Calibrating method for randomly placing fringe projection three-dimensional measuring system

A technology of three-dimensional measurement and fringe projection, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of expensive equipment, impracticality, and demanding system structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A full-coordinate calibration method for any fringe projection three-dimensional measurement system, characterized in that it includes the following steps:

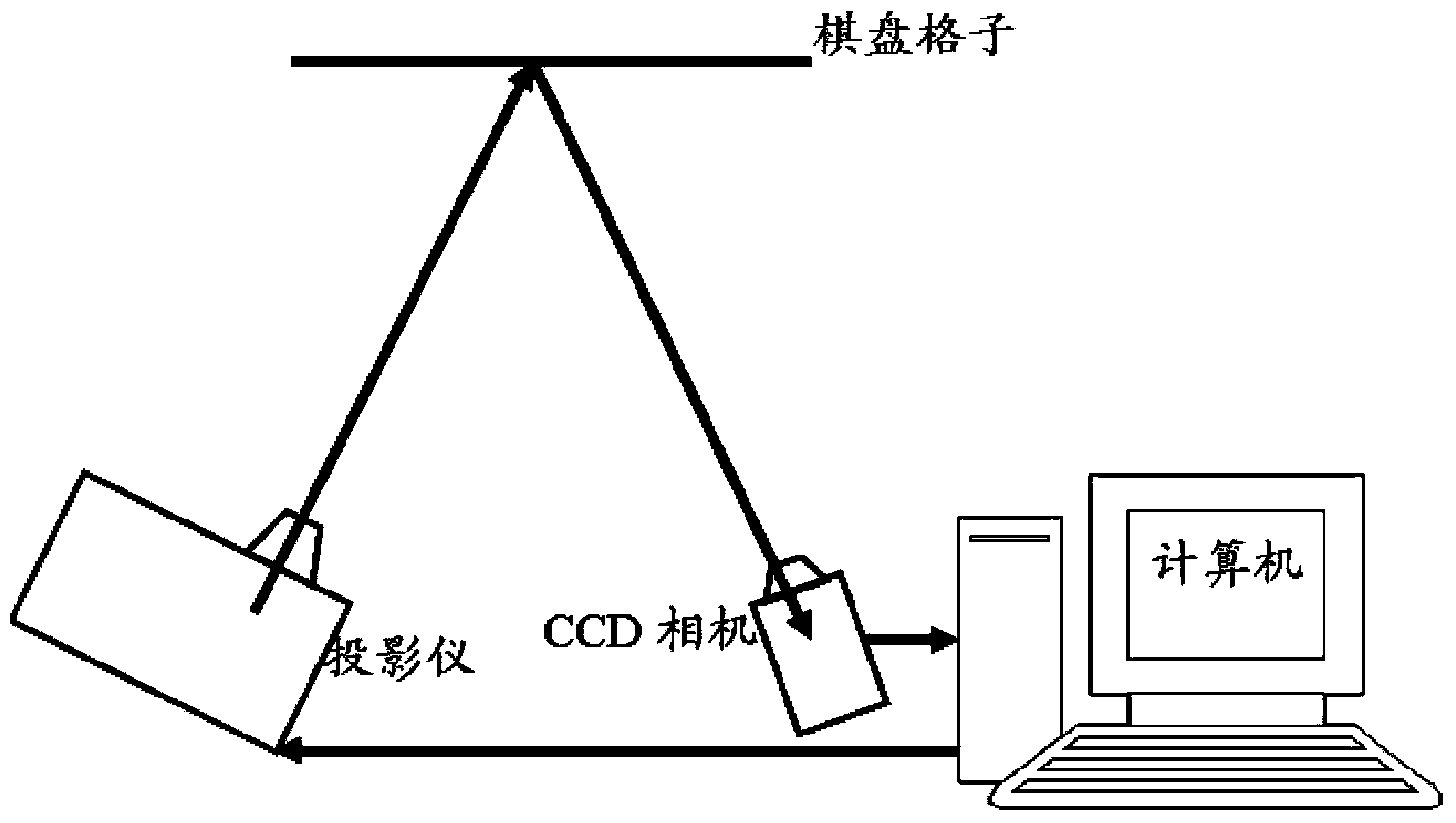

[0059] A. Set up the experimental measurement system: The system mainly includes cameras, projectors, calibration boards, objects to be measured, control computers and brackets. The distribution of projectors, cameras, and calibration boards is arbitrary, and the relative positions are arbitrary. Adjust the system so that the digital camera can capture the stripe patterns on the calibration plate and the surface of the object to be measured.

[0060] B. Place the calibration plate at multiple arbitrary positions in the field of view of the measurement system (in this example, place the calibration plate at 20 different positions arbitrarily). At each position, the computer controls the projector to generate and project 10 standard sinusoidal phase shift fringe patterns, and the digital camera captures the fringe p...

Embodiment 2

[0074] In order to verify the accuracy and validity of the phase-height relationship and the height-abscissa relationship calibrated by the method of the present invention, in the measurement field, the calibration plate is accurately positioned at two positions of 4mm and 16mm relative to the position of the reference surface. Its measurement results are as Figure 8 with Figure 9 shown. The mean values of the measurement results are 4.053mm and 16.057mm respectively, and the corresponding standard deviations are 0.028 and 0.033. For the measurement of the abscissa, we use the spacing of the grid corner points on the calibration board as an evaluation. At 4mm, the mean value in the X direction is 9.968mm, the mean value in the Y direction is 9.977mm, and the corresponding standard deviations are 0.062 and 0.075. At 16mm, the mean value in the X direction is 10.061mm, the mean value in the Y direction is 10.070mm, and the corresponding standard deviations are 0.064 and 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com