Sludge-based microporous frame capture net wall and method for remediating groundwater heavy metal pollution

A technology for capturing nets and groundwater, applied in the field of environmental engineering, can solve the problems of poor selectivity of adsorption materials, limited active centers, and easy falling off of loads, and achieves high strength stability, improved adsorption efficiency, and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

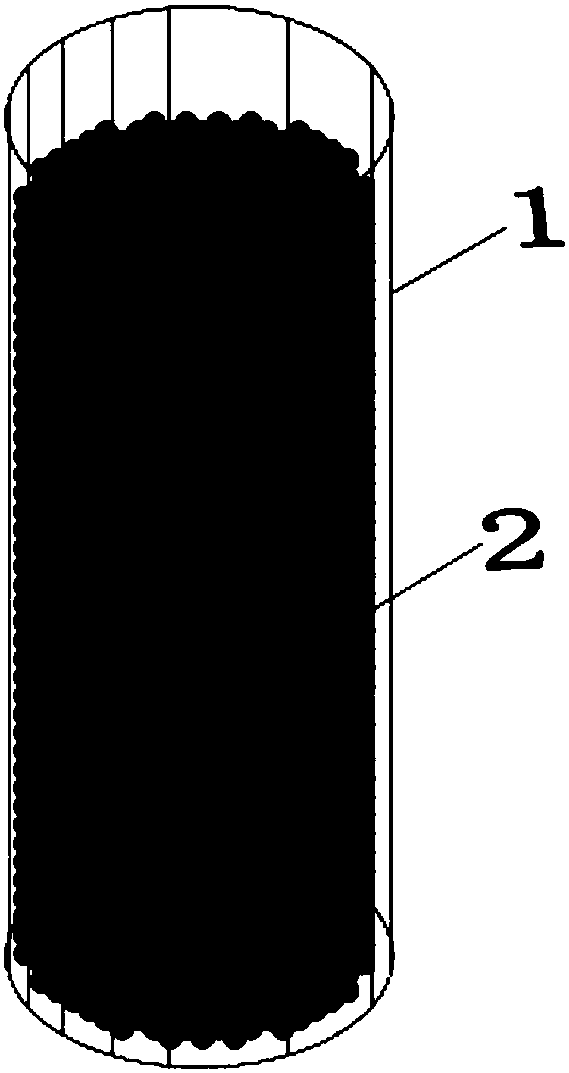

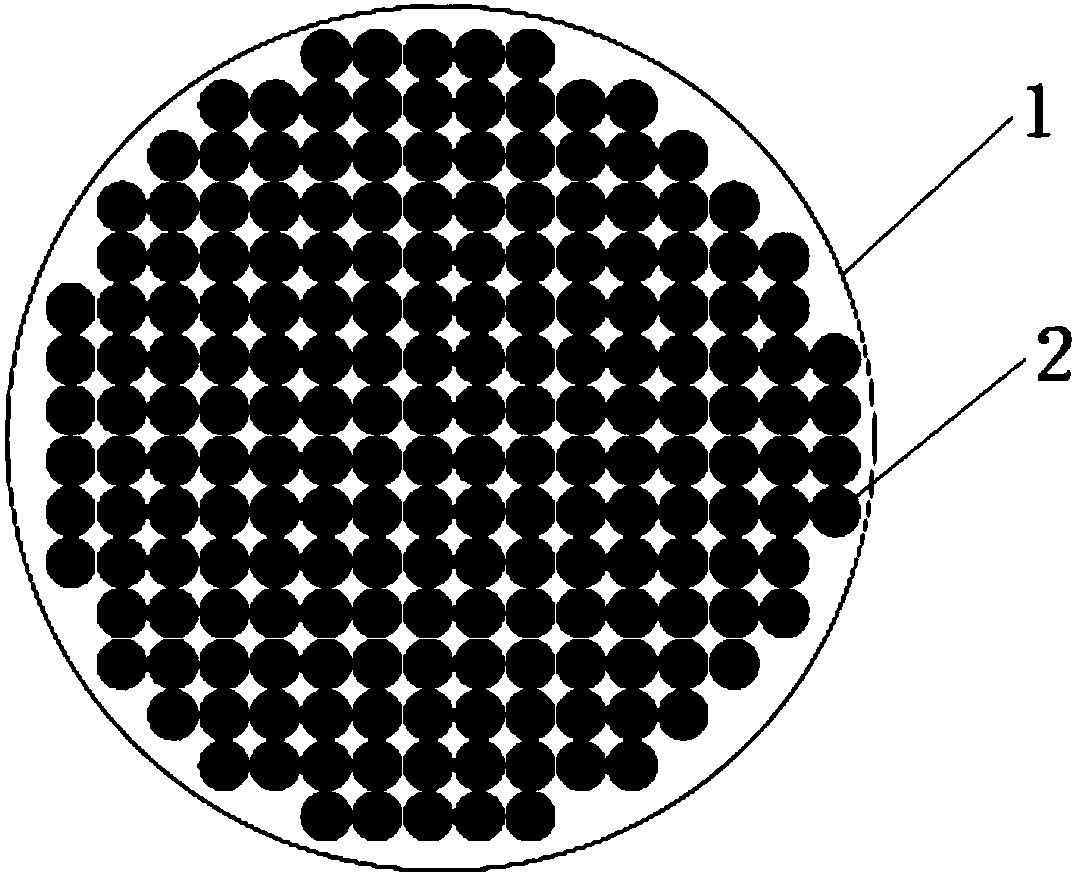

[0033] Such as figure 1 and figure 2 As shown, a sludge-based microporous frame capture net wall is composed of multiple three-dimensional capture modules to form a capture net wall. The three-dimensional capture module is composed of a core area and a membrane wall. The core area is Sludge-based microporous frame hard balls 2 carrying nano-Fe(0), the membrane wall is sludge-coal tar pitch carbonized membrane 1, and sludge-based micro-porous frame hard balls carrying nano-Fe(0) are filled in sludge —The cylindrical three-dimensional capture module is formed in the coal tar pitch carbonization membrane.

[0034] The sludge-based microporous framework hard ball carrying nano-Fe(0) of the present invention is made through the following steps:

[0035] (1) Take the dewatered sludge and heat it at 105°C for 26 hours, then heat it at 85°C for 10 hours, then dry it, crush it, and pass it through a 45mm sieve to make dewatered sludge dry powder;

[0036] (2) Get sodium lauryl sulf...

Embodiment 2

[0050] Such as figure 1 and figure 2 As shown, a sludge-based microporous frame capture net wall is composed of multiple three-dimensional capture modules to form a capture net wall. The three-dimensional capture module is composed of a core area and a membrane wall. The core area is Sludge-based microporous frame hard balls 2 carrying nano-Fe(0), the membrane wall is sludge-coal tar pitch carbonized membrane 1, and sludge-based micro-porous frame hard balls carrying nano-Fe(0) are filled in sludge —The cylindrical three-dimensional capture module is formed in the coal tar pitch carbonization membrane.

[0051] The sludge-based microporous framework hard ball carrying nano-Fe(0) of the present invention is made through the following steps:

[0052] (1) Take the dewatered sludge and heat it at 110°C for 30 hours, then heat it at 90°C for 12 hours, then dry it, crush it, and pass it through a 45mm sieve to make dewatered sludge dry powder;

[0053] (2) Get sodium lauryl sulf...

Embodiment 3

[0067] Such as figure 1 and figure 2 As shown, a sludge-based microporous frame capture net wall is composed of multiple three-dimensional capture modules to form a capture net wall. The three-dimensional capture module is composed of a core area and a membrane wall. The core area is Sludge-based microporous frame hard balls 2 carrying nano-Fe(0), the membrane wall is sludge-coal tar pitch carbonized membrane 1, and sludge-based micro-porous frame hard balls carrying nano-Fe(0) are filled in sludge —The cylindrical three-dimensional capture module is formed in the coal tar pitch carbonization membrane.

[0068] The sludge-based microporous framework hard ball carrying nano-Fe(0) of the present invention is made through the following steps:

[0069] (1) Take the dewatered sludge and heat it at 108°C for 28 hours, then heat it at 87°C for 11 hours, then dry it, crush it and pass it through a 45mm sieve to make dewatered sludge dry powder;

[0070] (2) Get sodium lauryl sulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com