Method for Operating a Work Station and a Work Station

A station and motion technology, applied in the directions of transportation and packaging, textile and papermaking, and conveying filamentous materials, etc., can solve the problems of high cost, damage to productivity, and time-consuming, and achieve the effect of simplifying equipment and improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

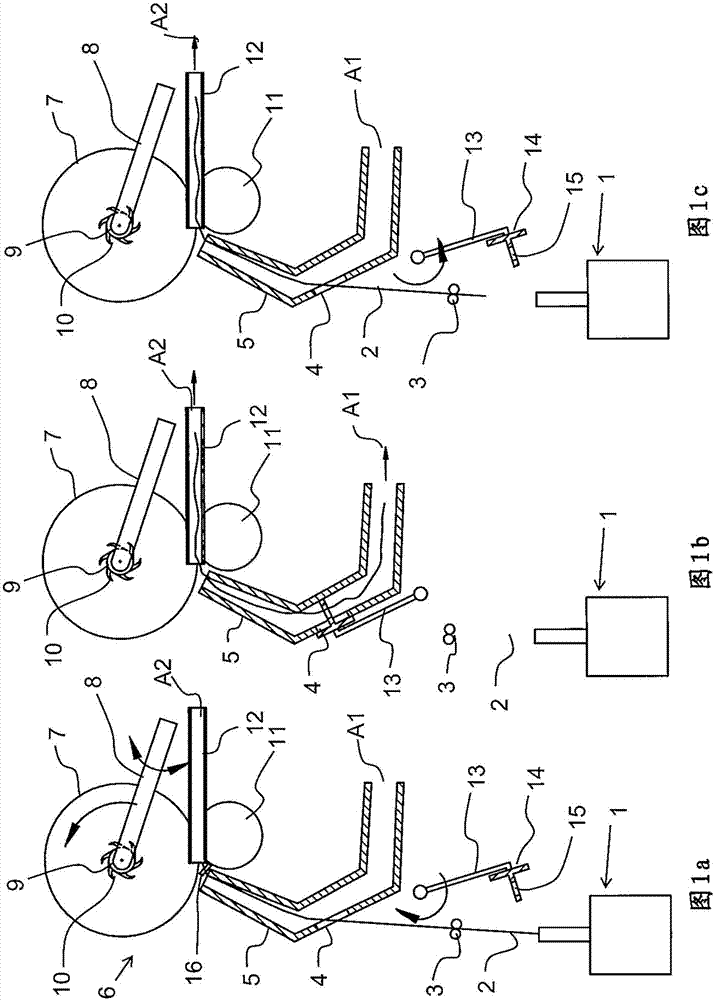

[0039] In Fig. 1a to Fig. 1c there is shown a roughly drawn side view of a spinning machine / winder, such as a rotor spinning machine or an open-end spinning machine, in which two a nozzle. The following exemplary embodiments relate accordingly to catch devices which are equipped with toothed bobbin holders. The capture device located on the bobbin or between the bobbin and the bobbin seat works according to the following description. In this case, the positioning of the yarn relative to the catching device can be modified so that the corresponding catching device can catch the yarn well and reliably.

[0040] In Fig. 1a the spinning / winding machine during production is shown. A yarn 2 is produced in a spinning device 1 and is withdrawn from the spinning device 1 by means of a driven take-off roller 3 . The yarn 2 travels through the opening 4 of the first suction nozzle 5 through the first suction nozzle 5 and to the winding device 6 . The winding device 6 has a bobbin 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com