Diesel oil/natural gas dual-fuel engine emission control strategy

A dual-fuel engine and emission control technology, applied in engine control, fuel injection control, machine/engine, etc., can solve the problem of inability to improve the trade-off relationship of combustion products in the cylinder, increase the workload of the post-processing device, etc. problems, to achieve controllable layered distribution, avoid poor cooling, and facilitate normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

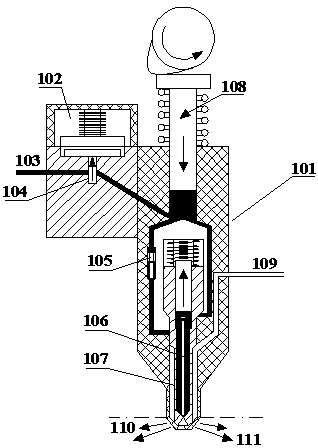

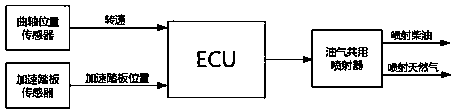

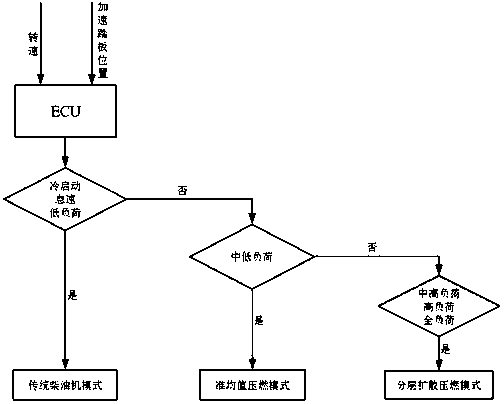

[0028] Such as Figure 1 to Figure 5 A diesel / natural gas dual-fuel engine emission control strategy is shown, and the specific control strategy is as follows:

[0029] S1: Crankshaft position sensing and load judgment: the dual-fuel ECU reads the crankshaft rotation angle and rotational speed signal sent by the crankshaft position sensor, and the position signal of the car accelerator pedal given by the accelerator pedal sensor is used to reflect the load of the engine, thereby providing The load level of the dual-fuel engine is obtained, that is, it is judged that the operating conditions of the engine are cold start, idle speed, low load, medium-low load, medium-high load, and heavy load.

[0030]S2: Control of the oil-gas common injector: The oil-gas common injector 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com