Door comprising drive system

A drive system, door leaf technology, used in manufacturing tools, door/window accessories, multi-purpose hand tools, etc., can solve problems such as cost and high structure, achieve high functional safety, simple structure, and prevent rope breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

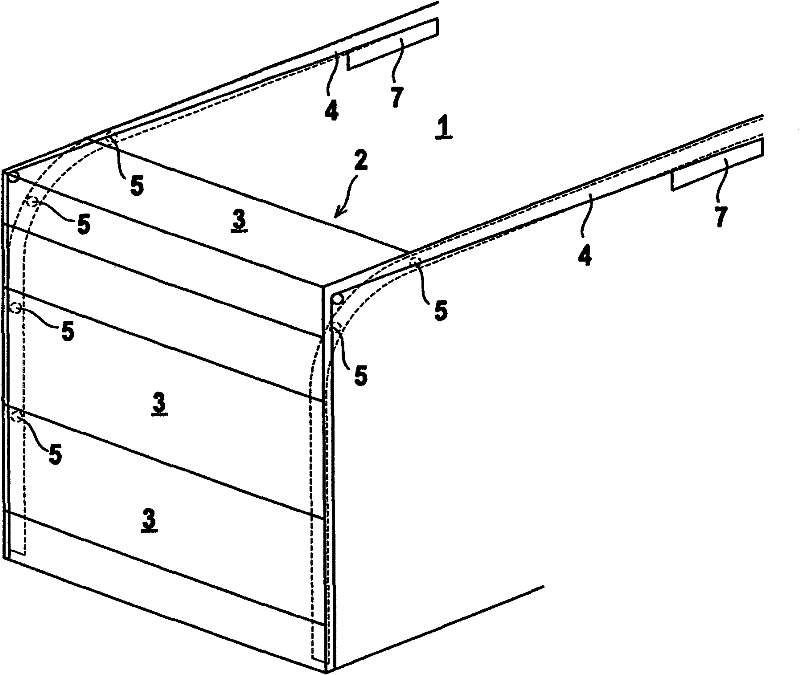

[0025] figure 1 An exemplary embodiment of a door 1 , in particular a ceiling door, is shown, which has a door leaf 2 formed from a multiple arrangement of panels 3 articulated to one another.

[0026] The door leaf 2 of the door 1 is guided laterally in guide rails which are installed in a building, in this example a garage.

[0027] Such as figure 1 As shown in , the opening of the garage can be closed with the door leaf 2 of the door 1 . In the closed state of the door 1 , the door leaf 2 is situated in the region of the section of the guide rail 4 extending in the vertical direction. In the open state of the door 1 , the door leaf 2 is located in the region of the section of the guide rail 4 that extends in the horizontal direction below the garage ceiling. Guide rollers 5 are arranged on the door leaf 2 in both side edges, said guide rollers being guided in the guide rails 4 .

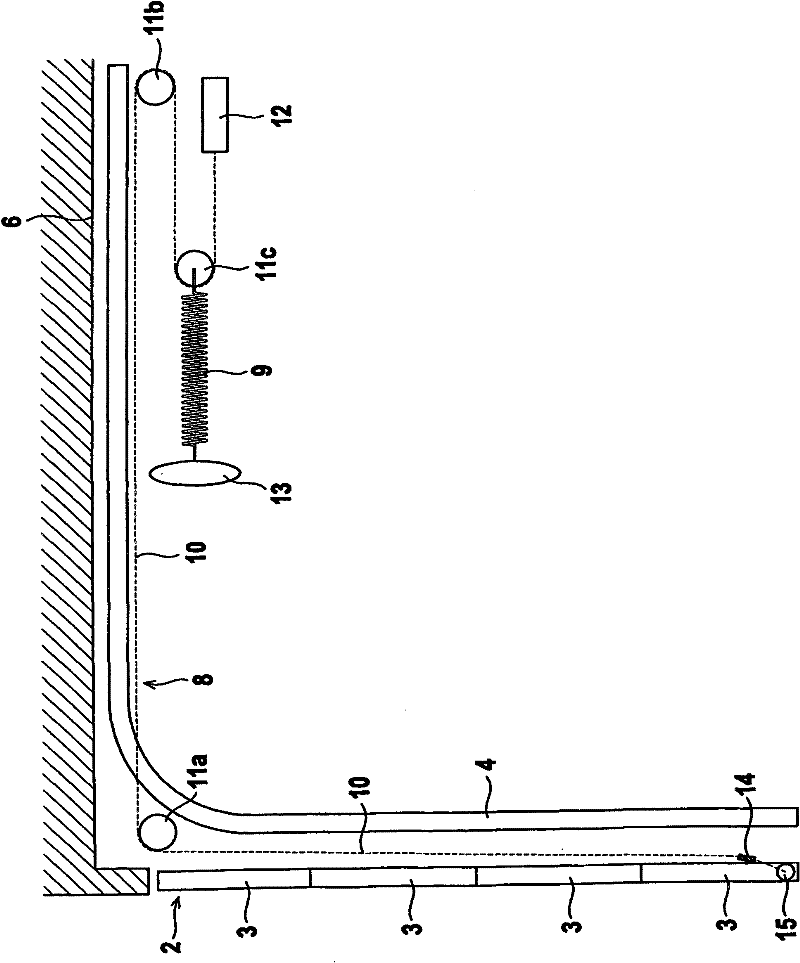

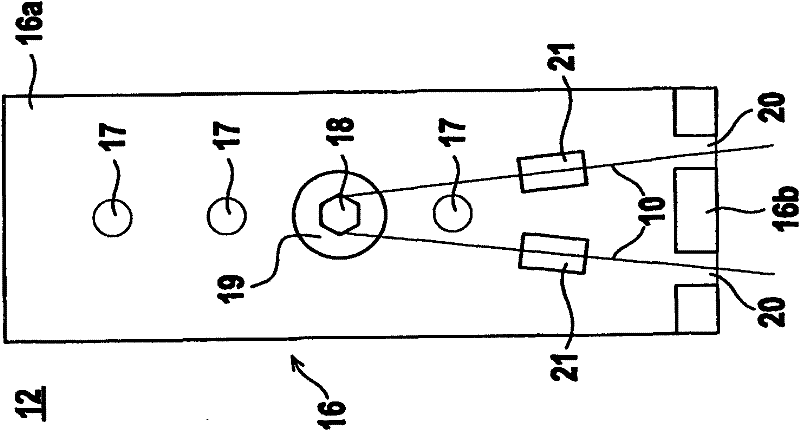

[0028] In order to open and close the door 1, a drive system (not shown) is provided. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com