A machine tool for machining a workpiece

A technology for processing workpieces and machine tools, which is applied in the direction of metal processing machinery parts, manufacturing tools, grinding workpiece supports, etc., can solve the problem of inaccurate working boards, and achieve the effect of reducing structural costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

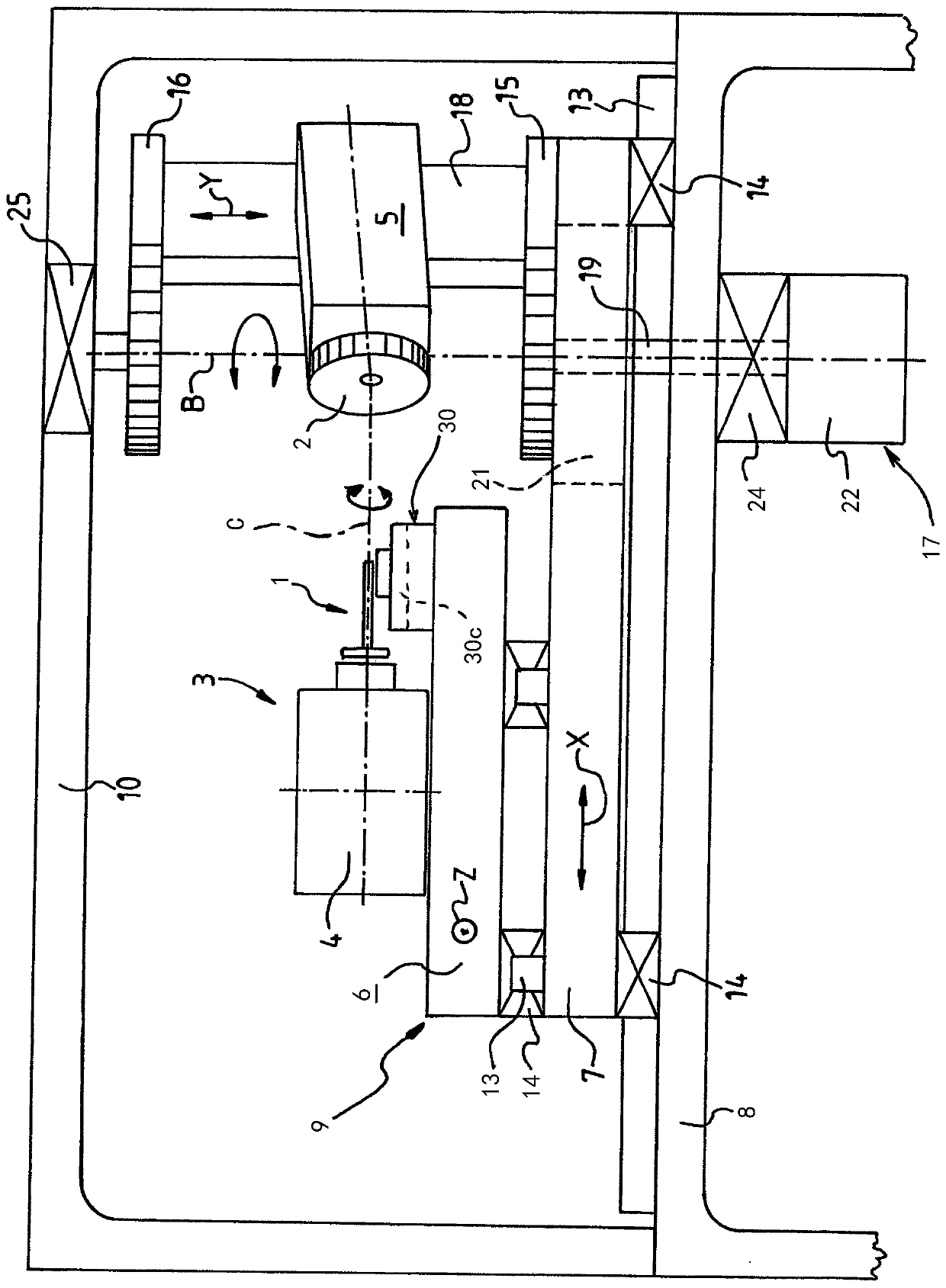

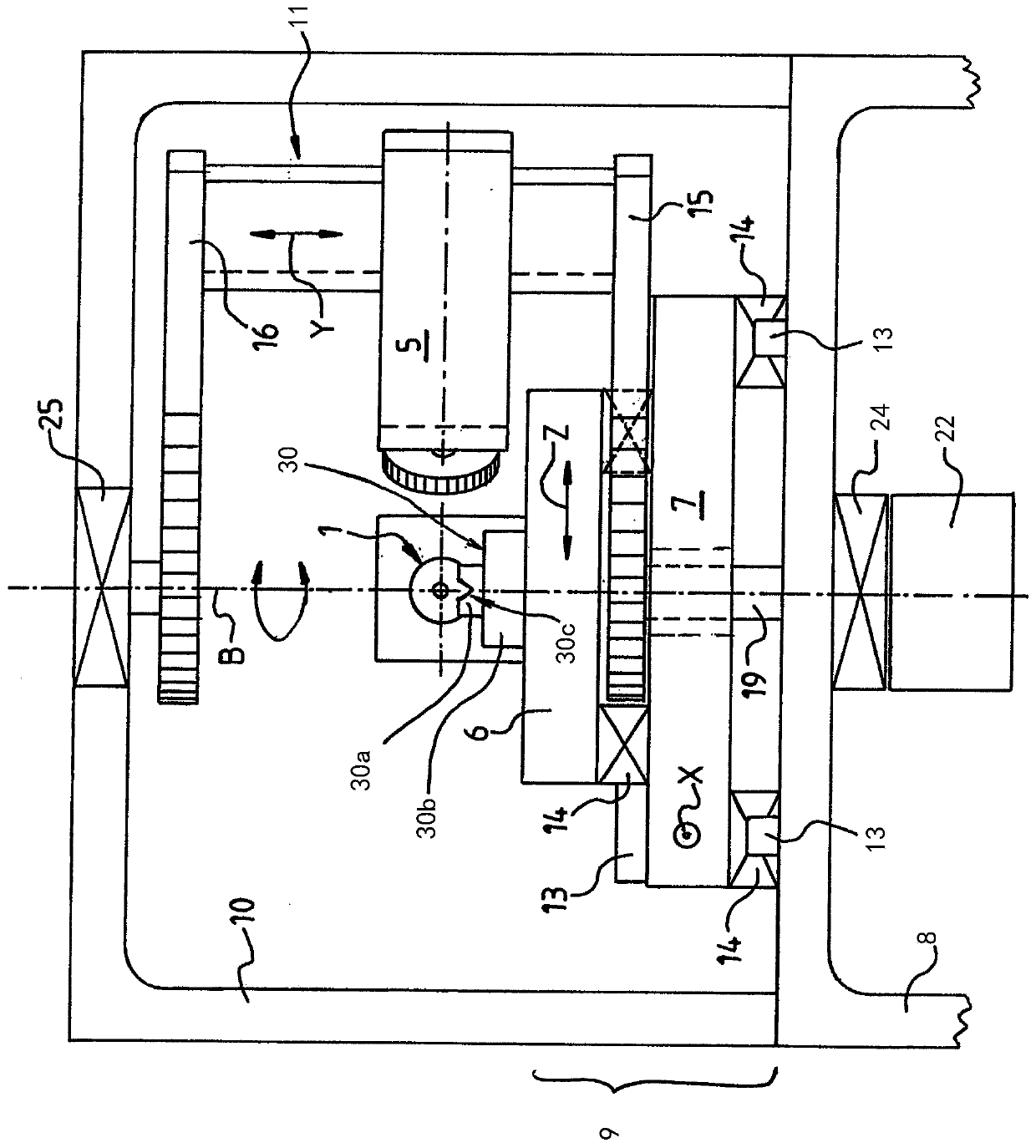

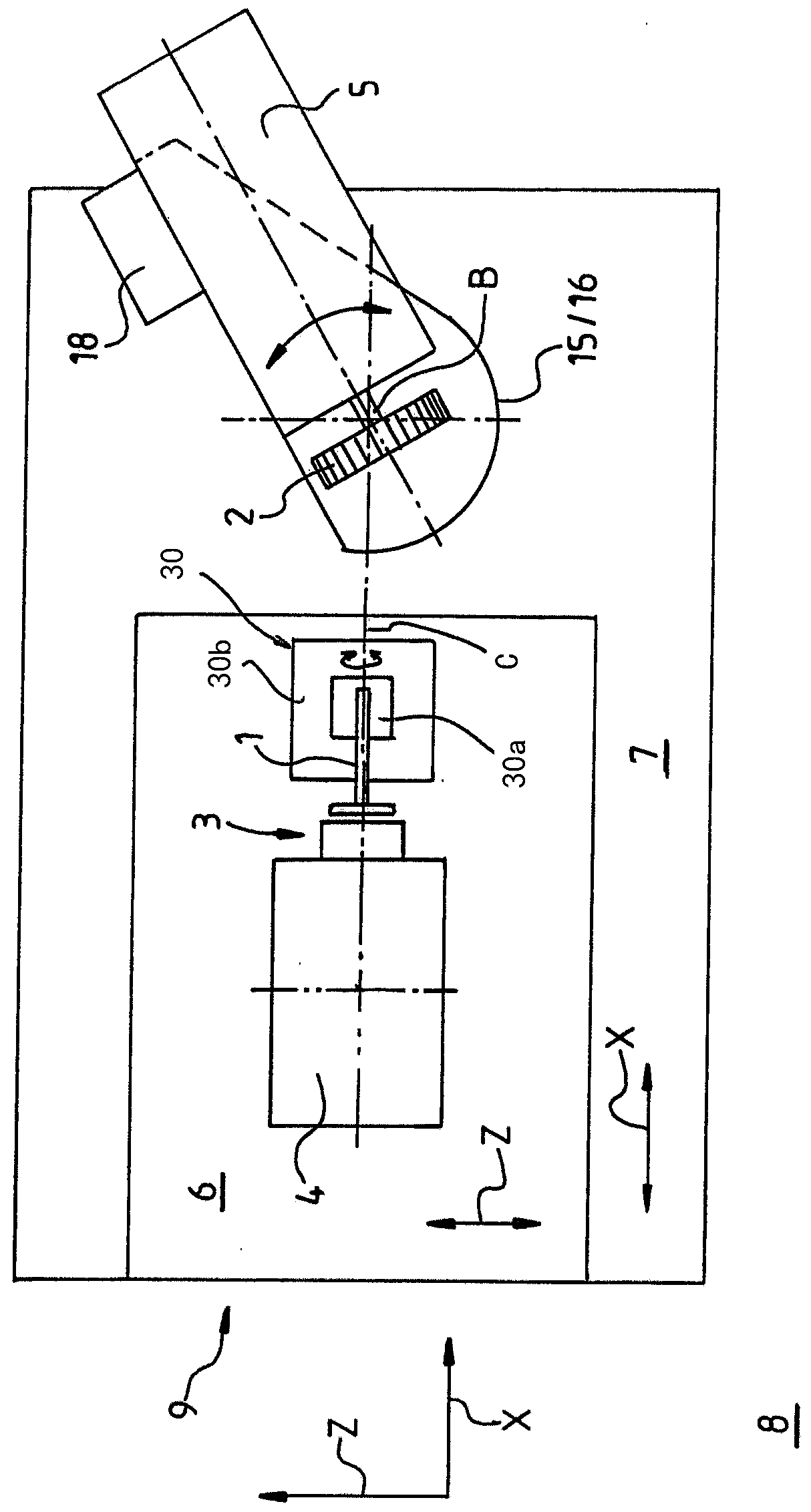

[0037] exist figure 1A mill according to the invention is shown in . The workpiece 1 is clamped in the workpiece holding device 3 , ie in the chuck of the motor spindle 4 , in order to be able to rotate it during its machining. The workpiece 1 is supported during processing by a support device 30 comprising a table of two stages 30a, 30b, wherein the stage 30b is height-adjustable and capable of supporting the workpiece directly, and the stage 30b (which in turn is supported on its The upper stage 30a) can again be adjusted horizontally in the X direction or along the C axis. The workpiece holding device 3 and the supporting device 30 stand on a granite table which is part of a second adjustment device 6 which is movable in the Z direction. For this purpose, the plate of the second adjusting device 6 is supported linearly displaceably via guide rails 13 or guide carriages 14 on the other plate of the first adjusting device 7 , which is displaceable in the X direction. An ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com