Method for repairing chilling ring of gasifier

A repair method and chilling ring technology, which is applied in the field of repairing the chilling ring of the waste coal-water slurry gasifier, can solve the problem of large erosion at the outlet of the water distribution hole, erosion and leakage of the outer ring pipe, and failure of the chilling ring. Repair and other problems to achieve the effect of reducing the number of stops, improving the strength, and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

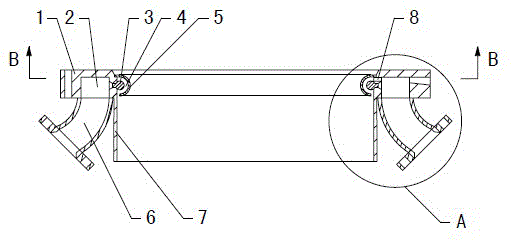

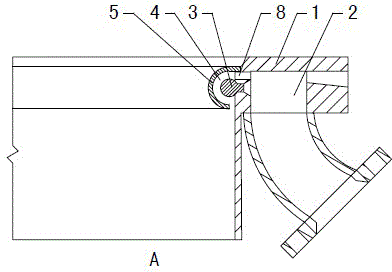

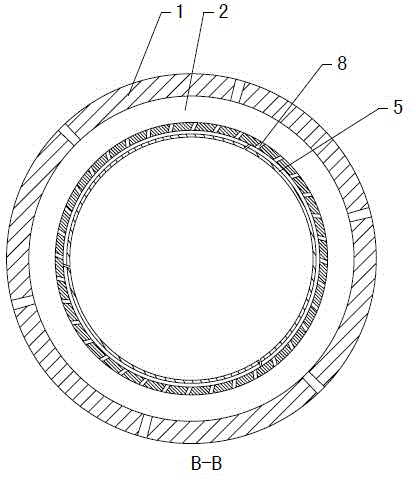

[0028] Attached below Figure 1~3 The method for repairing the chilling ring of the gasifier of the present invention will be further described.

[0029] refer to figure 1 , the chilling ring includes a chamber seat 1, a cylinder body 7, a water inlet pipe 6, an outer ring pipe 5 and an inner water distribution ring 3, the cylinder body 7 is fixed on the lower part of the annular chamber seat 1, and the lower part of the chamber seat 1 is on the circumference of the cylinder body 7 There is a quenching water chamber 2 on the outside, and four water inlet pipes 6 are evenly fixed on the lower side of the chamber seat 1 and communicate with the quenching water chamber 2. On the outside of the water inner ring 3, the ring chamber 4 is formed between the outer ring pipe 5 and the water distribution inner ring 3. The upper part of the outer ring pipe 5 is welded to the upper part of the inner ring of the cavity seat 1, and the lower part has a gap of 8.9 mm with the inner wall of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com