Novel hydraulic balance valve

A technology of hydraulic balance and balance valve, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., which can solve the problems of poor economy of the balance circuit, large vibration and noise, and large volume of the balance valve, so as to reduce system energy consumption , Improve production efficiency and improve system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

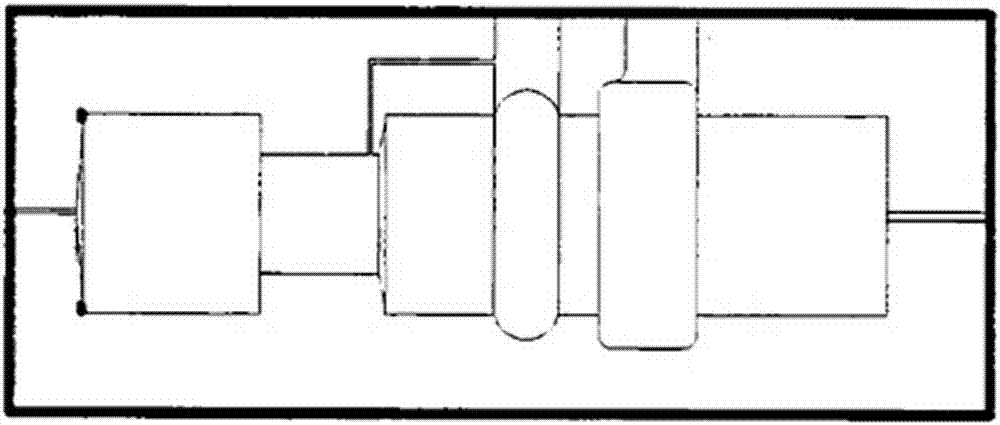

Image

Examples

Embodiment Construction

[0009] Preferably, the balance valve has a long-term maintenance state during work. At this time, the oil is locked for a long time. Considering the reduction of leakage and safety, the new balance valve adopts a cone valve with better orientation and better sealing. one-way valve.

[0010] Preferably, in order to save space, the check valve spool axis and the main spool axis of the new balance valve are arranged side by side in parallel, which makes the check valve adopt a right angle in structure. Meets structural requirements and reduces vibration and noise generation

[0011] Preferably, the matching length of the valve core and the valve sleeve is related to the leakage amount and the frictional resistance of the valve core movement. In order to ensure that the main valve core has good guidance, and when the matching two sides are under the conditions of the maximum pressure difference and the maximum fit clearance, The internal leakage shall not exceed the requirements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com