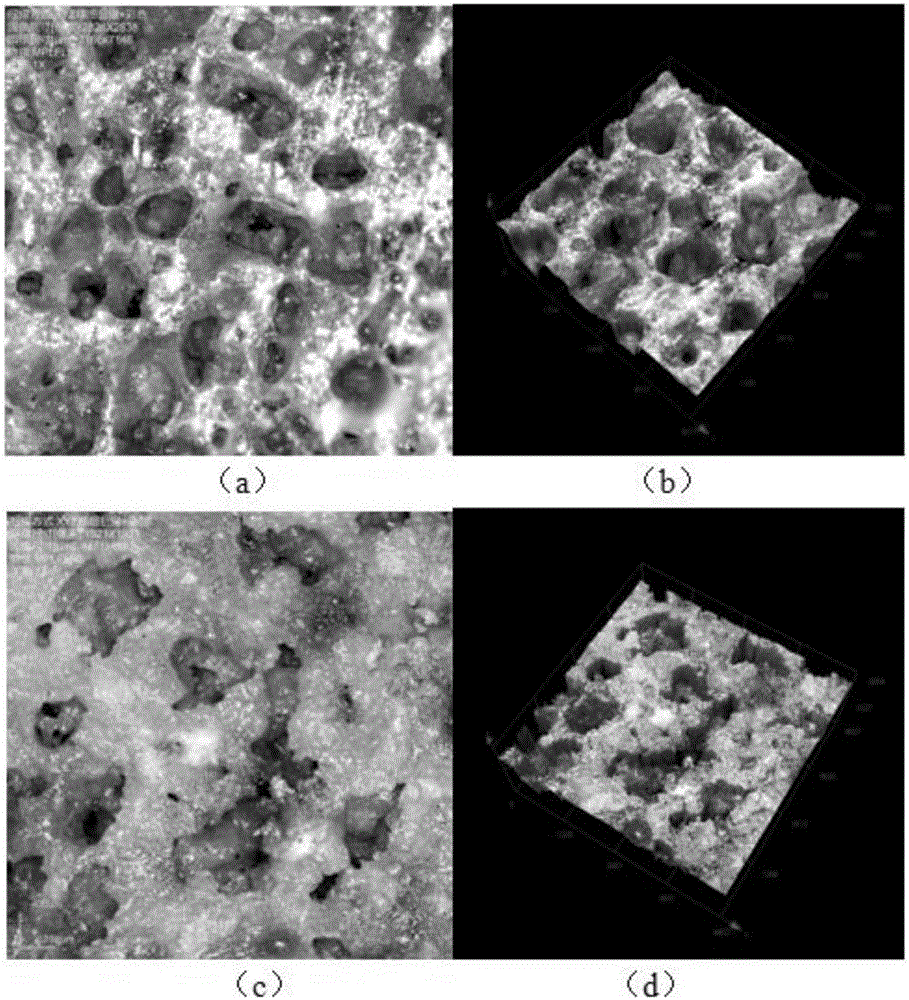

Low-energy-consumption sintering water seepage bricks and manufacturing method thereof

A manufacturing method and technology of permeable bricks, which are applied in the field of building materials, can solve the problems of high energy consumption, difficulty in expanding production, and no permeable bricks have been found, so as to reduce damage, increase the porosity of openings, and realize waste utilization and sustainability. The effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The low-energy sintered permeable brick of this embodiment includes the following raw materials in parts by weight: 50 parts of blast furnace water-quenched slag, 40 parts of coal gangue, 2 parts of cosolvent, 2 parts of plasticizer, and 6 parts of binder.

[0041] The flux is a mixture of albite, potassium feldspar and anorthite in a weight ratio of 2:1:1.

[0042] The plasticizer is a mixture of kaolin, bentonite and clay in a weight ratio of 2:1:1.

[0043]The binder is a mixture of sodium carboxymethylcellulose (CMC), starch and lignin in a weight ratio of 1:1:1.

[0044] The blast furnace water-quenched slag is passed through a 30-mesh sieve.

[0045] The coal gangue is divided into four different particle size intervals, which are larger than 10 mesh, 10 mesh to 30 mesh, 30 mesh to 100 mesh, and 100 mesh to 325 mesh. The weight ratio of the four different particle size intervals is 1:1 :1:1.

[0046] The manufacturing method of the low energy consumption sinter...

Embodiment 2

[0058] The low-energy sintered permeable brick of this embodiment includes the following raw materials in parts by weight: 60 parts of blast furnace water-quenched slag, 30 parts of coal gangue, 2 parts of cosolvent, 3 parts of plasticizer, and 5 parts of binder.

[0059] The flux is a mixture of albite and potassium feldspar in a weight ratio of 2:1.

[0060] The plasticizer is a mixture of kaolin and bentonite at a weight ratio of 1:1.

[0061] The binder is a mixture of CMC and lignin at a weight ratio of 1:1.

[0062] The blast furnace water-quenched slag is passed through a 30-mesh sieve.

[0063] The coal gangue is divided into four different particle size intervals, which are larger than 10 mesh, 10 mesh to 30 mesh, 30 mesh to 100 mesh, and 100 mesh to 325 mesh. The weight ratio of the four different particle size intervals is 2:1 :1:1.

[0064] The manufacturing method of the low energy consumption sintered seepage brick of this embodiment comprises the following st...

Embodiment 3

[0076] The low-energy sintered permeable brick of this embodiment includes the following raw materials in parts by weight: 70 parts of blast furnace water-quenched slag, 20 parts of coal gangue, 3 parts of cosolvent, 3 parts of plasticizer, and 4 parts of binder.

[0077] The flux is a mixture of albite, potassium feldspar and anorthite in a weight ratio of 2:1:1.

[0078] The plasticizer is a mixture of kaolin, bentonite and clay in a weight ratio of 2:1:2.

[0079] The binder is a mixture of CMC, starch and lignin in a weight ratio of 2:1:1.

[0080] The blast furnace water-quenched slag is passed through a 30-mesh sieve.

[0081] The coal gangue is divided into four different particle size intervals, which are larger than 10 mesh, 10 mesh to 30 mesh, 30 mesh to 100 mesh, and 100 mesh to 325 mesh. The weight ratio of the four different particle size intervals is 2:2 :1:1.

[0082] The manufacturing method of the low-energy sintered permeable brick in this embodiment is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com