Corrosion resistant PHC pipe pile and preparation method thereof

A PHC pipe pile, corrosion-resistant technology, applied in the field of pipe piles, can solve the problems of limited application and unsatisfactory corrosion resistance of PHC pipe piles, so as to improve fluidity, reduce land occupation, pollute the environment, and improve interface connection. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

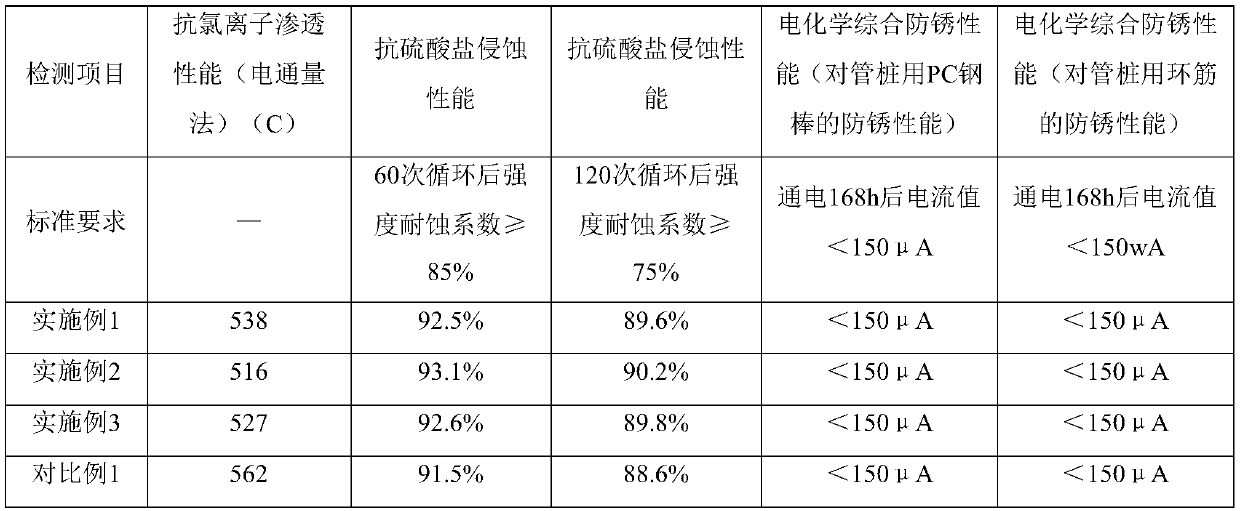

Embodiment 1

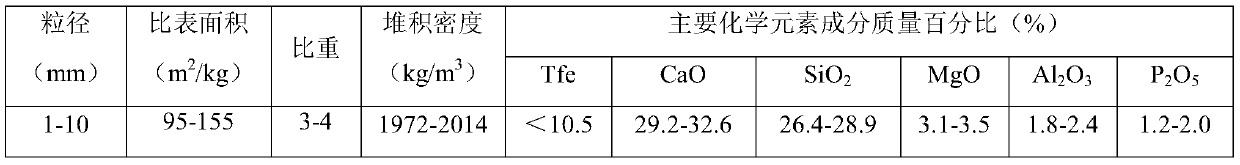

[0053] A corrosion-resistant PHC pipe pile. The raw materials used for the preparation of concrete include the following components in parts by weight: 280 parts of cement, 425 parts of stone, 420 parts of sand, 300 parts of steel slag powder, and 15 parts of modified hollow glass microspheres. 165 parts of water, 1.5 parts of water reducer, 85 parts of fly ash, 32 parts of redispersible latex powder, 10 parts of anhydrous aluminum silicate, 2 parts of anionic surfactant, 20 parts of sodium hydroxide;

[0054] The preparation method of the steel slag powder includes the following steps: grinding the steel slag to obtain steel slag powder with a particle size of 0.2-1 mm; 0.7%; in parts by weight, the compound grinding aid includes 3 parts of triethanolamine, 1.5 parts of Yuanming powder and 2 parts of colloidal graphite powder;

[0055] The preparation method of the modified hollow glass microspheres includes the following steps: soaking the hollow glass microspheres in an aqu...

Embodiment 2

[0061] A corrosion-resistant PHC pipe pile. The raw materials used for the preparation of concrete include the following components in parts by weight: 310 parts of cement, 395 parts of stone, 455 parts of sand, 275 parts of steel slag powder, and 18 parts of modified hollow glass beads. 155 parts of water, 2.2 parts of water reducing agent, 80 parts of fly ash, 36 parts of redispersible latex powder, 8 parts of anhydrous aluminum silicate, 3.5 parts of anionic surfactant, 17 parts of sodium hydroxide;

[0062] The preparation method of the steel slag powder includes the following steps: grinding the steel slag to obtain steel slag powder with a particle size of 0.2-1 mm; 1%; in parts by weight, the compound grinding aid comprises 4 parts of triethanolamine, 2.5 parts of Yuanming powder and 1.5 parts of colloidal graphite powder;

[0063] The preparation method of the modified hollow glass microspheres comprises the following steps: soaking the hollow glass microspheres in an ...

Embodiment 3

[0069] A corrosion-resistant PHC pipe pile. The raw materials for preparing concrete include the following components in parts by weight: 340 parts of cement, 365 parts of stone, 480 parts of sand, 250 parts of steel slag powder, and 20 parts of modified hollow glass beads. 140 parts of water, 2.5 parts of water reducing agent, 75 parts of fly ash, 40 parts of redispersible latex powder, 5.5 parts of anhydrous aluminum silicate, 5.5 parts of anionic surfactant, 15 parts of sodium hydroxide;

[0070] The preparation method of the steel slag powder includes the following steps: grinding the steel slag to obtain steel slag powder with a particle size of 0.2-1 mm; 1.3%; in parts by weight, the compound grinding aid comprises 5.5 parts of triethanolamine, 3 parts of Yuanming powder and 1 part of colloidal graphite powder;

[0071] The preparation method of the modified hollow glass microspheres includes the following steps: soaking the hollow glass microspheres in an aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com