Multi-speed gearbox

A technology of transmission and automatic transmission, applied in the direction of vehicle gearbox, multi-gear ratio transmission device, transmission device, etc., can solve problems such as high hydraulic pressure and loss, and achieve the effect of reducing structural space, reducing structural consumption, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

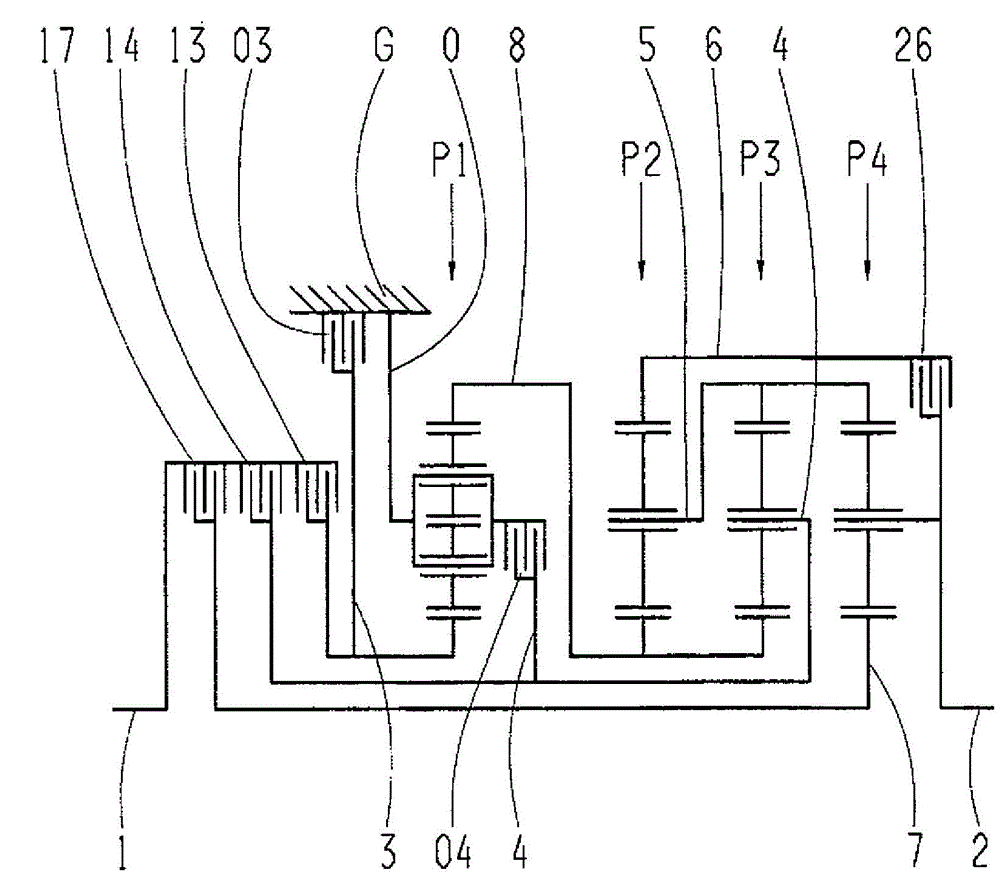

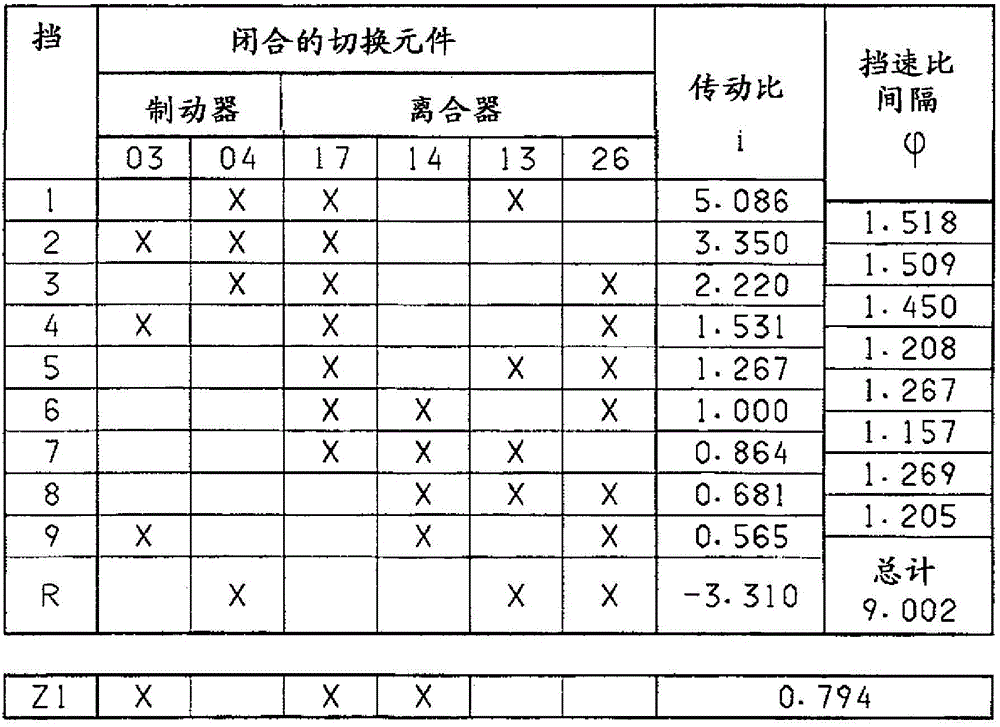

[0025] exist figure 1 A multi-stage transmission according to the invention is shown in , which comprises a drive shaft 1 , a driven shaft 2 and four planetary gearsets P1 , P2 , P3 and P4 arranged in a housing G. The first planetary gear set P1 is at figure 1 In the example shown, it is formed as a planetary gear set with a positive transmission ratio, and the second, third and fourth planetary gear sets P2, P3, P4 are formed as a planetary gear set with a negative transmission ratio. According to the present invention, if the connecting structure of the planetary carrier and the connecting structure of the ring gear are replaced at the same time and the numerical value of the fixed transmission ratio is increased by 1 compared with the implementation of the negative transmission ratio planetary gear set, then the negative transmission ratio planetary gear sets P2, P3, At least one of P4 may be configured as a positive ratio planetary gear set.

[0026] In the illustrated e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com