Drive axle for mobile working machine

A technology for driving axles and working machines, which is applied in the direction of motor vehicles, connected with control/drive circuits, and combined cooling of power plants, etc., which can solve the problems of expansion of cooler devices, cost of laying pipes, cost of laying hoses, etc. problems, to achieve the effect of reducing structural costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

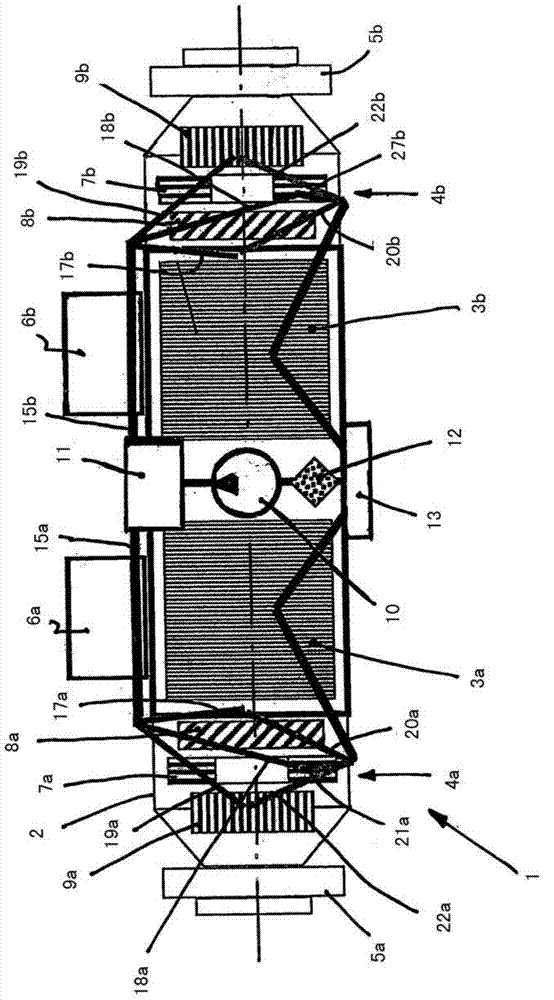

[0024] The drive axle 1 according to the invention is preferably designed as a dual-motor axle, wherein two electric traction motors 3 a , 3 b in the form of asynchronous motors are arranged in an axle housing 2 , which are each coupled to a transmission 4 a in between. In the case of , 4b, the drive hubs 5a, 5b are used to receive and fix a drive wheel not shown in each case. For controlling each electric traction motor 3a, 3b, an electric power electronics device 6a, 6b, for example a commutator, is provided, which are fastened directly to the axle housing 2 and are thus flanged to the drive axle 1 on.

[0025] In the exemplary embodiment shown, the transmissions 4a, 4b are designed as double-reduction transmissions with a braking device 7a, 7b. In the exemplary embodiment shown, the braking devices 7a, 7b are arranged between an inlet stage 8a, 8b and an outlet stage 9a, 9b of the transmission 4a, 4b, which are driven by the corresponding travel motor 3a, 3b drive, said out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com