Method for sintering chromite powder recycled based on ferronickel smelting furnace slag

A technology of sintering treatment and chromite, applied in the direction of improving process efficiency, etc., can solve the problems of high energy consumption of sintering, unfavorable energy saving and emission reduction, etc., and achieve the effect of improving economic benefits, realizing waste utilization, energy saving and emission reduction in links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

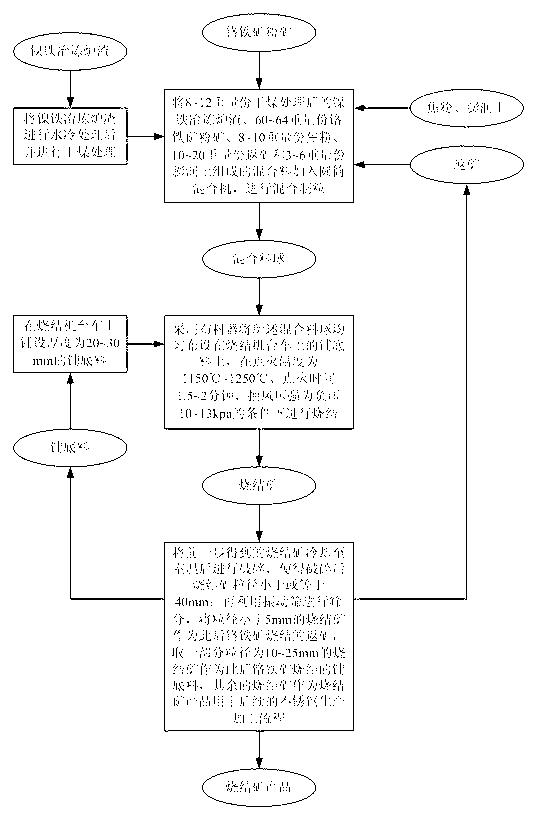

Method used

Image

Examples

Embodiment

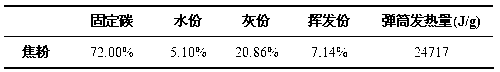

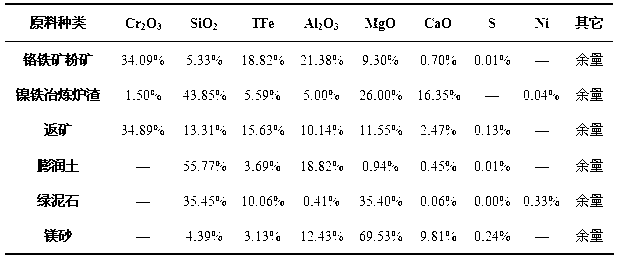

[0033] This embodiment adopts the method of the present invention to carry out three groups of chromite powder ore sintering experiments, and also adopts the method of adding flux in the prior art to carry out two groups of chromite ore powder ore sintering experiments, and then compares the sintering experiments of each group of chromite ore powder ores The physical indicators of the sintered ore products obtained in the experiment. The chemical composition of coke powder adopted in this embodiment is shown in Table 1, and the chemical composition of other raw materials is shown in Table 2:

[0034] Table 1

[0035]

[0036] Table 2

[0037]

[0038] In this example, 5 groups of chromite powder ore sintering experiments were carried out, respectively numbered as 1# group, 2# group, 3# group, 4# group, and 5# group, of which 1#~3# group chromite powder ore The sintering experiment adopts the chromite ore powder ore sintering treatment method of the present invention to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com