Vibration damper for a high-pressure fuel pump, high pressure fuel pump having a vibration damper, and method for controlling such a vibration damper

A technology of vibration damper and high pressure fuel pump, applied in the directions of fuel injection pump, vibration suppression adjustment, rotational vibration suppression, etc., can solve the problems of inability to match the operating conditions of the fuel pump, unadjustable torsional vibration damper, etc., to save the sensor Elements, reduced structural cost, effect of reduced structural cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

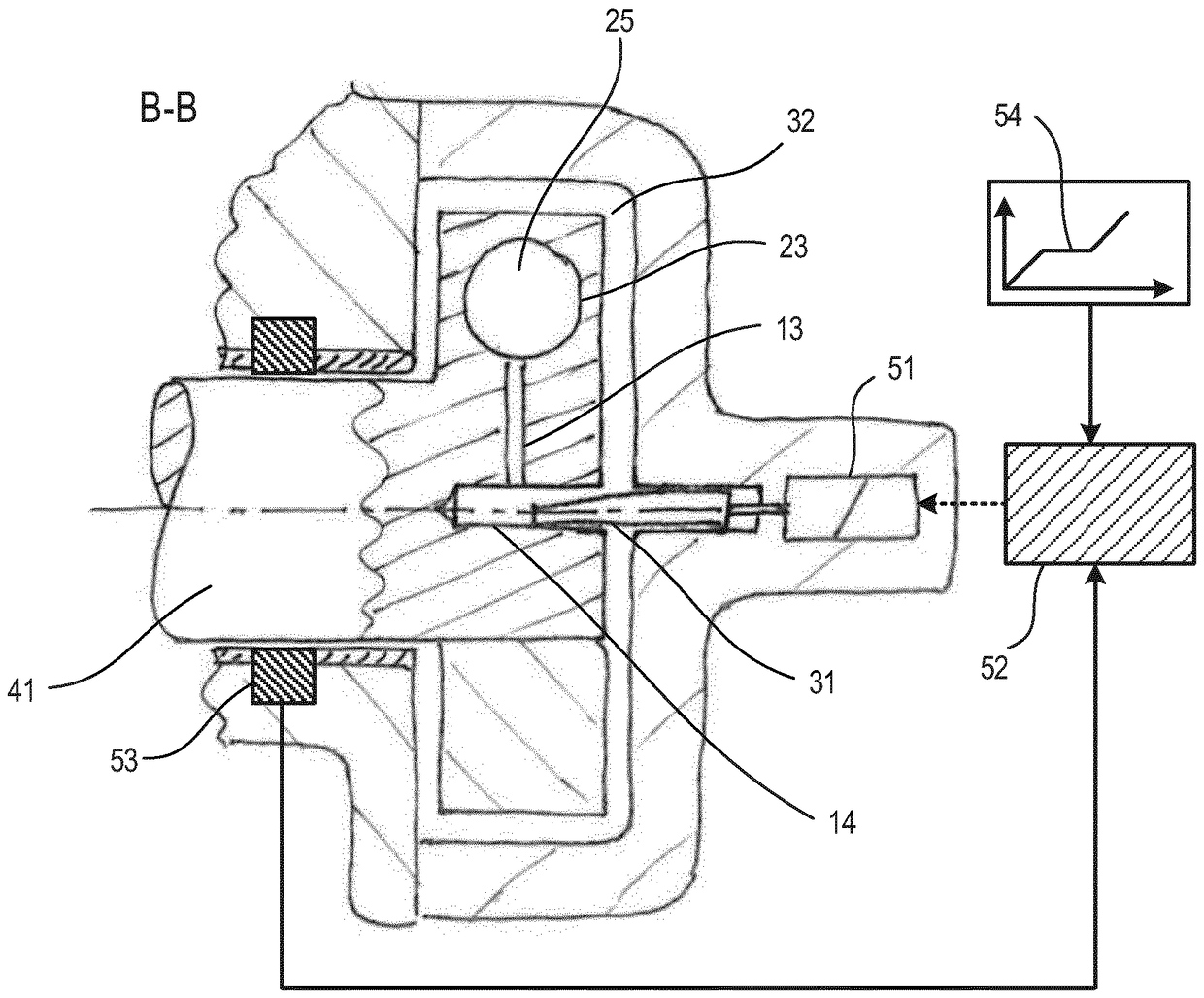

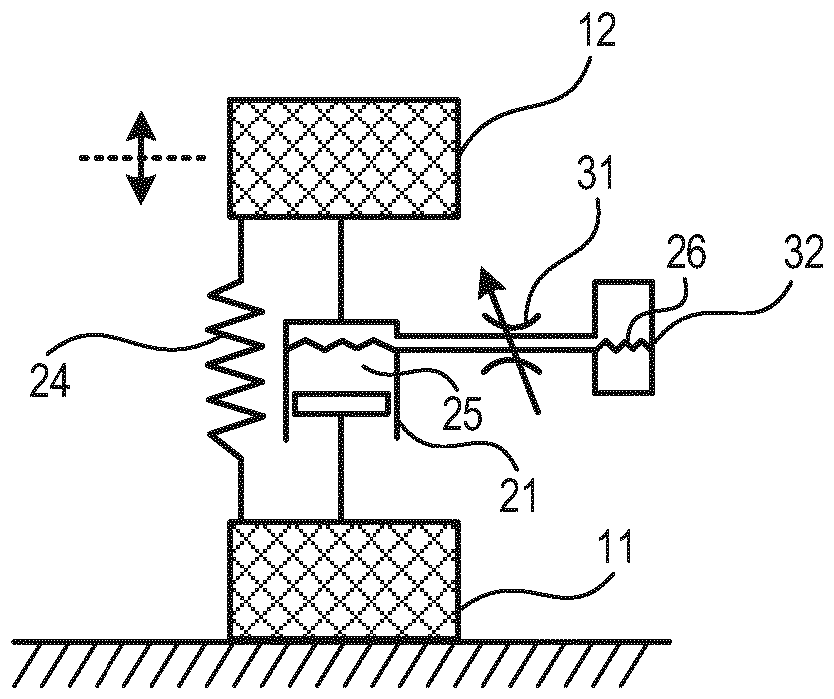

[0022] exist figure 1 A vibration damper is shown in , which may comprise a first flywheel mass 11 and a second flywheel mass 12 . The two flywheel masses 11 and 12 can be connected to one another via a hydraulic element 21 (hereinafter also referred to as damper element 21 ) and are designed to be movable relative to one another. The damper element 21 can have a working space 25 , a corresponding space 32 and a valve 31 . Furthermore, the damper element can also have a plurality of valves. The flow through the valve 31 can be controlled during operation of the damper element 21 . Not only can the valve 31 be controlled steplessly, but also the valve 31 can be controlled within arbitrarily short time intervals. The working space 25 and the corresponding space 32 may be hydraulically connected to each other. Said valve 31 can be arranged between the working space 25 and the corresponding space 32 and be hydraulically connected both to the working space 25 and to the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com