Coating system and method for the series coating of workpieces

A coating and equipment technology, which is applied in the direction of surface coating liquid devices, coatings, spray booths, etc., can solve the problems of increased flow speed, etc., and achieve the effects of reducing costs, avoiding control costs, and avoiding structure costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

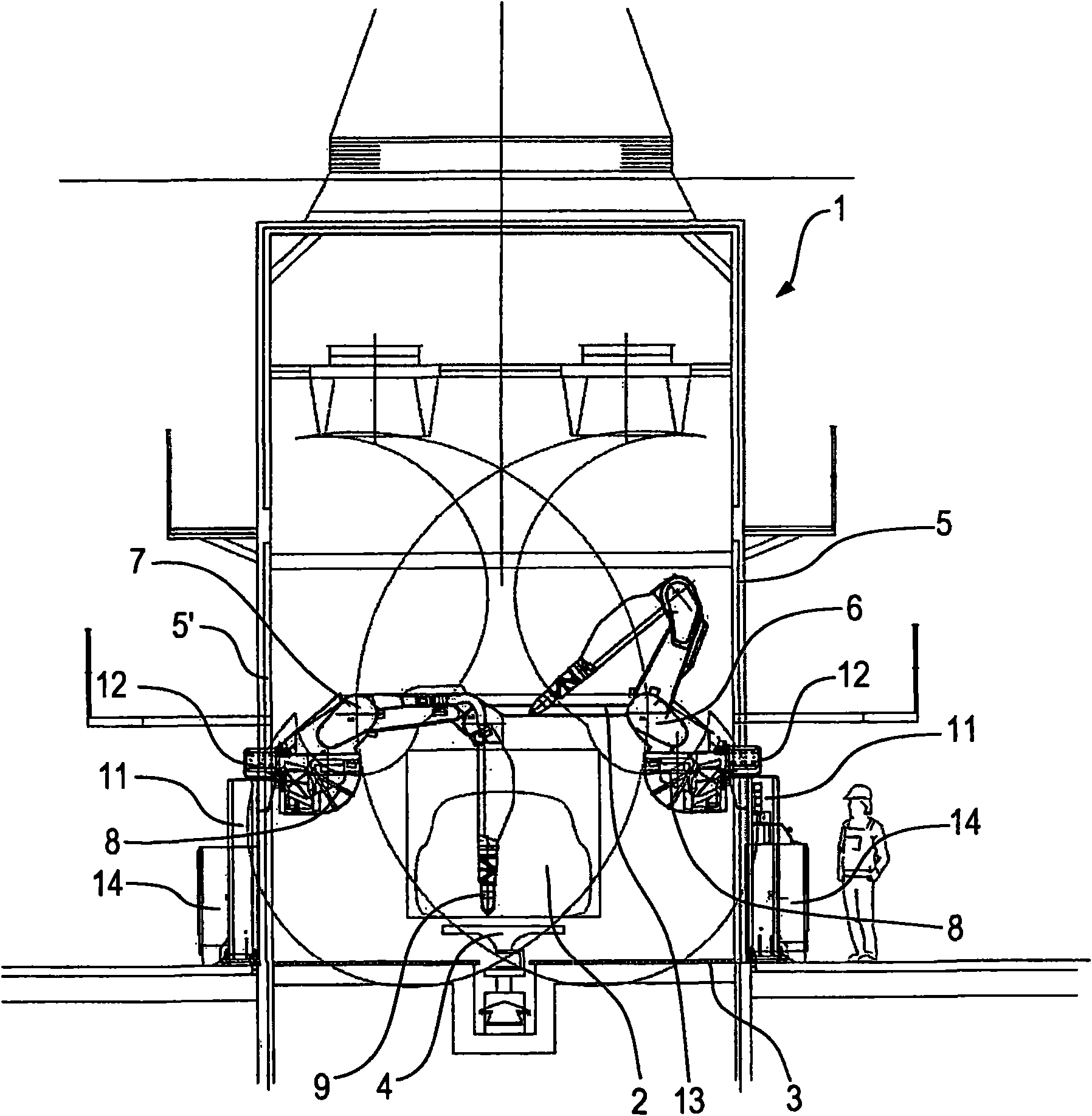

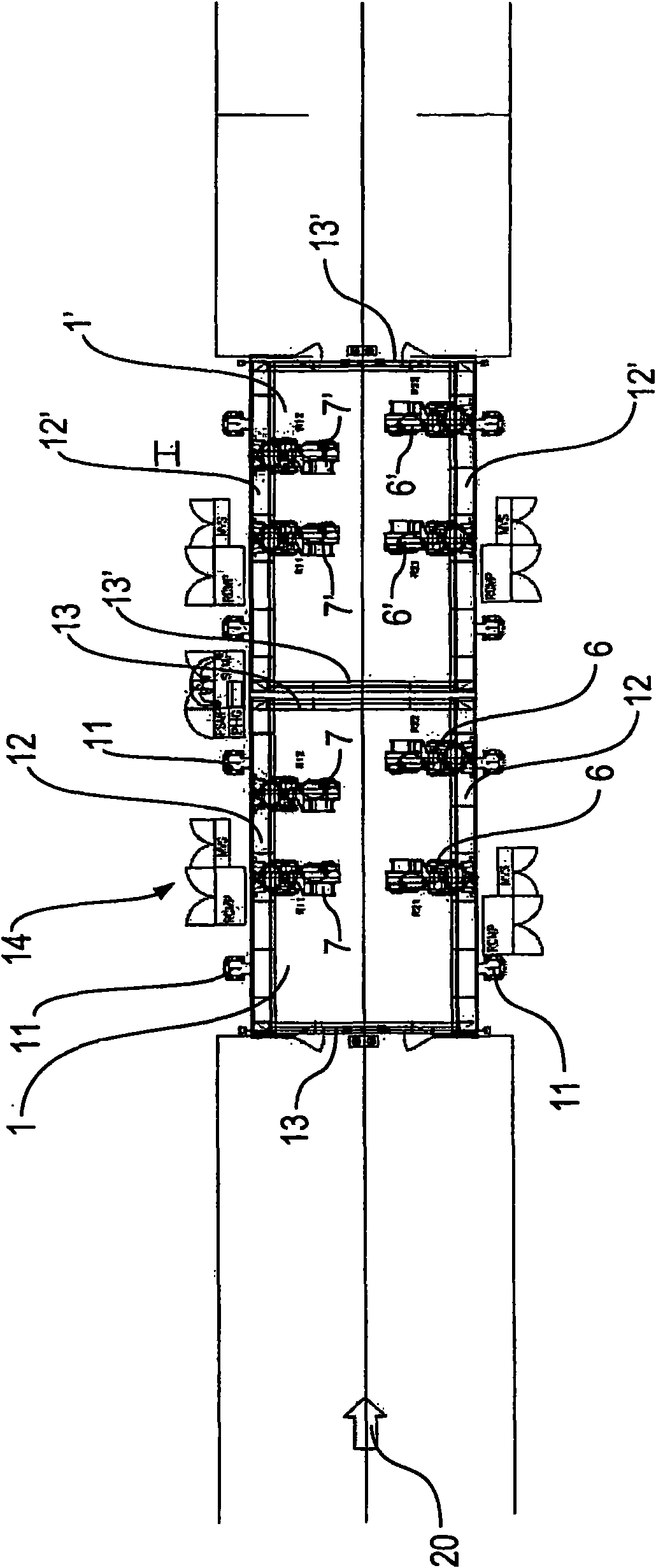

[0020] exist figure 1 In the shown spray booth 1 , paint is applied to a vehicle body 2 under the desired climatic conditions. The spray produced during painting is taken up by the air flowing vertically through the chamber and directed for flushing. The air supply device takes over the air supply function. Fresh air sucked in from the outside with a fan is filtered in multiple stages, heated, moistened, passed through the filter cover uniformly via the pressure chamber at a defined air settling velocity into the chamber and out through the grille bottom 3 . The bodywork can be conveyed by an underbody conveyor 4 through such a paint booth, which is known per se to the person skilled in the art (see eg DE 20313854).

[0021] The painting of the body 2 is carried out by, for example, four or more painting robots arranged on the side walls 5 and 5' of said chamber 1, wherein in figure 1 Painting robots 6 and 7 can be seen in . These painting robots can likewise be in a mann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com