A Method for Preparing Rare Earth Orthophosphate Monodisperse Spherical Up/Down Conversion Phosphor Powder Using Microwave Uniform Precipitation

A technology for single and uniform precipitation of orthophosphate, applied in the field of material science, to achieve mass production, low cost, great flexibility and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing rare earth orthophosphate monodisperse spherical up / down conversion phosphors by microwave uniform precipitation, comprising the following steps:

[0040] (1) 50mmol phosphoric acid, 2.5mmol ammonium sulfate and 250mmol urea are fully dissolved in water;

[0041] (2) Add 5mmol Y(NO 3 ) 3 ;

[0042] (3) while stirring, the pH of the resulting mixed solution was adjusted to 1.0 with nitric acid, and it was placed in a microwave reactor for 8 minutes, and the output power of the microwave reactor was 650W;

[0043] (4) centrifugal separation, cleaning and drying, obtain the rare earth yttrium phosphate monodisperse spherical powder;

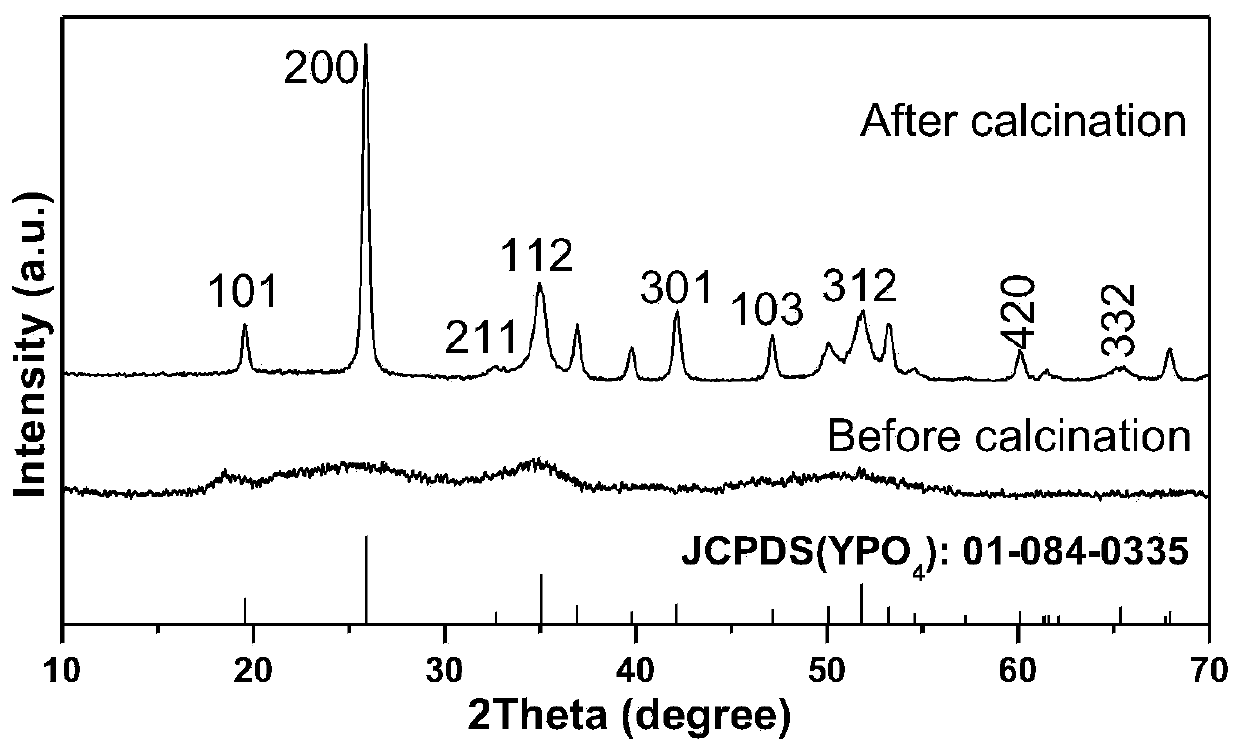

[0044] (5) Calcining the obtained rare earth yttrium phosphate monodisperse spherical powder at 1000° C. for 2 hours to obtain rare earth yttrium phosphate monodisperse spherical powder with good crystallinity.

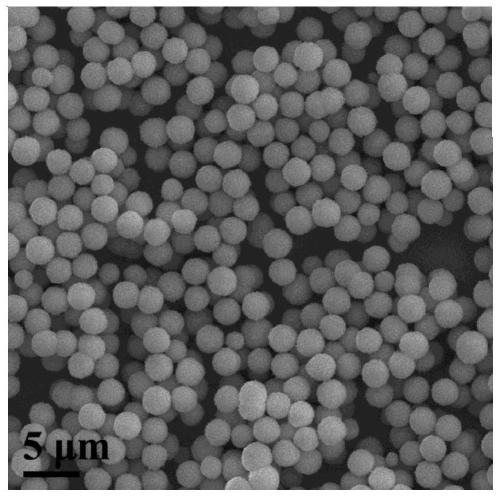

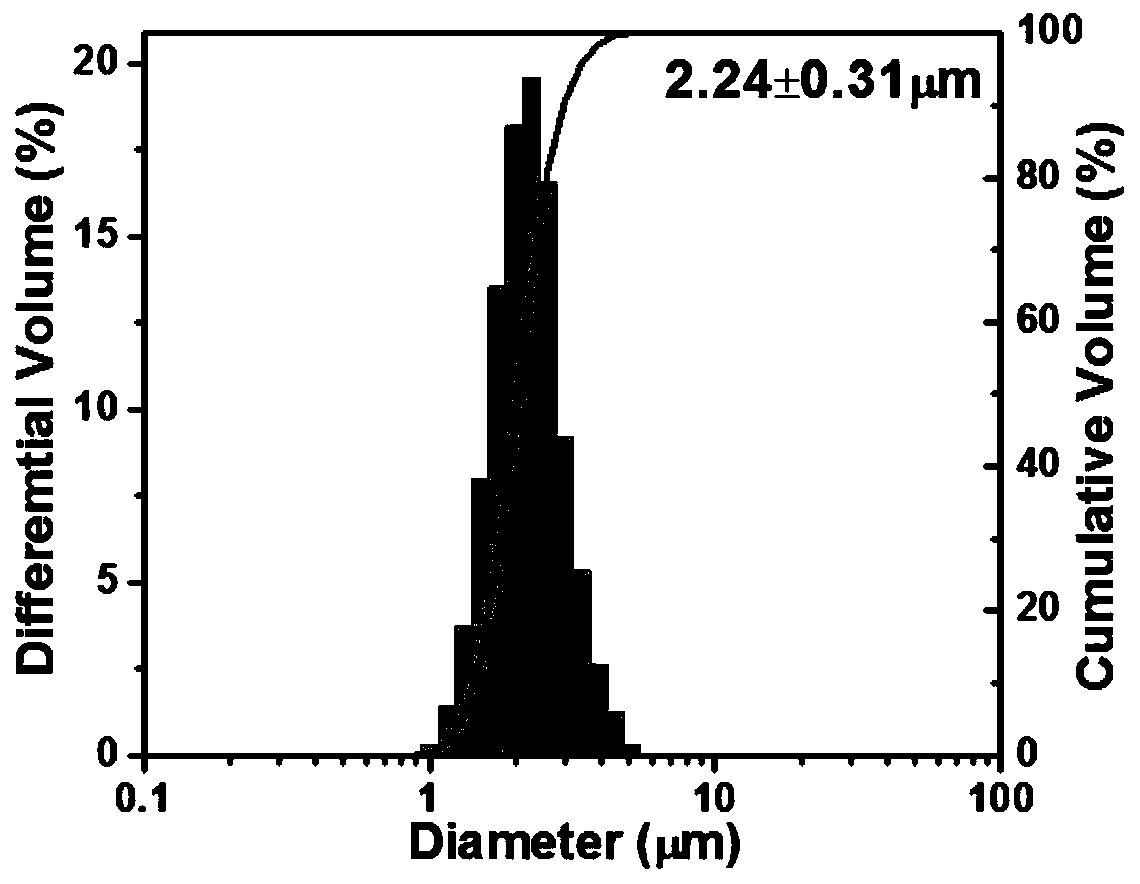

[0045]The obtained microwave homogeneous precipitation reaction product is a monodisperse spherical powd...

Embodiment 2

[0047] A method for preparing rare earth orthophosphate monodisperse spherical up / down conversion phosphors by microwave uniform precipitation, comprising the following steps:

[0048] (1) 50mmol phosphoric acid, 2.5mmol ammonium sulfate and 250mmol urea are fully dissolved in water;

[0049] (2) Add 5mmol La(NO 3 ) 3 ;

[0050] (3) while stirring, the pH of the resulting mixed solution was adjusted to 0.9 with nitric acid, and it was placed in a microwave reactor for 8 minutes, and the output power of the microwave reactor was 700W;

[0051] (4) centrifugal separation, cleaning and drying, to obtain monodisperse spherical powder of rare earth lanthanum phosphate;

[0052] (5) Calcining the obtained rare earth lanthanum phosphate monodisperse spherical powder at 1000° C. for 2 hours to obtain rare earth lanthanum phosphate monodisperse spherical powder with good crystallinity.

[0053] The resulting microwave homogeneous precipitation reaction product is a monodisperse hex...

Embodiment 3

[0056] A method for preparing rare earth orthophosphate monodisperse spherical up / down conversion phosphors by microwave uniform precipitation, comprising the following steps:

[0057] (1) fully dissolve 100mmol phosphoric acid, 2.5mmol ammonium sulfate and 250mmol urea in water;

[0058] (2) Add 5mmol Y(NO 3 ) 3 ;

[0059] (3) while stirring, the pH of the resulting mixed solution was adjusted to 1.2 with nitric acid, and it was placed in a microwave reactor for 8 minutes, and the output power of the microwave reactor was 750W;

[0060] (4) centrifugal separation, cleaning and drying, obtain the rare earth yttrium phosphate monodisperse spherical powder;

[0061] (5) Calcining the obtained rare earth yttrium phosphate monodisperse spherical powder at 800° C. for 4 hours to obtain rare earth yttrium phosphate monodisperse spherical powder with good crystallinity.

[0062] The diameter of the obtained microwave uniform precipitation reaction product is about 1.5 μm, and its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com