Work bench for machine tools

A technology of workbenches and machine tools, applied in the direction of manufacturing tools, wood processing equipment, metal processing equipment, etc., can solve the problems of complexity, limited usability of workbench movement, heavy workbench, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

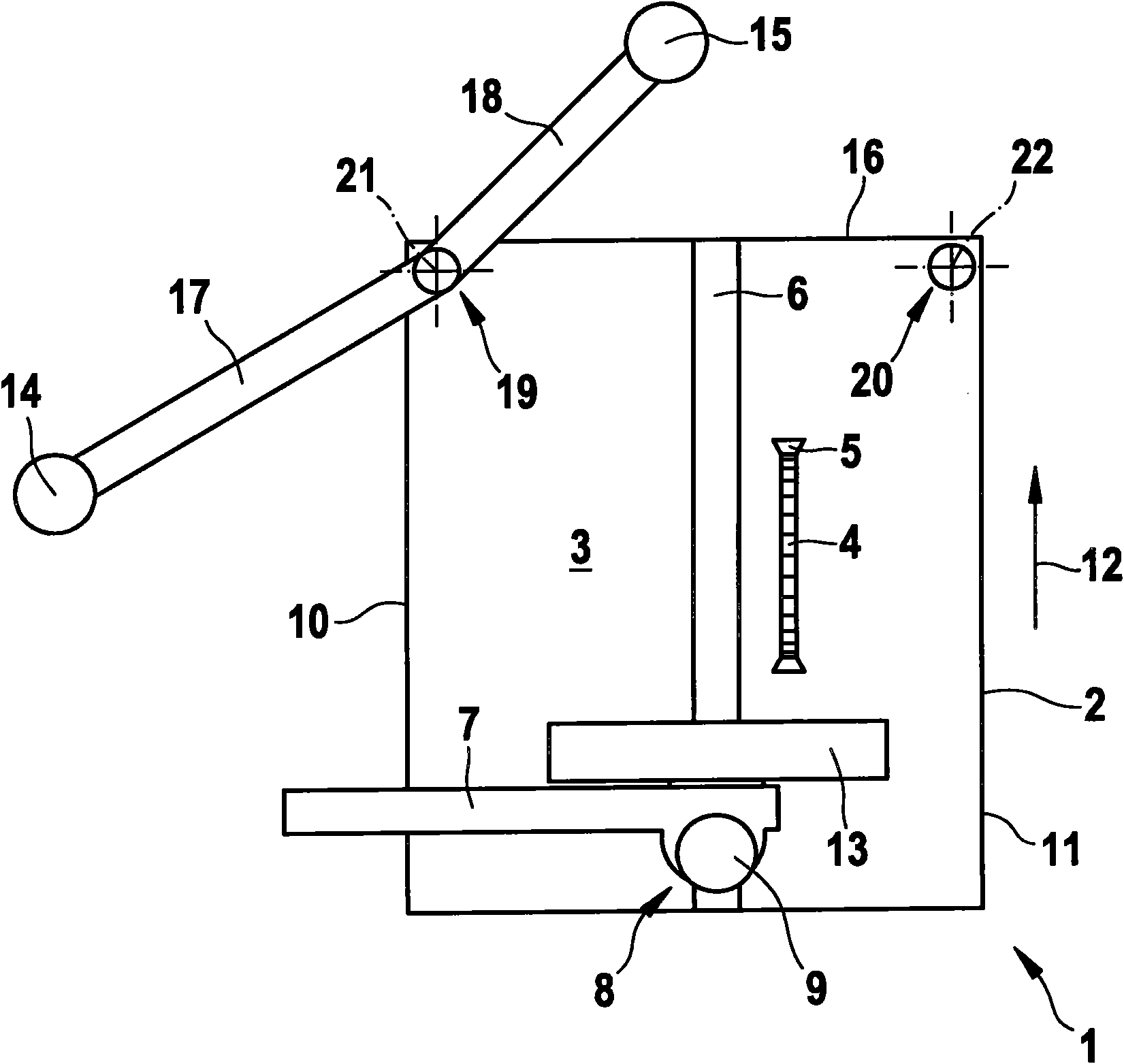

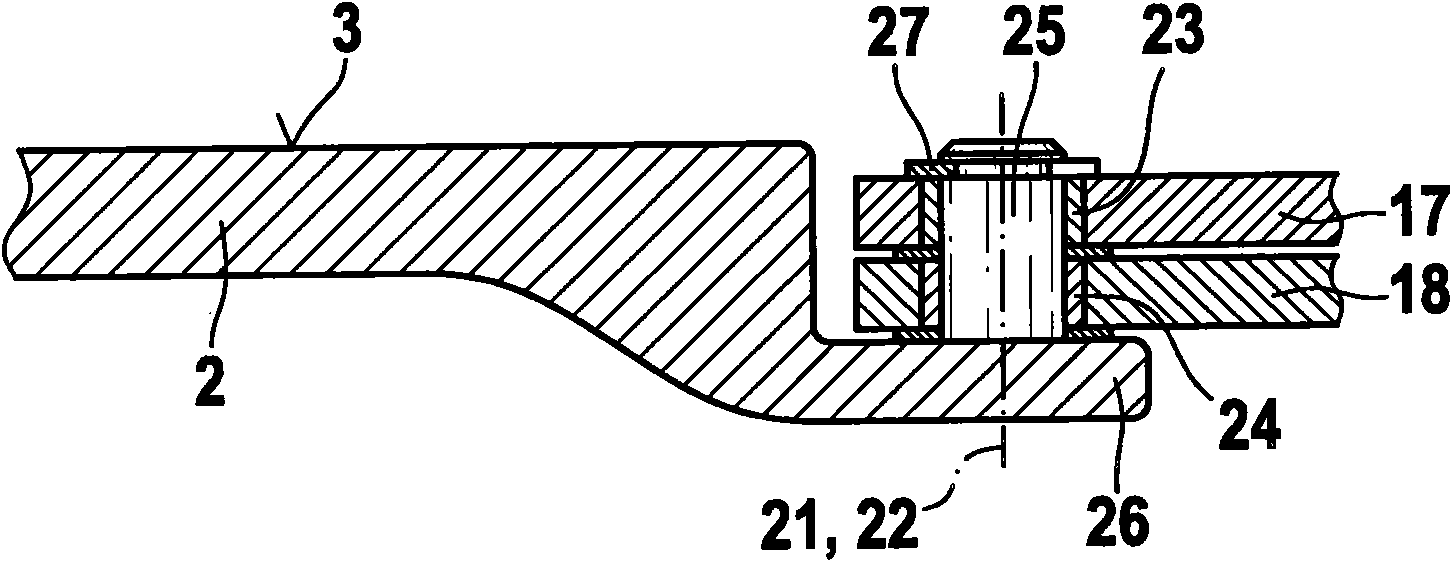

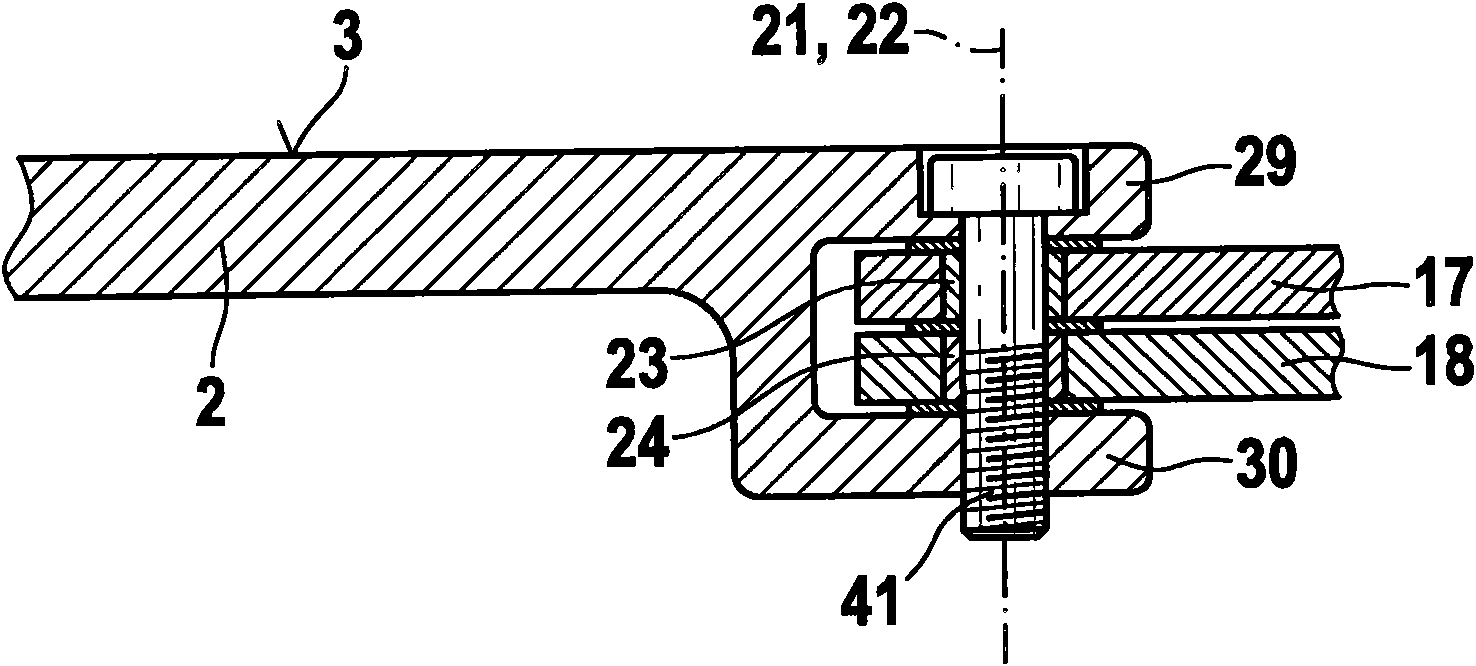

[0027] in figure 1 1 denotes the workbench of a machine tool configured as a circular saw. The single-piece or multi-piece structure of the table 2 has a table 3. The current working section of the saw blade 4 extends beyond the table top 3 at least during working operation, and the working section passes through the table top 2 in a longitudinally extending slot 5 of a corresponding size. The saw blade 4 is shown in its position perpendicular to the table top 3. In addition, in order to perform bevel cutting, the saw blade 4 can be deflected around a rotation axis extending parallel to the table surface 3 and can be adjusted to various angular positions relative to the table surface 3. The corresponding adjustment and support devices are the same as the lower structure of the workbench 1. figure 1 The view is covered by the platen 2 and is not shown.

[0028] The channel-like cut 6 extends parallel to the saw blade 4 or the slot 5 through which the saw blade passes. The cut ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com