Drive axle at least with one electric drive motor

A technology for driving axles and driving motors, applied in electric vehicles, motor vehicles, electric components, etc., can solve the problems of maintenance cost, unsealing, and affecting the efficiency of driving axles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

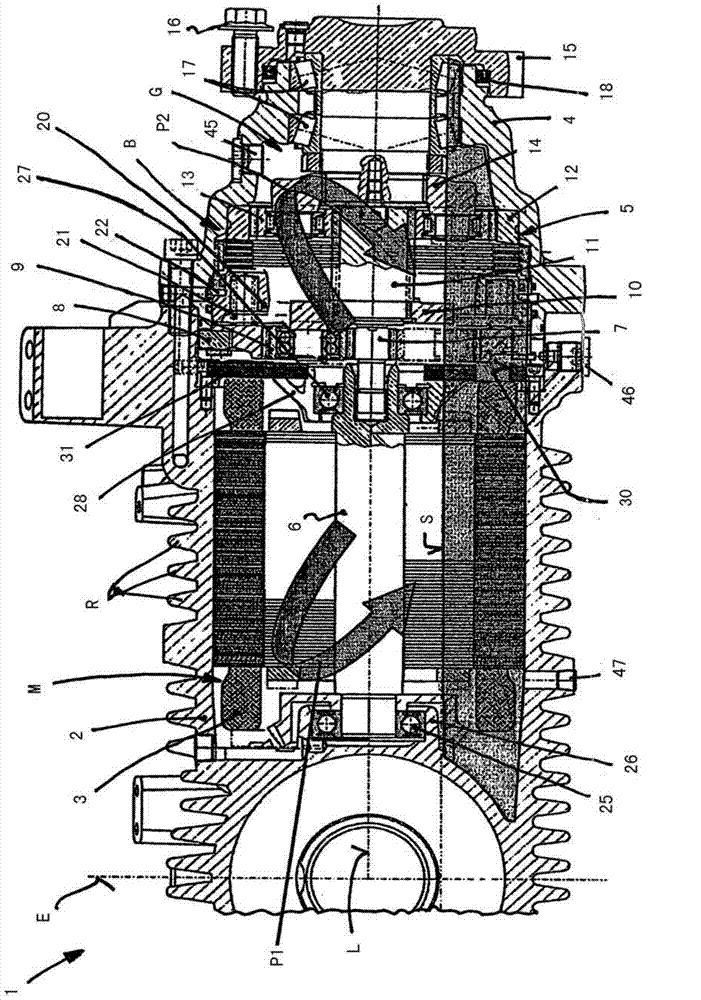

[0013] The drive axle 1 comprises a tubular axle housing 2 , which encloses a motor chamber M with its inner walls, in which an electric traction motor 3 is arranged. Travel motor 3 is preferably designed as an asynchronous electric motor. In the region of the motor chamber M, the outer wall of the axle housing 2 is provided with a ribbing R which forms corresponding cooling ribs.

[0014] A transmission housing 4 is flanged on the end of the wheel outer side of the axle housing 2, and the transmission housing surrounds a transmission chamber G with an inner wall, and the transmission 5 driven by the traveling motor 3 is arranged in the transmission compartment.

[0015] In the exemplary embodiment shown, the transmission 5 is designed as a two-stage planetary transmission, wherein the rotor shaft 6 of the travel motor 3 is drivingly connected to the sun gear 7 of the first planetary transmission stage. The ring gear 8 of the first planetary transmission stage is fixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com