Device and method for producing clean gasoline and increasing propylene yield through catalytic cracking and hydrogenation

A catalytic cracking and gasoline technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems that are not involved, increase energy consumption and equipment investment, and do not involve system coupling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: Two-stage riser reactor

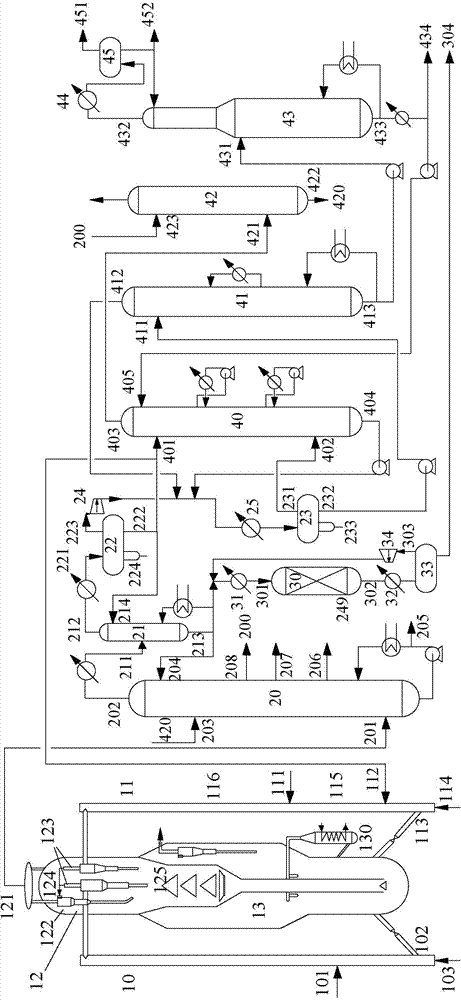

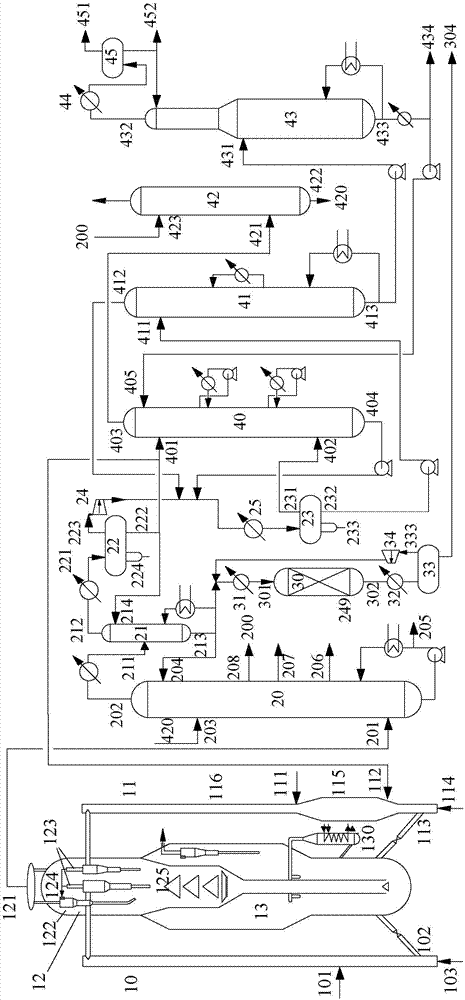

[0063] Such as figure 1 As shown, the unit of catalytic cracking and hydrofinishing combined to produce clean gasoline and increase the production of propylene provided in this example includes a reaction-regeneration system, a fractionation system, a hydrofinishing unit and an absorption-stabilization system,

[0064] Among them, the reaction-regeneration system includes a riser reactor, an oil separator and a catalyst regenerator,

[0065] The riser reactor is a two-stage riser reactor, comprising a first riser reactor 10 and a second riser reactor 11, the upper end of the first riser reactor 10 communicates with the oil separator 12, and the second riser reactor The upper end of the tube reactor 11 communicates with the oil separator 12, and the first riser reactor 10 is provided with a pre-lift gas inlet 103, a catalyst feed port 102 and a feedstock oil feed port 101 from bottom to top, and the second riser reactor The devic...

Embodiment 2

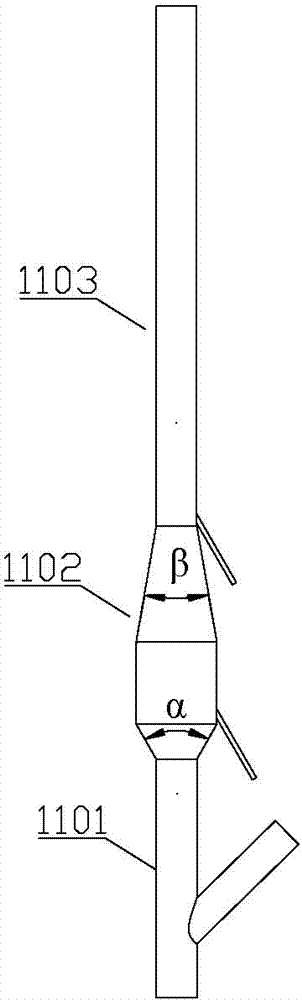

[0076] The device of the present invention see figure 2 , its structure is basically the same as that of Example 1, except that the second riser reactor adopts a turbulent bed or a combined reactor of a fast bed and a transport bed. Such as figure 2 with 3 As shown, the second riser reactor is composed of a pre-lift section 1101, a turbulent bed or fast bed reaction zone 1102, and a transport bed reaction zone 1103 from bottom to top. The specific design requirements are as follows: the total height of the reactor is 10~40m; The diameter of the pre-lift section 1101 is 0.2-5m, and its height accounts for 5-20% of the total height of the reactor; the height of the turbulent bed or fast bed reaction zone 1102 accounts for 5-50% of the total reactor height, and its diameter is the same The diameter ratio of 1101 is 1.2~5.0:1; the height of transport bed reaction zone 1103 accounts for 20~90% of the total height of the reactor, and the ratio of its diameter to the diameter of ...

Embodiment 3

[0078] Embodiment 3: single-stage riser reactor

[0079] Such as Figure 4 As shown, the device for the joint production of clean gasoline and increased propylene production by catalytic cracking and hydrofining provided in this example is similar to Example 1, except that the riser reactor of the reaction regeneration system in this example is a single-stage riser reactor.

[0080] Knot Figure 4 , the difference between the two devices is described as follows:

[0081] The upper end of the riser reactor 11' communicates with the oil separator 12', and the riser reactor 11' is provided with a pre-lift gas inlet 114', a catalyst feed port 113', and a naphtha light fraction feed port 112 from bottom to top. ', raw oil feed port 101' and circulating oil feed port 111', the solid phase outlet of the oil separator 12' communicates with the catalyst regenerator 13, and the catalyst regenerator 13 is connected to the catalyst of the riser reactor 11' through a pipeline The feedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com