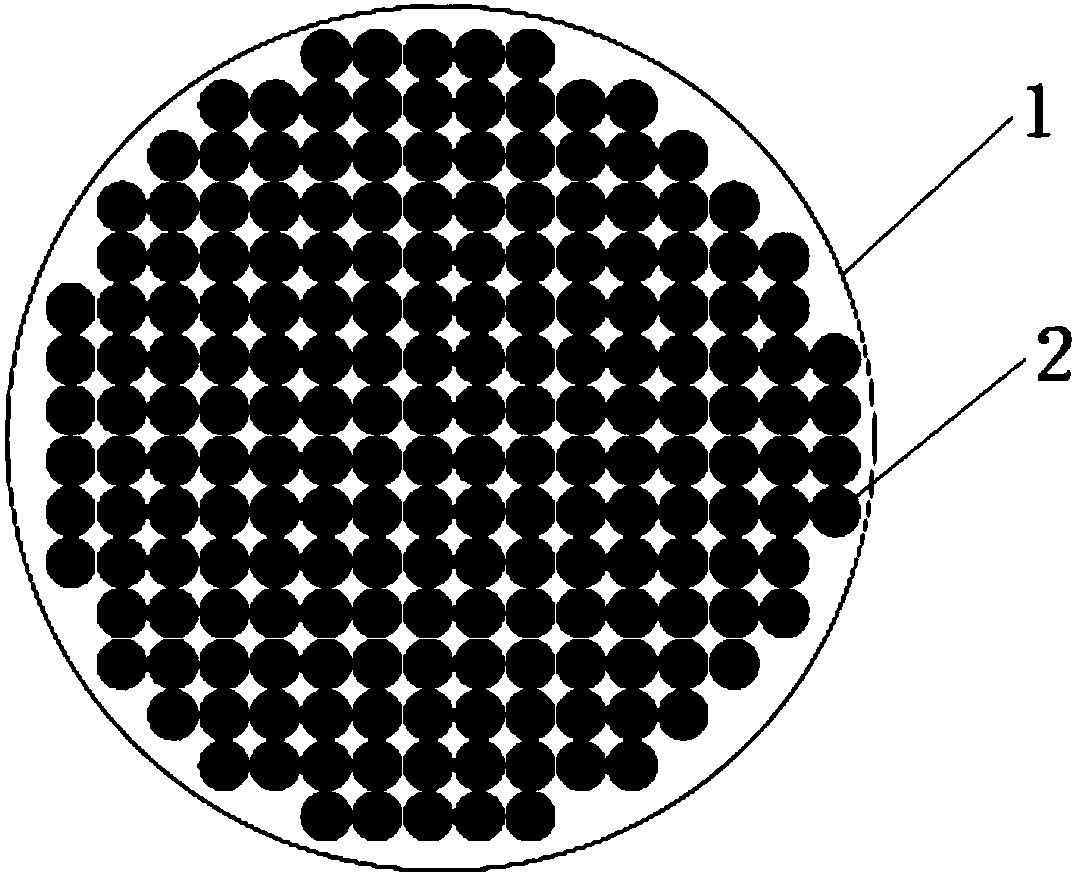

Sludge-based micro-pore framework capturing mesh wall and method for repairing heavy-metal pollution of underground water

ActiveCN106975435ARealize waste utilizationImprove reduction efficiencyOther chemical processesWater contaminantsSludgeEngineering

The invention relates to a sludge-based micro-pore framework capturing mesh wall and a method for repairing heavy-metal pollution of underground water and belongs to the technical field of environmental engineering. The invention aims at providing the sludge-based micro-pore framework capturing mesh wall which takes modified sludge as a foundation and the method for repairing the heavy-metal pollution of the underground water, which can be used for carrying out targeting reduction and adsorption aiming at a target on heavy-metal pollutants in the underground water. The sludge-based micro-pore framework capturing mesh wall provided by the invention is characterized in that a capturing mesh wall is composed of a plurality of stereoscopic capturing modules; each stereoscopic capturing module is formed by a core region and a membrane wall through compounding, wherein each core region is a sludge-based micro-pore framework hard ball carrying nano Fe (0) and each membrane wall is a sludge-coal pitch carbonized membrane; the sludge-based micro-pore framework hard balls carrying the nano Fe (0) are filled into the sludge-coal pitch carbonized membranes to form the cylindrical stereoscopic capturing module.

Owner:山西青舟环境科技有限公司

Environmental protection mechanism fuel production method

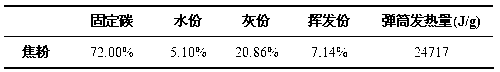

The invention relates to an environmental protection mechanism fuel production method. The method comprises the steps that waste of semi-coke or anthracite or coke is adopted for being prepared into carbon dust through crushing, an adhesive is added in carbon dust, the mixture is stirred to be uniform, forming is performed through a forming machine, drying is performed, and environmental protection mechanism fuel is obtained. Due to the fact that the semi-coke or the anthracite or the coke is adopted as the raw material to manufacture, carbonization is not needed, new waste is not produced inthe mechanism fuel preparation process, the cost is low, no toxicity or smoke exists, waste utilization is achieved, the environmental protection is facilitated, and by means of detection, all indexesconform to relevant standards of the country.

Owner:NINGXIA PAGODA CHEM CENT LAB CO LTD

Building material utilizing seabed sludge and preparation method of building material

InactiveCN103145383ASolve environmental problemsSave natural resourcesSolid waste managementWater contentBuilding material

The invention discloses a building material utilizing seabed sludge. The building material is formed by mixing and stirring tailing sand, sludge and a curing agent, wherein the moisture content of the sludge is 60%-100%; the weight ratio of the sludge to the tailing sand to the cement is 1:(1-3):(0.04-0.12). Stones are further added in the building material disclosed by the invention. The invention further discloses a preparation method of the building material. According to the building material utilizing seedbed sludge and the preparation method of the building material disclosed by the invention, the tailing sand can be recycled, the outlet problem of the tailing sand is solved, the environment-friendly problem is saved, the natural resources of sand-stone building materials are saved, the strength is as high as 6MPa and the manufacturing cost is low. The building material disclosed by the invention can be applied to the projects including a cement stabilization layer below a road storage yard, a vacuum preloading working cushion layer, concrete materials, land backfilling and the like.

Owner:连云港港口工程设计研究院有限公司

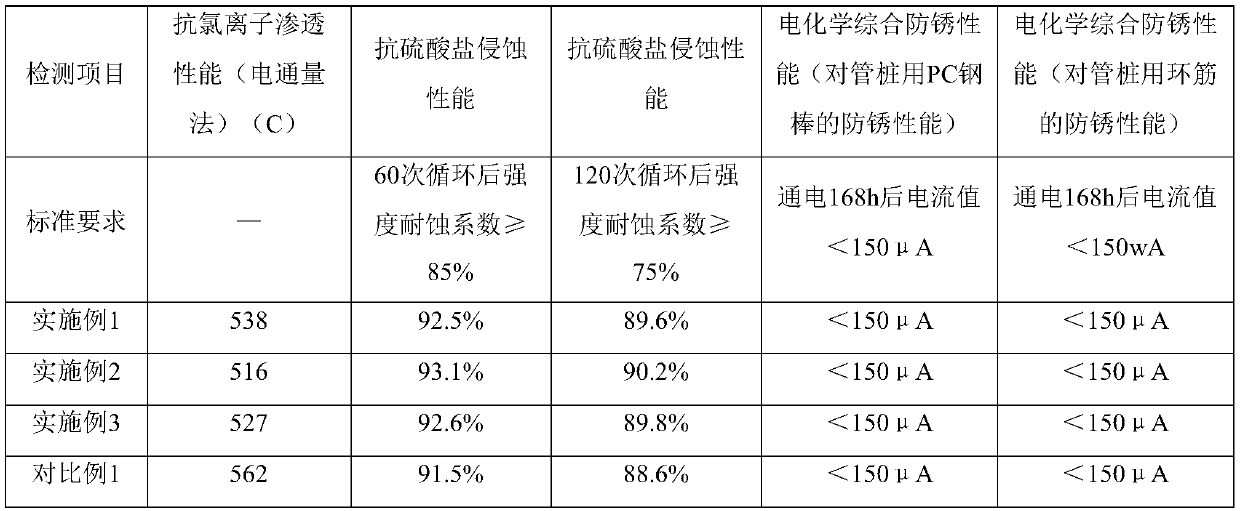

Corrosion resistant PHC pipe pile and preparation method thereof

The invention discloses a corrosion resistant PHC pipe pile and a preparation method thereof. Concrete is prepared from the raw materials in parts by weight: 280-340 parts of cement, 365-425 parts ofstone, 420-480 parts of sand, 250-300 parts of steel slag powder, 15-20 parts of modified hollow glass beads, 140-165 parts of water, 1.5-2.5 parts of a water reducing agent, 75-85 parts of fly ash, 32-40 parts of redispersible powder, 5.5-10 parts of anhydrous aluminium silicate, 2-5.5 parts of an anionic surfactant and 15-20 parts of sodium hydroxide. A silane coupling agent is adopted for modifying hollow glass beads to obtain the modified hollow glass beads; steel slag is subjected to grinding to obtain the steel slag powder, and during grinding, 0.7-1.3% of the mass of the steel slag of acompound grinding aid is added; and the compound grinding aid is prepared from the components in parts by weight: 3-5.5 parts of triethanolamine, 1.5-3 parts of anhydrous sodium sulphate and 1-2 parts of colloidal graphite powder. Preparation of the corrosion resistant PHC pipe pile comprises the steps that concrete preparation, concrete forming and maintenance of warm keeping. The corrosion resistant PHC pipe pile has the characteristics of high corrosion resistance and high strength simultaneously.

Owner:TIANJIN JIANCHENGJIYE GRP

Preparation method of high-specific-surface-area carbon molecular sieve for preparing nitrogen

The invention discloses a preparation method of a high-specific-surface-area carbon molecular sieve for preparing nitrogen. The preparation method includes: sufficiently mixing flower mud materials, coal and phenolic resin, and using the mixture as the raw material. The preparation method has the advantages that the raw material is low in cost, the waste flower mud materials can be utilized, the raw material is low in ash content, and subsequent processing is benefited; by adding graphene during the activating process, the specific surface area of the carbon molecular sieve for preparing nitrogen reaches 3500-4000m<2> / g.

Owner:宁夏天利丰能源利用有限公司

Method for preparing basalt fiber reinforced foam glass

The invention relates to a method for preparing basalt fiber reinforced foam glass. The method includes the following steps that firstly, glass powder and fly ash pass a 200-mesh screen for use; secondly, 70-80 parts by mass of glass powder obtained in the first step, 20-30 parts by mass of fly ash obtained in the first step, 0.151-0.757 part by mass of basalt fiber, 2-6 parts by mass of sodium carbonate, 2 parts by mass of trisodium phosphate, 2 parts by mass of borax and 30-35 parts by mass of water are weighed and evenly mixed to prepare a mixed material; thirdly, the mixed material obtained in the second step is placed in a high-temperature-resistant mould and then vibrated for 5-10 min on a vibrating table; fourthly, the vibrated mould is placed in an oven and dried for 0.5-2 h at 100 DEG C to obtain a blank; fifthly, the blank obtained in the fourth step is fired at 840-850 DEG C, and the basalt fiber reinforced foam glass is obtained.

Owner:SHIHEZI UNIVERSITY

Preparation method of natural zephyranthes grandiflora capsule dye-stuff and application thereof

InactiveCN101880468ARealize waste utilizationSecurity distributionNatural dyesDyeing processEcological environmentOrganic solvent

The invention provides a preparation method of a natural zephyranthes grandiflora capsule dye-stuff and application thereof. The preparation method comprises the following steps: washing, draining and then grinding zephyranthes grandiflora capsules into slurry; adding an organic solvent into the slurry, and then dipping the mixed slurry under a normal-temperature enclosed condition; and merging, filtering and then spray-drying the obtained impregnation liquid to obtain the natural zephyranthes grandiflora capsule dye-stuff. The application method of the natural zephyranthes grandiflora capsule dye-stuff comprises the following steps: firstly taking 10-20% of the natural zephyranthes grandiflora capsule dye-stuff and 2-10% of a mordant based on the mass of the dyed fabric; adding water to form dye liquor with the liquor ratio of 1:45-55; adjusting pH value of the dye liquor to 3-4; and finally placing the fabric fully moistened with hot water into the dye liquor for dyeing at the temperature of 60-80 DEG C for 30-60 minutes. The invention realizes waste utilization of the zephyranthes grandiflora capsules and improves dyeing effect and grade of fabrics, thus being especially applicable to dyeing silk fabrics and ensuring safe wearing of the fabrics; and the invention has the advantages of no any anaphylactic reaction, good ecological environment compatibility, biodegradability, rich raw materials and simple preparation process and simple dyeing process of the dye-stuff.

Owner:YANCHENG INST OF IND TECH

Method for carrying out aerobic composting by utilizing pond sludge

InactiveCN112430168AAchieve maturityDecompose thoroughlyBio-organic fraction processingExcrement fertilisersMicroorganismSoil science

The invention belongs to the technical field of composting treatment, and particularly relates to a method for aerobic composting by using pond sludge. The method comprises the following steps: putting a mixture containing pond sludge, silkworm excrement and mushroom residues as a composting raw material in an environment with initial water content of 40-55% and room temperature for natural fermentation, carrying out primary fermentation to a high temperature of 50-65 DEG C, maintaining the temperature, carrying out irregular turning, supplementing water to 40-55%, continuously conducting heating for secondary fermentation, completing compost maturity within 25-30 days, taking a compost sample, and determining the germination index which can exceed 80% which indicats that the pond sludge is thoroughly matured by the method. Silkworm excrement rich in microorganisms and mushroom residues rich in organic matter are added to serve as a conditioner, aerobic composting decomposition of thepond sludge is achieved, and fertilizer application of the pond sludge is achieved. By adopting the pond sludge, various nutrients can be supplied to crops, a plough layer can be thickened, the physical properties of soil can be improved, and the fertilizer retention capacity of the soil can be improved.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

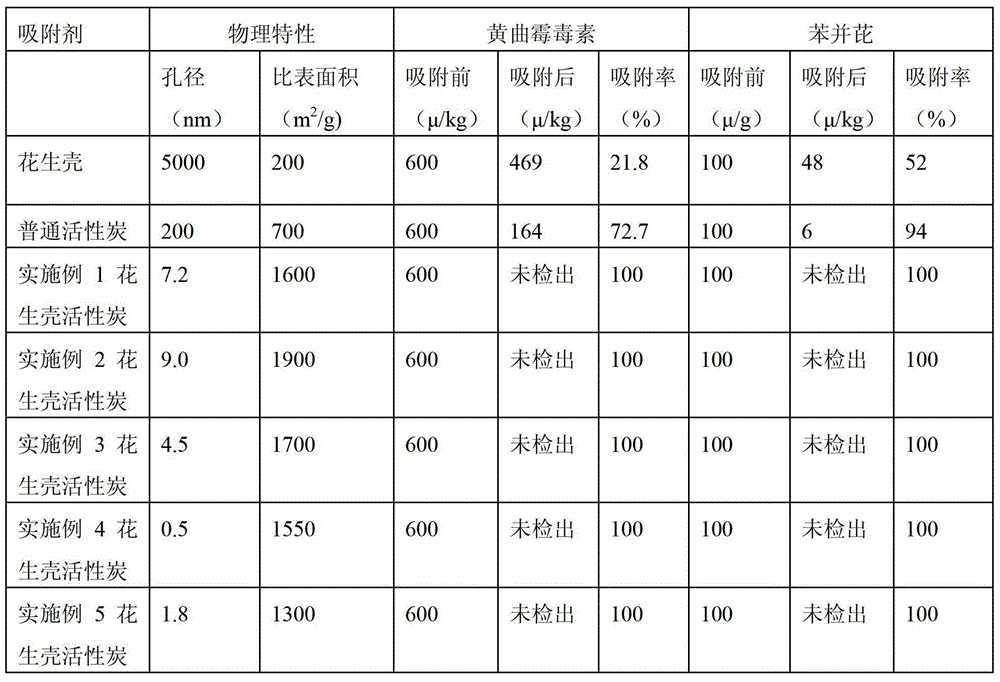

Peanut shell activated carbon for removing toxins in peanut oil and preparation method thereof

InactiveCN103224236BSmall apertureLarge specific surface areaCarbon compoundsActivated carbonHazardous substance

The invention belongs to the technical field of activated carbon, and particularly relates to a peanut shell activated carbon for removing toxins in peanut oil and a preparation method thereof. The peanut shell activated carbon is prepared by carrying out pretreatment, extrusion molding, carbonization and activation on peanut shells. The preparation method comprises the following steps: pretreatment: carrying out hydrothermal treatment on the peanut shells, and pulverizing; extrusion molding: carrying out pressure molding with a granulator to obtain cylindrical granules of which the diameters are 4-8 mm and the lengths are 10-20 mm; heating, cooling in the absence of oxygen, crushing and screening to control the granule diameters at 1-3 mm; and introducing isothermal superheated vapor, storing in a sealed environment, and cooling to obtain the finished product. The activated carbon is prepared from the peanut shells which are accessible raw materials, thereby implementing utilization of waste peanut shells; and the obtained peanut shell activated carbon has the advantages of large specific area and small pore size, can simultaneously adsorb benzopyrene, aflatoxin and other harmful substances, and can prevent the peanut oil from oxidative rancidity.

Owner:山东沂蒙山花生油股份有限公司

Harbor construction land reclamation material composition prepared from silt

InactiveCN108726927ASolve environmental problemsSave natural resourcesSolid waste managementClimate change adaptationWater contentSurface-active agents

The invention relates to a harbor construction land reclamation material composition prepared from silt. The composition is prepared by mixing the following raw materials in weight proportion: 1 to 5of silt, 1 to 5 of tailing sand, 1 to 5 of carbon residue, 0.04 to 0.06 of cement and 0.004 to 0.006 of non-ionic surface active agent, wherein a water content of the silt is 70 to 90%, and the non-ionic surface active agent is chosen from high-carbon fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether or fatty acid polyoxyethylene ester. By means of the composition disclosed bythe invention, waste use of the tailing sand and silt is achieved. The composition disclosed by the invention has the advantages of high strength and low construction cost; furthermore, quick solidification of the silt is achieved, and a lot of natural resources are saved. The composition disclosed by the invention can be applied to projects of hydraulic reclamation of sand, a filter guiding layer, a sand cushion layer, land area backfill and the like.

Owner:连云港港口工程设计研究院有限公司

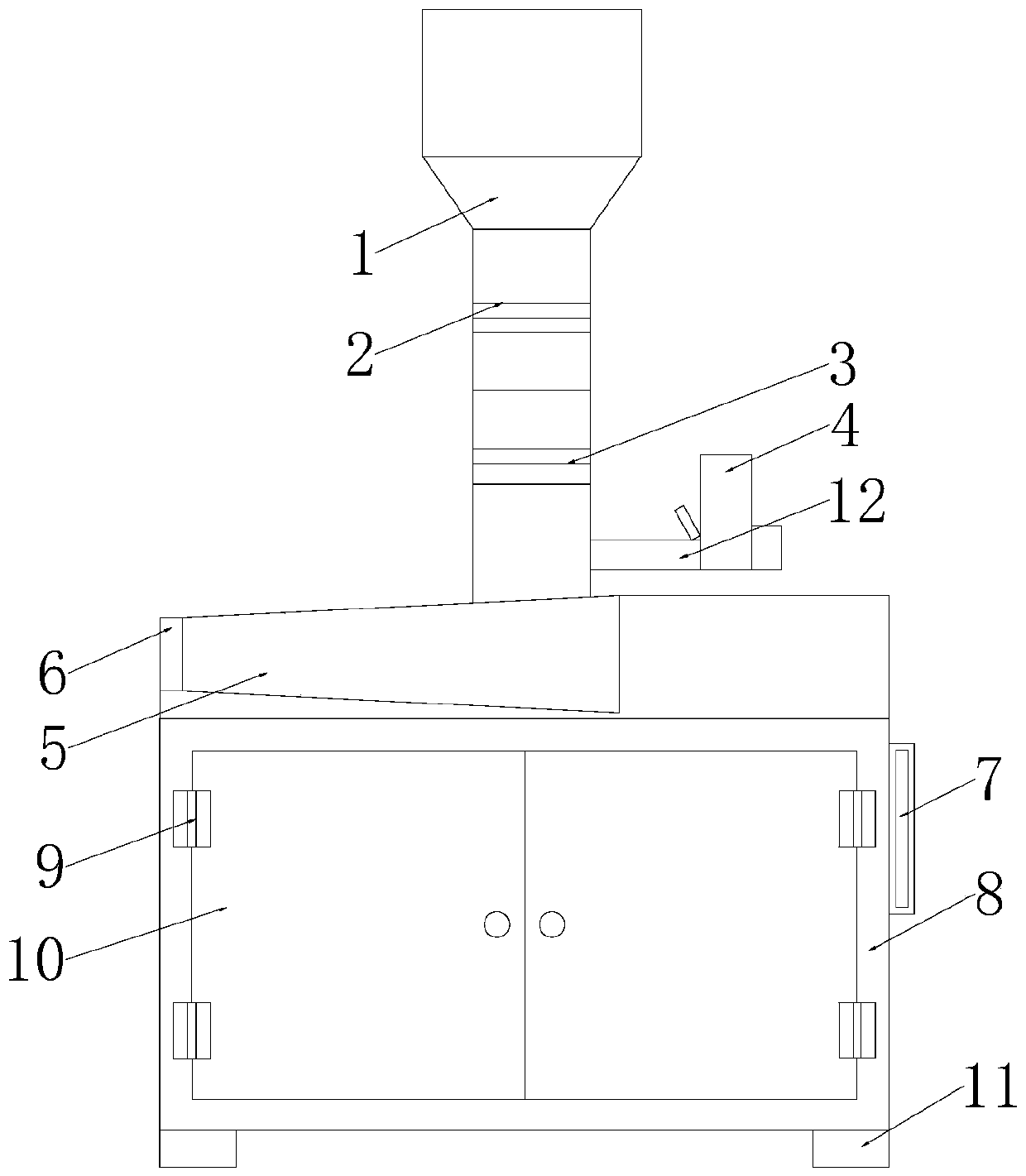

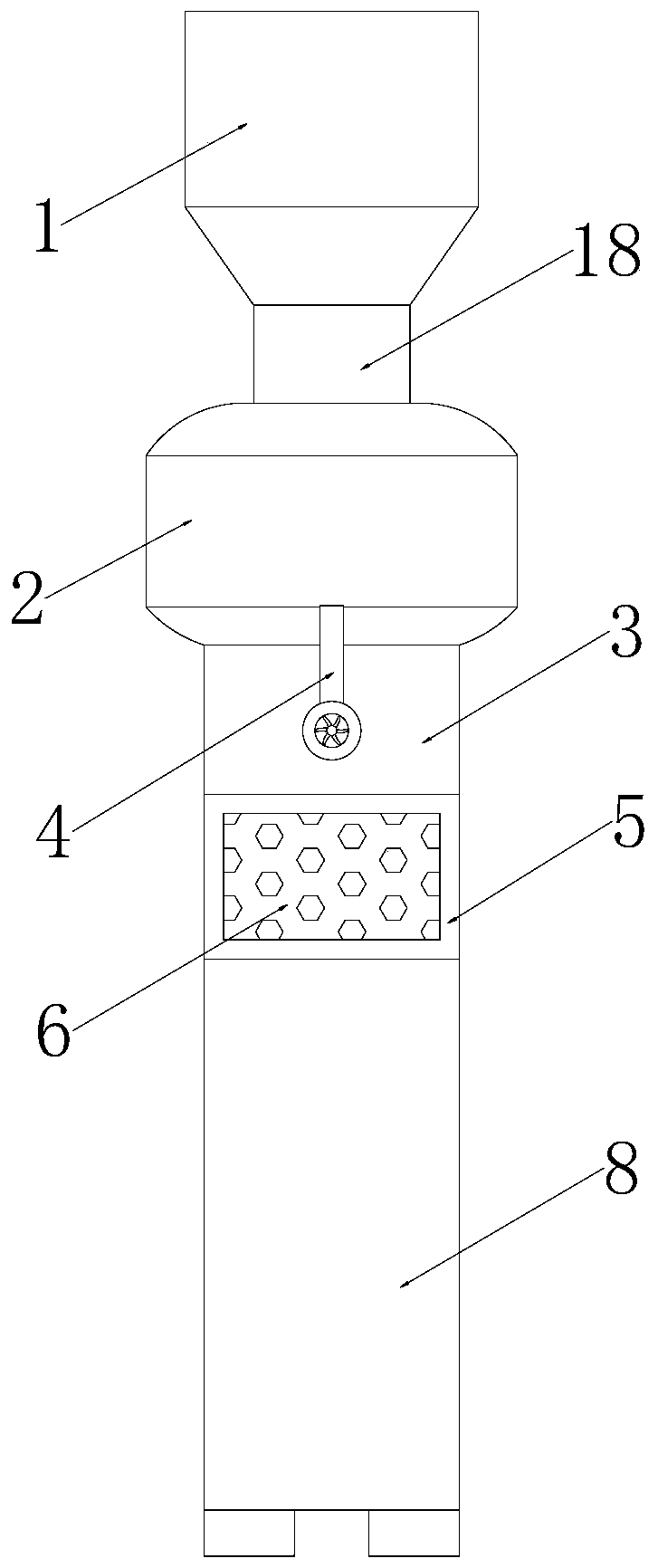

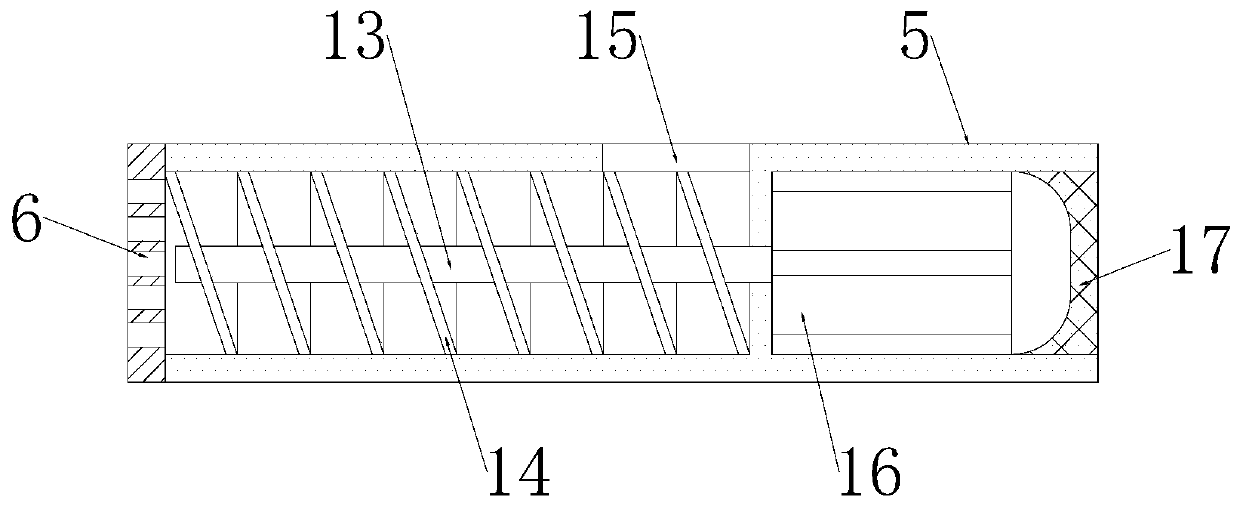

Household garbage disposal machine

PendingCN110142282ASolve storage difficultiesRealize waste utilizationFeeding-stuffTransportation and packagingEngineeringCrusher

The invention discloses a household garbage disposal machine which comprises a bearing box, wherein a support foot pad is mounted at the bottom of the bearing box; a movable door is mounted on the side face of the bearing box; a controller is mounted on one side of the bearing box; a feeding box is mounted at the top of the bearing box; a motor is mounted in the feeding box; a radiating net is mounted on one side of the motor; a rotary rod is mounted on the other side of the motor; a spiral blade is arranged on the side face of the rotary rod in an embedded manner; and a porous plate is mounted at one end of the rotary rod and is welded with the feeding box. Through arranging a crusher, a drying cavity, a warm air blower and the feeding box, the household garbage disposal machine solves the following problems: in general, household garbage is not poured until being accumulated to certain amount, peculiar smell is generated when the household garbage is heaped indoors for a long time toaffect the life of a user, and resource waste is caused and the environment is polluted when certain household waste is directly discarded.

Owner:江苏建中环保科技有限公司

Sludge-based microporous frame capture net wall and method for remediating groundwater heavy metal pollution

ActiveCN106975435BRealize waste utilizationImprove reduction efficiencyOther chemical processesWater contaminantsSludgeNetwork architecture

The invention relates to a sludge-based micro-pore framework capturing mesh wall and a method for repairing heavy-metal pollution of underground water and belongs to the technical field of environmental engineering. The invention aims at providing the sludge-based micro-pore framework capturing mesh wall which takes modified sludge as a foundation and the method for repairing the heavy-metal pollution of the underground water, which can be used for carrying out targeting reduction and adsorption aiming at a target on heavy-metal pollutants in the underground water. The sludge-based micro-pore framework capturing mesh wall provided by the invention is characterized in that a capturing mesh wall is composed of a plurality of stereoscopic capturing modules; each stereoscopic capturing module is formed by a core region and a membrane wall through compounding, wherein each core region is a sludge-based micro-pore framework hard ball carrying nano Fe (0) and each membrane wall is a sludge-coal pitch carbonized membrane; the sludge-based micro-pore framework hard balls carrying the nano Fe (0) are filled into the sludge-coal pitch carbonized membranes to form the cylindrical stereoscopic capturing module.

Owner:山西青舟环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com