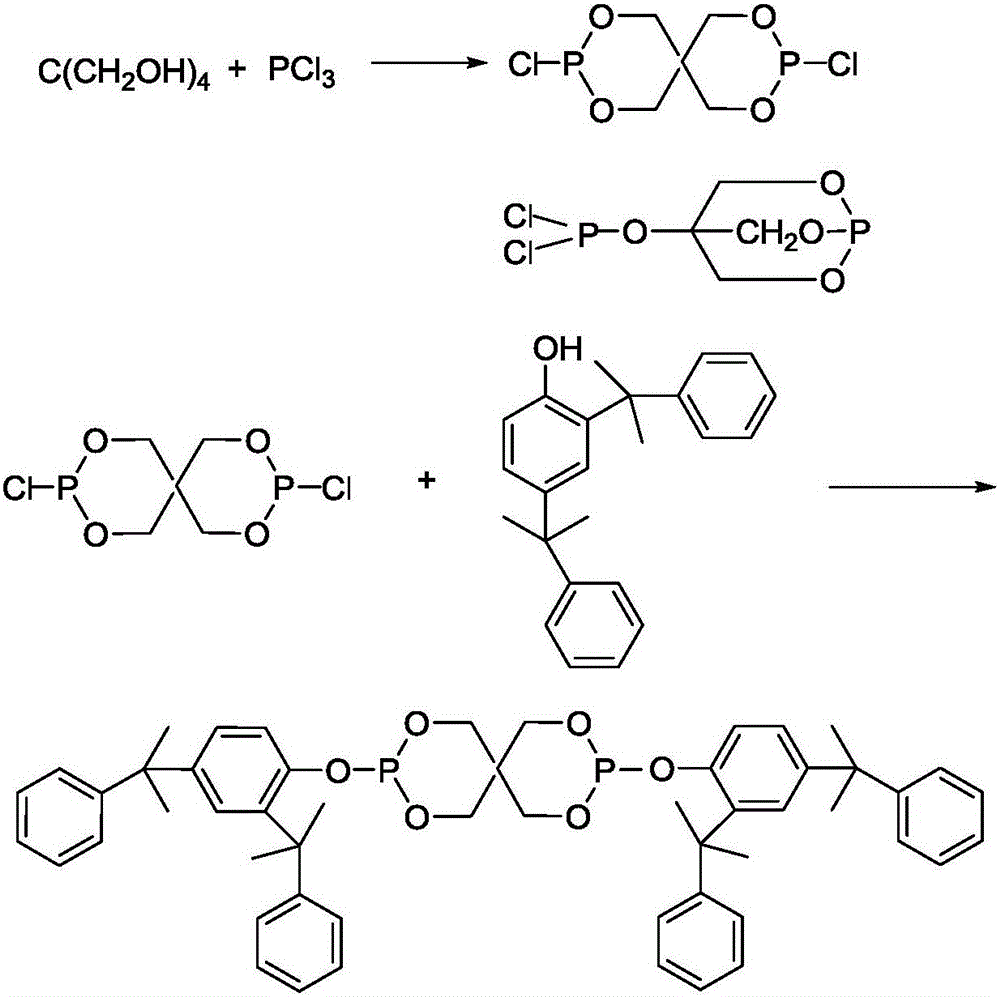

Preparation method of bis(2,4-dicumylphenyl)pentaerythritol diphosphite antioxidant

A technology of pentaerythritol diphosphite and cumyl phenyl, which is applied in the field of preparation of phosphite antioxidants, can solve problems such as unsatisfactory yield levels, and achieves simple and easy operability, high selectivity, low The effect of raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Add 41.0 grams of pentaerythritol, 2.05 grams of N, N-dimethylhexadecylamine, and 190 grams of xylene into a four-neck flask equipped with a stirrer, a thermometer, a condenser, and a nitrogen conduit in a 1000 ml bottle, and feed nitrogen to install hydrogen chloride Absorption device, dropping funnel; add 94.9 grams of phosphorus trichloride weighed dropwise at 10-15 ° C, dropwise in 1.5 hours, and slowly heat up to 25-30 ° C within 2-3 hours, the hydrogen chloride gas generated through the absorption The device absorbs treatment; after 2-3 hours, the temperature is raised to 38-40°C, and after 2-3 hours, the temperature is raised to 80-85°C and kept for 0.5 hours, and the nitrogen gas is stopped, and the vacuum gauge pressure is - (0.05-0.06MPa) Reaction under reduced pressure and reflux for 1 hour, remove hydrogen chloride and excess phosphorus trichloride, stop decompression at 70-80°C and fill with nitrogen for protection, to obtain dichloropentaerythritol dipho...

Embodiment 2

[0026] 1) Add 41.0 grams of pentaerythritol, 1.7 grams of N,N-dimethylhexadecylamine, 165 grams of toluene, and feed nitrogen into a four-neck flask equipped with a stirrer, thermometer, condenser, and nitrogen conduit in a 1000ml device, and the device absorbs hydrogen chloride Device, dropping funnel; add 96.0 grams of phosphorous trichloride weighed dropwise at 10-15°C, drop it in 1 hour, then slowly heat up to 20-25°C in 2 hours, and the hydrogen chloride gas generated is absorbed and treated by the absorption device; After another 3 hours, the temperature was raised to 30-35 ° C, and after 2 hours, the temperature was raised to 80-82 ° C, and the temperature was kept for 0.5 hours, and the nitrogen gas was stopped, and the vacuum gauge pressure was - (0.06-0.07 MPa) under reduced pressure and reflux for 1 hour. Remove hydrogen chloride and excess phosphorus trichloride, stop decompression at 70-80°C and fill with nitrogen for protection, to obtain dichloropentaerythritol d...

Embodiment 3

[0029]1) Add 41.0 grams of pentaerythritol, 1.8 grams of N,N-dimethyltetradecamine, 123 grams of xylene, and feed nitrogen into a four-neck flask equipped with a stirrer, a thermometer, a condenser, and a nitrogen conduit in 1000 ml, and install hydrogen chloride Absorption device, dropping funnel; dropwise add 92.9 grams of phosphorus trichloride weighed at 10-15 °C, dropwise addition is completed in 1.5 hours, and slowly heat up to 25-30 °C in 3 hours, and the hydrogen chloride gas generated is absorbed and treated by the absorption device ; After 2.0 hours, the temperature was raised to 35-40°C, and after 3 hours, the temperature was raised to 80-85°C, and kept for 0.5 hours, and the nitrogen gas was stopped, and the vacuum gauge pressure was - (0.06-0.07MPa) decompression and reflux reaction for 1 hour , remove hydrogen chloride and excess phosphorus trichloride, stop depressurization at 70-80°C and fill with nitrogen for protection, to obtain dichloropentaerythritol diphos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com