Turbine arrangement

A turbine and turbine technology, applied in the combustion method, combustion chamber, combustion control and other directions, can solve the problems of limiting the load range and reducing the combustion temperature, and achieve the effect of reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

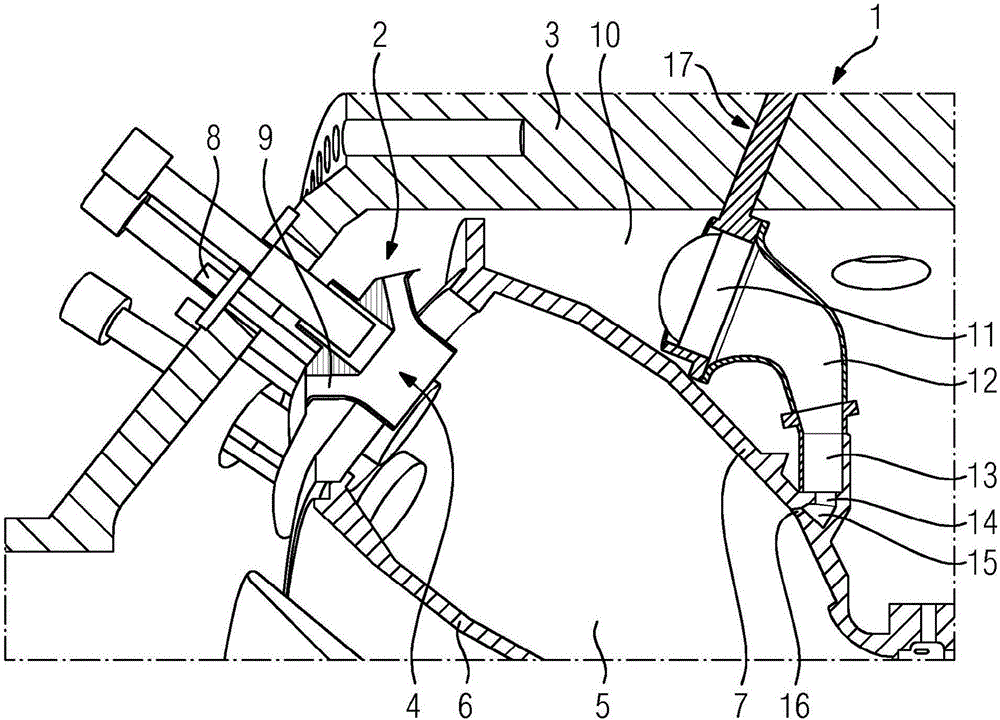

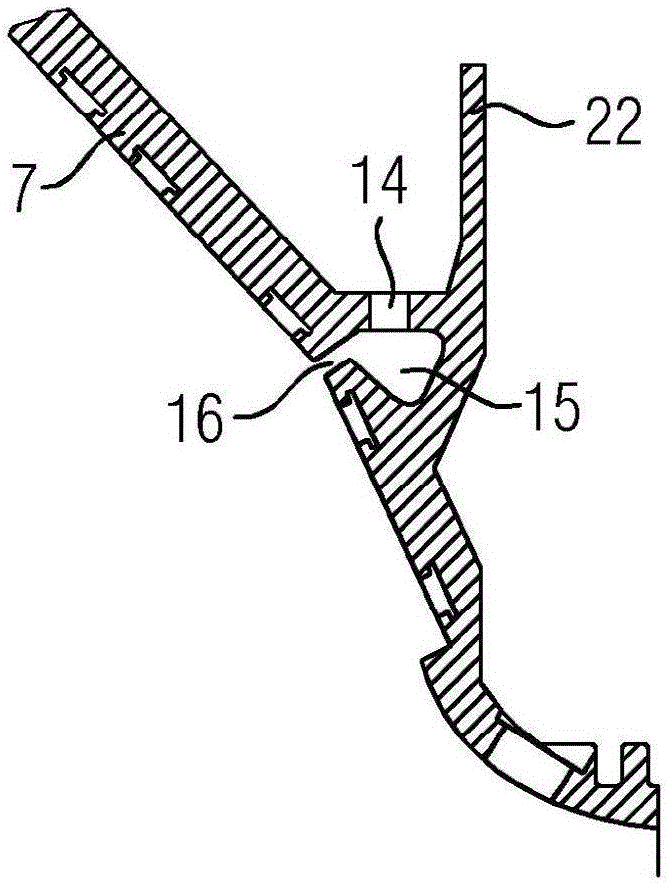

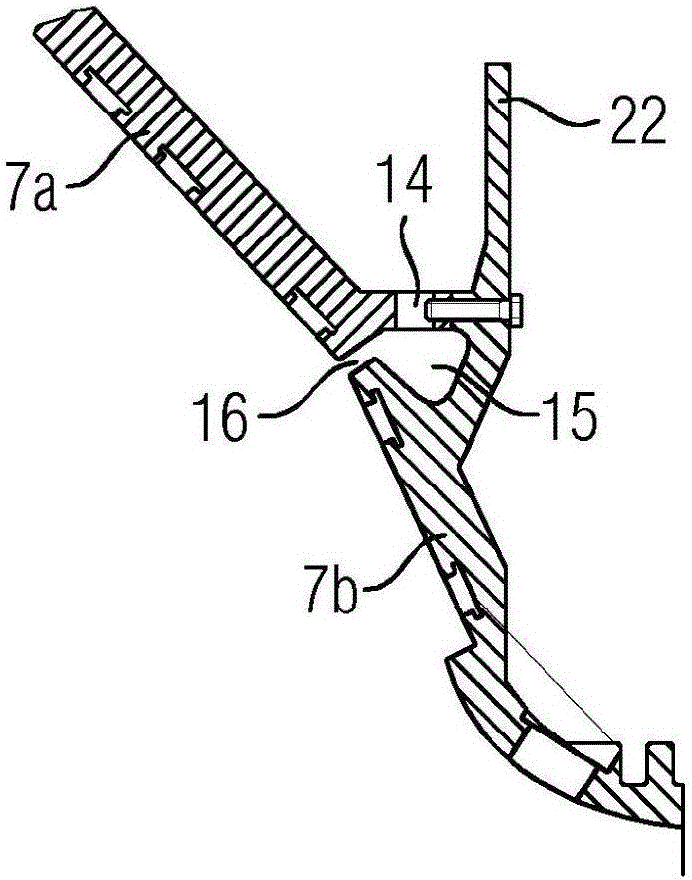

[0040] Figures 1 to 8 A partial area of a turbine arrangement 1 according to a first embodiment of the invention is shown. The turbo device 1 comprises a compressor (not further shown), at least one combustion device 2 and a turbine (also not further shown), which is arranged in a machine housing 3 . The machine housing 3 is assembled from a number of machine housing parts, but this will not be discussed in more detail below.

[0041] The combustion device 2 has several annular burners 4 and opens into a stone-paved combustion chamber 5 formed by a combustion chamber sleeve 6 and a housing 7 connected to the combustion chamber sleeve 6 . Each burner 4 includes a fuel delivery pipe 8 and an air outlet 9, and the fuel delivery pipe 8 extends through the mechanical housing 3, so that the burner 4 can deliver fuel through a fuel delivery device arranged outside the mechanical housing 3, through The air supply port 9 introduces the ambient air compressed by the compressor into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com