Method of resourcefully utilizing sludge containing manganese, aluminum, and iron in water treatment plant

A water purification plant and resource-based technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as unreasonable development methods and unstable ions. , to achieve the effect of low cost, simple preparation method and good adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Materials

[0028] The methods used in this example are conventional methods known to those skilled in the art unless otherwise specified, and the reagents and other materials used are all commercially available products unless otherwise specified.

[0029] 2. Method

[0030] 2.1 Preparation of adsorbent

[0031] 2.1.1 Sampling and dehydration

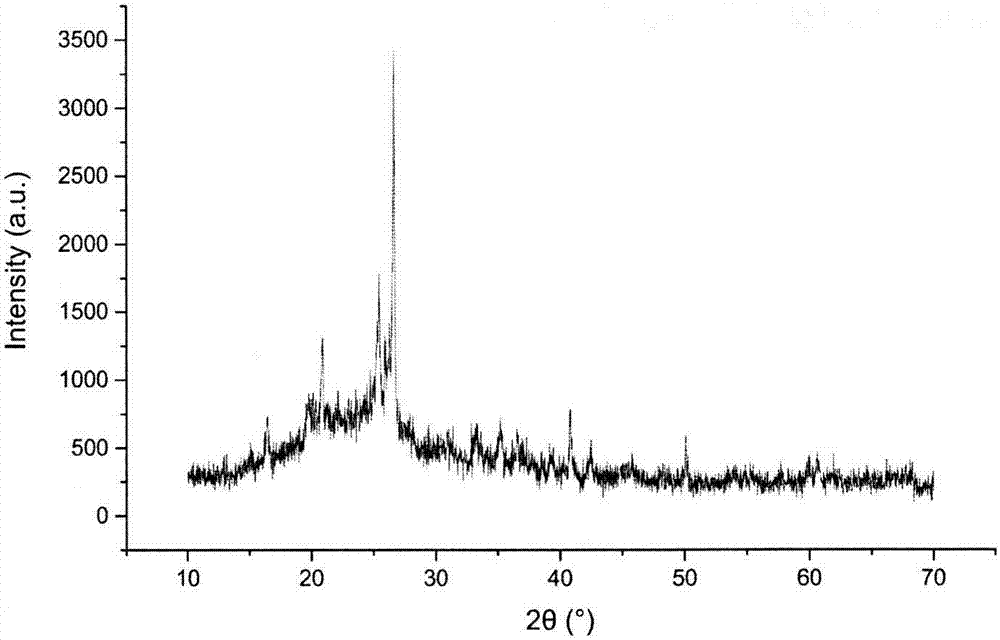

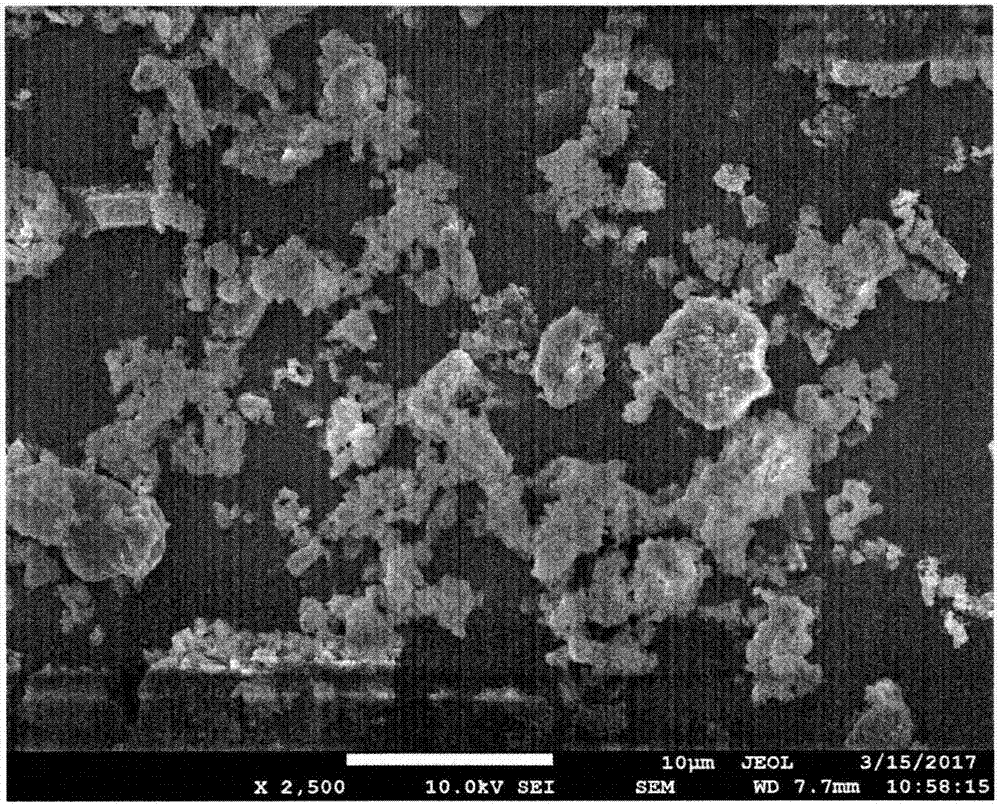

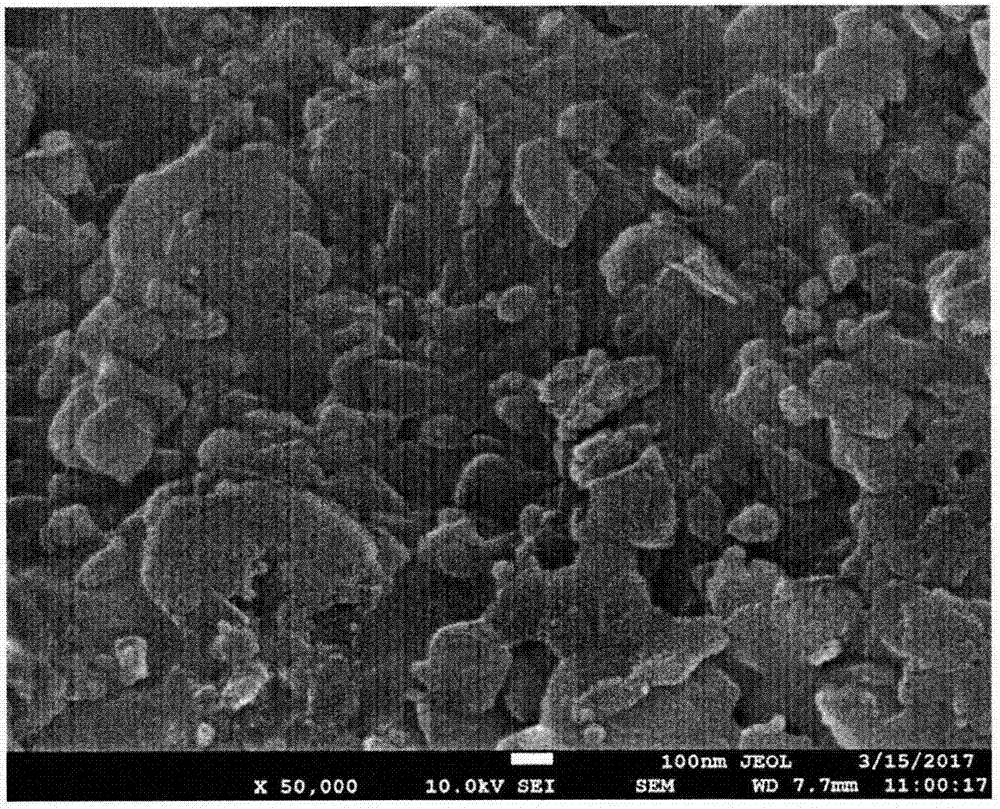

[0032] Take 500g of wet sludge from the drainage pond of a water purification plant as the raw material for the preparation of adsorbent. The main components in the wet sludge are: Fe content 24.34-31.22mg / g; Al content 4.091-6.515mg / g; Mn content 5.25-13.4mg / g; Si content 0.817-3.31mg / g, the rest is mainly water (about 95%) and organic matter (about 1.0-1.2%), the average element molar ratio Fe:Al:Mn≈13:6: 5. Aluminum-silicon ratio ≈3~7).

[0033] According to 0.5% of sludge dry mass, polyacrylamide (being called for short PAM, molecular formula: [C 3 h 5 NO] n , monomer molecular weight: 71.07, purchased from Sinopha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com