Patents

Literature

75results about How to "Reduce structural costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

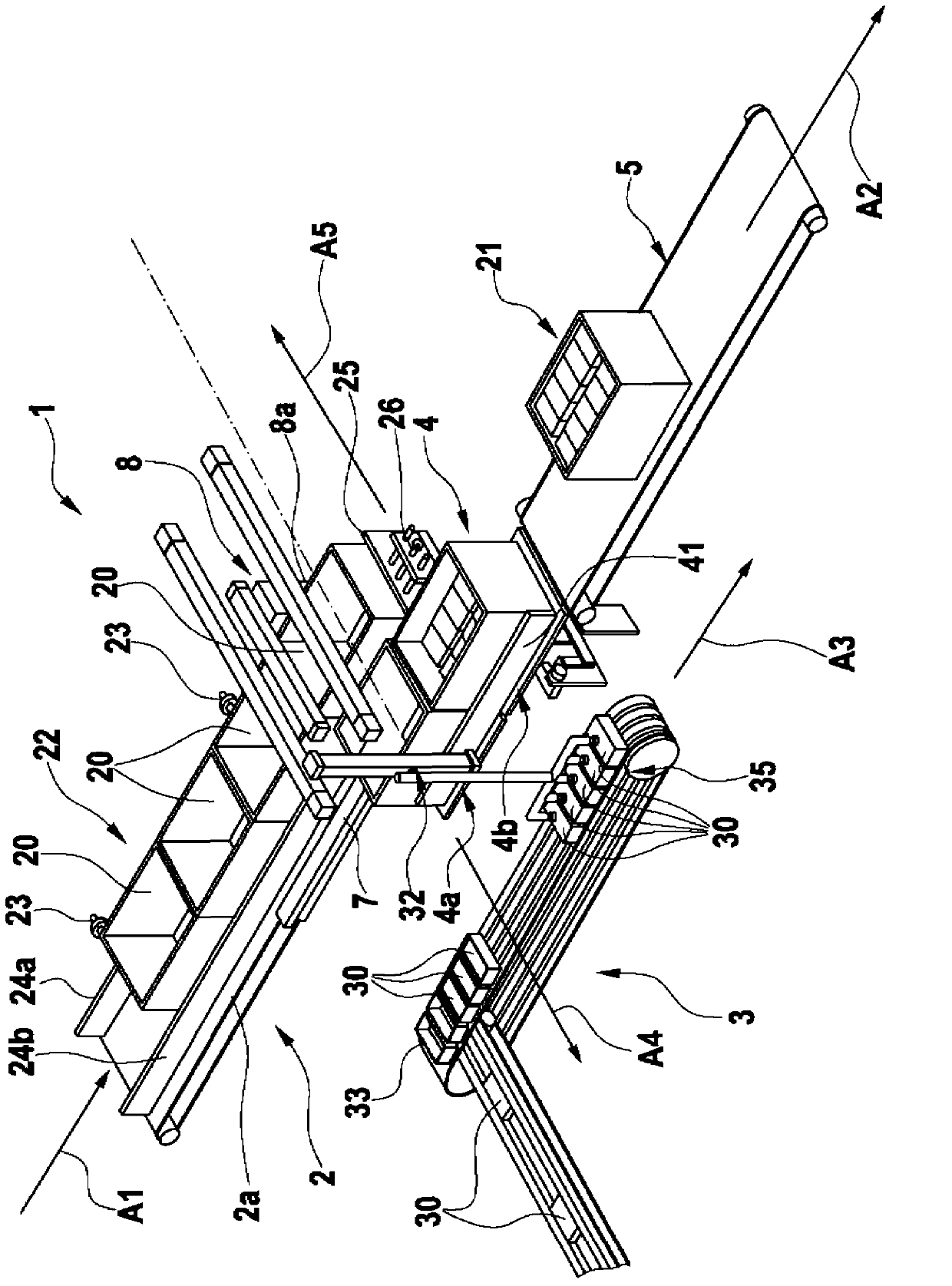

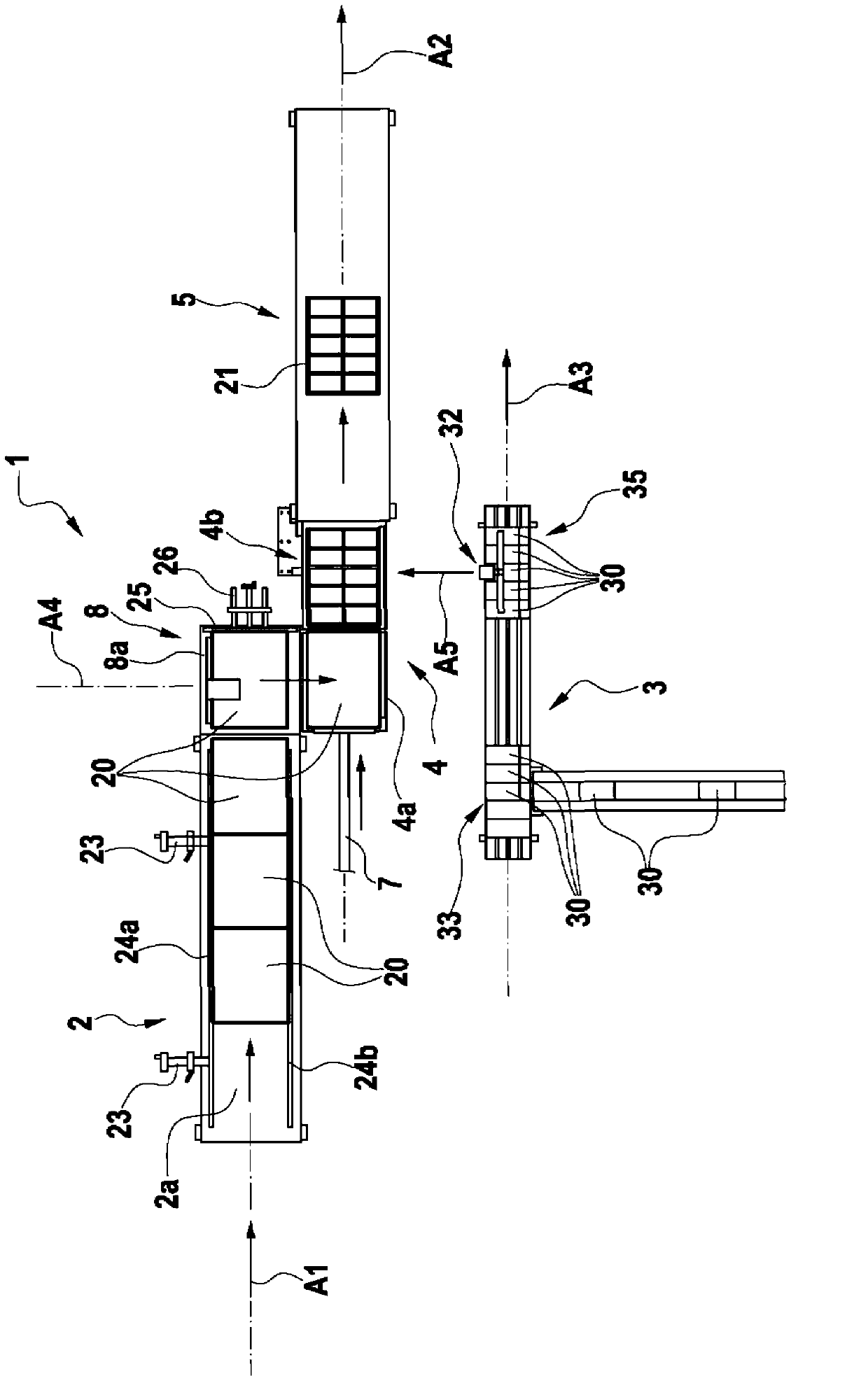

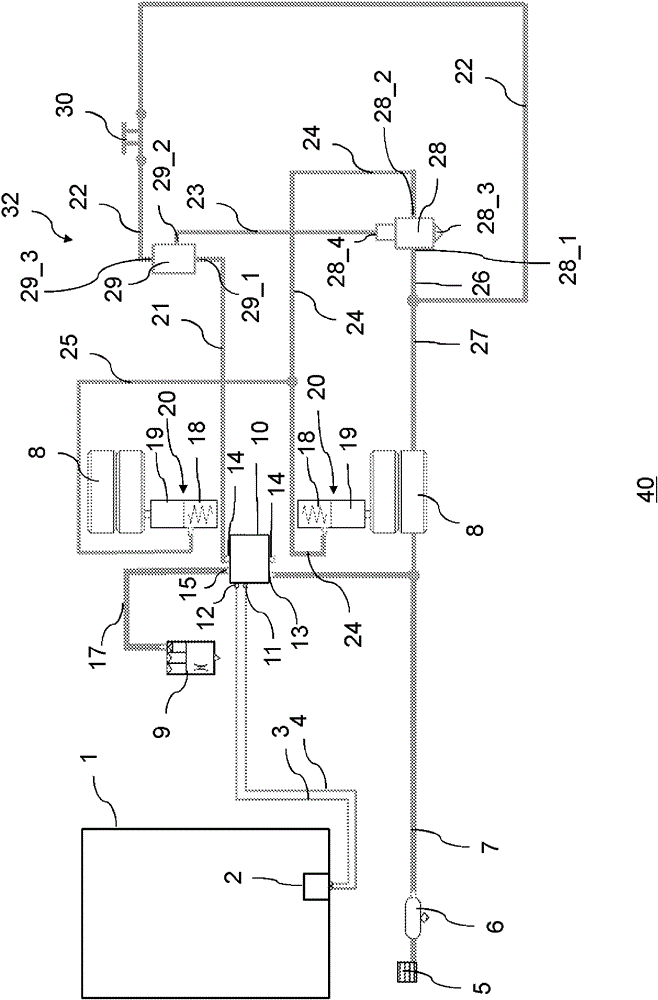

Packaging device

InactiveCN103298696AShort cycle timeContinuous packaging stepsIndividual articlesMechanical engineeringCardboard box

The invention relates to a modularly constructed packaging device, comprising: a package feed (2) for feeding empty packages (20), a product feed (3) for feeding products (30, 40), a loading station (4), in which the products are packed into the empty package in order to provide a packaging container (21), and a cardboard-box discharge (5), which leads away the packaging container.

Owner:ROBERT BOSCH GMBH

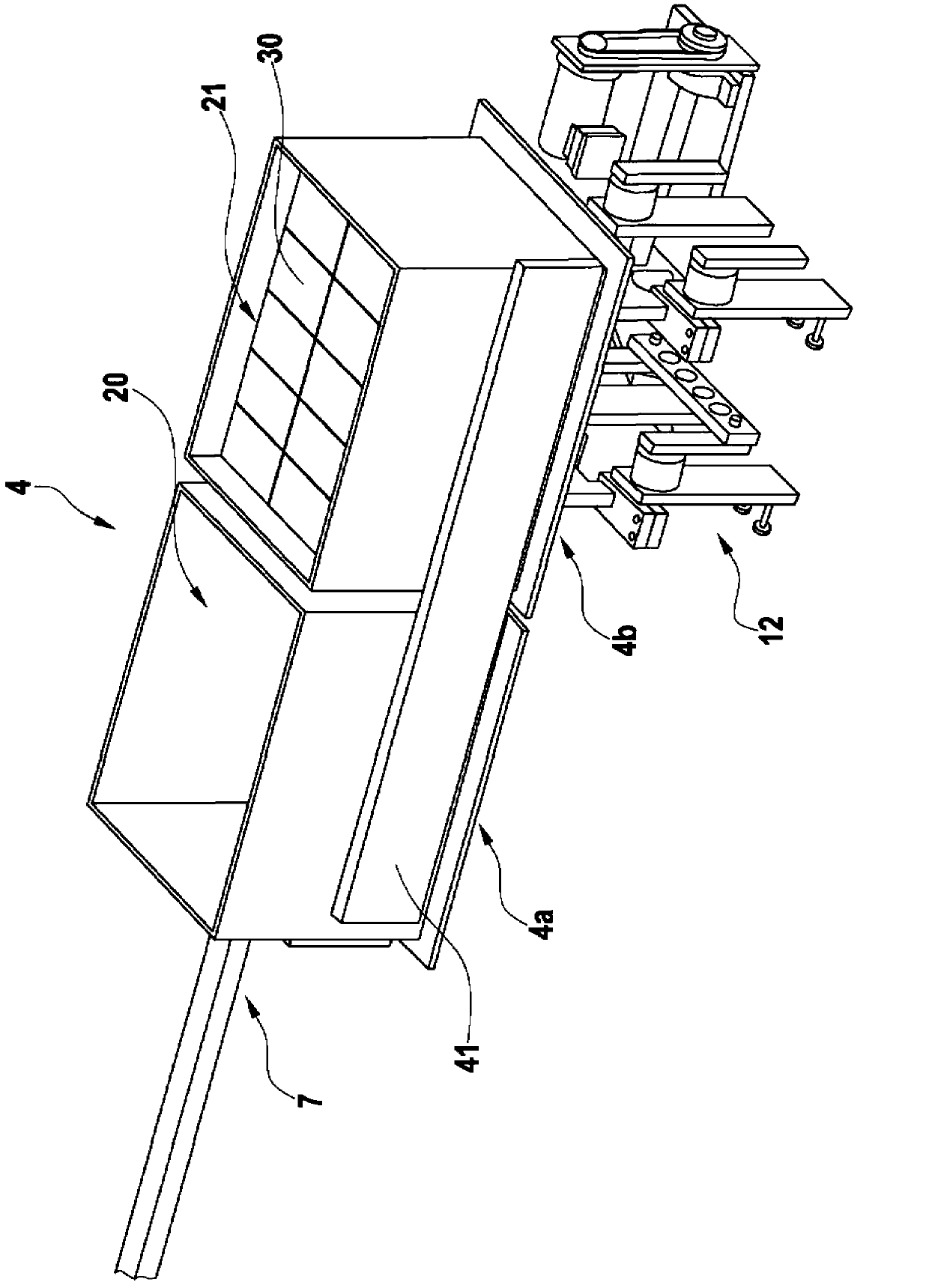

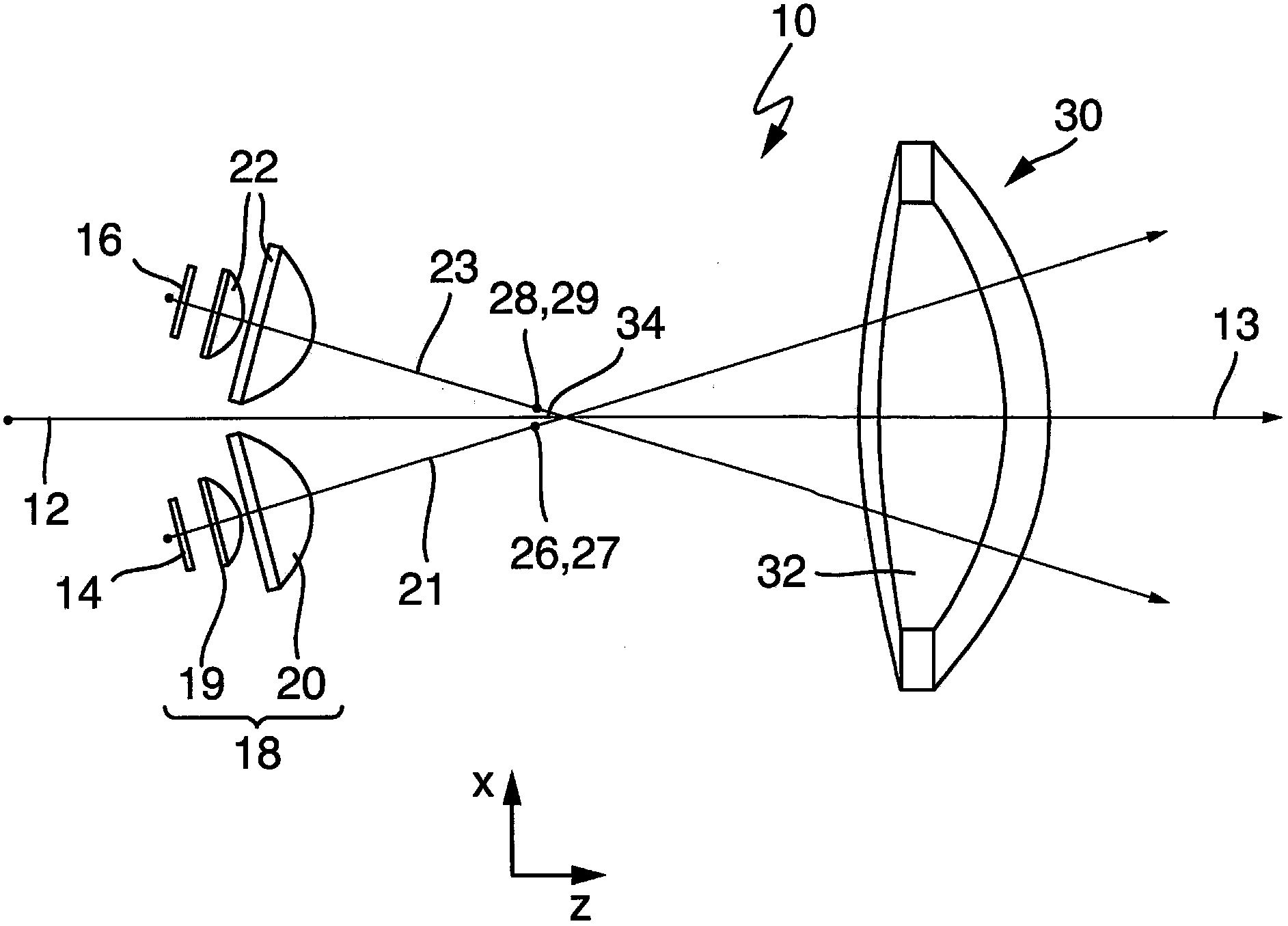

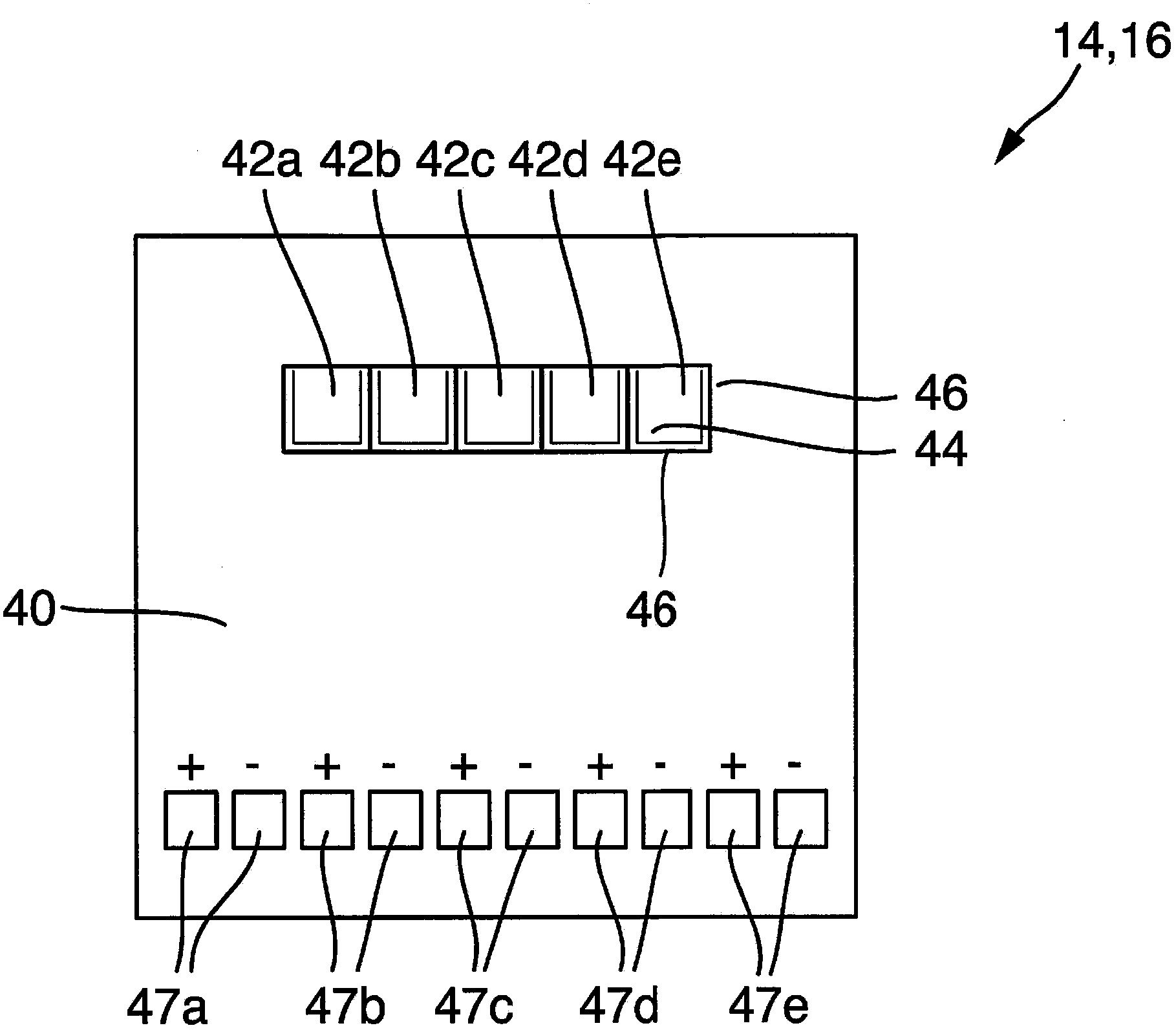

Optical module

ActiveCN103528006ALow costReduce structural costsVehicle headlampsPoint-like light sourceOptical ModuleIntermediate image

A light module having a first and a second primary optics device wherein the individual LEDs of a first and a second semiconductor light source can be reproduced as real intermediate images on an intermediate image surface, wherein an intermediate image assigned to the first semiconductor light source is overlapping with at least one intermediate image assigned to a second semiconductor light source, and that a secondary optics device is arranged in such a way that the intermediate images can be projected as assigned light beam segments of the light beam distribution.

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

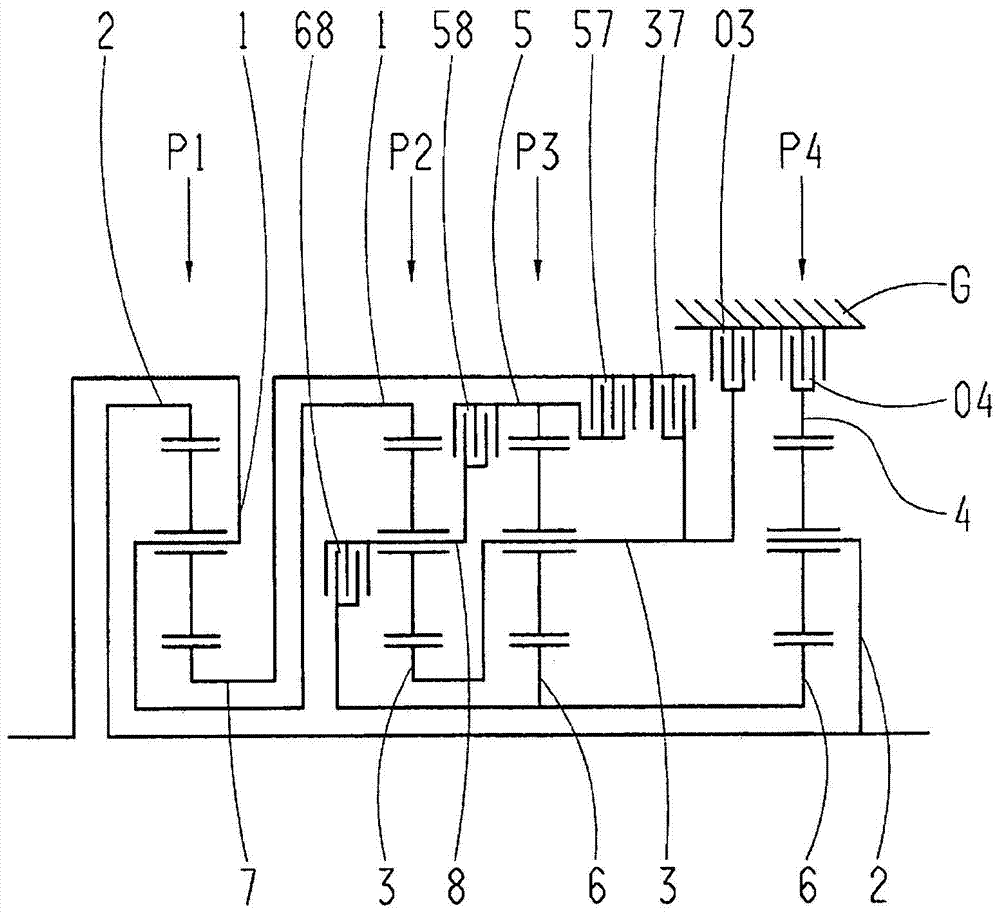

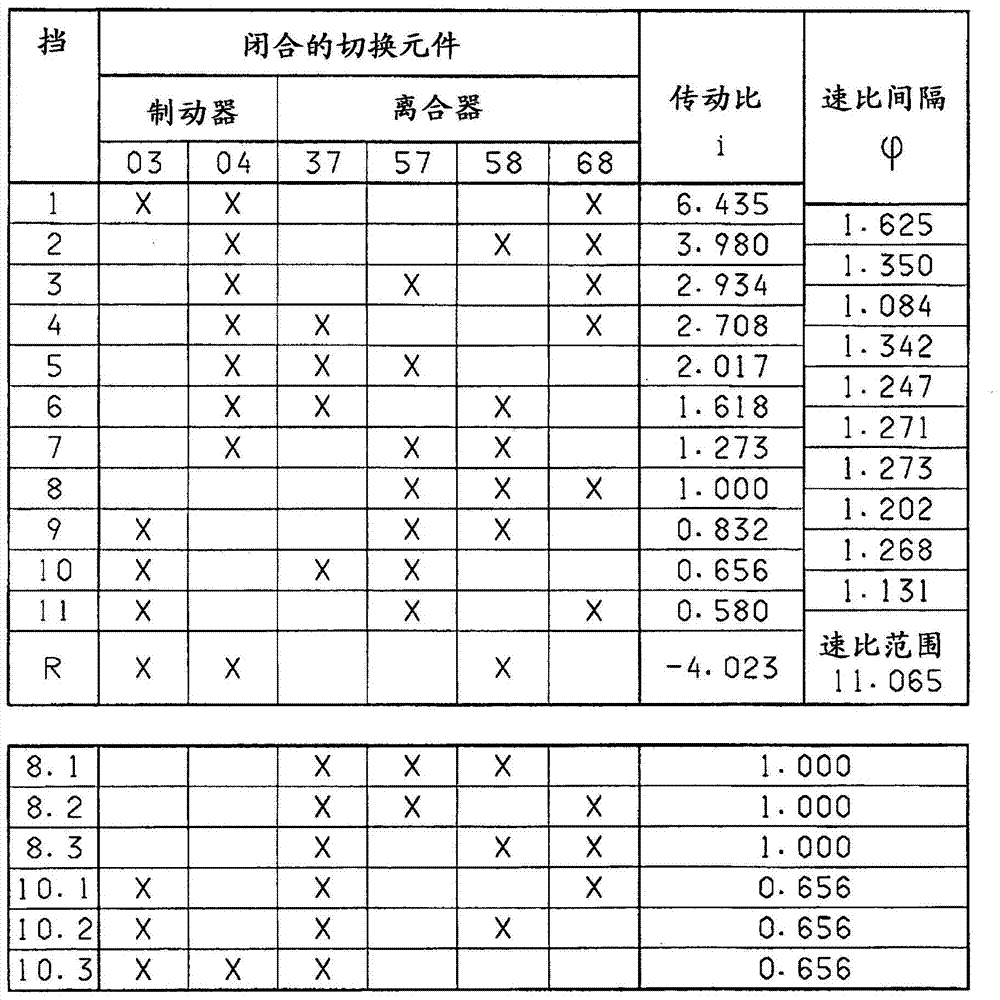

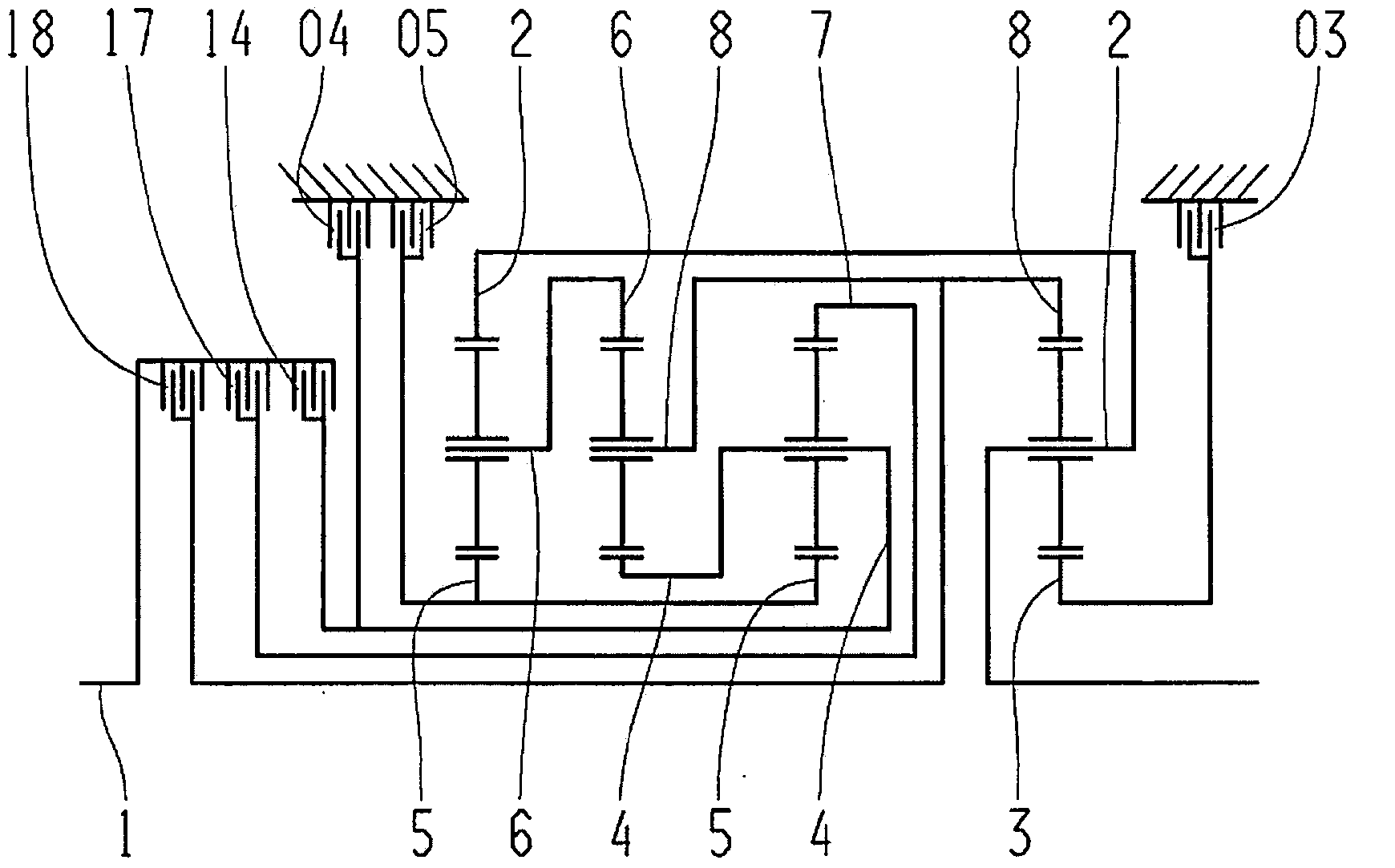

Multi-speed gearbox

InactiveCN104334920AExpand the ratio rangeImprove driving comfort performanceToothed gearingsTransmission elementsGear wheelEngineering

The invention relates to a multi-speed gearbox having four planetary gear sets (P1, P2, P3, P4), eight rotatable shafts (1, 2, 3, 4, 5, 6, 7, 8) and six shift elements (03, 04, 37, 57, 58, 68), wherein the sun gear of the first planetary gear set (P1) is connected to the seventh shaft (7), which can be connected to the third shaft (3) by means of a first clutch (37), which connects to the sun gear of the second planetary gear set (P2), to the planet carrier of the third planetary gear set (P3) and can be coupled to the housing (G) by means of a first brake (03). The seventh shaft (7) can be connected to the fifth shaft (5) by means of a second clutch (57), which connects to the planet carrier of the third planetary gear set (P3) and can be coupled to the eighth shaft (8) which is connected to the planet carrier of the second planetary gear set (P2) by means of a third clutch (58), which can be connected to the sixth shaft (6) which is connected to the sun gear of the third planetary gear set (P3) and to the sun gear of the fourth planetary gear set (P4) by means of a fourth clutch (68). The input shaft (1) is connected to the planet carrier of the first planetary gear set (P1) and to the ring gear of the second planetary gear set (P2) and the fourth shaft (4) connected to the ring gear of the fourth planetary gear set (P4) can be coupled by means of a second brake (04) to the housing (G) and the output shaft (2) is connected to the ring gear of the first planetary gear set (P1) and to the planet carrier of the fourth planetary gear set (P4).

Owner:ZF FRIEDRICHSHAFEN AG

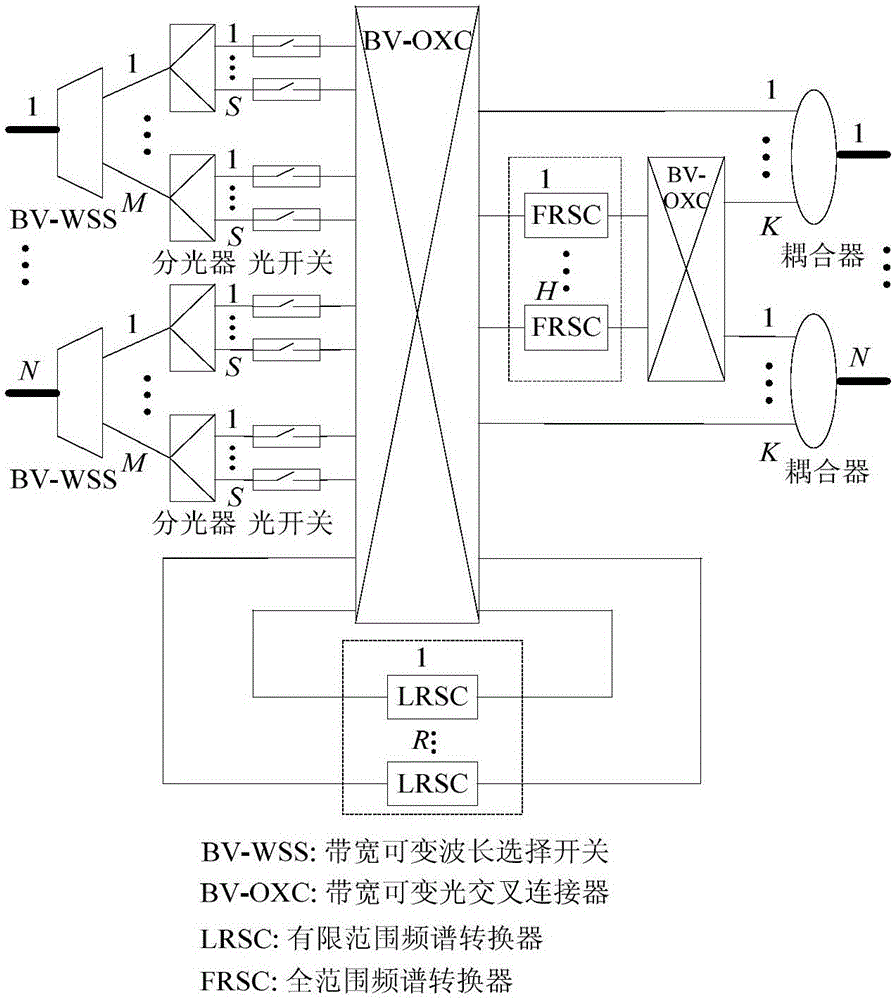

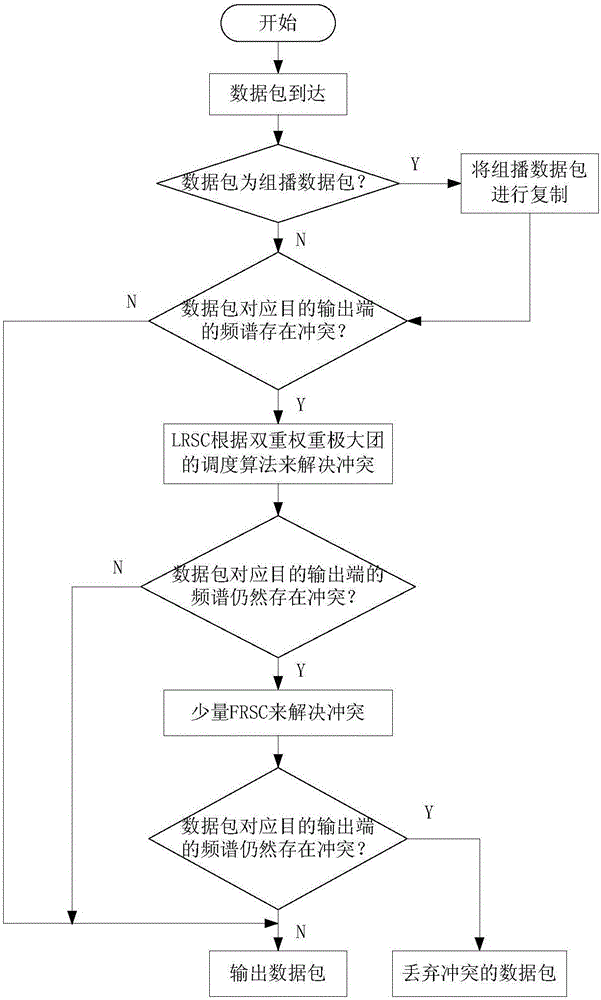

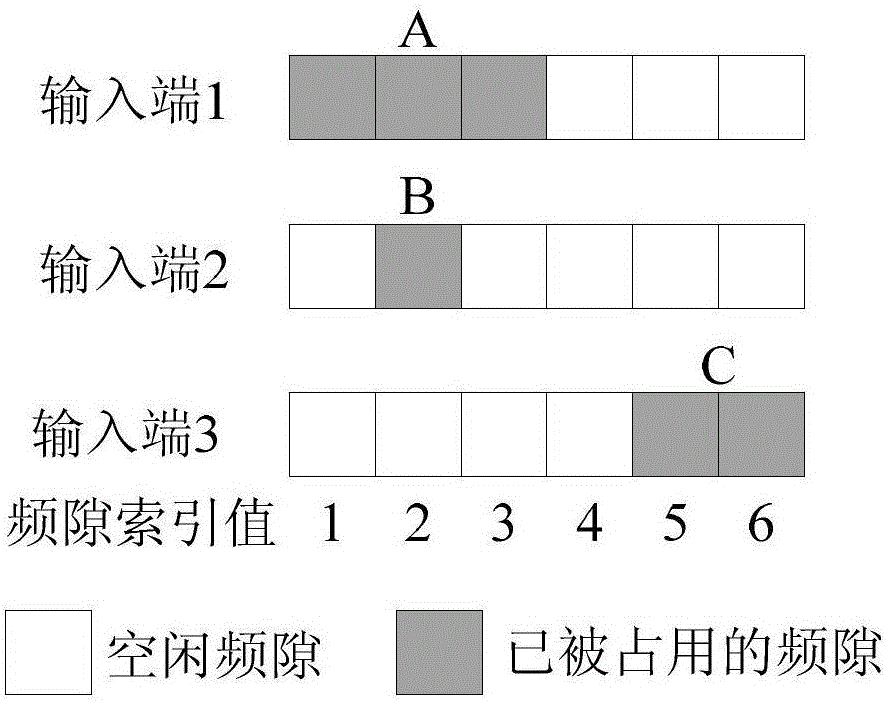

Dual-weight maximum-clique scheduling method for elastic optical multicast switching node structure based on shared frequency spectrum converter

ActiveCN106792285AIncrease profitImprove abilitiesMultiplex system selection arrangementsFrequency spectrumPacket loss

The invention relates to a dual-weight maximum-clique scheduling method for an elastic optical multicast switching node structure based on a shared frequency spectrum converter. When an optical multicast fails to directly schedule an output port, the confliction in an optical frequency spectrum domain of the conflicted optical multicast is firstly solved by virtue of an LRSC (Limited Range Spectrum Converter), a conflict auxiliary graph of a frequency spectrum occupied by each data packet is established by virtue of a dual-weight maximum-clique scheduling algorithm, the frequency slot number occupied by the data packet and the number of the used LRSCs are taken as two weights, and a scheduling scheme in which the number of the used LRSCs is minimum when the total frequency slot number of output data packets are maximum is selected by virtue of a graph coloring algorithm, so that the utilization rate of the frequency spectrum converter is increased, and the packet loss probability and the node structure cost are reduced. If optical multicasts are still in a confliction state after the LRSCs are used, the confliction is solved by virtue of a small amount of FRSCs (Full Range Spectrum Converters), and frequency spectrums of conflicted data packets can be converted to any one section of idle frequency spectrum in an optical fiber frequency spectrum range by virtue of the FRSCs, so that the capability of solving the confliction of a switching node is further improved, and the packet loss probability is further reduced.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Electrical spring-operated parking brake

ActiveCN105035056AExhaustRelieve pressureBraking action transmissionBraking componentsAutomotive engineeringArresting gear

The invention relates to an electrical spring-loaded parking brake for a vehicle, preferably for a utility vehicle, comprising a parking brake valve assembly; and at least one spring-loaded brake cylinder via a supply line and the parking brake valve arrangement is connectable to a compressed air source, which is acted upon in the released state of the parking brake device with pressure of the compressed air source on the parking brake valve arrangement and in the inserted state of the parking brake device on the parking brake valve assembly having a pressure sink is connected. The parking brake valve assembly is adapted to be controlled electro-pneumatically in a first mode for inserting the dissolved or pickled condition. The parking brake valve assembly further comprises a muscular force operating element and is further adapted to be dissolved or to insert the inserted state in a second mode using the muscular force operating element pneumatically controlled.

Owner:MAN NUTZFAHRZEUGE AG

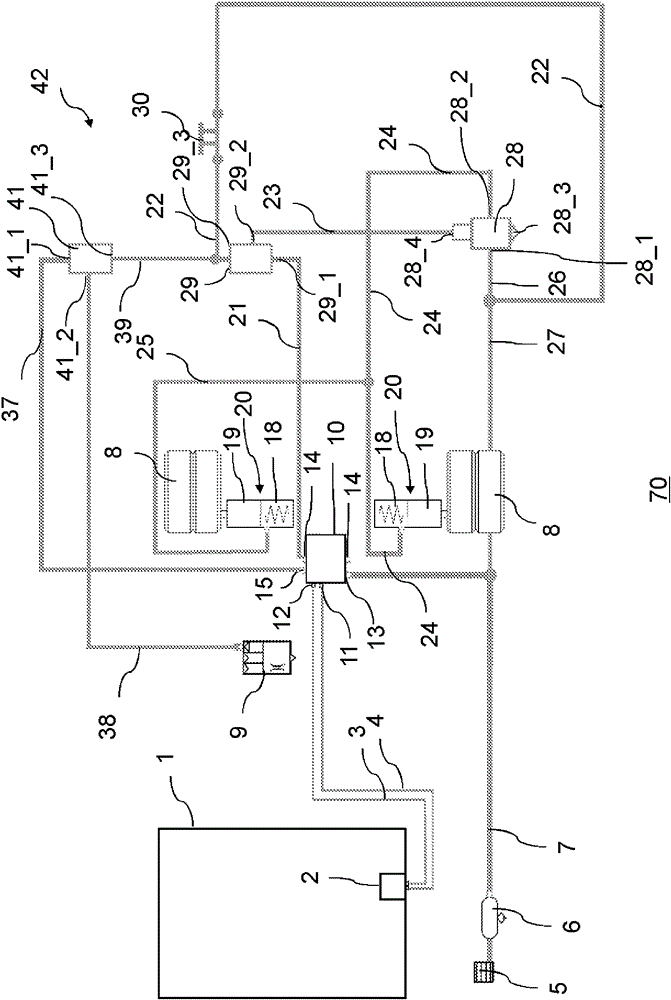

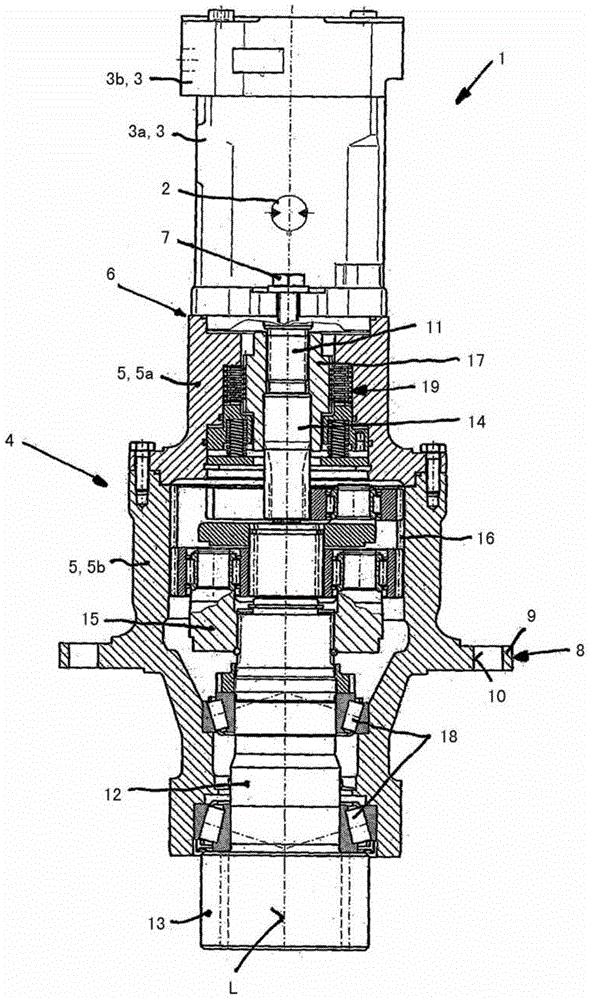

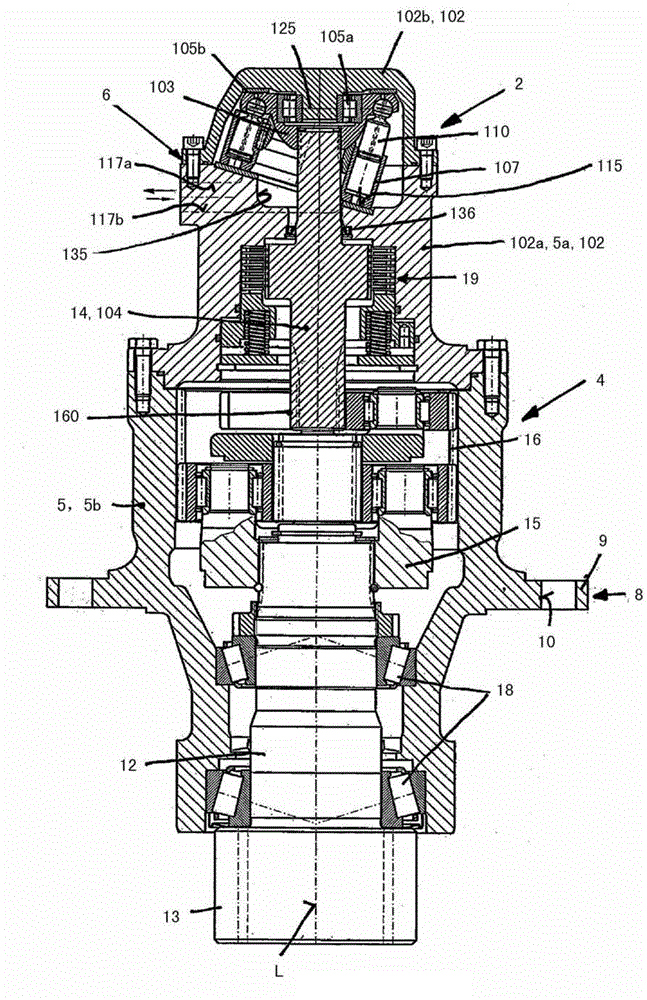

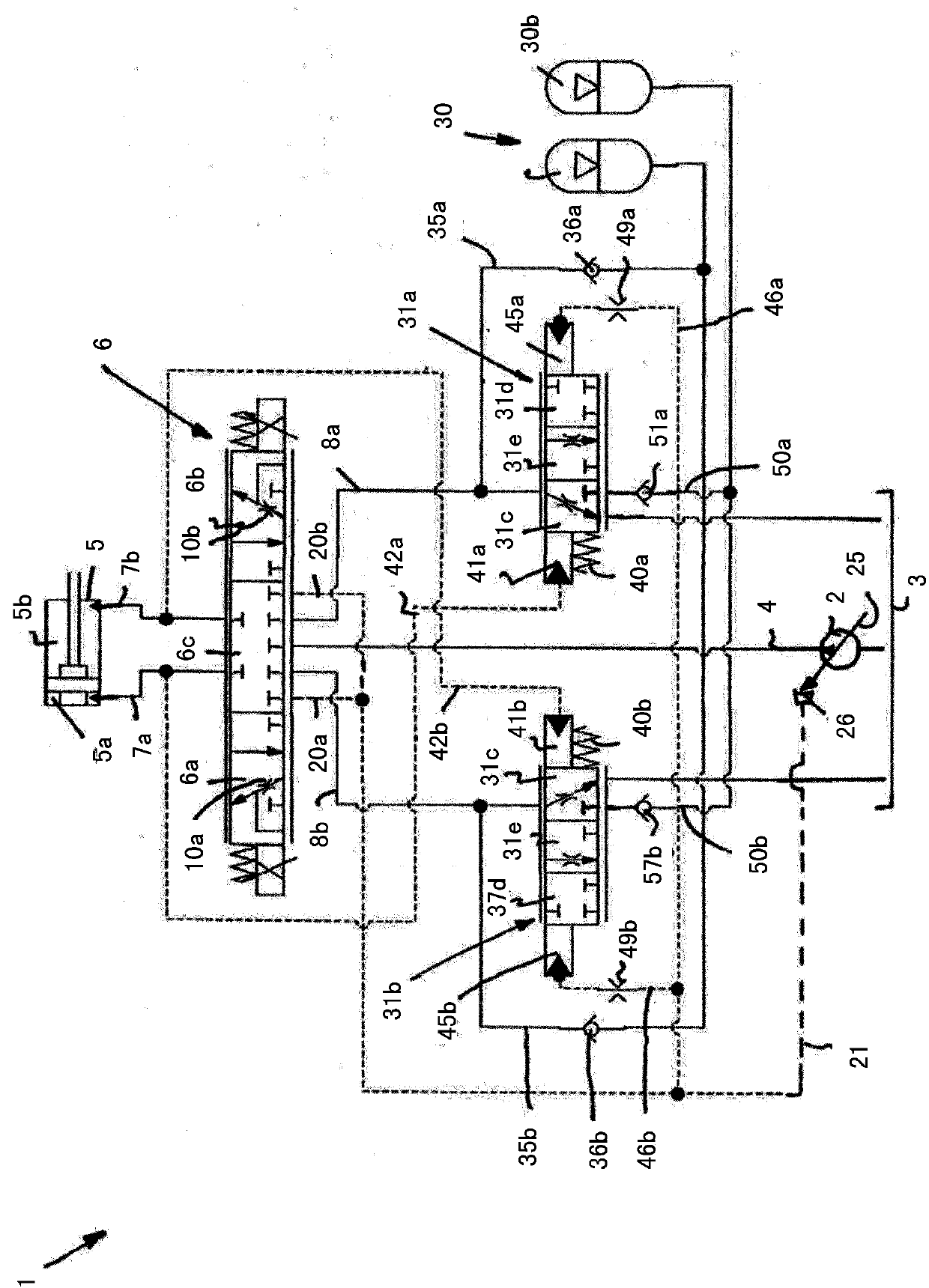

Drive axle for mobile working machine

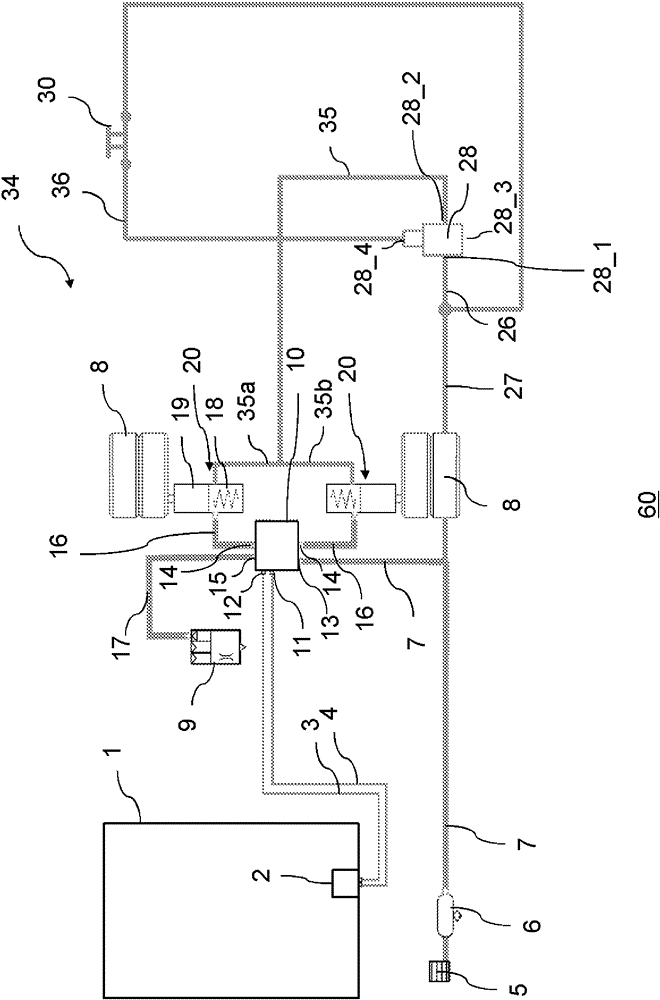

ActiveCN103863078ALower system temperatureEasy maintenanceAssociation with control/drive circuitsElectric propulsion mountingDrive motorElectric drive

The invention relates to a drive axle (1) for a mobile working machine, especially for a ground conveying machine. The drive axle at least comprises electric drive motors (3a; 3b), power electronic devices (6a; 6b) manipulating the drive motors (3a; 3b), and speed changers (4a; 4b) driven by the drive motors (3a; 3b). The speed changers drive hubs (5a; 5b). A liquid cooling device which is used for the drive motors (3a; 3b), the power electronic device (6a; 6b) and the speed changers (4a; 4b) is equipped with a liquid loop. One or more following parts, a circulating pump (10), a heat exchanger device (11) and a filter (12), of the liquid loop are assembled or attached onto the drive axle (1).

Owner:LINDE MATERIAL HANDLING

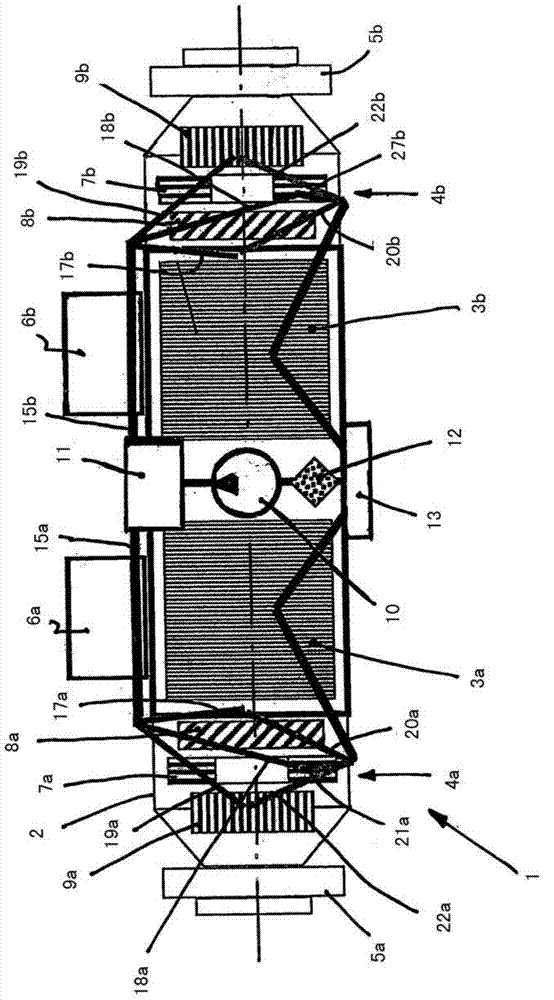

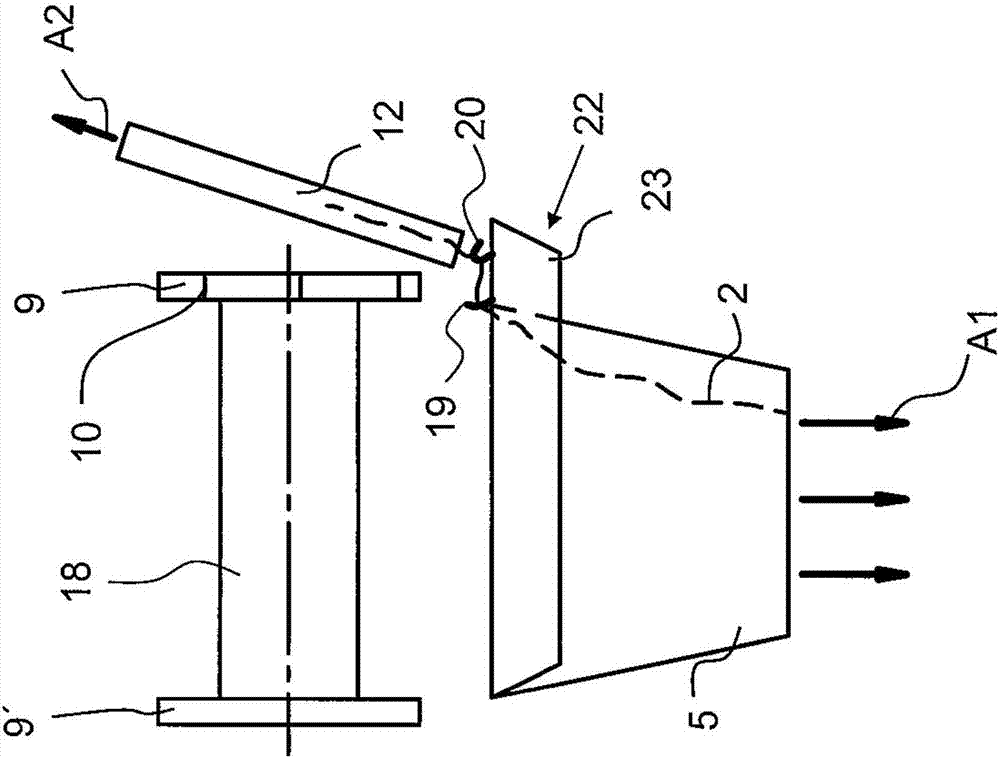

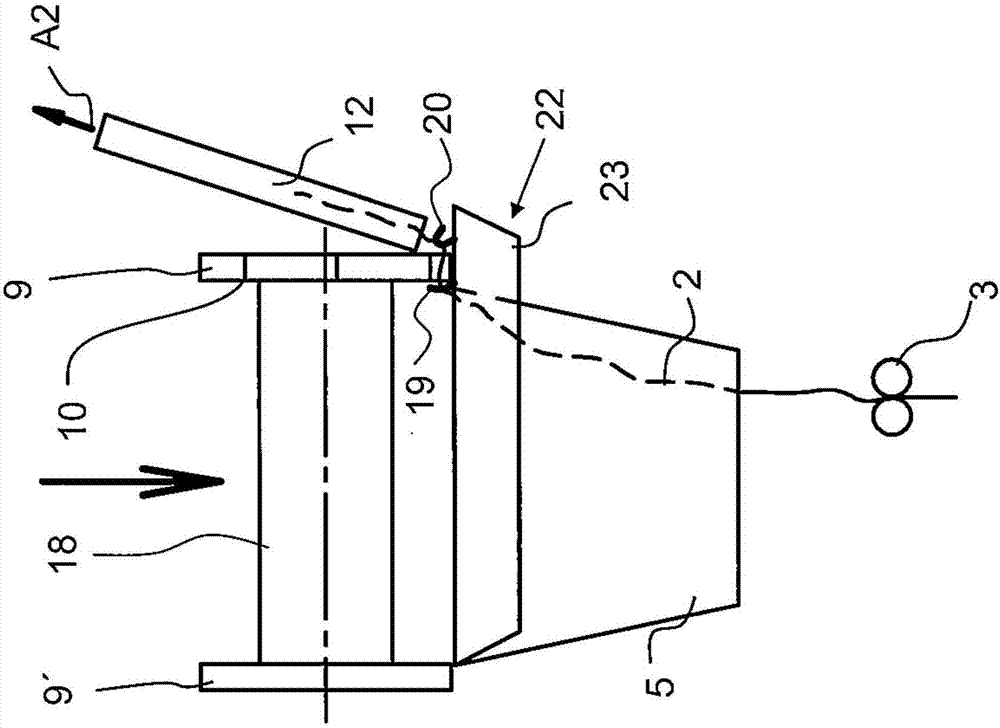

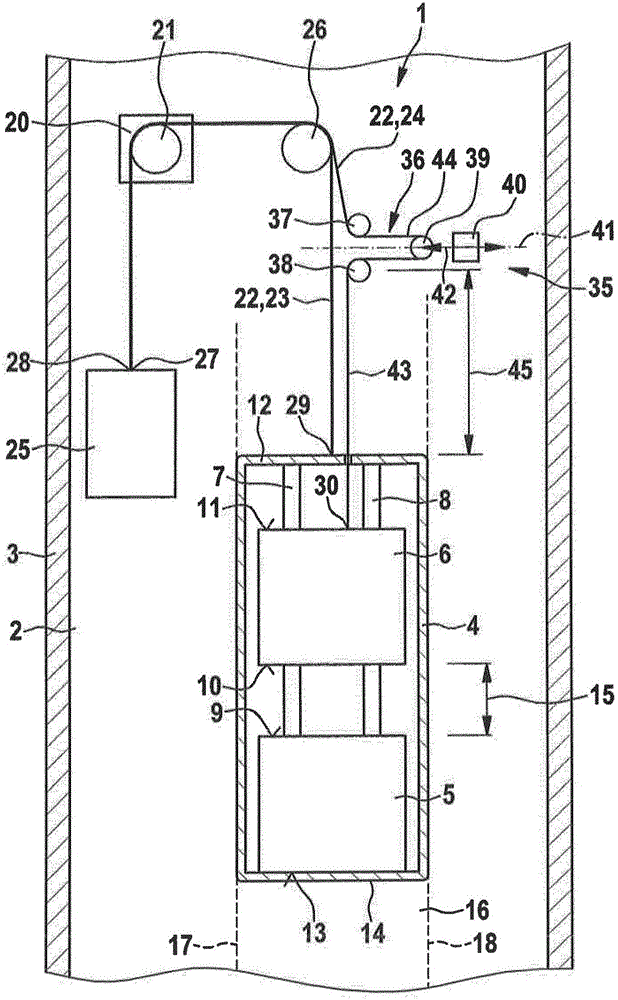

Method for Operating a Work Station and a Work Station

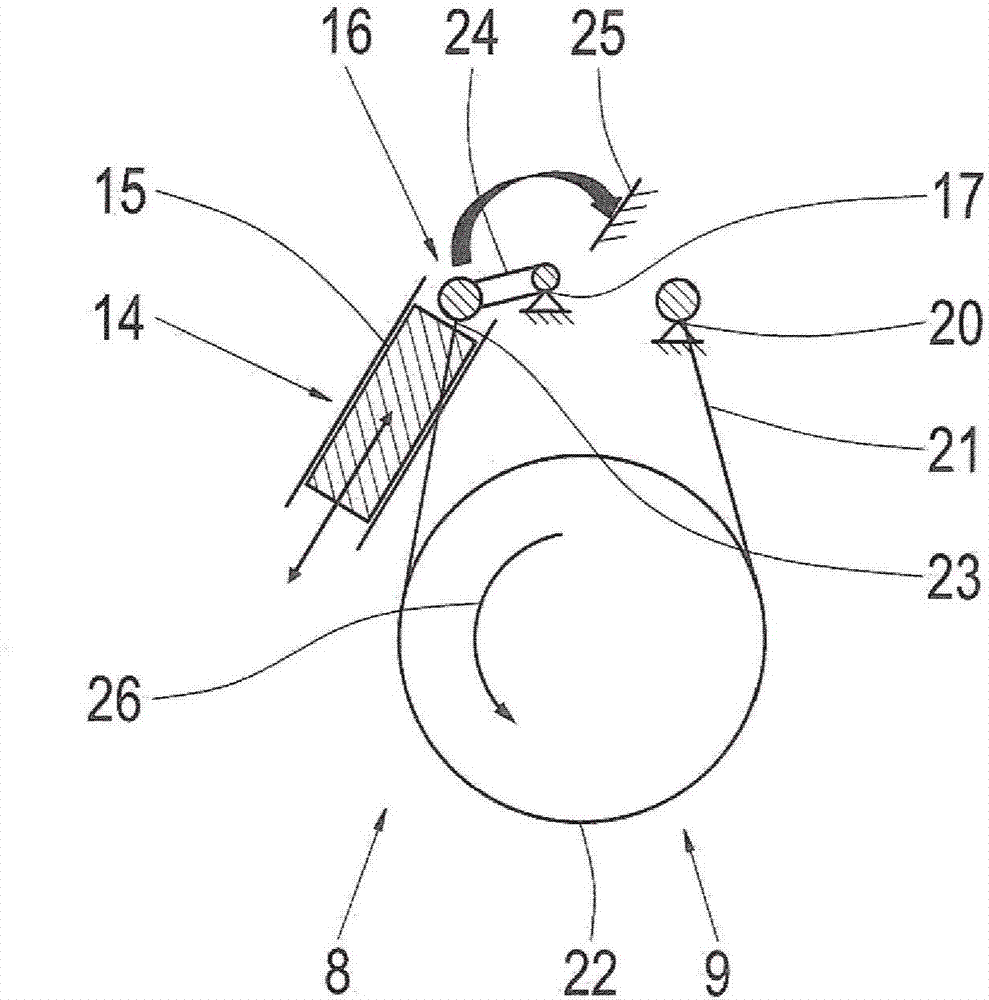

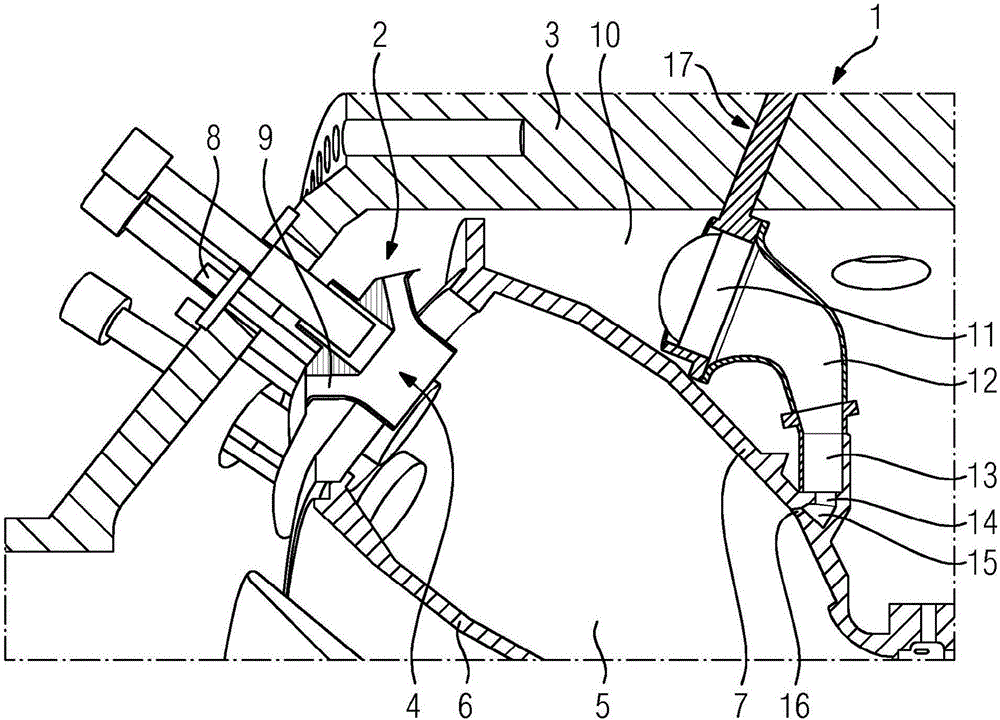

ActiveCN107055212AFlexible approachReduce structural costsFilament handlingTextiles and paperYarnEngineering

The invention provides a method for operating a work station and a work station. The work station has a spinning device or a head for delivering a thread along with a winding device for producing a cross wound package on a sleeve, wherein the winding device features a package holder with a package plate for receiving the sleeve and for catching a thread, a powered winding roller for rotating the sleeve and / or the package along with a thread traversing device. The work station is equipped with a first suction nozzle and a second suction nozzle. The thread is arranged for attachment on an empty sleeve in the two suction nozzles, and is stretched between in particular by means of negative pressure. Subsequently, the thread stretched between the two suction nozzles is captured by a catching device, in order to catch the thread and subsequently wind it onto the sleeve. With a corresponding work station, the two suction nozzles are arranged at each other in such a manner that the thread may be arranged for the attachment to an empty sleeve in the two suction nozzles and may be stretched between the two suction nozzles by means of negative pressure in at least the second suction nozzle in such a manner that the stretched thread can be captured between the two suction nozzles by a catching device, in order to catch the thread and subsequently wind it onto the sleeve.

Owner:RIETER INGOLSTADT GMBH

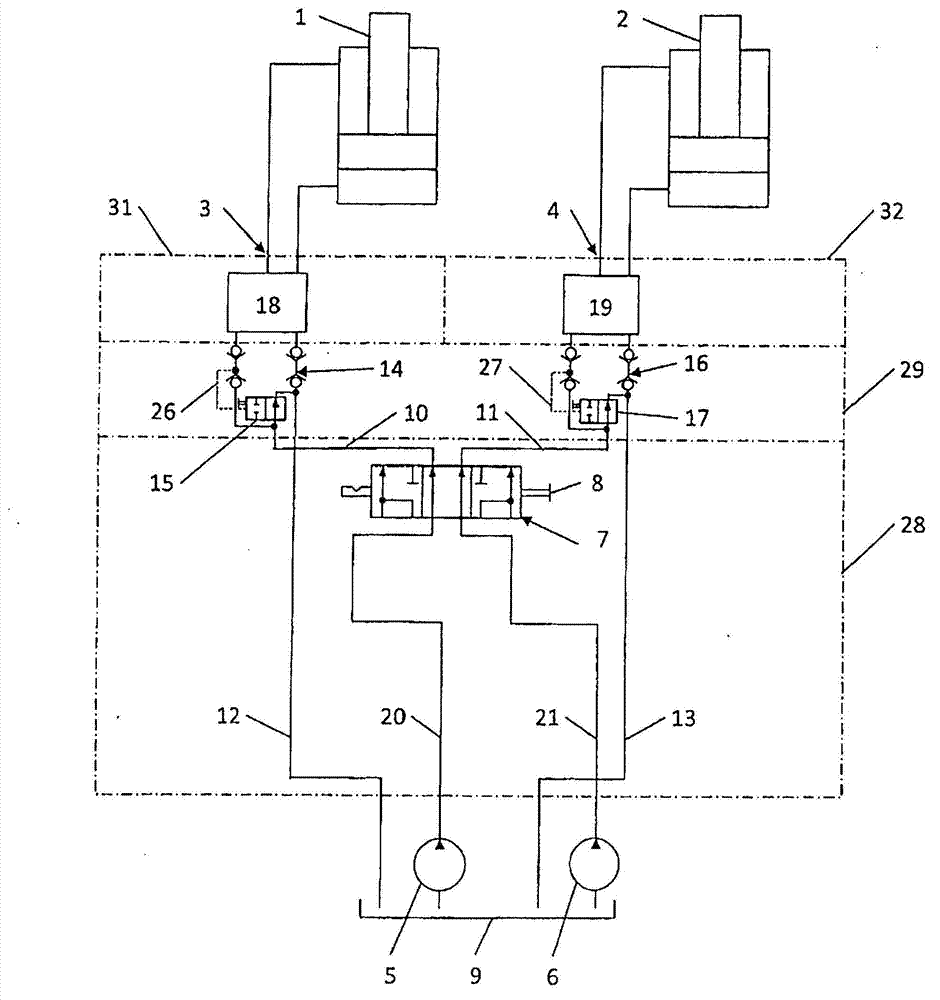

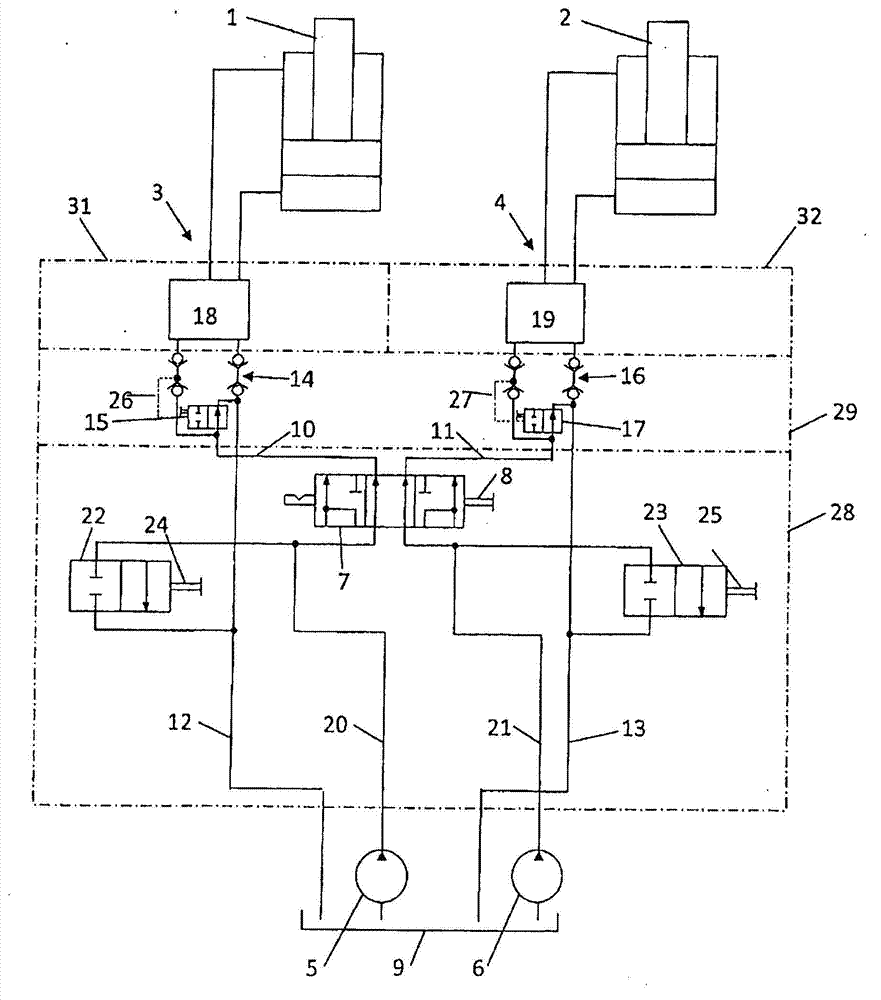

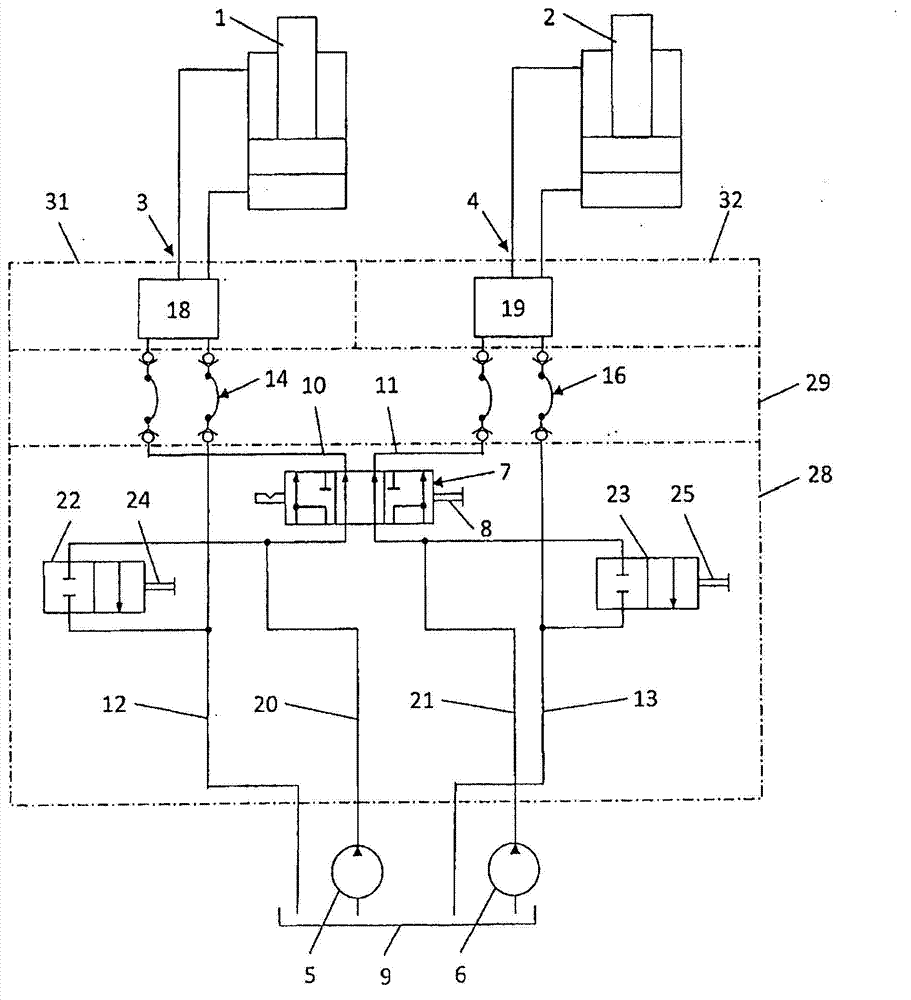

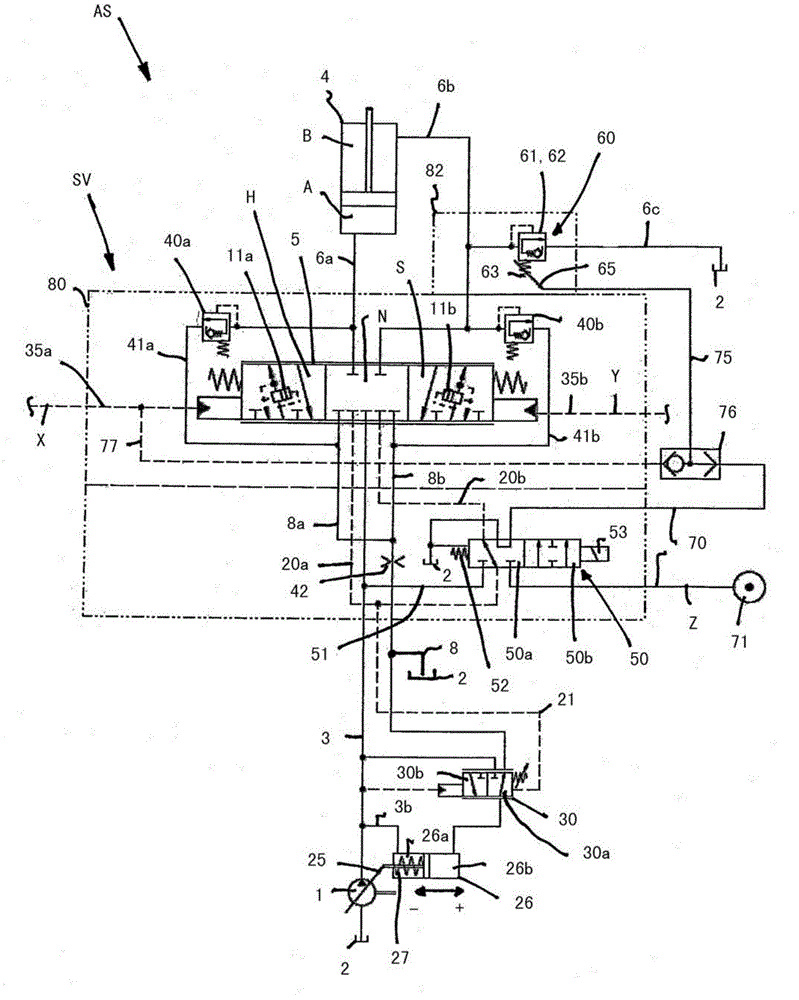

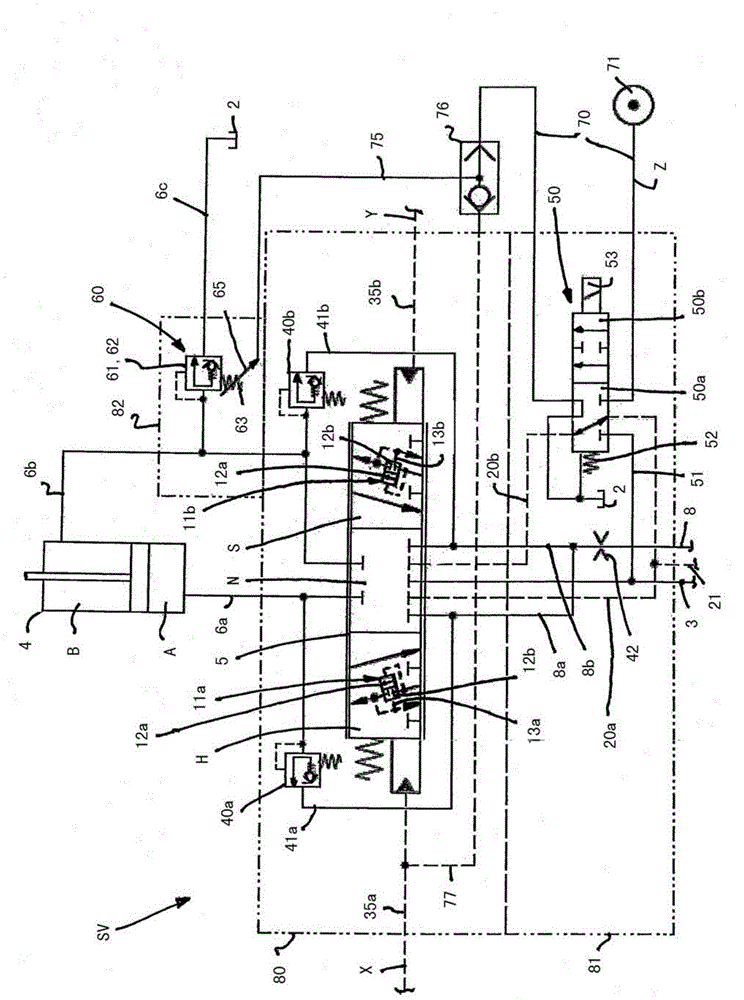

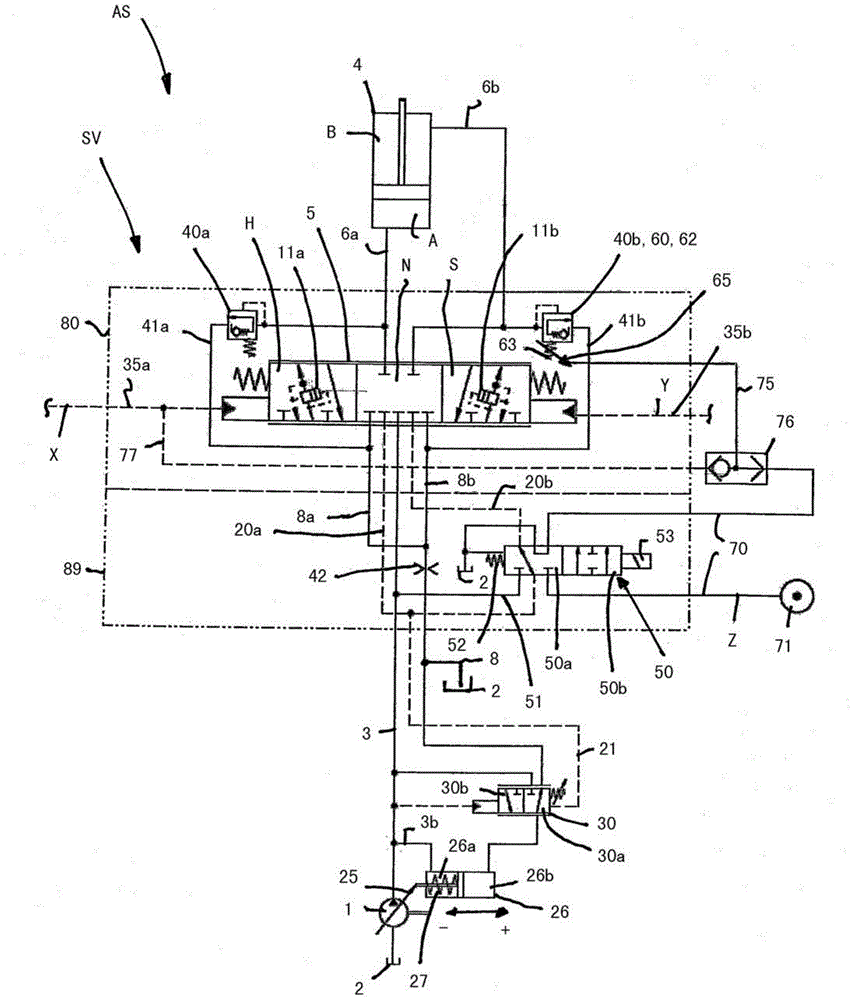

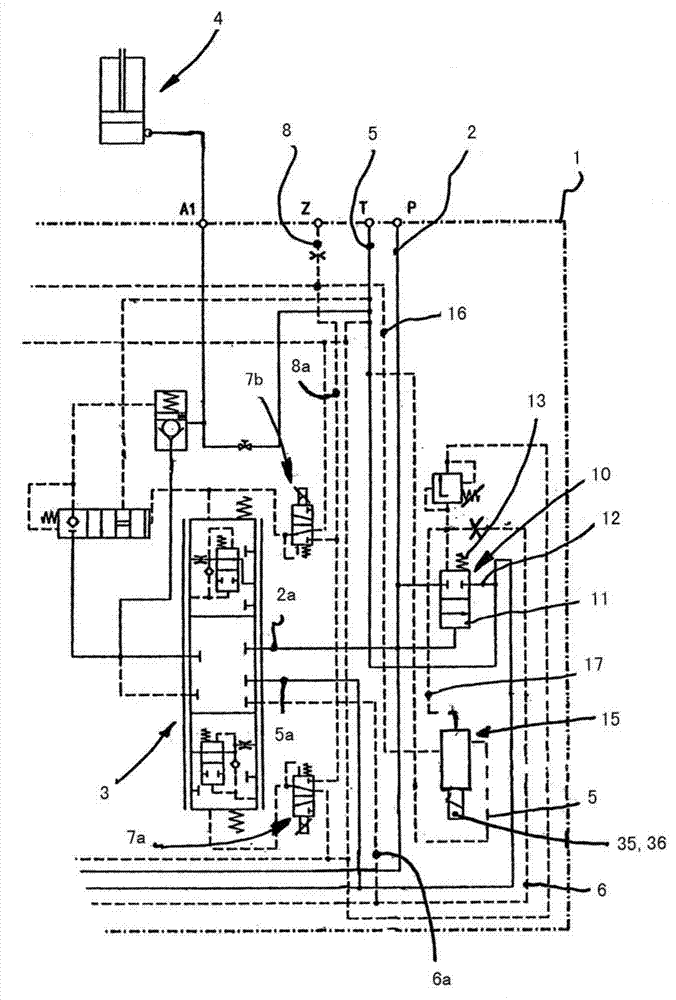

Control apparatus for a first tool and a second tool

ActiveCN103119306ASimple structureReduce structural costsServomotorsServometer circuitsUsabilityControl valves

The invention relates to a control apparatus for a first and a second tool (1, 2) operated by means of a pressure medium, in particular hydraulic oil, comprising a first supply circuit (3) for the first tool (1) and a second supply circuit (4) for the second tool (2). The control apparatus is or at least can be connected to a first pressure line (20) and to a second pressure line (21) of a control device to be operated in particular manually, by means of which control device the flow rate at the first tool (1) and at the second tool (2) can be changed.; In order to improve the usability and to simplify the design, a novel control device is proposed, which is characterized in that a control valve (7) is provided jointly for the first and second supply circuits (3, 4) as the control device, the control valve (7) has three switching positions, namely: (a) the flow rate from the first pressure line (20) is available only to the first tool (1) and the flow rate from the second pressure line (21) is available only to the second tool (2), (b) the flow rate from the first and second pressure lines (20, 21) is available preferably to the first tool (1), (c) the flow rate from the first and second pressure lines (20, 21) is available preferably to the second tool (2).

Owner:LUKAS HYDRAULIK

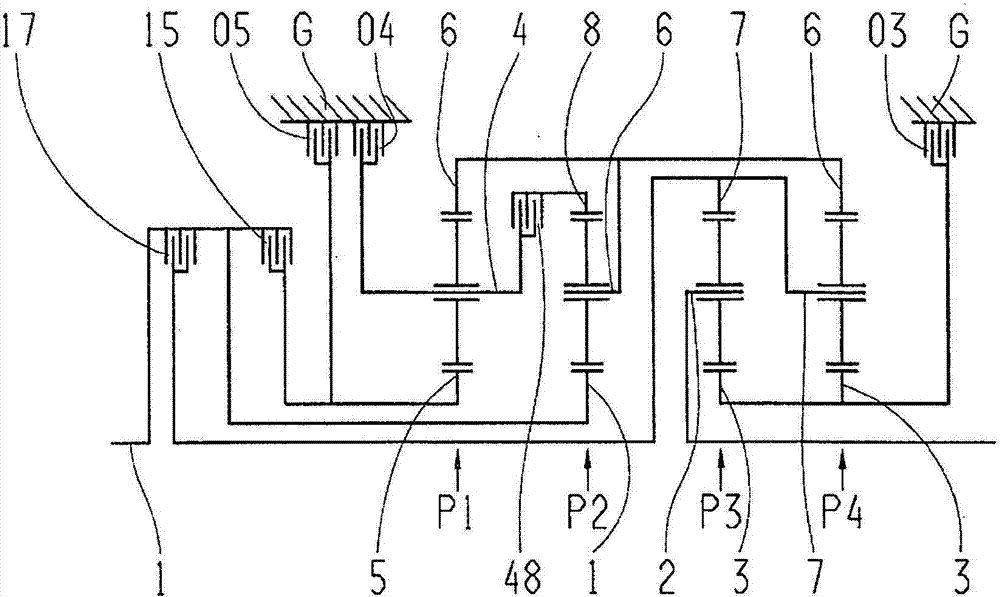

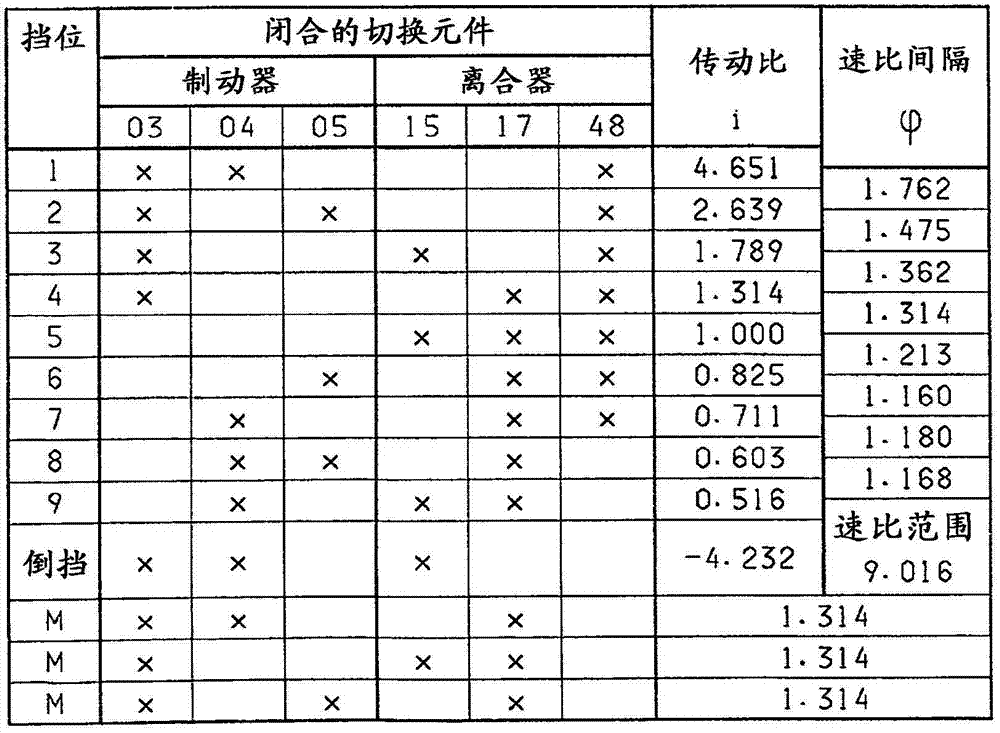

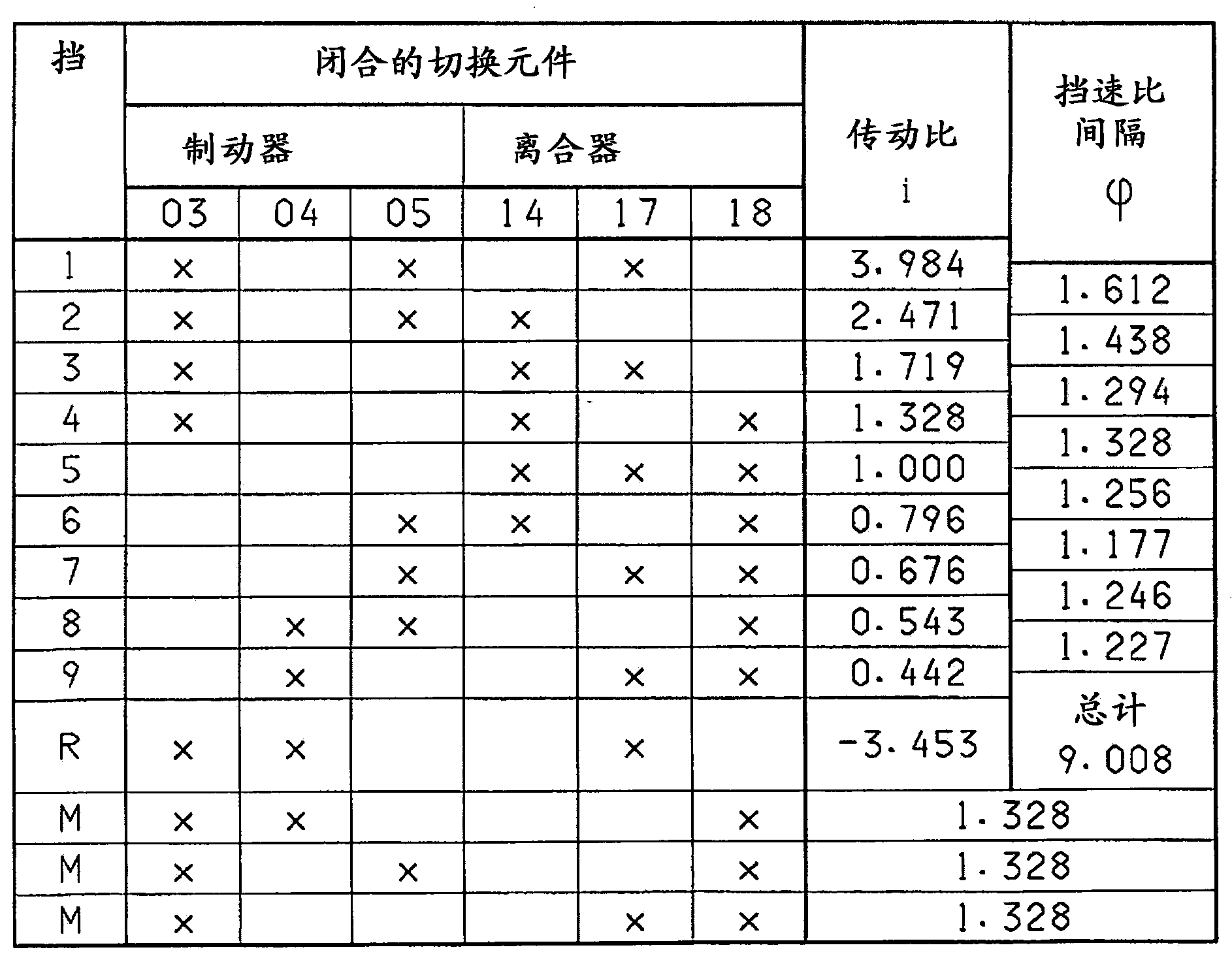

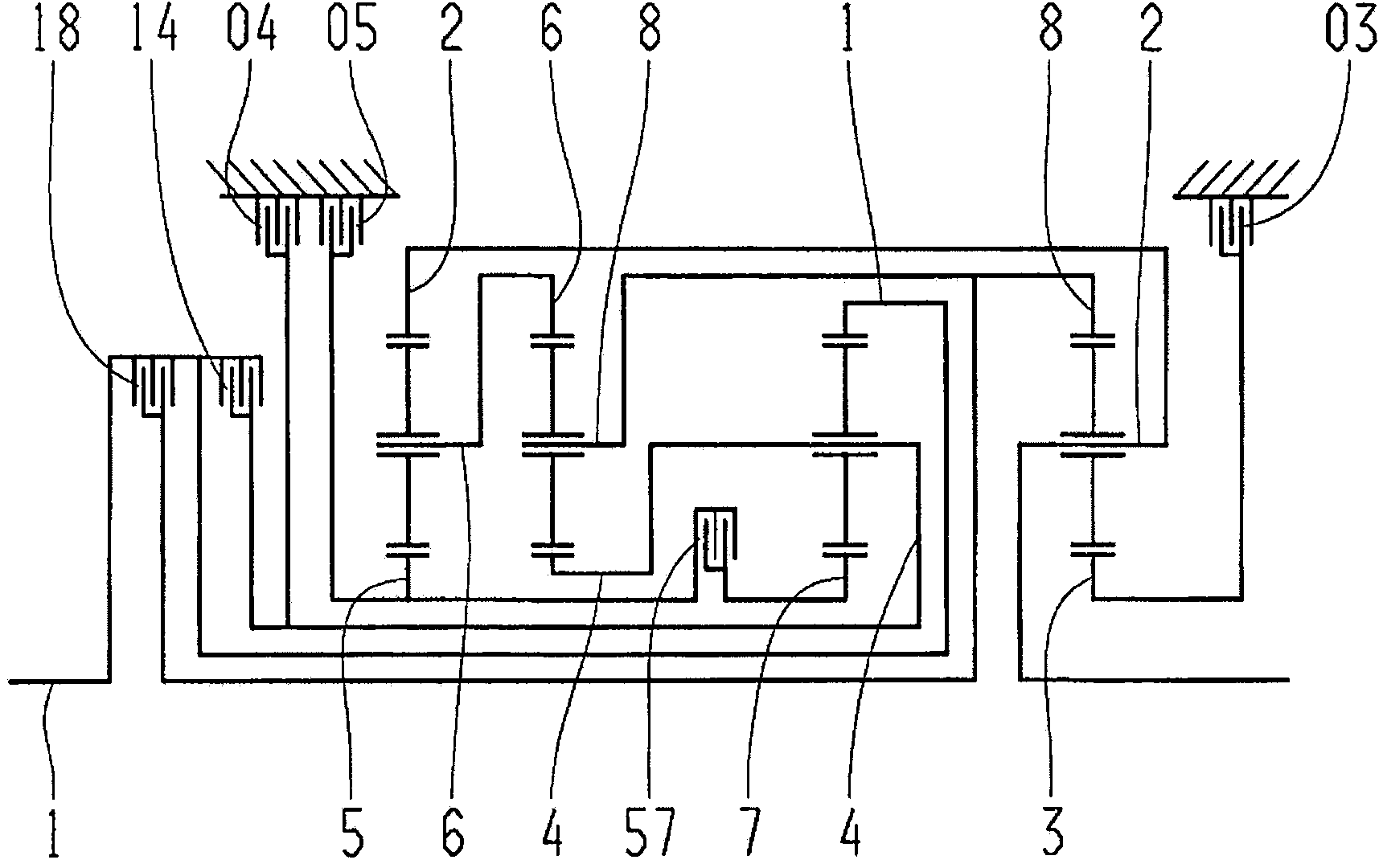

Multi-stage transmission

InactiveCN104718399AIncrease overall speed ratio rangeImprove driving comfort performanceToothed gearingsTransmission elementsCouplingGear wheel

The invention relates to a multi-stage transmission comprising four planetary gear wheel sets (P1, P2, P3, P4), eight rotatable shafts (1, 2, 3, 4, 5, 6, 7, 8) and six shifting elements (03, 04, 05, 15, 17, 48), wherein the sun gear of the first planetary gear wheel set (P1) is connected to the fifth shaft (5), which can be connected to the drive shaft (1) by a first coupling (15) and can be coupled to the housing (G) via a third brake (05), wherein the drive shaft (1) can be connected via a second coupling (17) to the seventh shaft (7), connected to the web of the fourth planetary gear wheel set (P4) and the ring gear of the third planetary gear wheel set (P3), and is connected to the sun gear of the second planetary gear wheel set (P2), wherein the sixth shaft (6) is connected to the ring gear of the first planetary gear wheel set (P1), the web of the second planetary gear wheel set (P2) and the ring gear of the fourth planetary gear wheel set (P4) and the third shaft (3) is connected to the sun gear of the third planetary gear wheel set (P3) and the sun gear of the fourth planetary gear wheel set (P4) and can be coupled to the housing (G) via a first brake (03), wherein the fourth shaft (4) is connected to the web of the first planetary gear wheel set (P1), can be coupled to the housing (G) via a second brake (04) and can be connected via a third coupling (48) to the eight shaft (8), which is connected to the ring gear of the second planetary gear wheel set (P2), and wherein the drive shaft (2) of the transmission is connected to the web of the third planetary gear wheel set (P3).

Owner:ZF FRIEDRICHSHAFEN AG

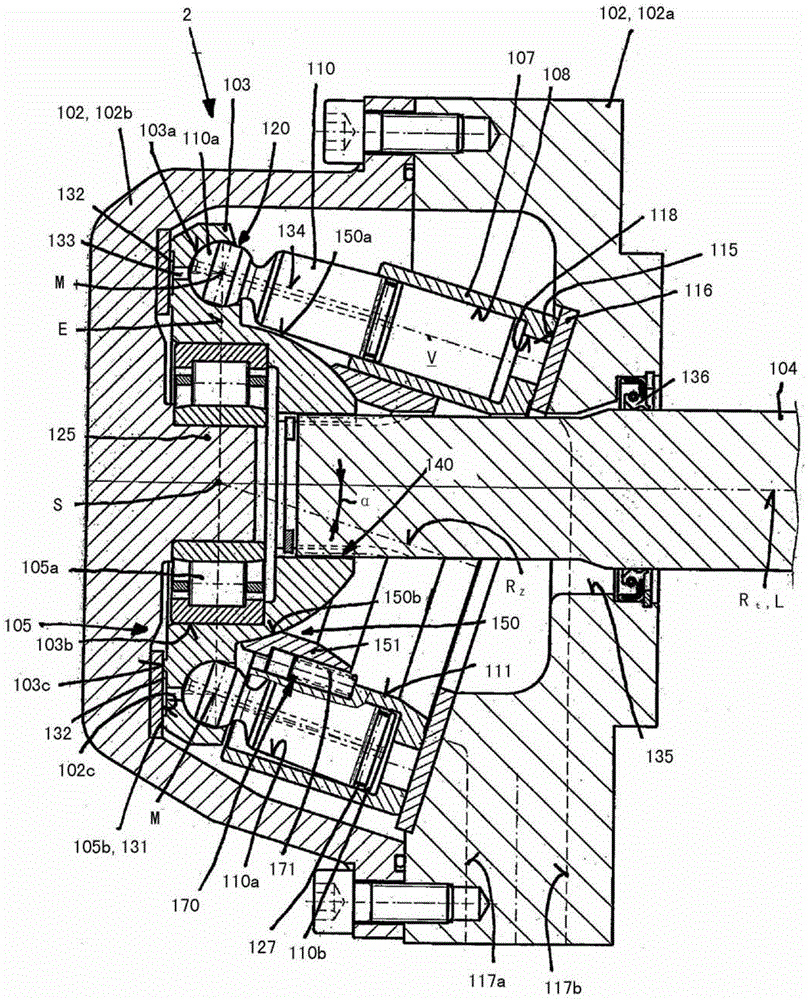

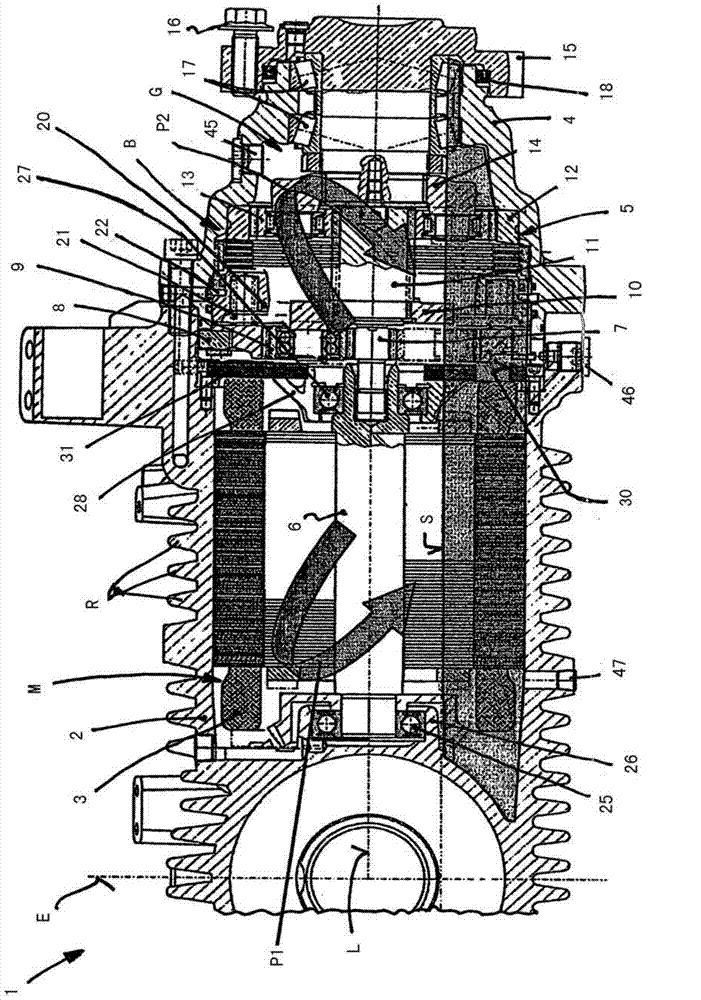

Hydrostatic axial piston engine with inclined axes

ActiveCN104976087AReduce lossLean structurePositive displacement pump componentsReciprocating piston enginesTransverse forceEngineering

The invention relates to a hydrostatic axial piston engine (2) with inclined axes. The piston engine has: a driveshaft (104) rotatable in a housing (102) around an axis of rotation (Rt); a drive flange (3) rotatable inside the housing (102); and a cylinder barrel (107) rotatable around the axis of rotation (Rt) inside the housing (102) of the axial piston engine (2). The cylinder barrel (107) is provided with a plurality of piston spaces (108), and each piston (110) is longitudinally and movably arranged in the piston space. The pistons (110) are articulated and fixed on the drive flange (3). A support device (105) is arranged to drive support the drive flange (103) on the housing (102). According to the invention, the support device (105) of the drive flange (3) includes a radial bearing (105a) which receives a transverse force of the drive flange (103) and is raidally arranged between the drive flange (103) and a support seat (125) arranged on the housing (102).

Owner:LINDE HYDRAULICS

Multi-ratio transmission

InactiveCN104145135AAccessibilityIncrease overall speed ratio rangeToothed gearingsTransmission elementsDrive shaftEngineering

Owner:ZF FRIEDRICHSHAFEN AG

Control Valve Device With A Float Position

ActiveCN104863913AReduce structural costsRealize unloadingServomotor componentsServomotorsLine tubingEngineering

The invention relates to a control valve device used for controlling a double-acting hydraulic pressure cylinder of a mobile operation machine. The control valve device includes a control valve connected to a conveying pipeline, a container pipeline, an ascending pipeline and a descending pipeline of a pump. The control valve has a middle position, an ascending position and a descending position. The control valve device has a floating position. When the control valve is moved to the descending position, the ascending pipeline is connected with the container pipeline and the pump is connected with a descending side and switching meets failure. A release valve is arranged, so that the descending side can bypass the control valve to connect with the container and the descending side can be connected with the container in the floating position. When the control valve moves to the ascending position during ascending operation, the conveying pipeline is connected with the ascending pipeline and the descending side is enabled to connect with the container by the aid of the release valve during ascending operation, so that the descending pipeline is connected with the container through the release valve and pressure medium flow from the descending side flows to the container via the release valve.

Owner:LINDE HYDRAULICS

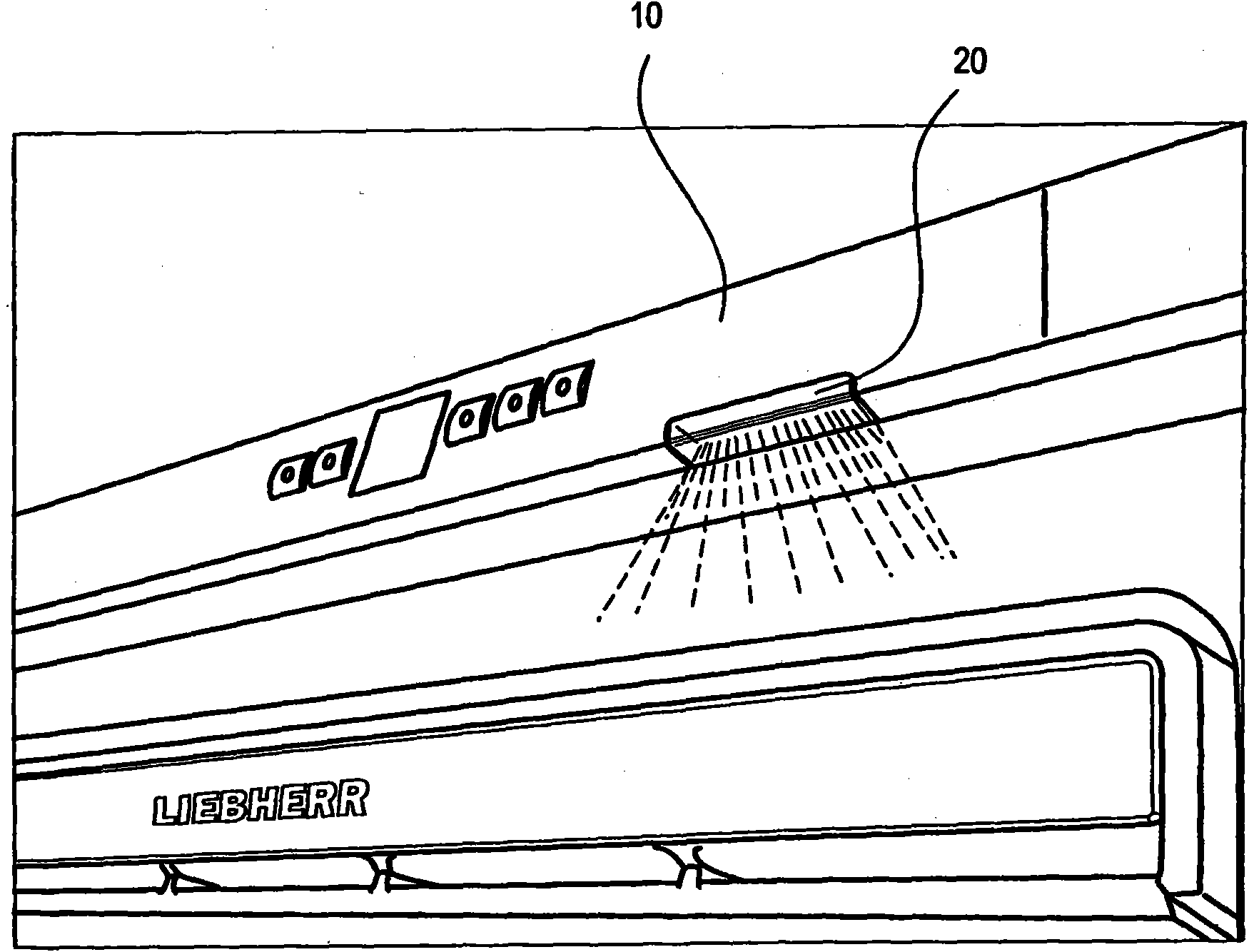

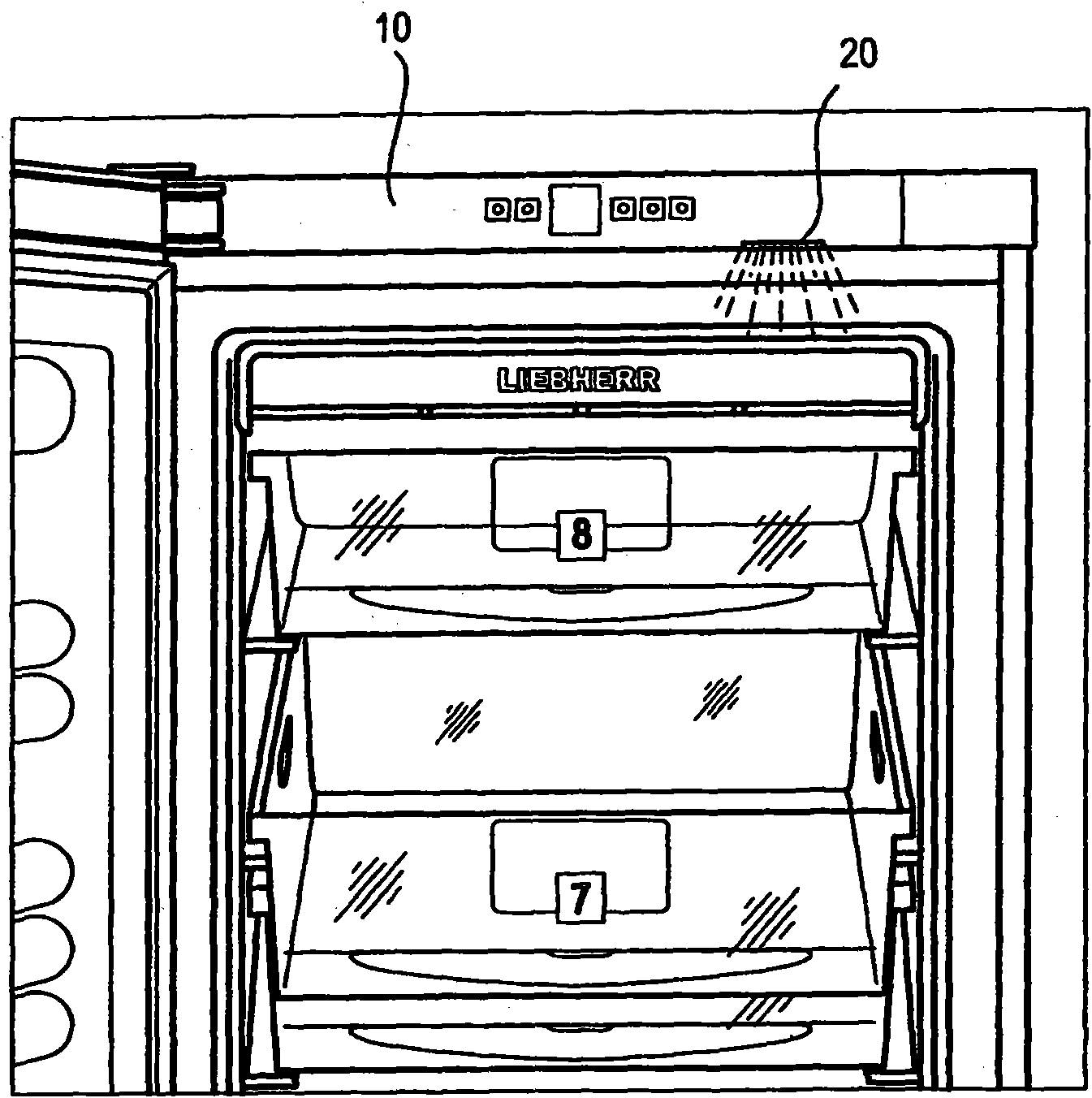

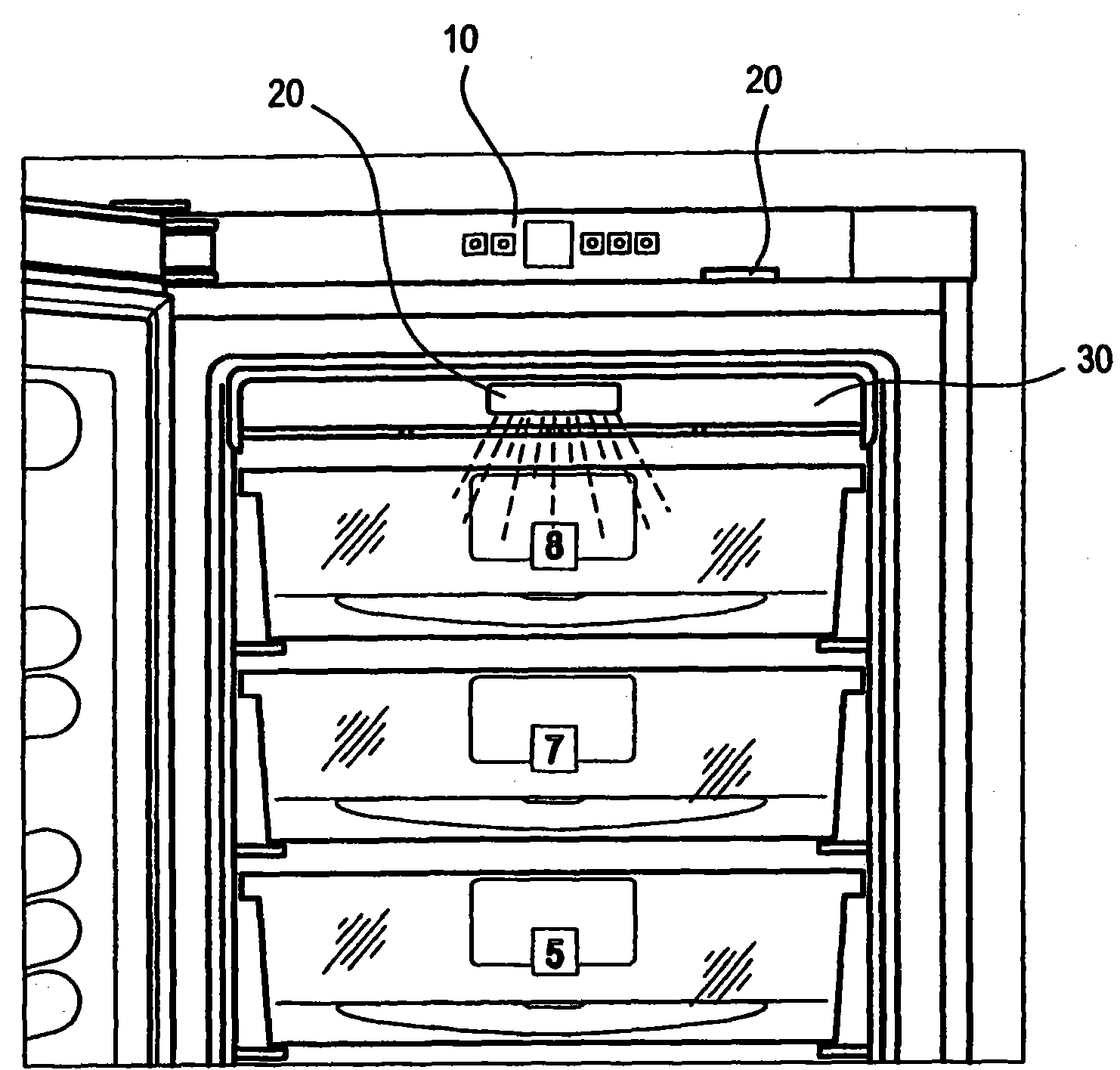

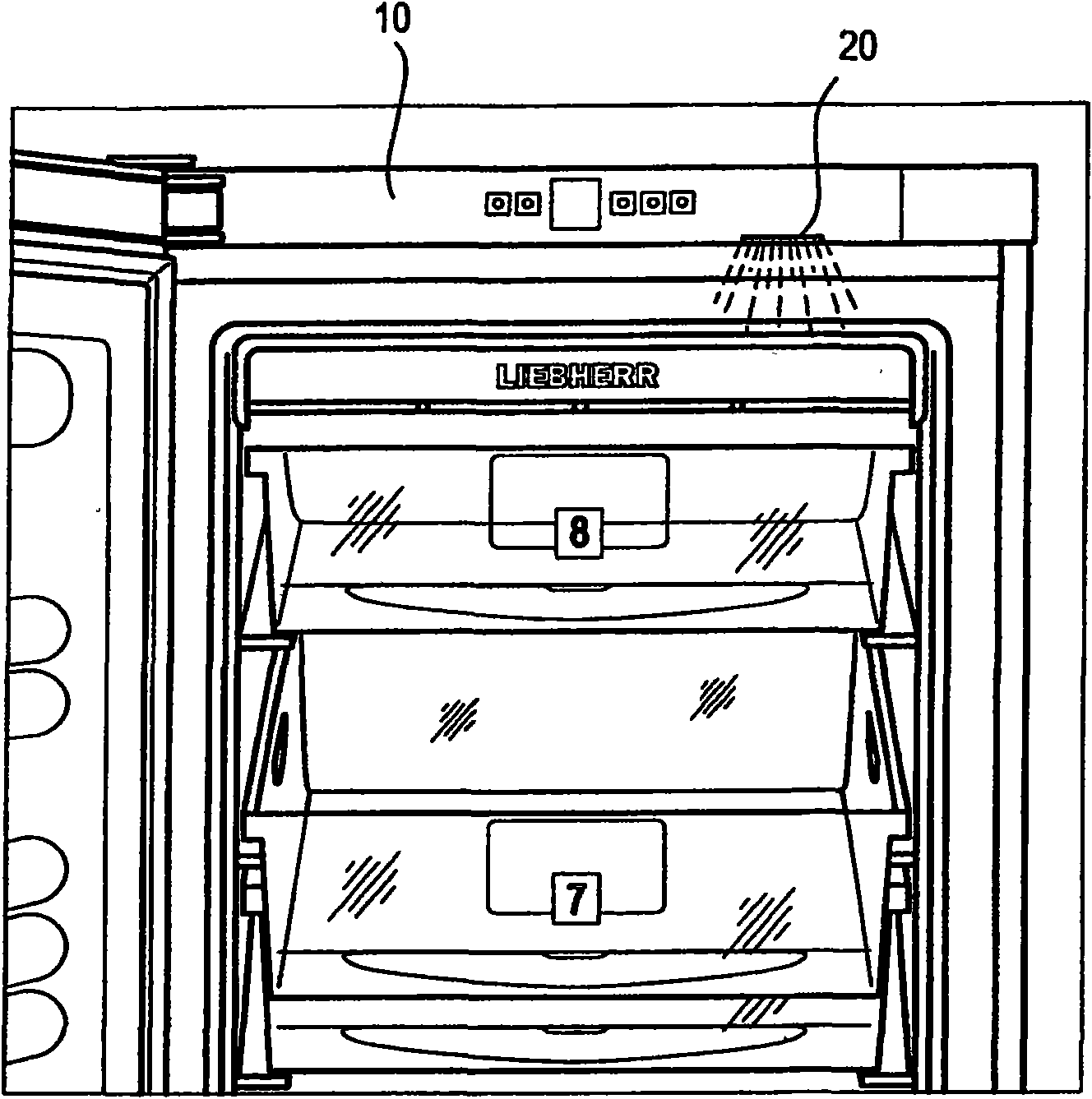

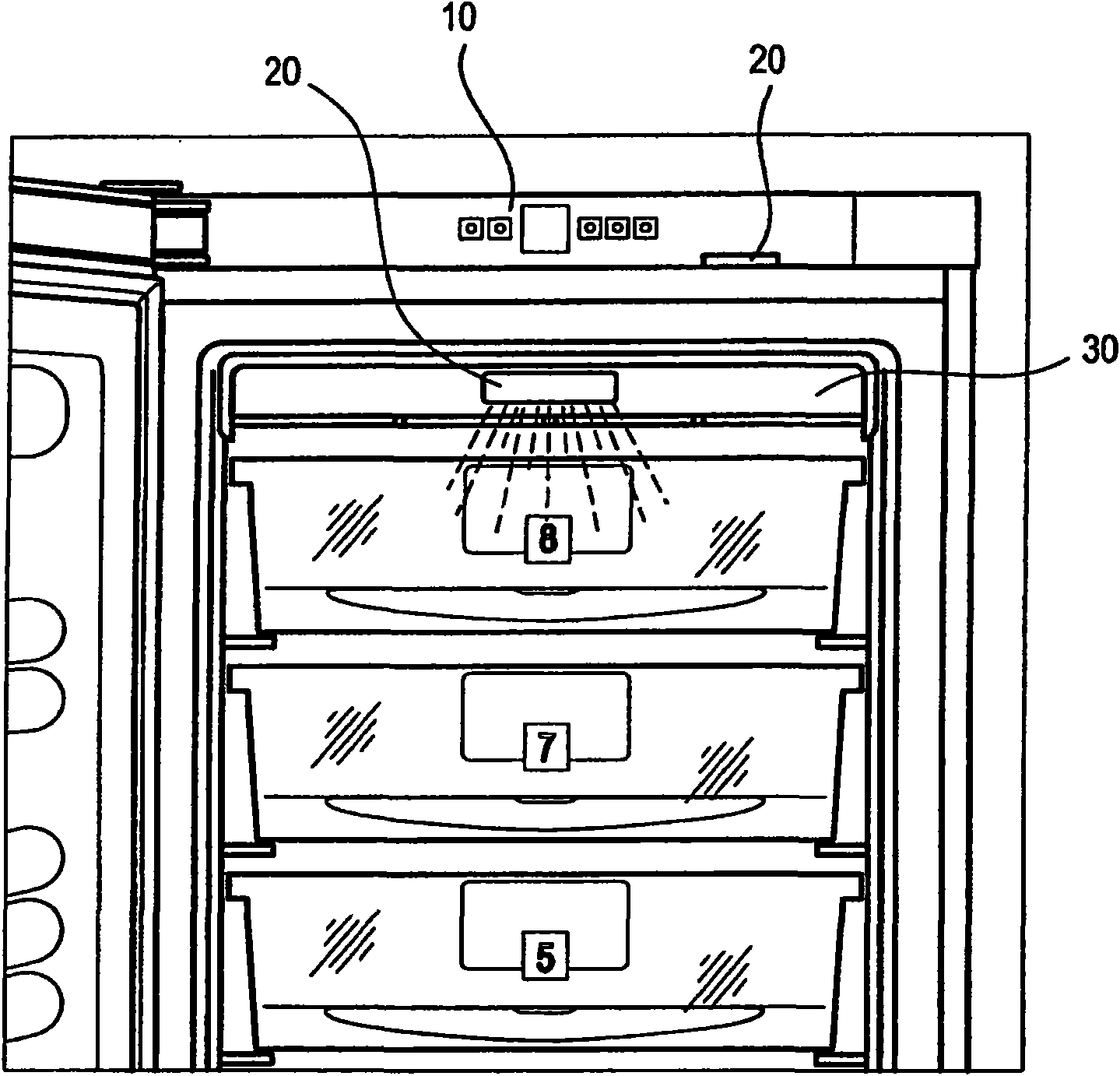

Refrigerator and/or freezer

InactiveCN102135370AReduce diversityEasy to assembleMechanical apparatusDomestic lightingEngineeringRefrigerated temperature

The invention relates to a refrigerator unit and / or a freezer unit comprising at least one operating and / or control unit for the operation and / or control of the refrigerator unit and / or freezer unit and / or comprising at least one evaporator module for the cooling of the inner space of the unit as well as comprising illumination means by means of which the inner space of the unit and / or the region located in front of the inner space of the unit from the viewpoint of the user can be illuminated at least partly, wherein the illumination means are arranged in or at the operating and / or control unit and / or in or at the evaporator module.

Owner:LIEBHERR HAUSGERATE OCHSENHAUSEN

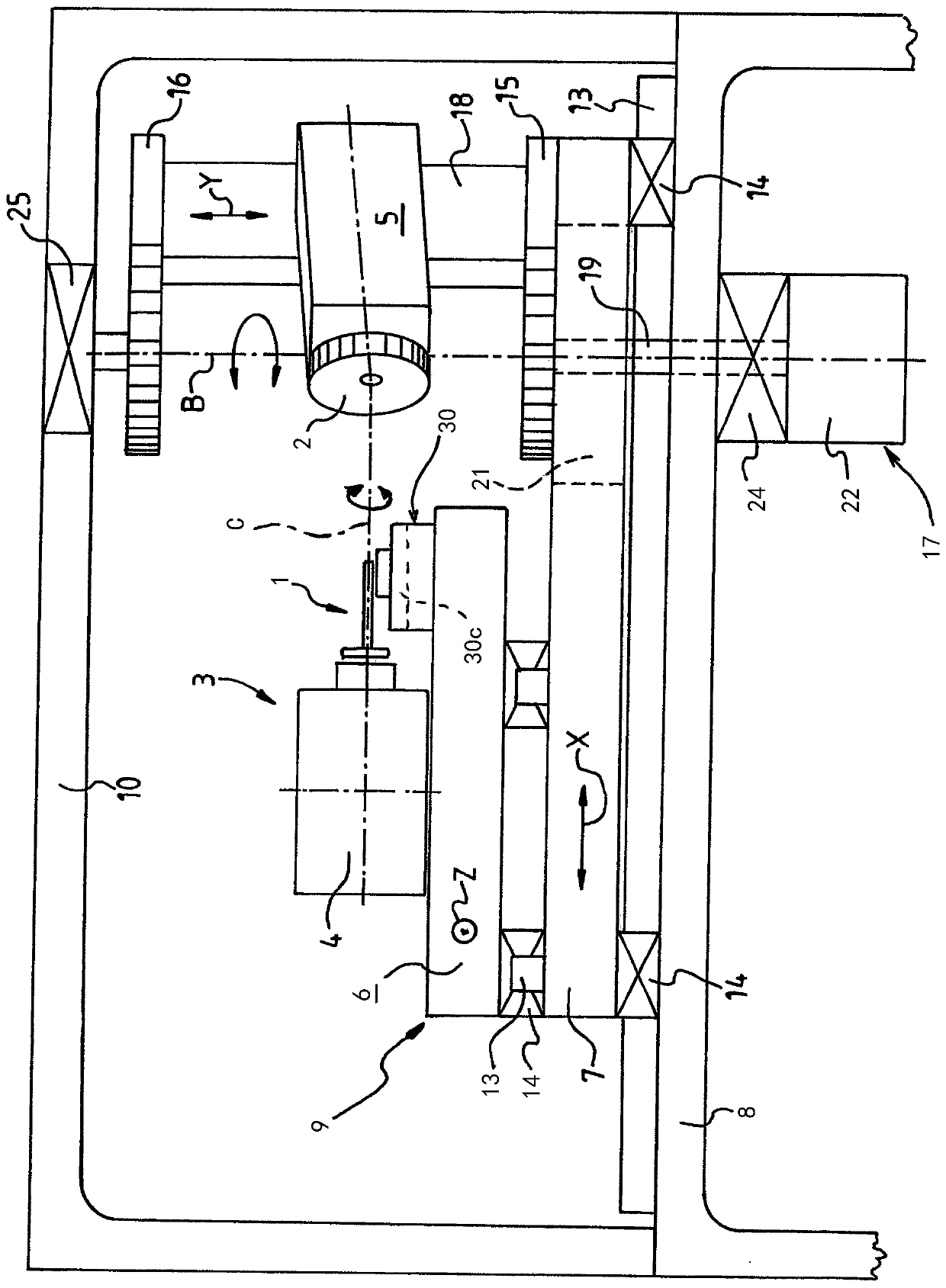

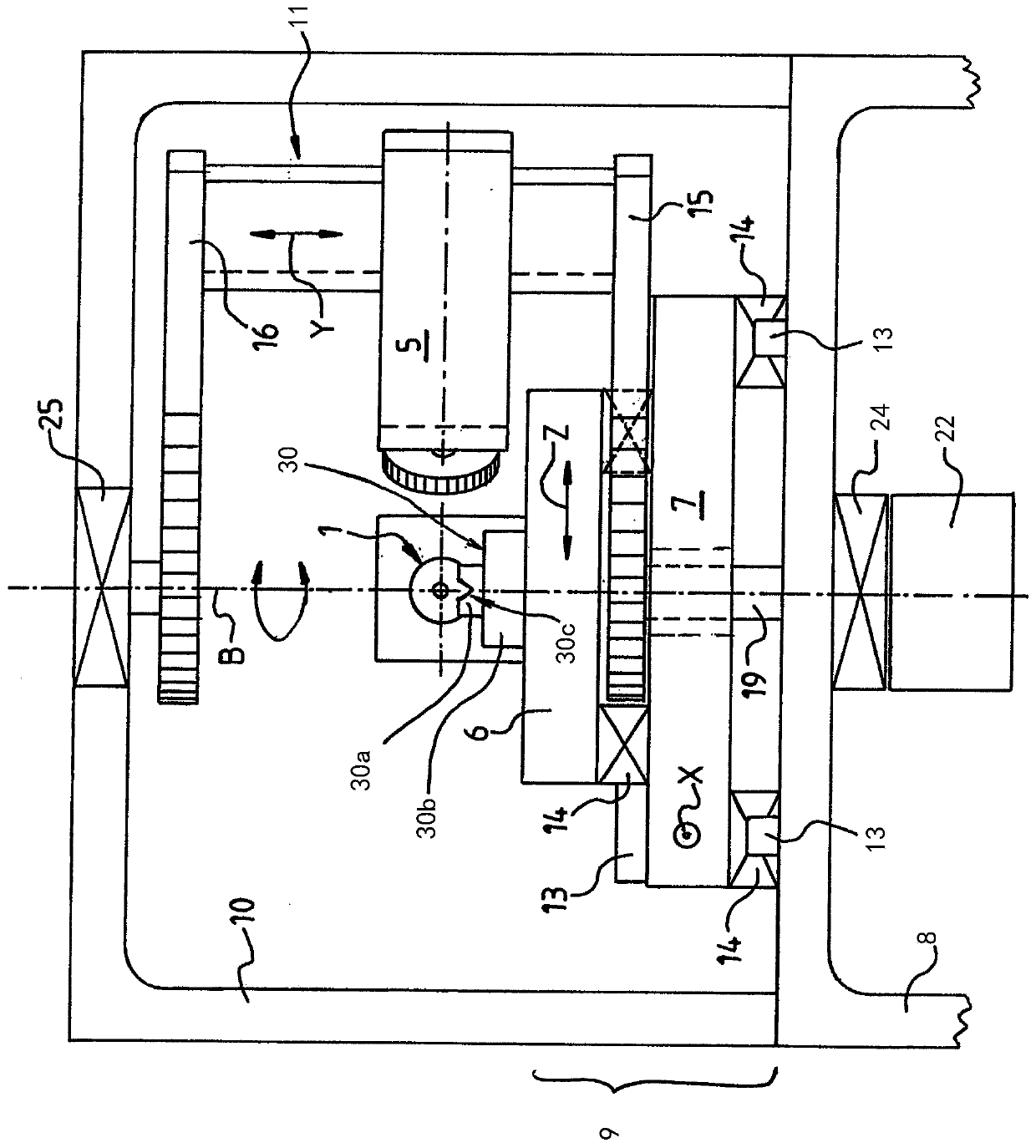

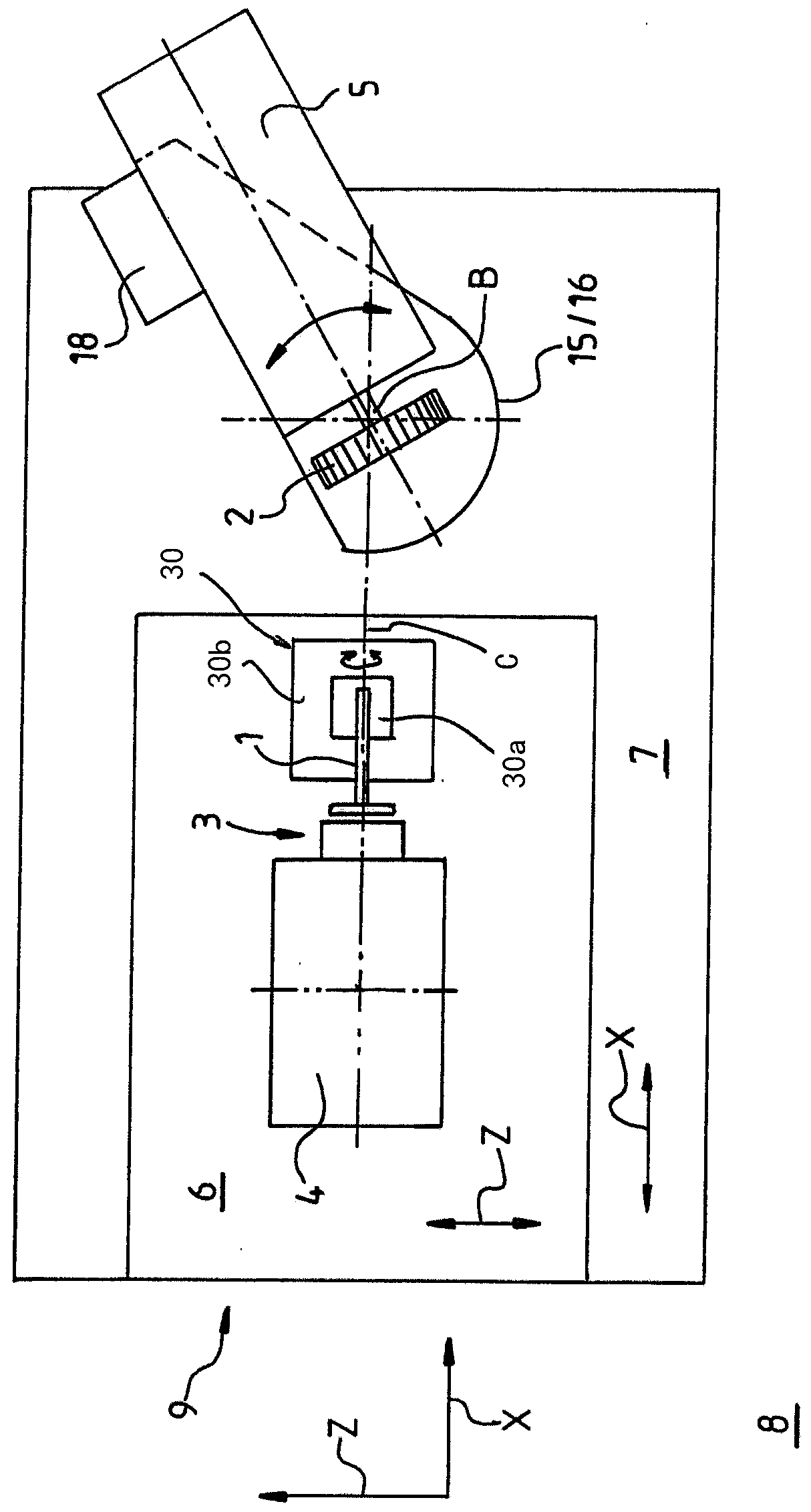

A machine tool for machining a workpiece

InactiveCN110315427AStable supportFor particularly high demands on precisionGrinding carriagesGrinding machinesEngineeringMachine tool

The invention relates to a machine tool for machining a workpiece (1), in particular a mill, wherein at least one workpiece holding device (3), a horizontal adjustment unit (9) for a first direction (X-axis) and a second direction (Z-axis), and a pivot unit (17) about a pivot axis (B-axis) oriented along a third direction (Y-axis) are provided. The machine tool has a tool unit (5) and at least onesupport arm for supporting a third adjustment device (18) in a third direction (Y-axis); in order to improve the precision, when observed in the third direction and / or the vertical direction (Y axis), at least one of the support arms (15) is arranged between first and the second adjustment device (6, 7), and / or at least one of the support arms (15) is arranged between the tool (2) and / or the workpiece (1) and the first and / or the second adjustment device (6, 7).

Owner:WORF SERVICE & KONSTRUKTION GMBH

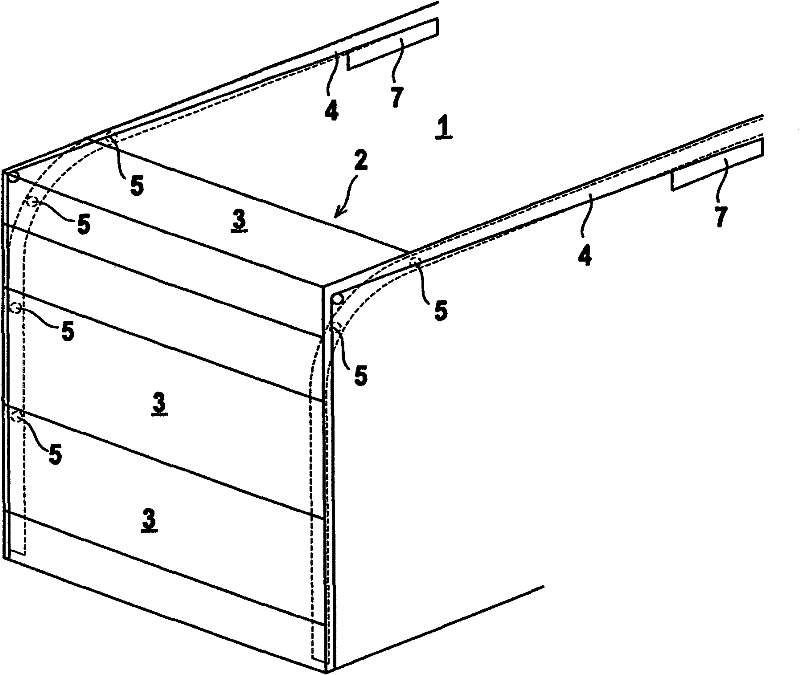

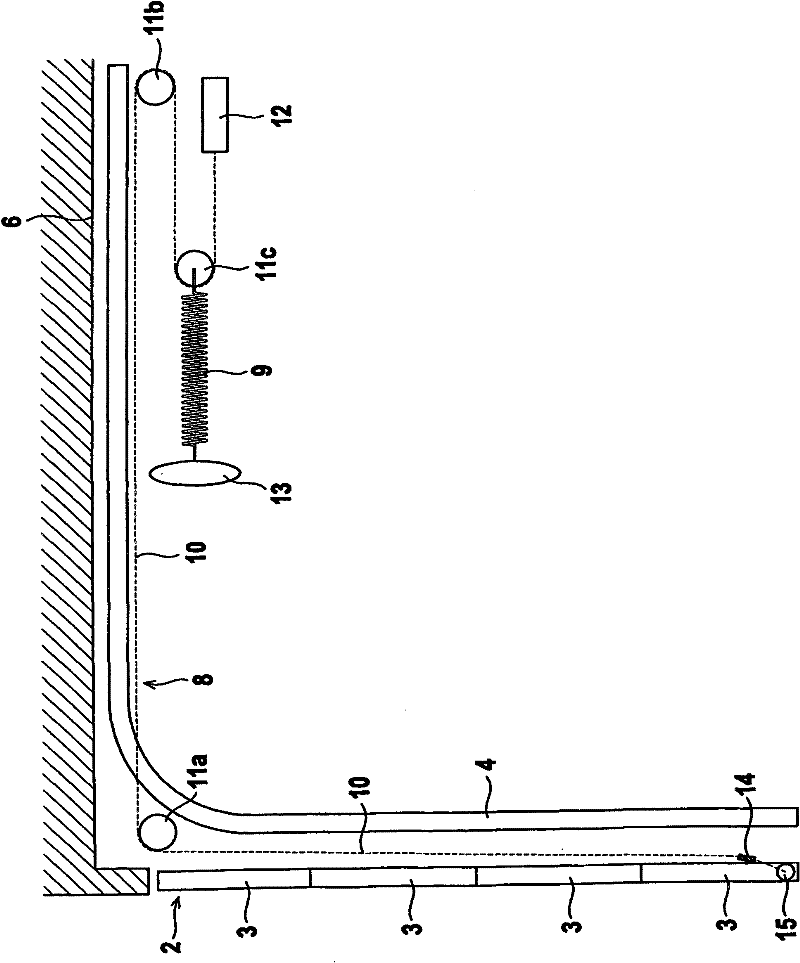

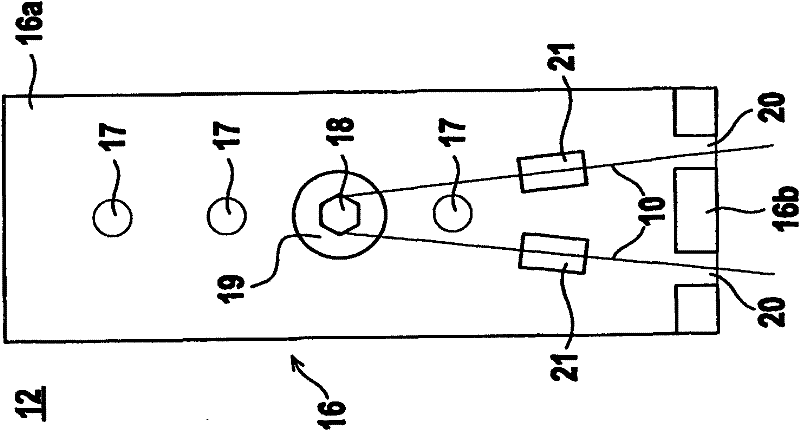

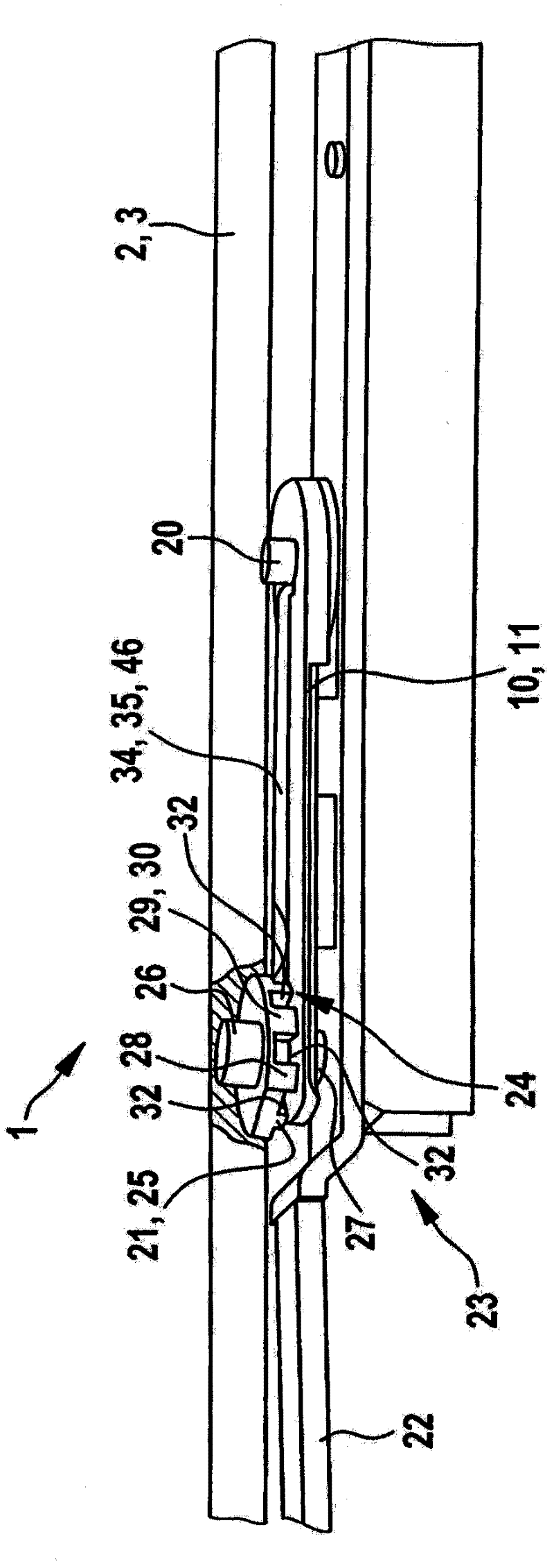

Door comprising drive system

InactiveCN102472066AAvoid breakingImprove functional safetyWing suspension devicesEngineeringMechanical engineering

The invention relates to a door (1) comprising a drive system by means of which a door leaf (2) can be moved between an open position and a closed position, said door leaf being laterally guided in guide rails. A weight compensation device comprises a cable unit (8) and a spring unit (9) on one or each side of the door leaf, as well as a cable tension compensation device (12) associated with the cable unit (8). The or each cable tension compensation device (12) is protected against cable breakage. The or each cable unit (8) consists of one cable (10) which is deflected in the cable tension compensation device (12), said device being fixed in place, such that two cable strands are obtained which run at a distance from each other. The free ends of the cable (10) are guided together and fixed to the door leaf (2). Alternatively, the cable tension compensation device (12) can be fixed to the door leaf (2). In this case the free ends of the cable (10) are fixed in place.

Owner:SOMMER ANTRIEBS & FUNKTECHNIK GMBH

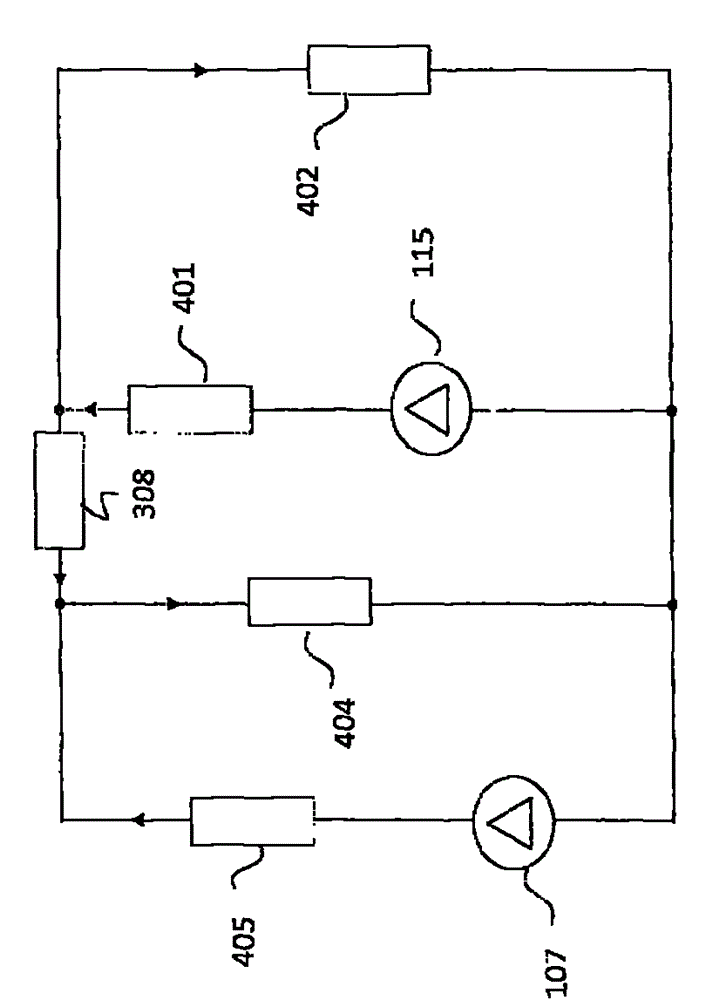

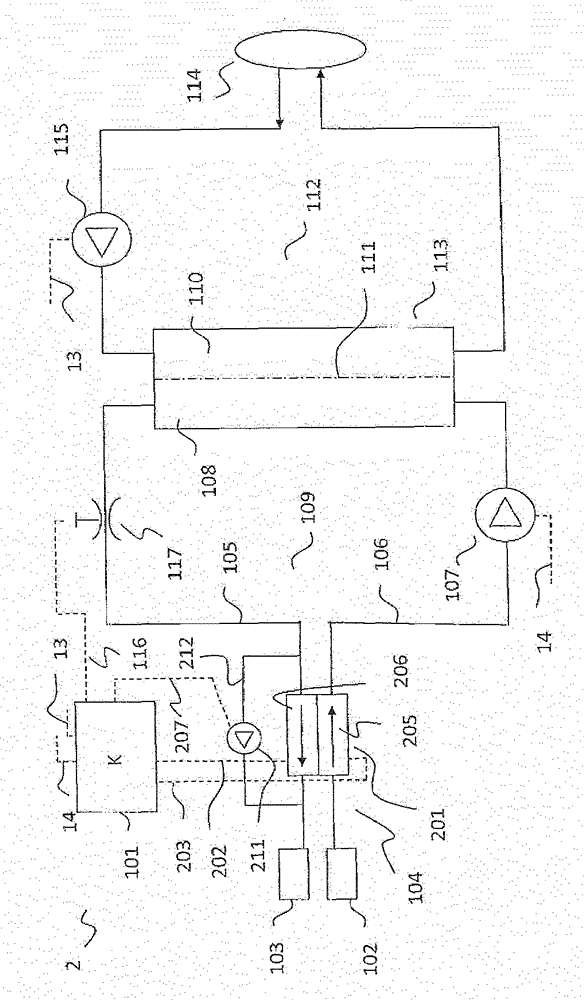

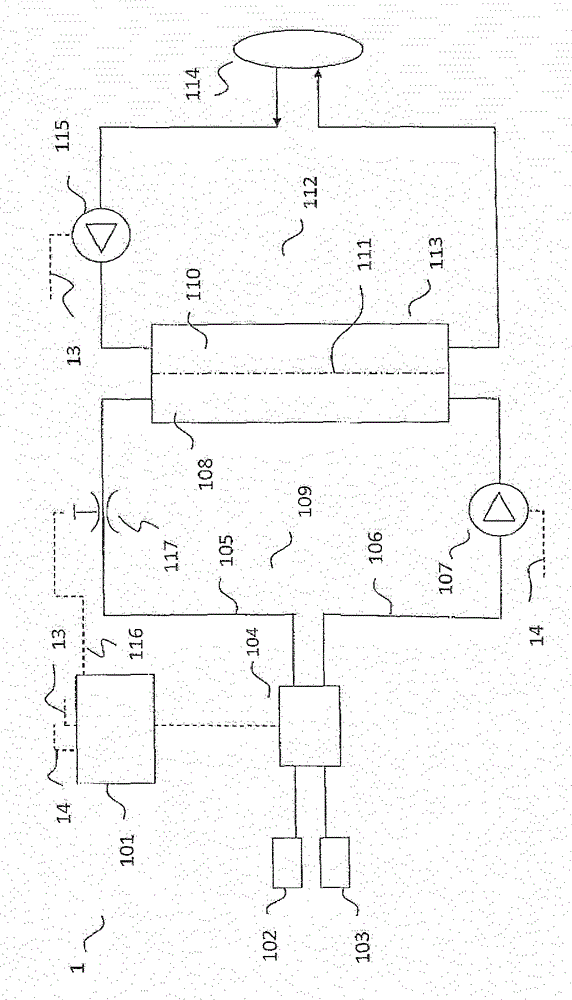

Device and method for regulating a treatment device

A method and a device are disclosed for regulating an ultrafiltration in a dialysis treatment, in which the blood to be ultrafiltered in an extracorporeal blood circulation (109) flows through a blood chamber (110) of a dialyzer (113), which is subdivided by a semipermeable membrane (111) into a blood chamber (110) and a dialysis fluid chamber (108), and dialysis fluid in a dialysis fluid circulation (109) flows through the dialysis fluid chamber (108) of the dialyzer (113),. The device has a blood pump (115) for controlling a blood flow in the extracorporeal blood circulation (112), a dialysis fluid pump (107) for controlling a dialysis fluid flow in the dialysis fluid circulation (109) upstream or downstream from the dialyzer (113), for controlling the dialysis fluid flow upstream of downstream from the dialyzer, a balancing device (104) for setting up a fluid balance in the dialysis fluid circulation between an inflow (106) and an outflow (105) of the dialysis fluid chamber (113) as a measure of the ultrafiltration, as well as a regulating unit (101) for regulating the blood pump (115), the throttle (117) and / or the dialysis fluid pump (107). The pumps or the throttles (117) are regulated so that a predetermined ultrafiltration is achieved.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

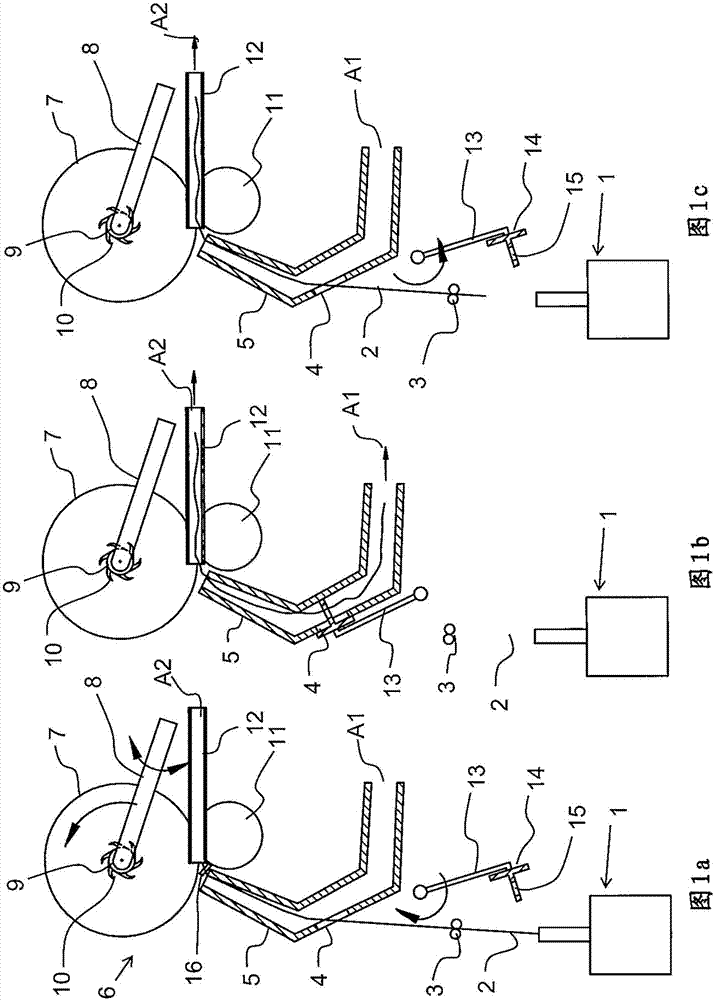

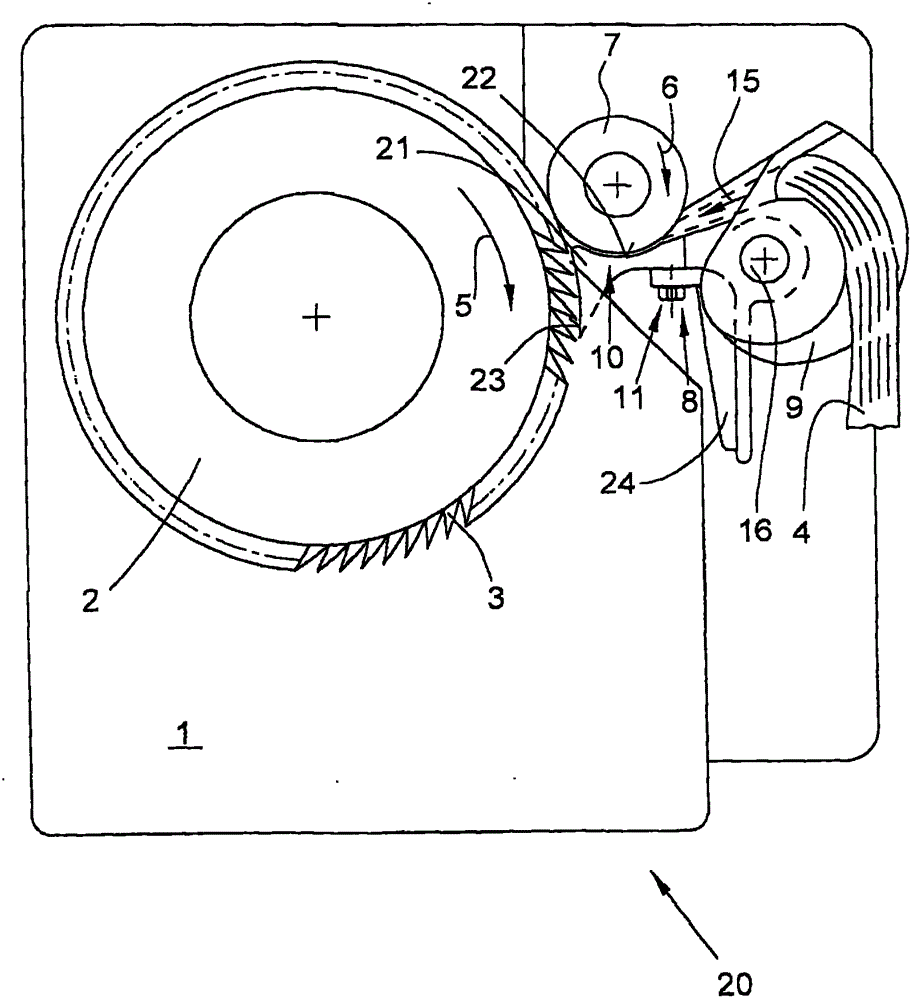

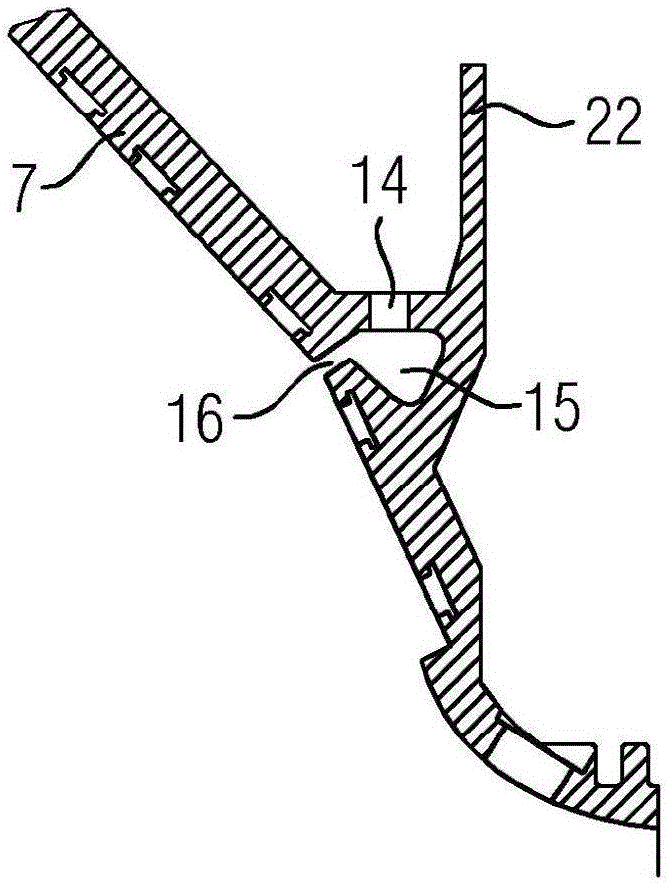

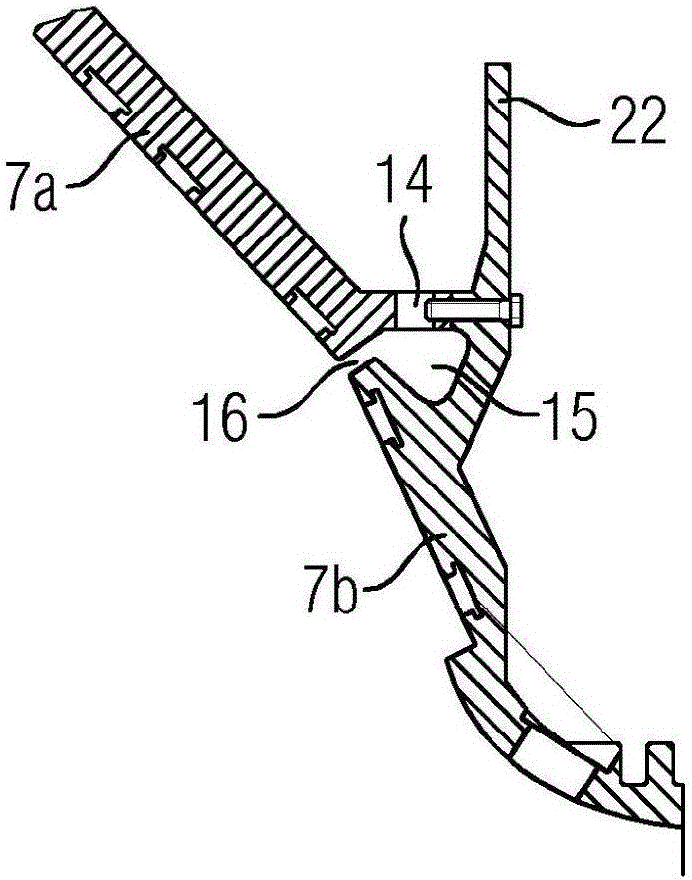

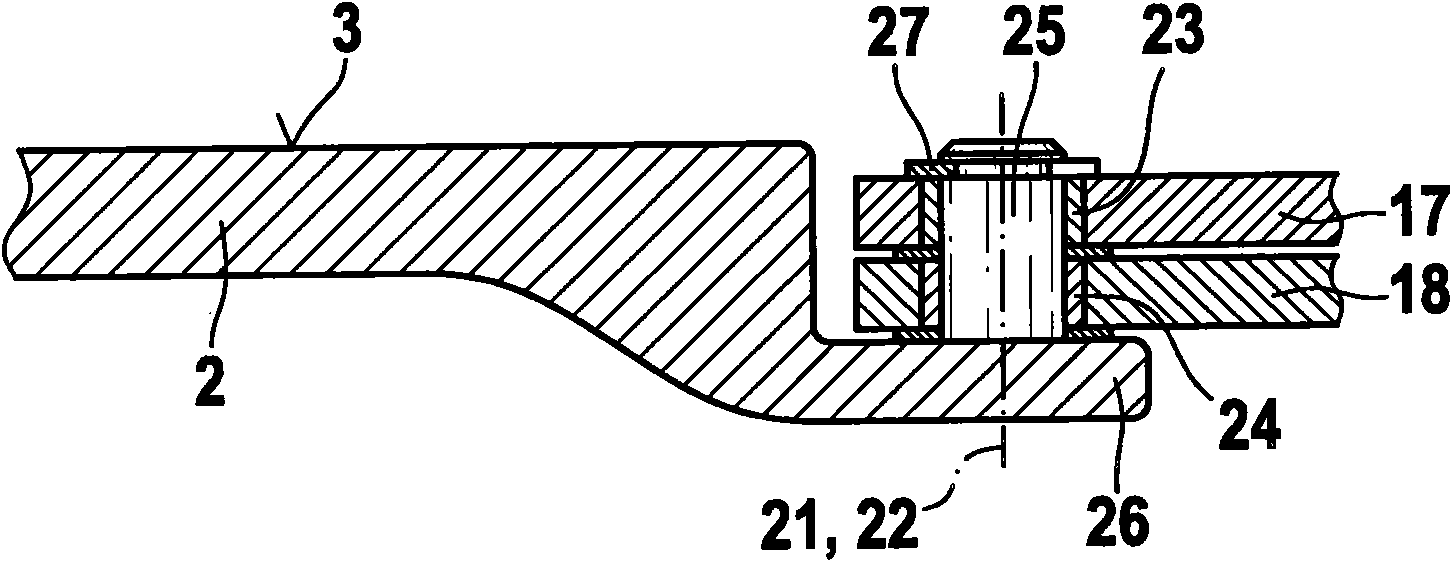

Feed plate of fiber rod opening device of free end spinning machine

InactiveCN103060965AReduce structural costsAchieve fixationContinuous wound-up machinesOpen-end spinning machinesFiberSupport surface

The invention relates to a feed plate of a fiber rod opening device of a free end spinning machine. The feed plate a concave clamp region and a concave support surface. The clamp region is for conveying feed fiber rods using fiber rod feed rollers. The support surface is for fixing fiber fringings formed with opening rollers when carding the feed fiber rods. According to the regulations of the invention, the feed plate (8) has a feed plate component (21) which is changeable and fixed on a feed plate support (24). The feed plate component has a slide for the feed fiber rods. The slide seamlessly extends from the clamp region (22) of the feed plate component (21) to a fiber fringing support surface (23). The feed plate component (21) is made through MIM technology and has smooth hard material layers at least in the clamp region (22) and the fiber fringing support surface (23).

Owner:SAURER GERMANY GMBH & CO KG

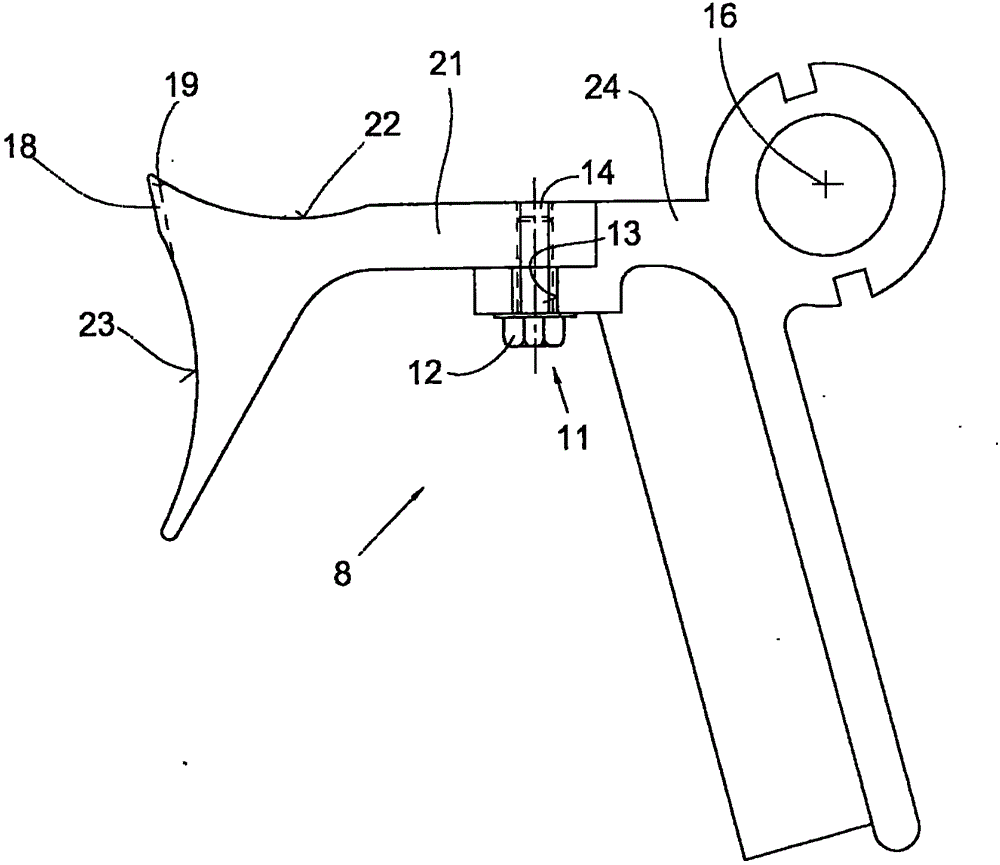

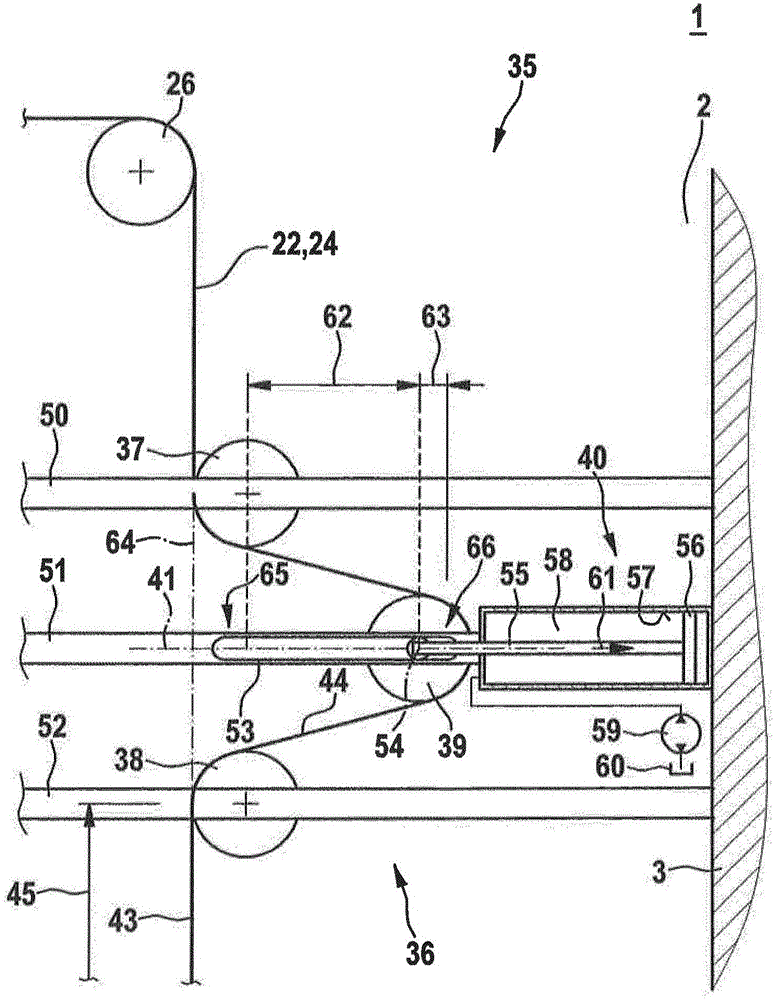

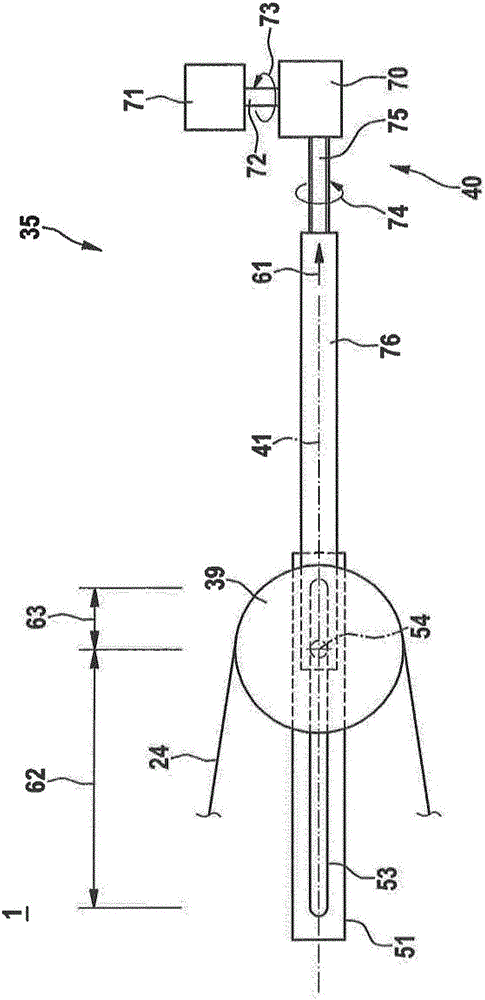

Lift installation

InactiveCN105764830AReduce mechanical loadReduction in Strength Achieving RequirementsBuilding liftsEngineeringFixed position

A lift installation (1) comprises a first lift car (5), a second lift car (6), a drive-machine unit (20) and a plurality of traction means (22) running over a driving sheave (21) of the drive-machine unit (20). The lift cars (5, 6) here can be displaced one above the other by the drive-machine unit (20), using the traction means (22), in a passageway (16) provided for the joint travel of the lift cars (5, 6). The traction means (20) are divided up into a first traction-means assembly (23) and a second traction-means assembly (24). Also provided is an adjustment mechanism (35) which is in a fixed position relative to the passageway (16) and interacts with the second traction-means assembly (24) between the driving sheave (21) and the second lift car (6). The adjustment mechanism (35) here interacts with the second traction-means assembly (24) such that it is possible to vary a distance (15) between the lift cars (5, 6). The lift installation (1) is distinguished in that the distance (15) can be adjusted independently of the driving sheave (21), in particular even with the driving sheave (21) at a standstill. It is specifically possible for the adjustment mechanism (35) to have a roller arrangement (36), wherein an adjustable roller (39) of the roller arrangement (36) can be adjusted by an adjustment drive (40) in order to vary the length (45) of a portion (43) of the second traction-means assembly (24) between the adjustment mechanism (35) and the second lift car (6).

Owner:INVENTIO AG

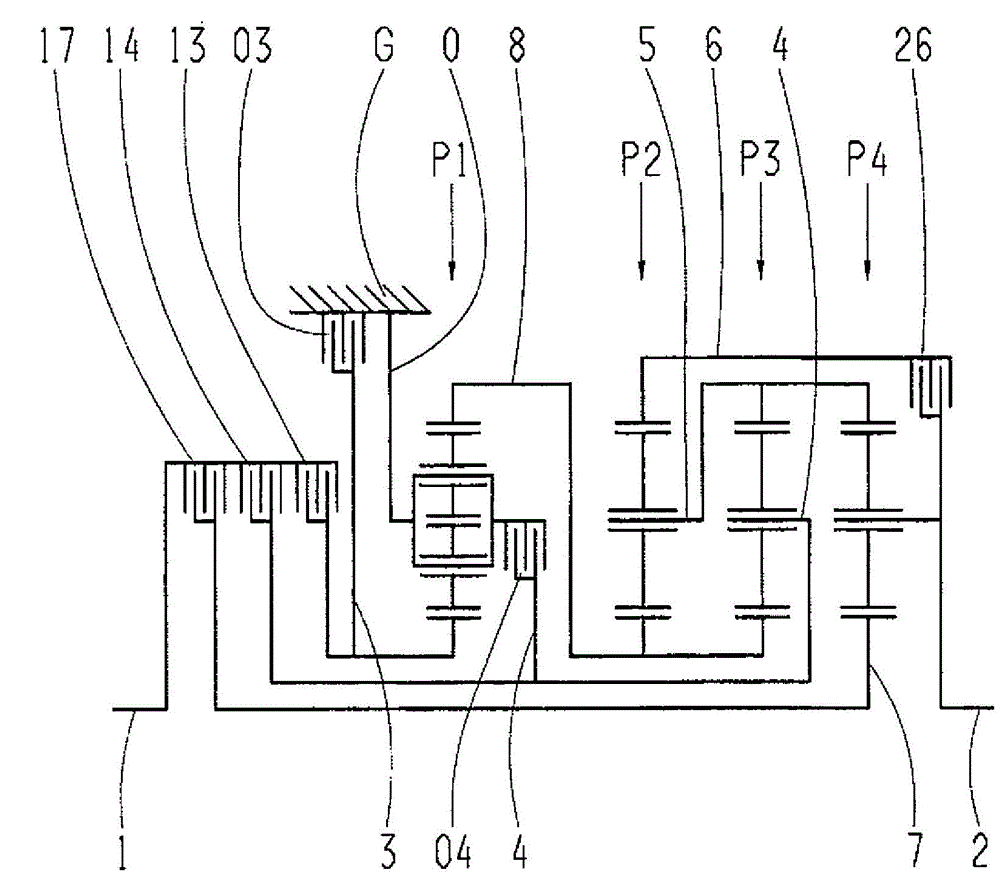

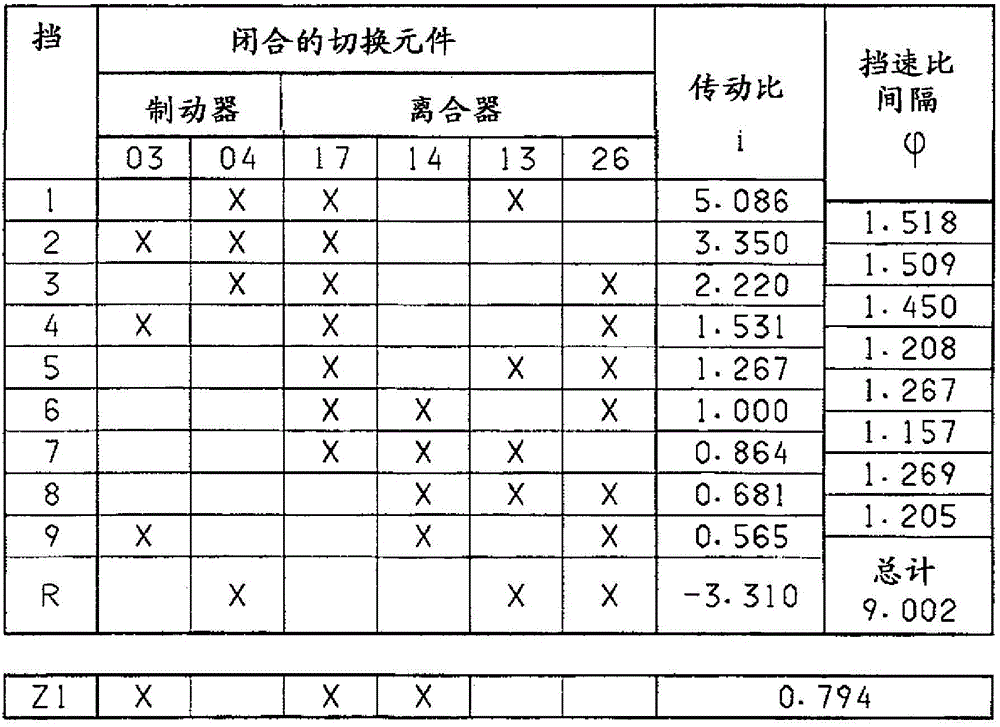

Multi-speed gearbox

InactiveCN104379967AIncrease overall speed ratio rangeImprove driving comfort performanceToothed gearingsTransmission elementsDrive shaftGear wheel

The invention relates to a multi-speed gearbox having four planetary gear sets (P1, P2, P3, P4), eight rotatable shafts (1, 2, 3, 4, 5, 6, 7, 8) and six shift elements (03, 04, 13, 14, 17, 26), wherein the sun gear of the first planetary gear set (P1) is connected to the third shaft (3), which is detachably connected to the drive shaft (1) by means of a first clutch (13) and can be coupled to the housing (G) by means of a first brake (03). The drive shaft (1) can be detachably connected to the fourth shaft (4) which is connected to the planet carrier of the third planetary gear set (P3) by means of a second clutch (14), which can be coupled to the planet carrier of the first planetary gear set (P1) by means of a second brake (04) and is coupled to the housing (G). The drive shaft (1) can be detachably connected to the seventh shaft (7) which is connected to the sun gear of the fourth planetary gear set (P4) by means of a third clutch (17). The eighth shaft (8) is connected to the ring gear of the first planetary gear set (P1), to the sun gear of the second planetary gear set (P2) and to the sun gear of the third planetary gear set (P3). The fifth shaft (5) is connected to the planet carrier of the second planetary gear set (P2), to the ring gear of the third planetary gear set (P3) and to the ring gear of the fourth planetary gear set (P4). The sixth shaft (6) is connected to the ring gear of the second planetary gear set (P2) and can be detachably connected to the output shaft (2) of the gearbox which is connected to the planet carrier of the fourth planetary gear set (P4) by means of a fourth clutch (26).

Owner:ZF FRIEDRICHSHAFEN AG

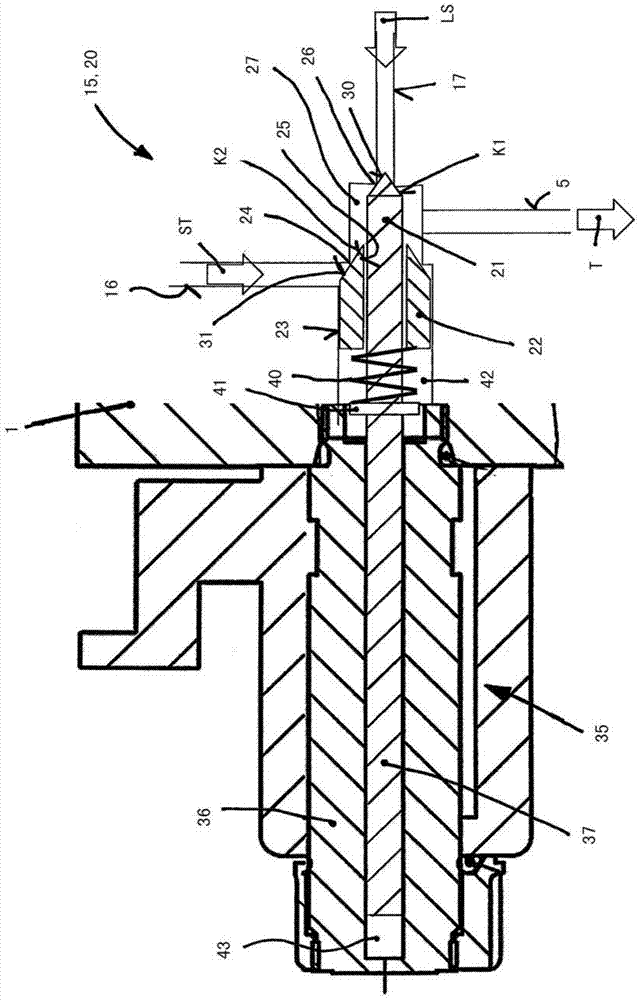

Release valve for a hydrostatic drive system

ActiveCN104329322ASimple structureSmall structural space requirementsFluid-pressure actuator safetyOperating means/releasing devices for valvesEngineeringControl valves

The invention relates to a release valve (15) for a hydrostatic drive system. The release valve controls a control pressure connecting head (ST) and a load pressure connecting head (LS). The release valve has a function position and an unloading position. The release valve is configured to be a double pressure limiting valve (20) having a seat valve structure, and the pressure limiting valve has a first valve seat body (21) used for controlling a valve seat (26) of the load pressure connecting head and a second valve seat body (22) used for controlling valve seat (24) of the control pressure connecting head. A load pressure loading control face (30) stored in the load pressure connecting head is formed on the first valve seat body, and the first valve seat body is loaded onto the unloading position; in the unloading position, the load pressure connecting head unloads to a box connecting head (T). A control pressure loading control face (31) formed in the control pressure connecting head is formed on the second valve seat body, and the second valve seat body is loaded onto an unloading position; on the unloading position, the control pressure connecting head unloads toward the box connecting head.

Owner:LINDE HYDRAULICS

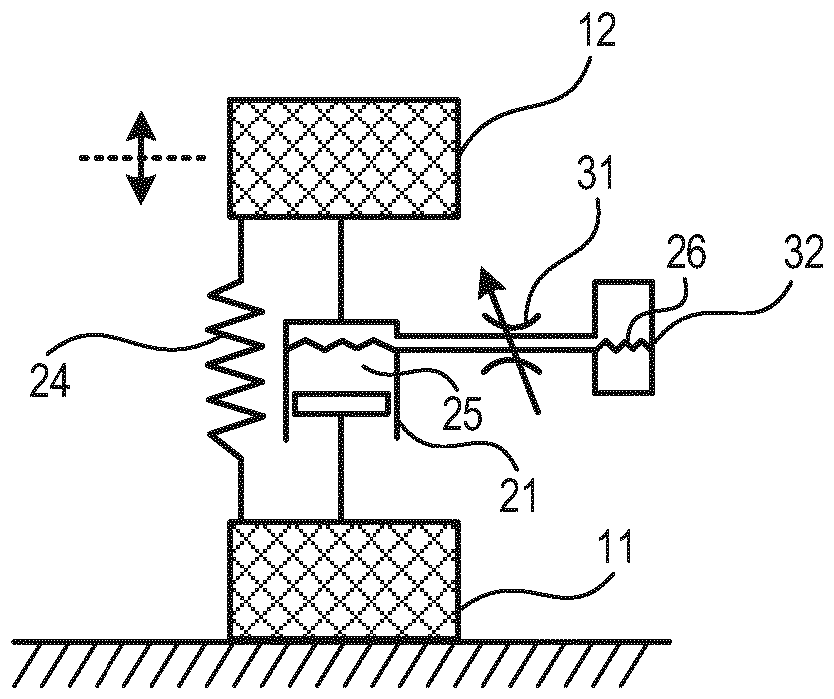

Vibration damper for a high-pressure fuel pump, high pressure fuel pump having a vibration damper, and method for controlling such a vibration damper

ActiveCN108138905AReduce structural costsEliminate the sensor unitRotating vibration suppressionMachines/enginesEngineeringHigh pressure

The invention relates to a vibration damper for a high-pressure fuel pump in internal combustion engines, to a high pressure fuel pump, and to a method for controlling a vibration damper. The vibration damper comprises a first centrifugal mass and a second centrifugal mass, which are designed to be rotatable relative to one another, and a damping element having a valve, wherein the damping elementconnects the first centrifugal mass and the second centrifugal mass to one another, and wherein the valve has a continuously controllable flow.

Owner:CONTINENTAL AUTOMOTIVE GMBH

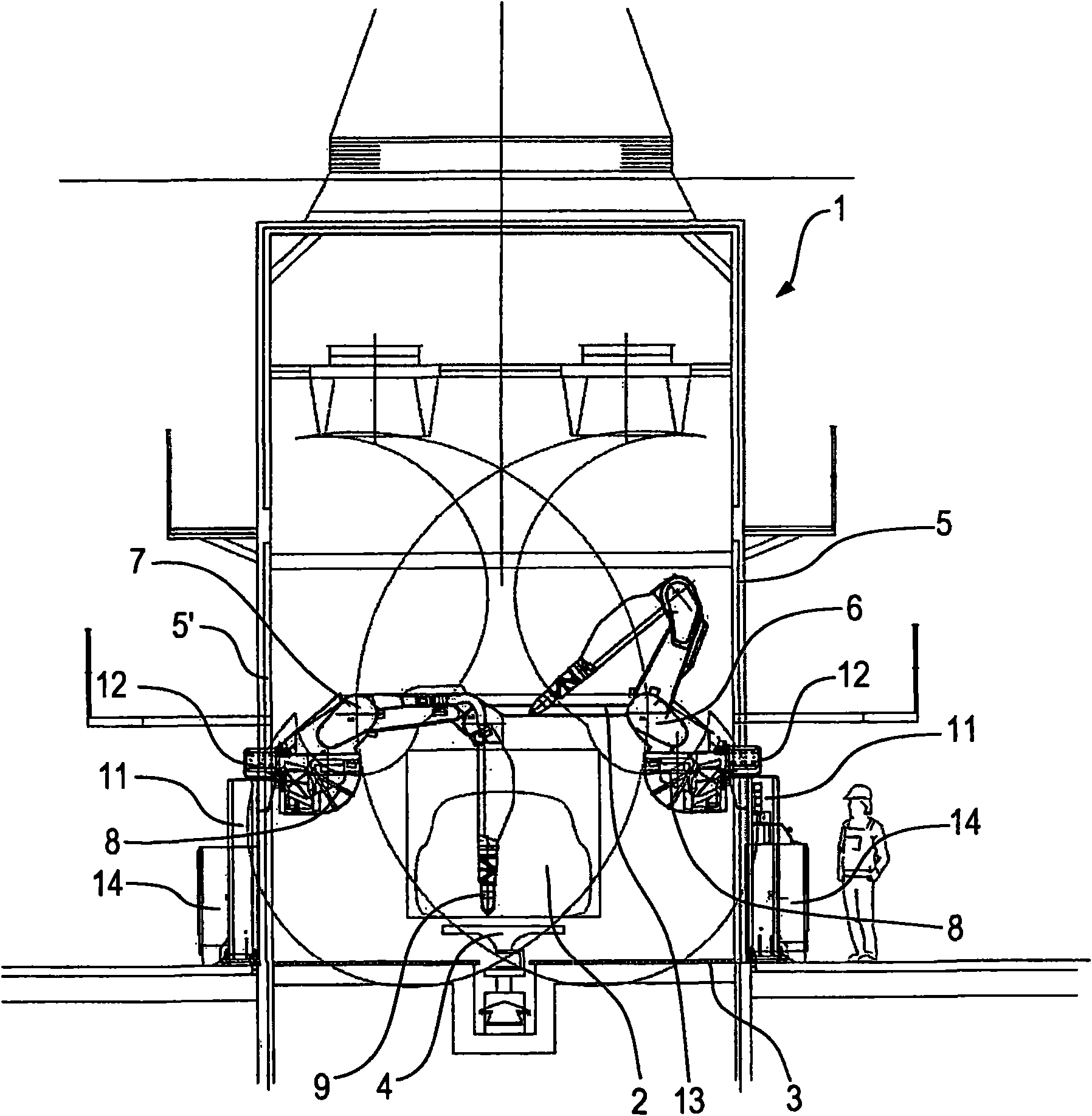

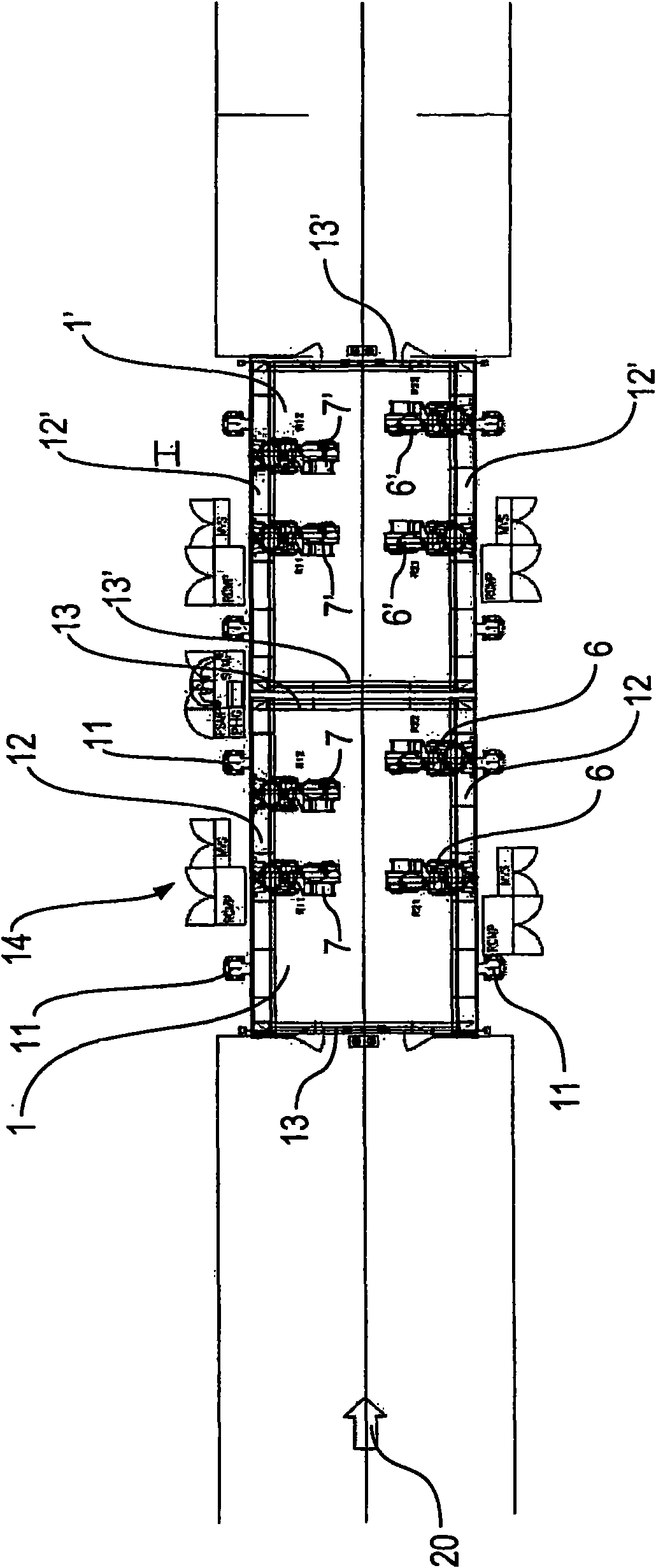

Coating system and method for the series coating of workpieces

InactiveCN101626839AReduce structural costsLiquid surface applicatorsCoatingsCoating systemMechanical engineering

Owner:DUERR SYST GMBH

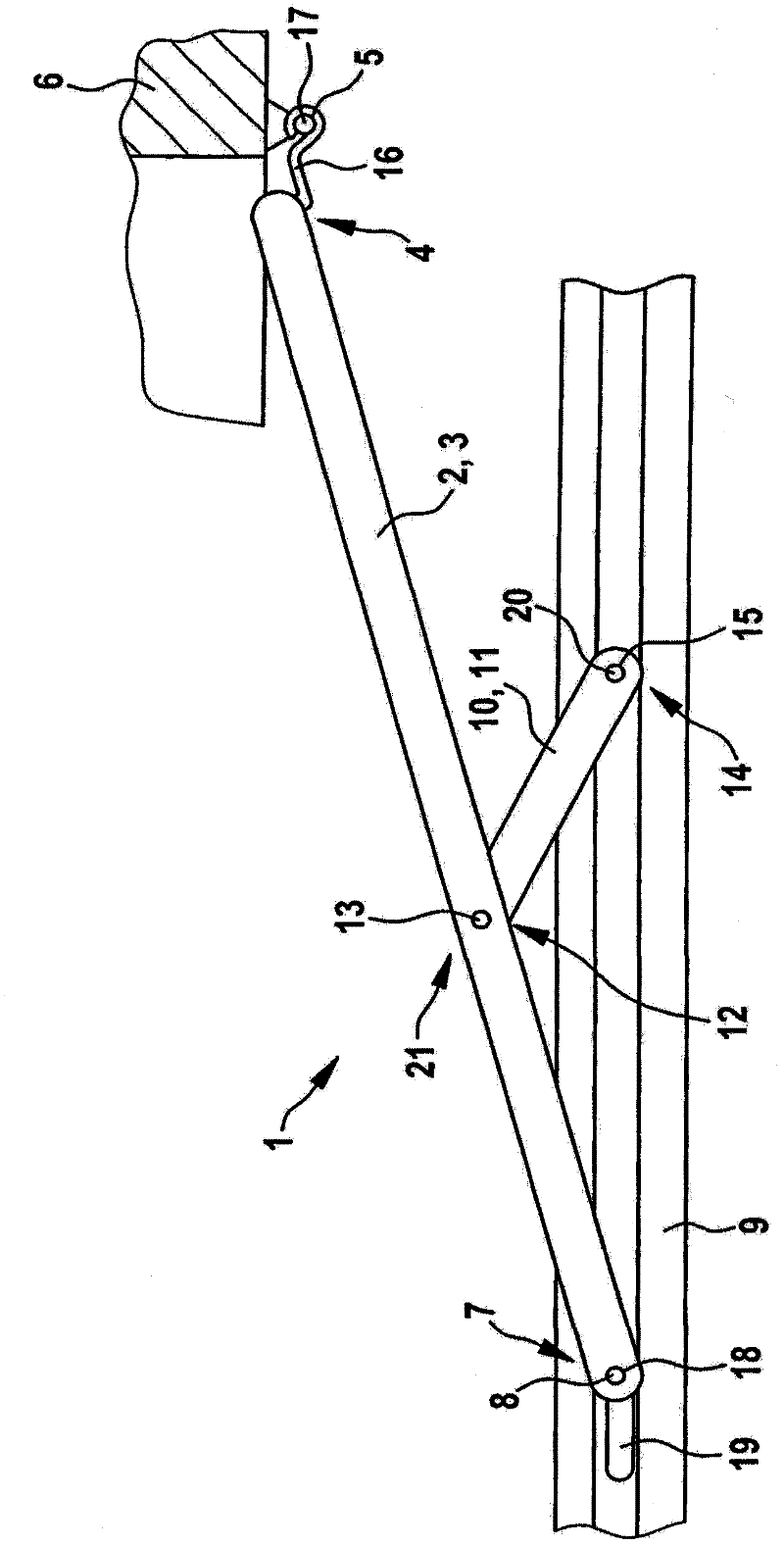

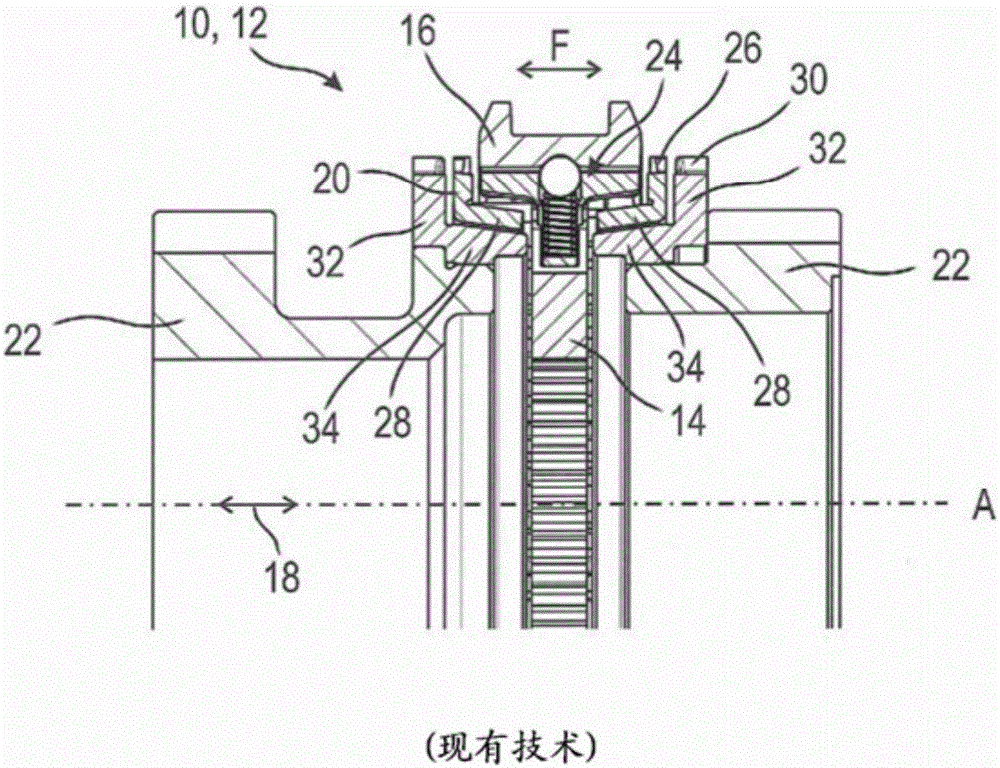

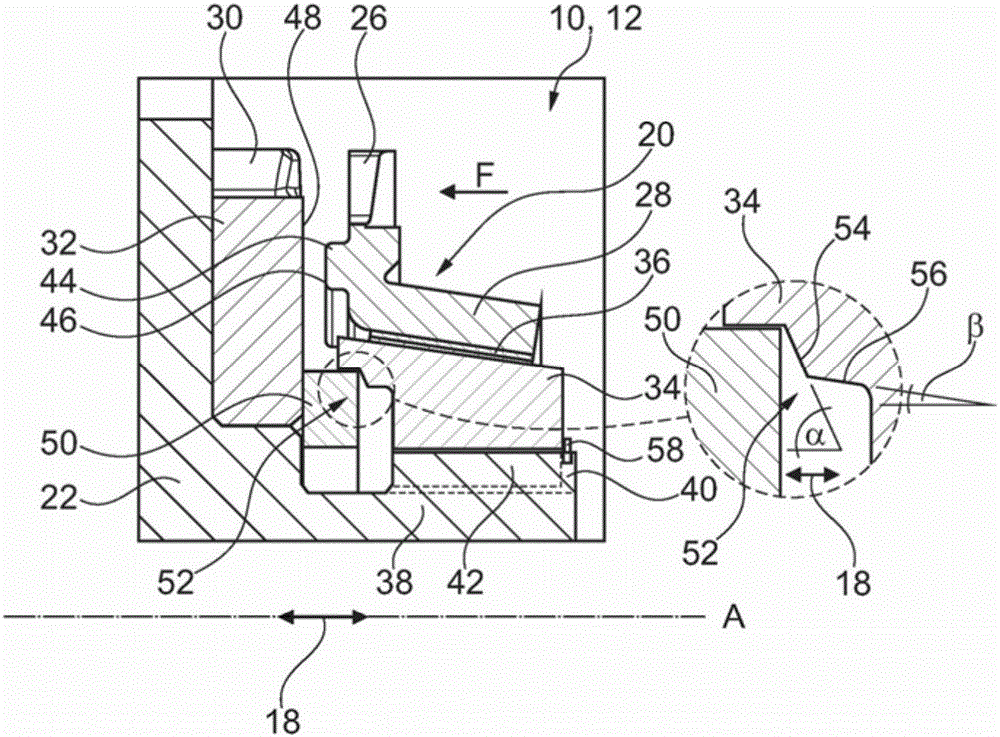

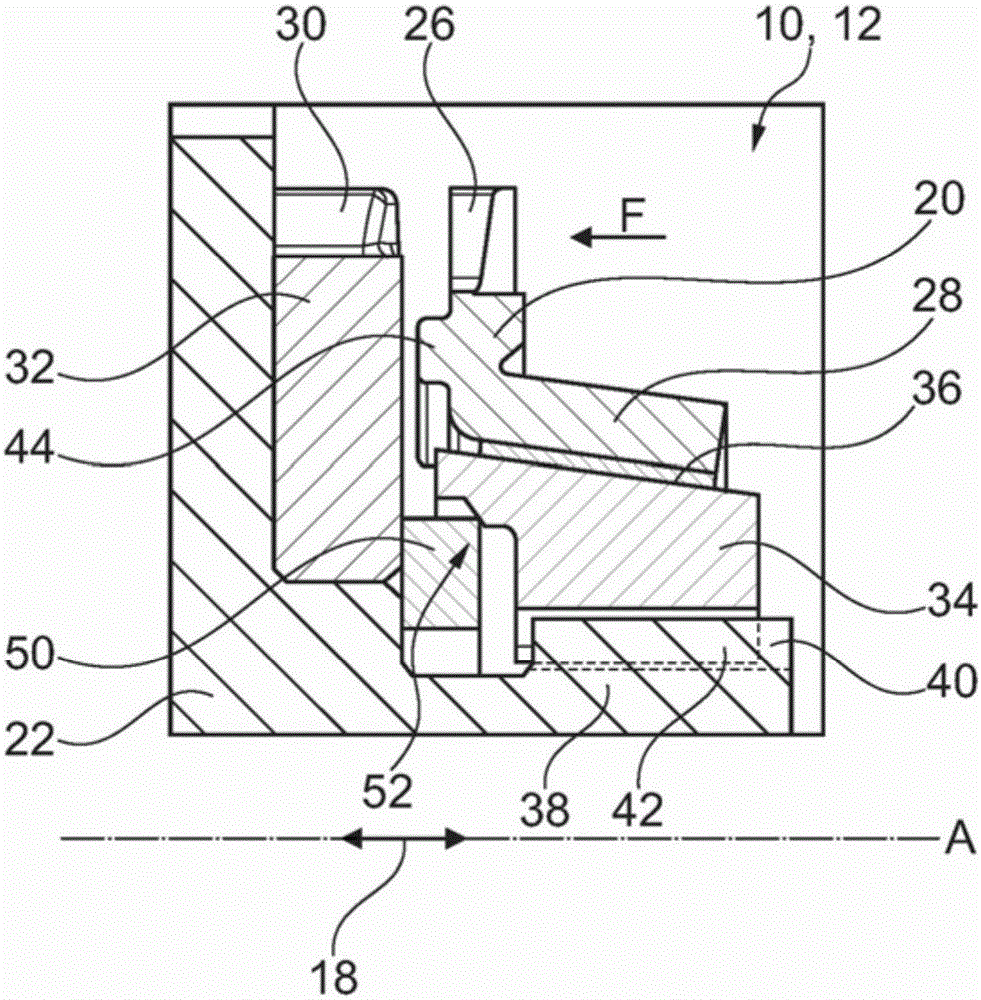

Hinged opening device for a window, a door, or the like

InactiveCN102057120AReduce structural costsReliable anti-twist stopHingesWing suspension devicesEngineeringMechanical engineering

Owner:ROTO FRANK AG

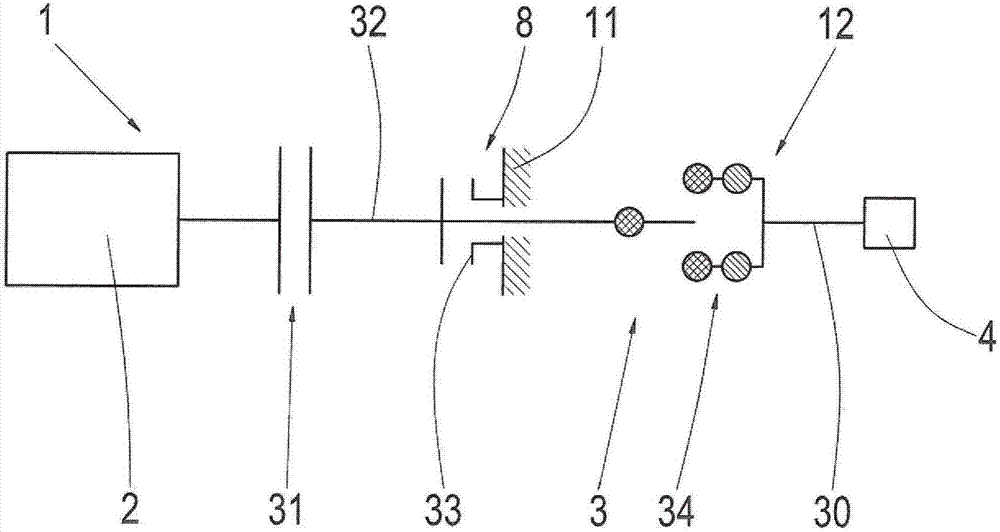

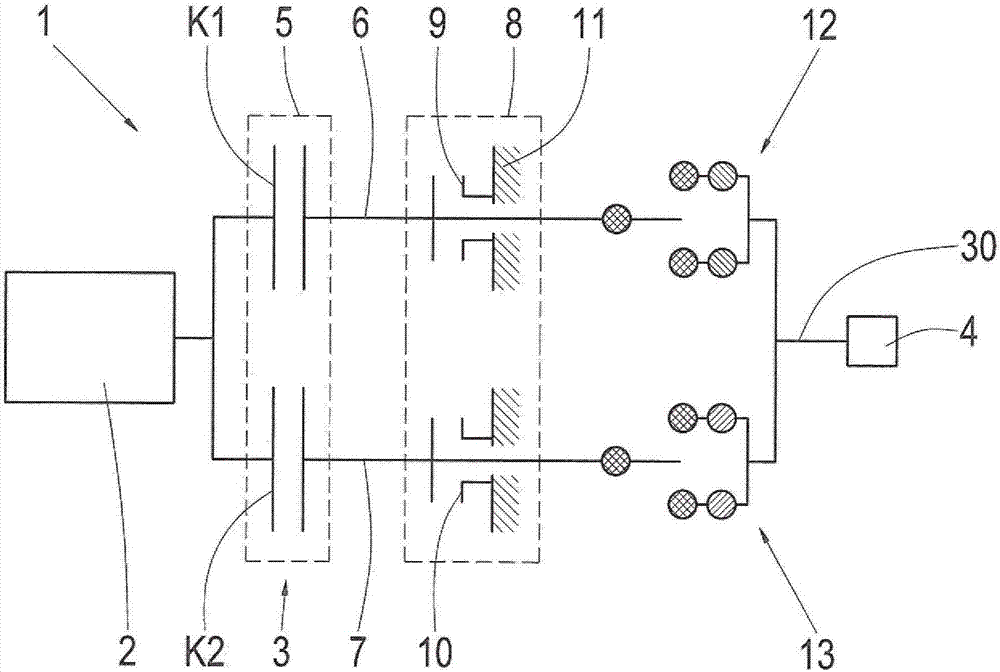

Automatic transmission of a vehicle, comprising a central synchronizing device, and method for operating an automatic transmission

InactiveCN107429840AReduce structural costsSimple and durable structureBraking element arrangementsToothed gearingsAutomatic transmissionControl engineering

The invention relates to an automatic transmission (3) of a vehicle, comprising a central synchronizing device (8), and to a method for operating an automatic transmission (3). A brake (33) is converted into an operating state via the actuating device paired with the brake at least when an operative connection is provided between a transmission input shaft (32) and a transmission output shaft (30) and in the event of a request to hold the transmission output shaft (30) in a rotationally fixed manner. In the operating state, the transmission input shaft (32), which interacts with the brake, is held by the brake (33) in a rotationally fixed manner, and the brake (33) can be kept in the operating state by the actuating device without a supply of energy.

Owner:ZF FRIEDRICHSHAFEN AG

Turbine arrangement

InactiveCN106233072ARaise the combustion temperatureEnsure normal dischargeContinuous combustion chamberCombustion regulationCombustion chamberCombustor

The invention relates to a turbine arrangement (1; 30; 45; 47) with a compressor, at least one burner arrangement (2; 31; 48) comprising multiple burners (4) and a combustion chamber (5; 34; 51), and a turbine (49), wherein the compressor, the at least one burner arrangement (2; 31; 48) and the turbine (49) are fluidically connected to one another such that, during proper operation, air compressed by the compressor is guided through the burners (4) and is mixed with fuel, whereupon the fuel-air mixture produced is burnt in the combustion chamber (5; 34; 51) and the combustion gases are fed to the turbine (49), characterized in that there is provided a bypass device which is designed such that part of the air compressed by the compressor can be guided, as a bypass flow, past the burners (4) into the region of the outlet end of the combustion chamber (5; 34; 51).

Owner:SIEMENS AG

Drive axle at least with one electric drive motor

ActiveCN103863077AAchieve lubricationLow maintenanceElectric devicesElectric propulsion mountingLiquid cooling systemDrive motor

The drive axle (1) has liquid cooling system for drive motor (3) for lubrication of gear box (5) in gear box housing (G). The drive motor is designed as a wet-running electric motor, such that drive motor and the transmission have a common closed oil circuit. The engine compartment (M) and transmission chamber (M) are located adjacent to one another in the axle housing (2) of the drive axle and are fluidly connected to each other through opening (30). The engine compartment and the gear housing are partially filled with lubricating oil.

Owner:LINDE MATERIAL HANDLING

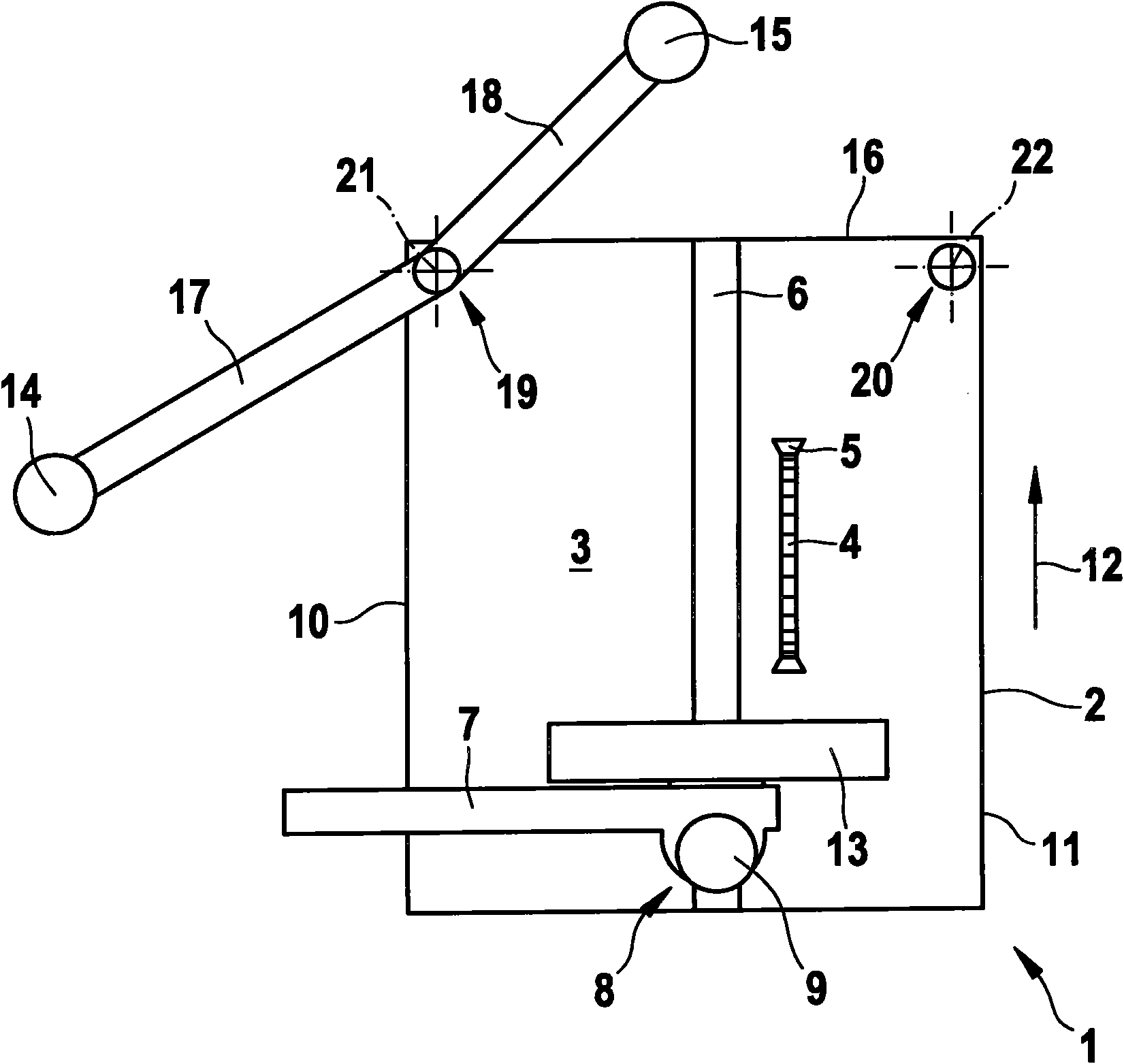

Work bench for machine tools

ActiveCN102015177AReduce consumptionReduce structural costsMetal sawing devicesCircular sawsEngineeringWorkbench

A workpiece support (14, 15) which is especially designed for work benches of machine tools forms a separate part of a workpiece support having a bench surface (3) and is supported so as to be pivotable in parallel to the bench surface (3), while projecting from the bench surface (3), via a pivoting arm (17, 18) which itself may form part of the workpiece support.

Owner:ROBERT BOSCH GMBH

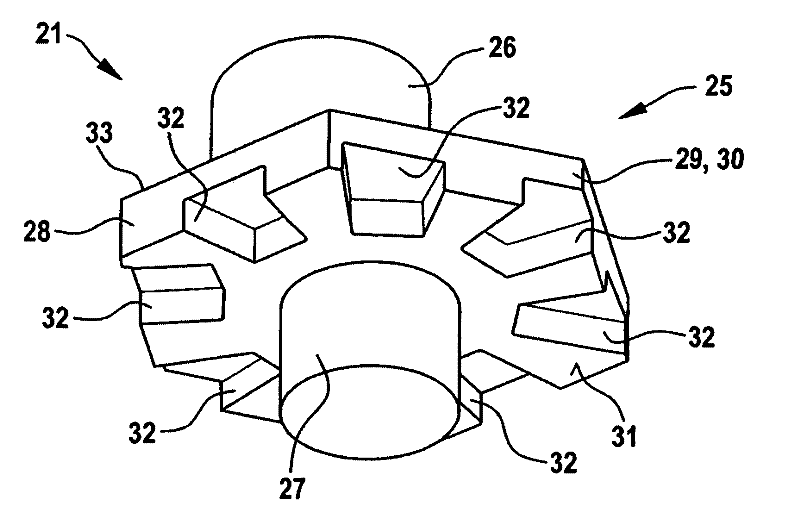

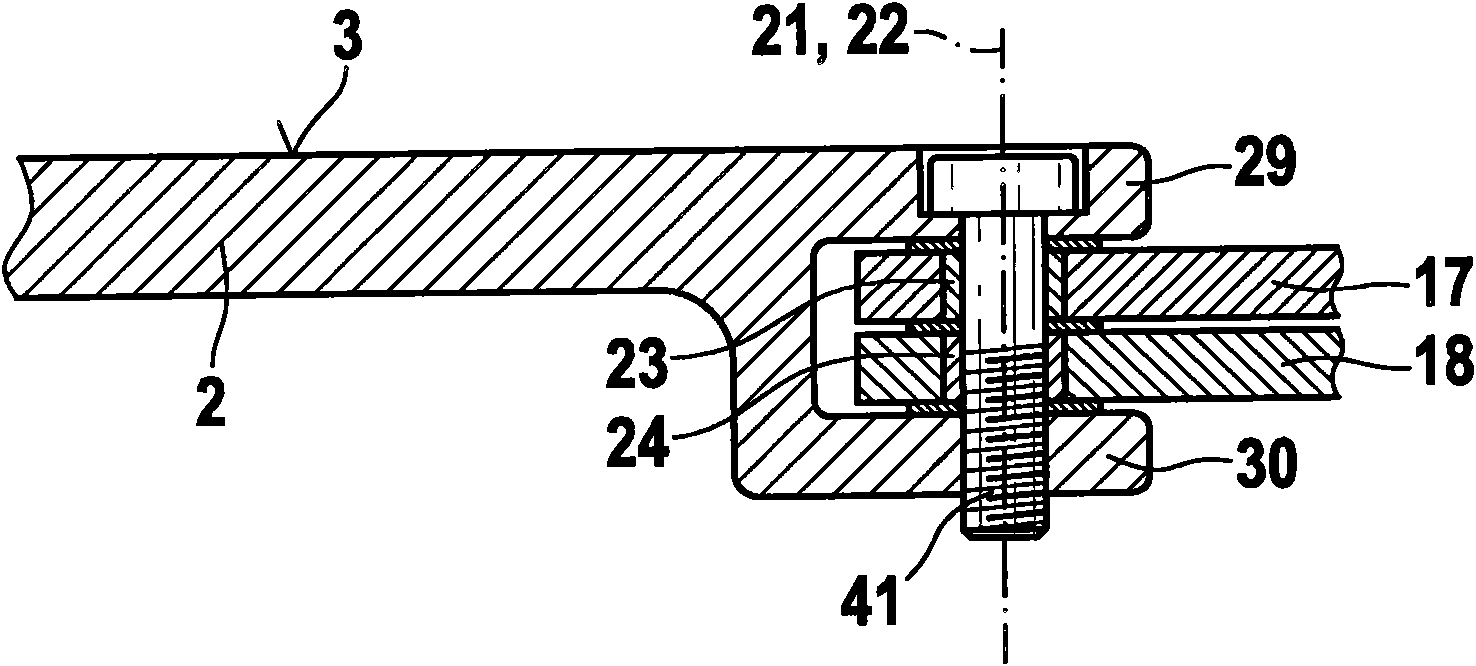

Locking synchronizing module of shift transmission, as well as method for shifting shift transmission with lock synchronizing module

ActiveCN106402192AReliable speedReduce structural costsMechanical actuated clutchesEngineeringFriction cone

The invention relates to a locking synchronizing module of a shift transmission. The locking synchronizing module comprises a synchronizing ring which is rotatable about a shift transmission axis and has a locking engagement part and a frictional cone, a coupling disc which has a shifting engagement part and is in fixed connection with a shift gear which is rotatable about the shift transmission axis in a state that the locking synchronizing module is installed; and a mating cone which is adjacent to a friction cone of the synchronizing ring and in friction connection with a friction cone when the synchronizing ring moves towards an axis of the coupling disc, wherein the matching cone is connected to the shift gear of the shift transmission in a torsion resistant and axially-movable manner in a circumferential direction in the state when the locking synchronizing module is installed. Further, the invention also relates to a method for shifting the shift transmission with the lock synchronizing module.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

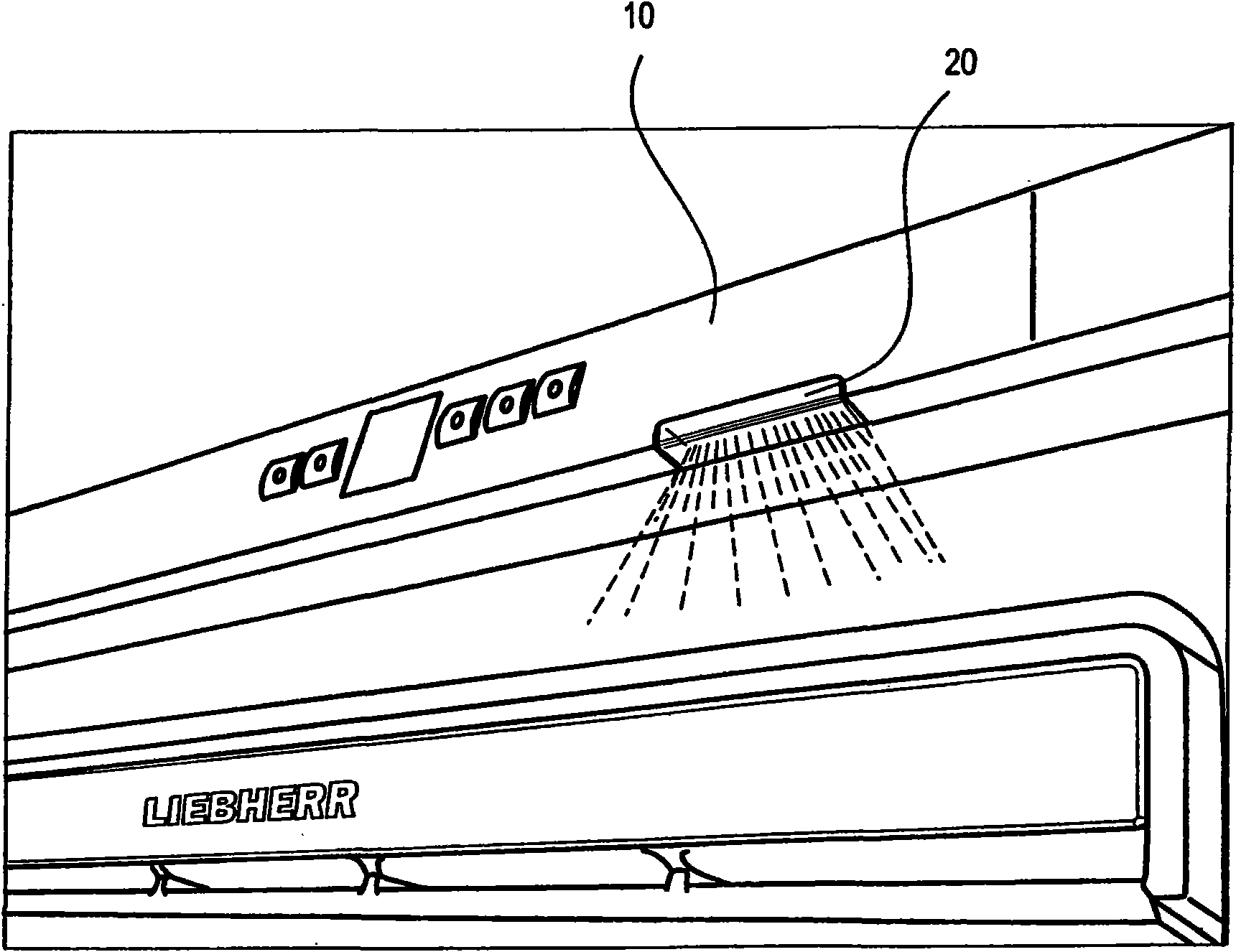

Refrigerator and/or freezer

InactiveCN101600923AReduce diversityEasy to assembleDomestic lightingLighting elementsInterior spaceRefrigerated temperature

The invention relates to a refrigerator and / or freezer comprising at least one operating and / or control unit for operating or controlling the refrigerator and / or freezer and / or comprising at least one evaporator module for cooling the interior of the refrigerator or freezer. The invention also relates to illumination means, which are used to at least partially illuminate the interior of the refrigerator or freezer and / or the region lying in front of the interior, when viewed from the user's perspective. According to the invention, the illumination means are located in or on the operating and / or control unit and / or in or on the evaporator module.

Owner:LIEBHERR HAUSGERATE OCHSENHAUSEN

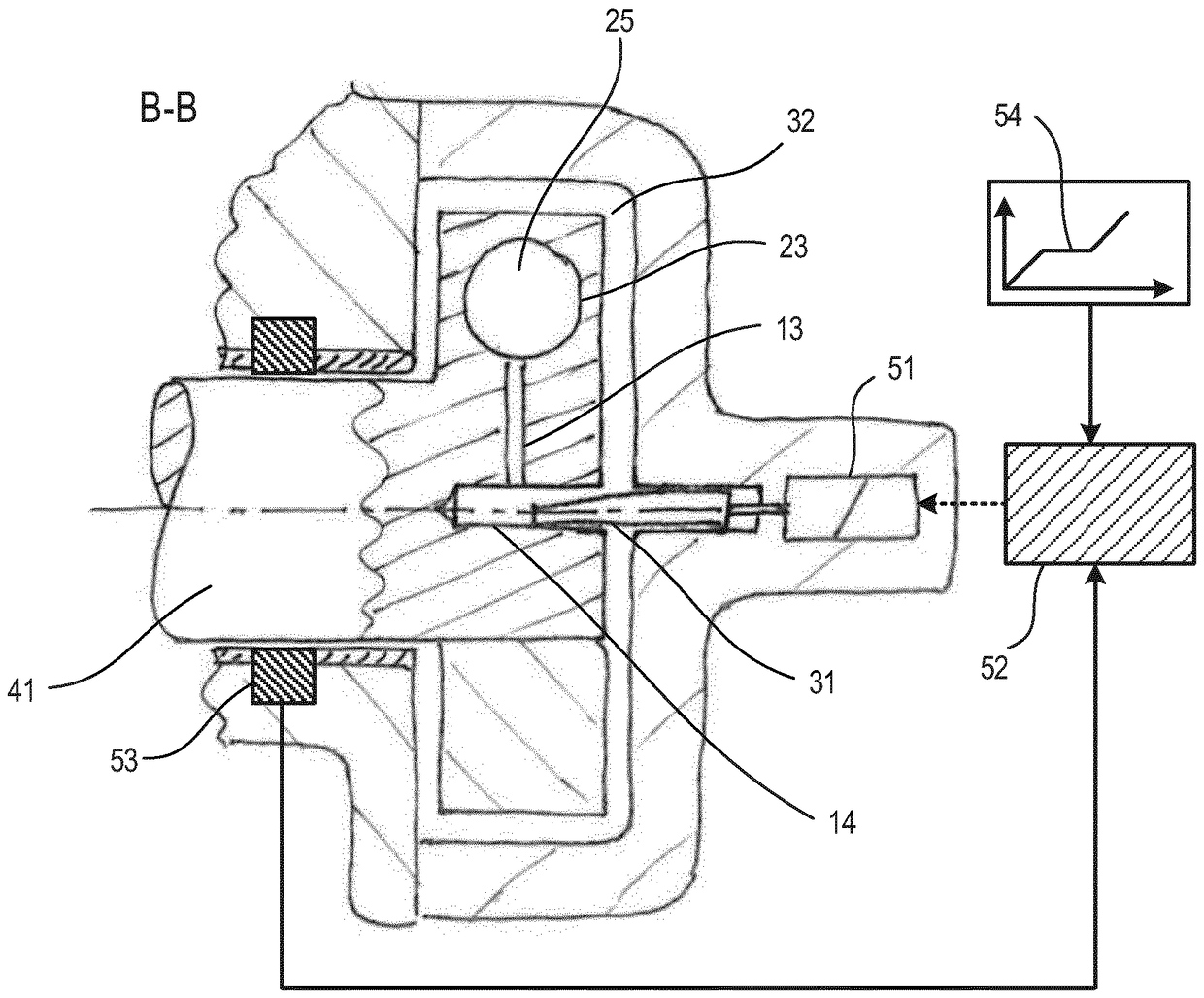

Load sensing type driving system

ActiveCN107816468ASimple structureReduce structural costsServomotor componentsServomotorsLoad sensingEngineering

The invention relates to a load sensing type driving system. The system comprises a pump, and at least a double-effect consumer whose pressure medium is supplied by the pump, especially a differentialcylinder. To control each consumer, a control directional valve and a pressure medium storage device are provided, and the connections from the pressure medium storage device and the corresponding directional valve to return pipes of a container are respectively controlled through feedback valves. The feedback valves are respectively loaded through a load of the consumer and a spring device towards a direction of a drainage position, and loading is performed towards the direction of a loading direction of a memory through a maximum loading pressure of the consumer of the driving system. In the drainage position, the allocated return pipeline is connected with the container, and in the loading position of the memory, the allocated return pipe is connected with the pressure medium storage device.

Owner:LINDE HYDRAULICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com