Optical module

A light module and light source technology, applied in the field of light modules, can solve the problems of high manufacturing cost, side lighting, daytime driving lights, flash or low beam or blocked low beam distribution, cost coordination and adjustment, etc., to achieve The effect of low cost, saving structural space and saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

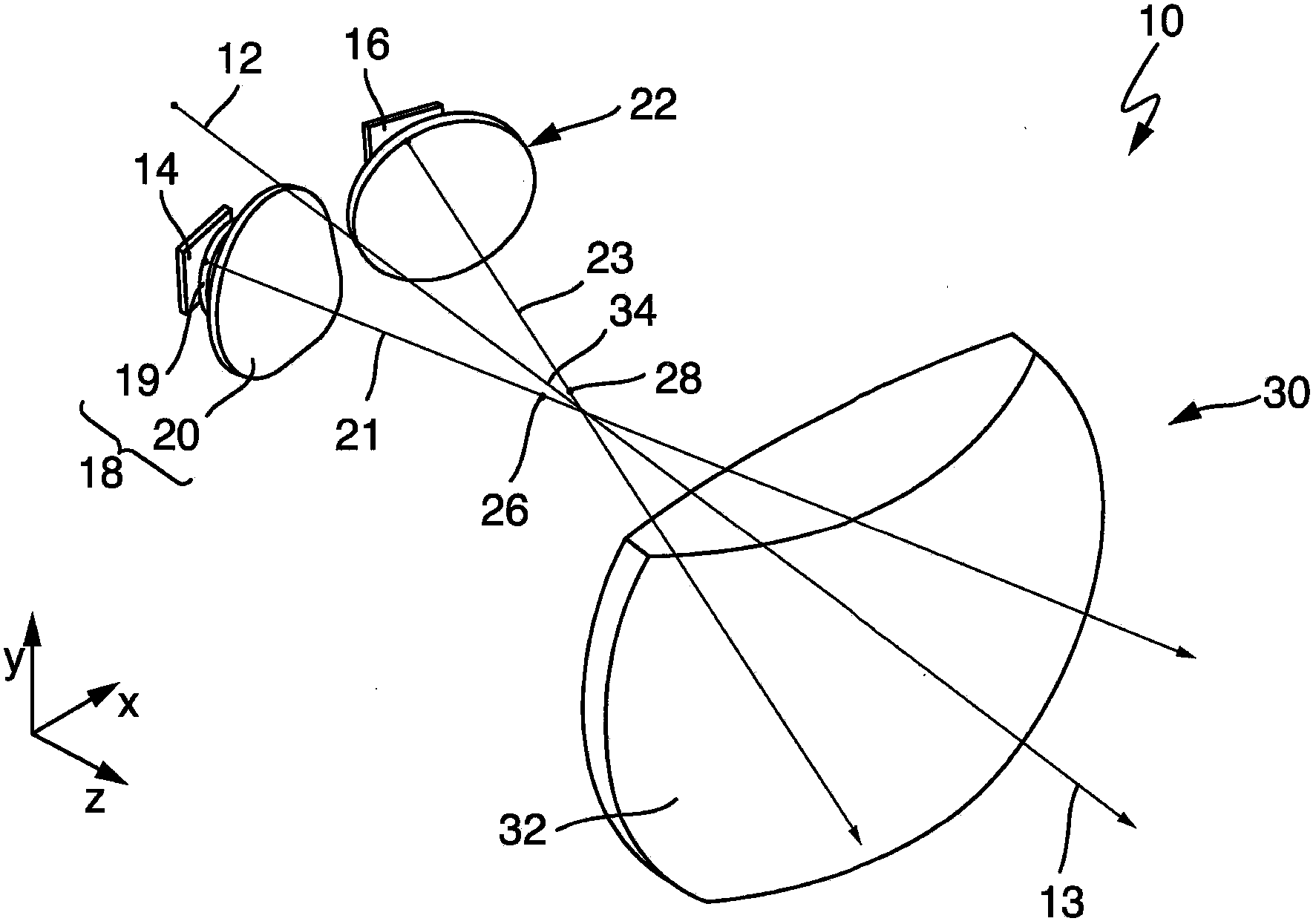

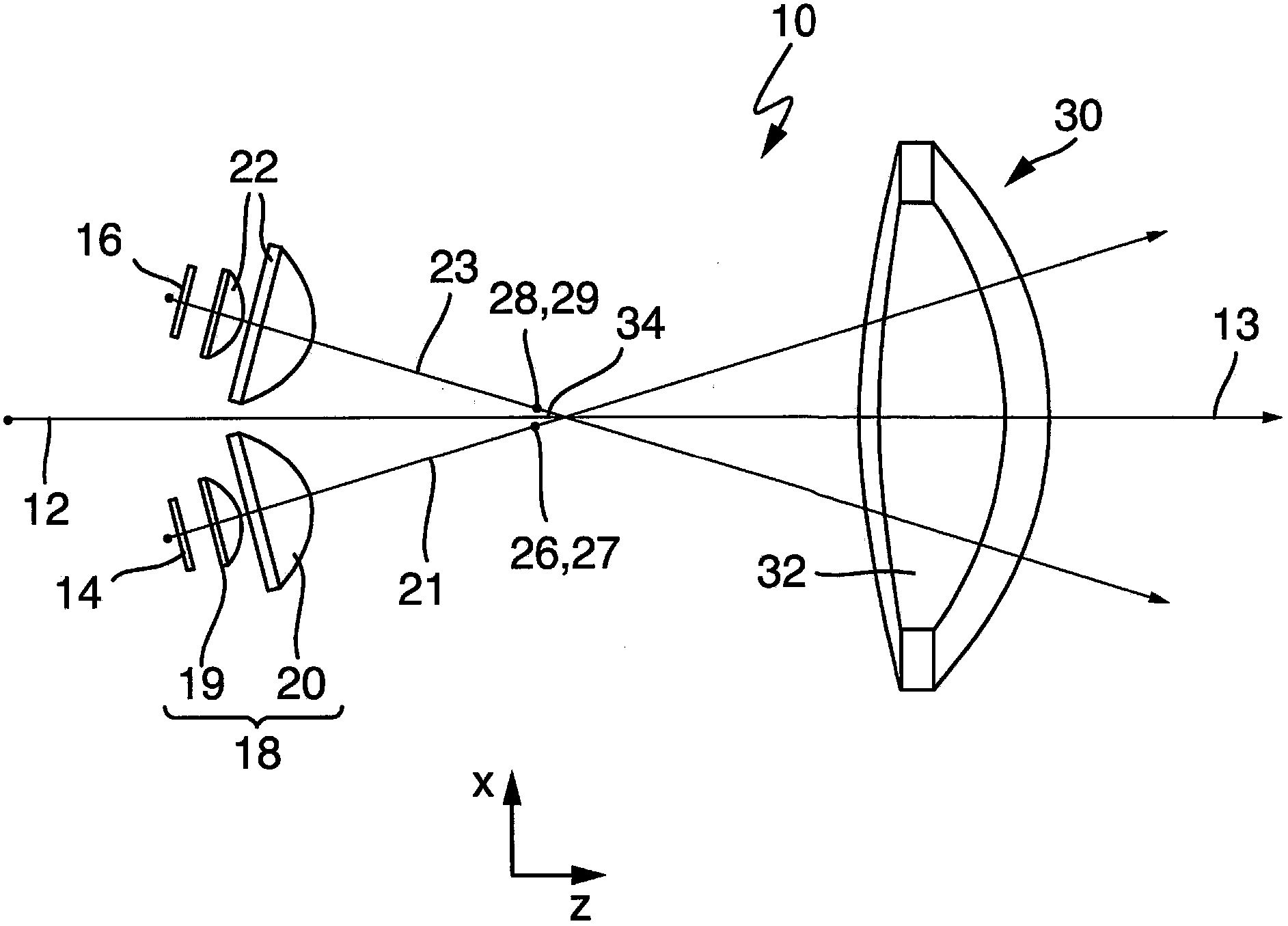

[0057] figure 1 A light module 10 according to the invention is shown, which can be used, for example, in motor vehicle headlights for high beams. For the light module 10 , an optical axis 12 is defined, which lies in a main radiation direction 13 . For better illustration, the light module 10 is shown without a housing, wherein any desired type of housing can of course be provided.

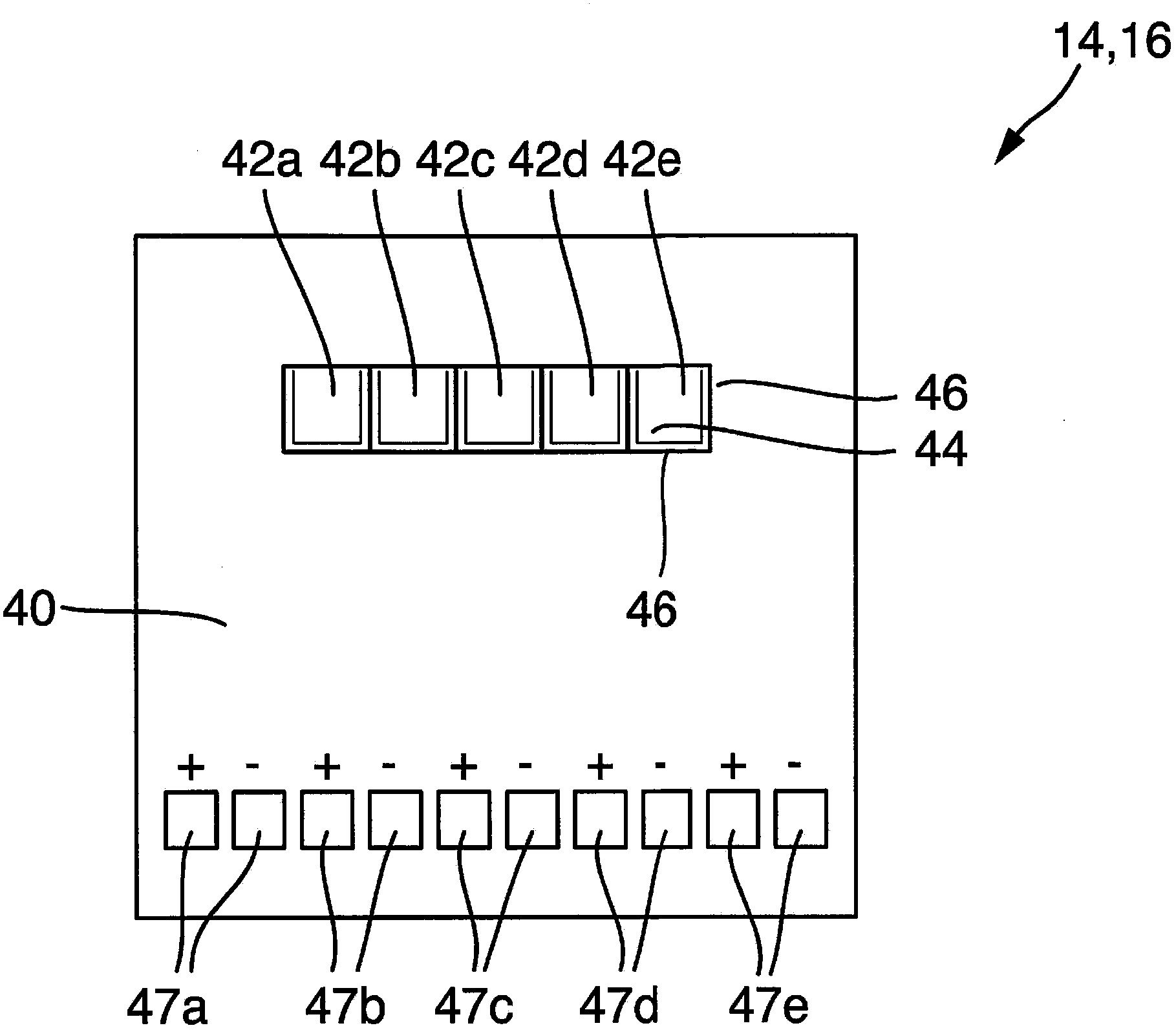

[0058]The optical module 10 has a first semiconductor light source 14 and a second semiconductor light source 16, further referring to image 3 and 7 Describe its precise design in detail. In each case, each semiconductor light source has a plurality of light-emitting diodes (LEDs) arranged in groups, wherein each LED of each semiconductor light source 14 or 16 is configured such that the source light segment corresponding to the respective LED can be emitted .

[0059] The first semiconductor light source 14 is associated with a first primary optics device 18 so that the source light segmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com