Method used for preparing ZSM-5 molecular sieve taking white mud as raw material, and ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the field of molecular sieves, can solve the problems of large emissions and environmental pollution, and achieve the effects of low production costs, improved economic benefits, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

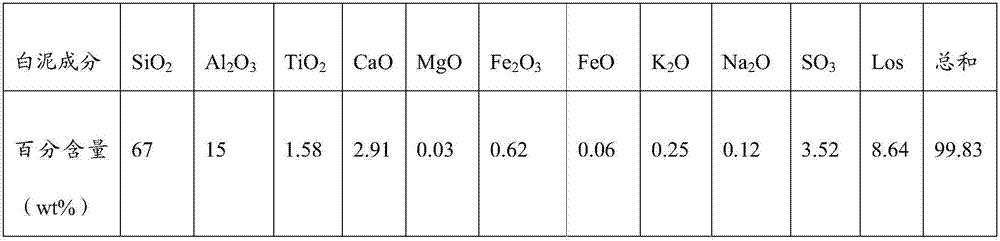

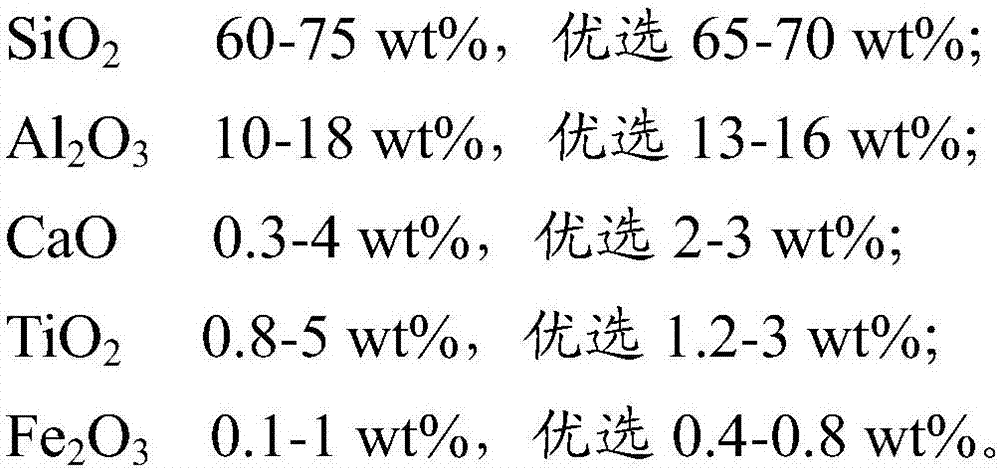

[0038] (1) After mixing 20g of lime mud and 28g of sodium hydroxide evenly, calcining and activating at 650°C for 2 hours to obtain clinker;

[0039] (2) add deionized water and tetrapropyl ammonium hydroxide respectively in the clinker that step (1) obtains, make the add-on of deionized water be 20ml / 1g white mud, tetrapropyl ammonium hydroxide and deionized water The mol ratio is 1:160, then stir 5h to obtain silica-alumina gel;

[0040] (3) Put the silica-alumina gel obtained in step (2) in a crystallization kettle, crystallize at 180°C for 36 hours to obtain a crystallized product, filter, wash and dry the crystallized product to obtain a ZSM-5 molecular sieve.

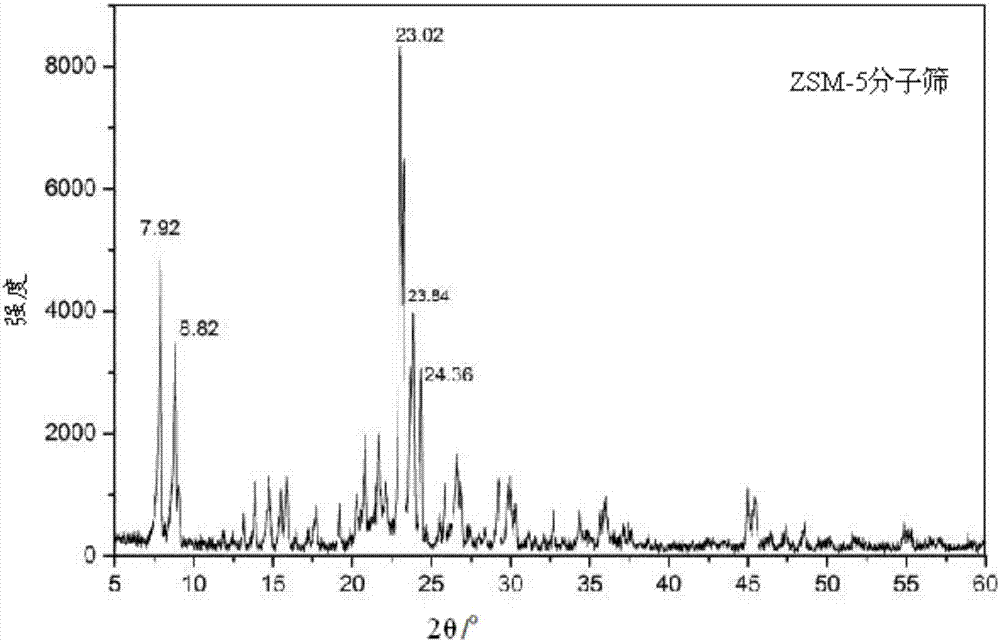

[0041] The XRD spectrum pattern of this ZSM-5 molecular sieve is as figure 1As shown, compared with the standard spectrum, what is obtained is indeed a ZSM-5 molecular sieve; the catalytic performance of the ZSM-5 molecular sieve in the toluene disproportionation reaction (reaction temperature is 450 ° C) is as f...

Embodiment 2

[0043] (1) After mixing 20g of white mud and 26g of sodium hydroxide evenly, calcining and activating at 600°C for 3 hours to obtain clinker;

[0044] (2) add deionized water and tetrapropyl ammonium hydroxide respectively in the clinker that step (1) obtains, make the add-on of deionized water be 10ml / 1g white mud, tetrapropyl ammonium hydroxide and deionized water The mol ratio is 1:100, then stir 5h to obtain silica-alumina gel;

[0045] (3) Put the silica-alumina gel obtained in step (2) in a crystallization kettle, crystallize at 165° C. for 48 hours to obtain a crystallized product, filter, wash and dry the crystallized product to obtain a ZSM-5 molecular sieve.

[0046] The characteristic peak position of the XRD spectrogram of this ZSM-5 molecular sieve and figure 1 Identical; The catalytic performance of this ZSM-5 molecular sieve in toluene disproportionation reaction (reaction temperature is 450 ℃) is as follows: the productive rate of benzene is 24.05%, and the pr...

Embodiment 3

[0048] (1) After mixing 20g of white mud and 30g of sodium hydroxide evenly, calcining and activating at 700°C for 1 hour to obtain clinker;

[0049] (2) add deionized water and tetrapropyl ammonium hydroxide respectively in the clinker that step (1) obtains, make the add-on of deionized water be 30ml / 1g white mud, tetrapropyl ammonium hydroxide and deionized water The mol ratio is 1:200, then stir 5h to obtain silica-alumina gel;

[0050] (3) Put the silica-alumina gel obtained in step (2) in a crystallization kettle, crystallize at 190° C. for 48 hours to obtain a crystallized product, filter, wash and dry the crystallized product to obtain a ZSM-5 molecular sieve.

[0051] The characteristic peak position of the XRD spectrogram of this ZSM-5 molecular sieve and figure 1 Identical; The catalytic performance of this ZSM-5 molecular sieve in toluene disproportionation reaction (reaction temperature is 450 ℃) is as follows: the productive rate of benzene is 24.20%, and the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com