Patents

Literature

105results about How to "Avoid fire and explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

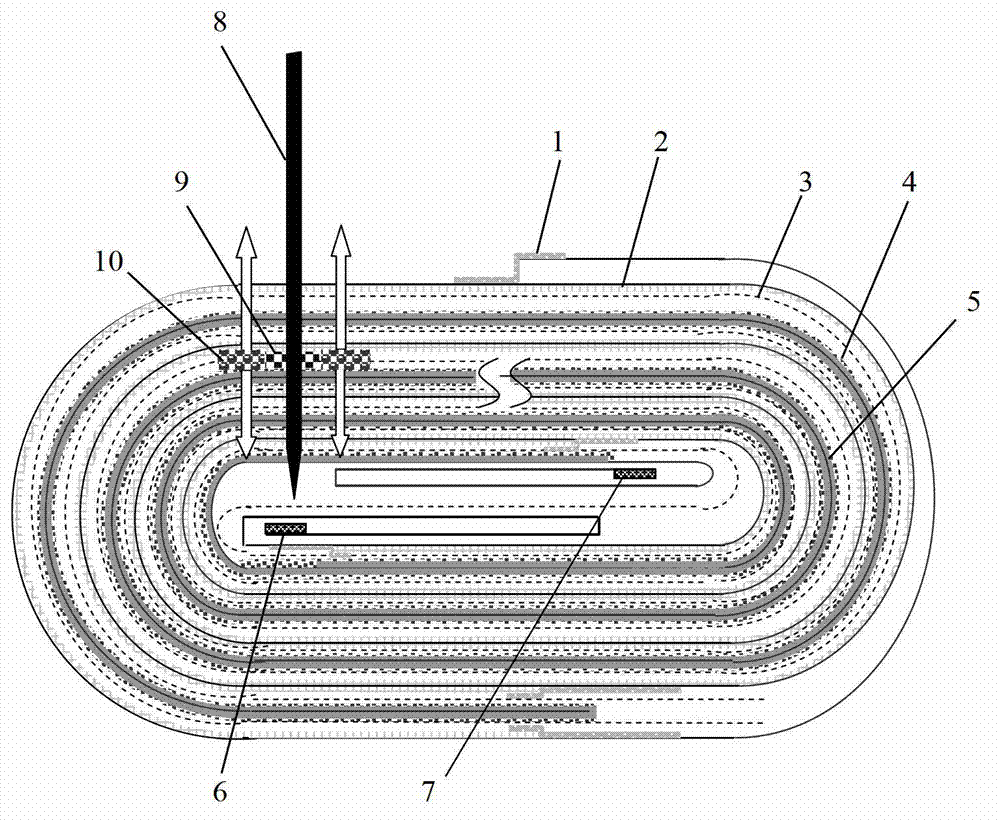

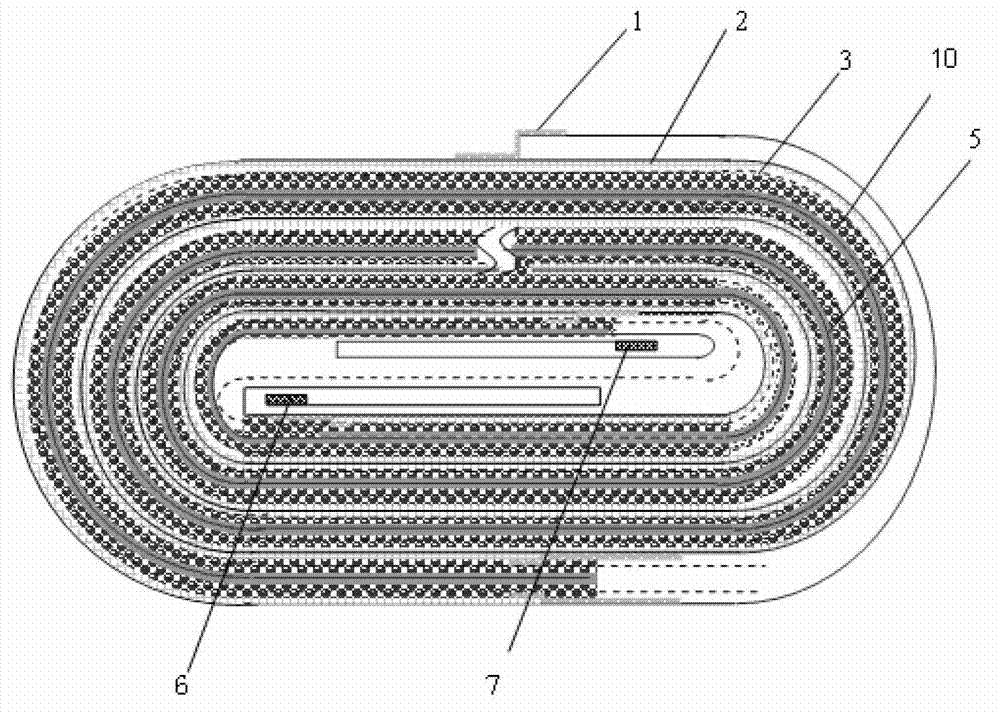

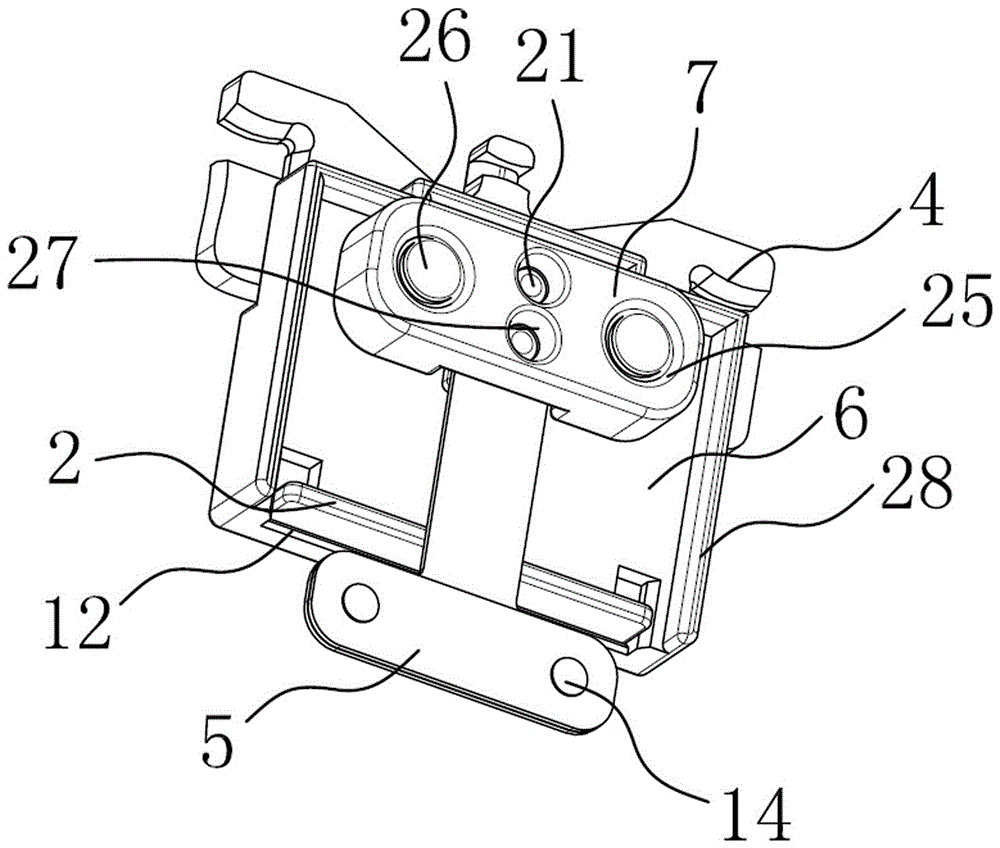

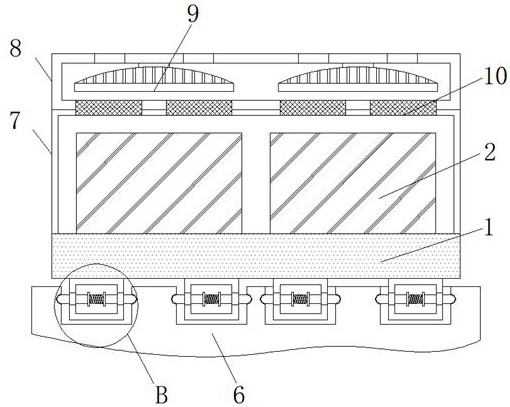

Battery pack capable of preventing thermal runaway spreading

PendingCN110660945ARapid and effective fire extinguishing and coolingAvoid fire and explosionFire rescueCell component detailsMechanical engineeringExhaust pipe

The invention discloses a battery pack capable of preventing the spread of thermal runaway. The battery box comprises a battery box body and a plurality of battery packs arranged in the battery box body, wherein each battery pack is correspondingly provided with a fire extinguishing and cooling mechanism, each fire extinguishing and cooling mechanism comprises a storage box filled with a fire extinguishing agent, an exhaust pipe connected with the storage box, a low-melting-point metal sealing plug arranged at a liquid outlet of the exhaust pipe and a heat conduction sheet arranged on the battery pack, and the heat conduction sheet is in heat conduction connection with the low-melting-point metal sealing plug. According to the battery pack capable of preventing the spread of thermal runaway, when the fire extinguishing agent is discharged from the outlet end of the exhaust pipe and sprayed on the battery pack, the battery pack is subjected to fire extinguishing and cooling quickly andeffectively, after the fire extinguishing agent in the storage box is completely discharged, the battery pack is soaked in the fire extinguishing agent, the heat of the battery pack is fully absorbedto completely eradicate further deterioration and spread of thermal runaway of the battery pack, the battery pack is prevented from being on fire and exploding, and the safety performance of an automobile is improved.

Owner:FOSHAN UNIVERSITY

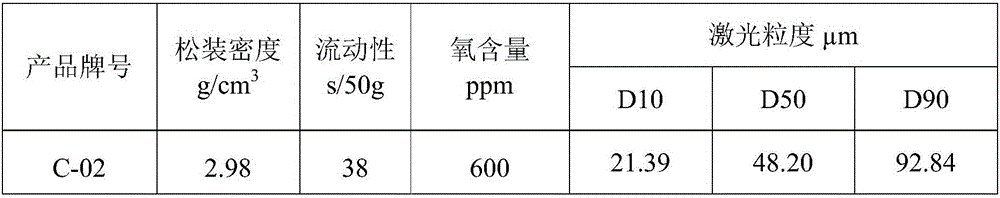

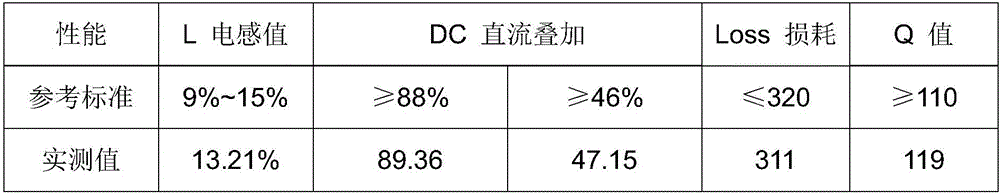

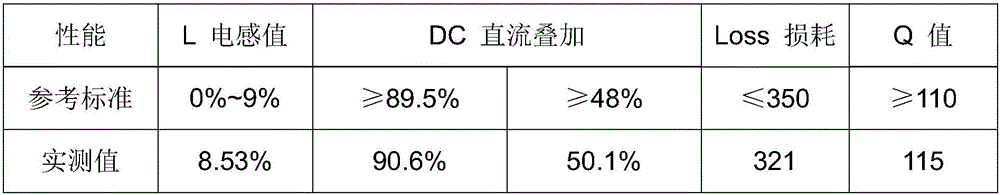

Manufacturing process for iron-silicon-aluminum alloy powder

InactiveCN105970083AVolatile fastNo safety accidentsTransportation and packagingMetal-working apparatusCooking & bakingShielding gas

The invention discloses a manufacturing process for iron-silicon-aluminum alloy powder and belongs to the technical field of metal soft magnetic materials. The manufacturing process for the iron-silicon-aluminum alloy powder includes the manufacturing steps that A, raw materials are weighed and mixed; B, a crucible is preheated; C, iron and silicon are added, aluminum is added after the iron and the silicon are completely molten, silicon-calcium alloy is added after the aluminum is molten, and the mixture is cooled into an iron-silicon-aluminum alloy block after boiling; D, the alloy block is crushed into alloy materials of 0.1-0.8 cm<2>; E, the alloy materials are subjected to ring milling, so that powder smaller than 60 meshes is obtained; F, ethyl alcohol is added, wet milling is conducted for 1-30 h, and then solid powder is obtained; G, open-area baking is conducted for 1-2 h at the temperature of 30-80 DEG C, and then screening is conducted; and H, the screened powder is placed in an annealing furnace with protective gas to be subjected to annealing heat treatment for 1-2.5 h at the temperature of 850-890 DEG C. By manufacturing the iron-silicon-aluminum alloy powder according to the above steps, burning loss of the aluminum can be reduced, the production cost is reduced, and an oven is prevented from catching a fire and exploding.

Owner:古前春

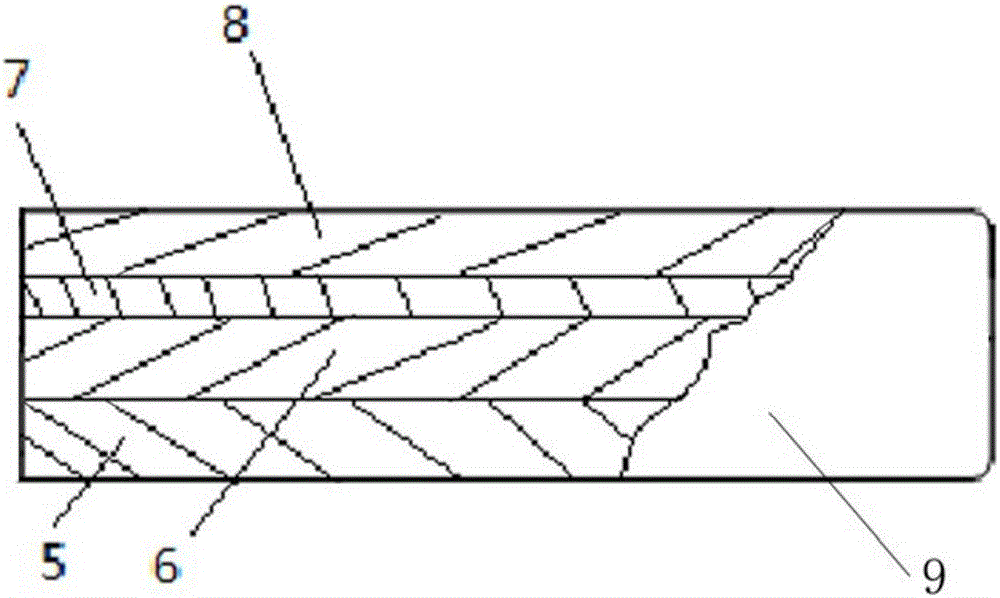

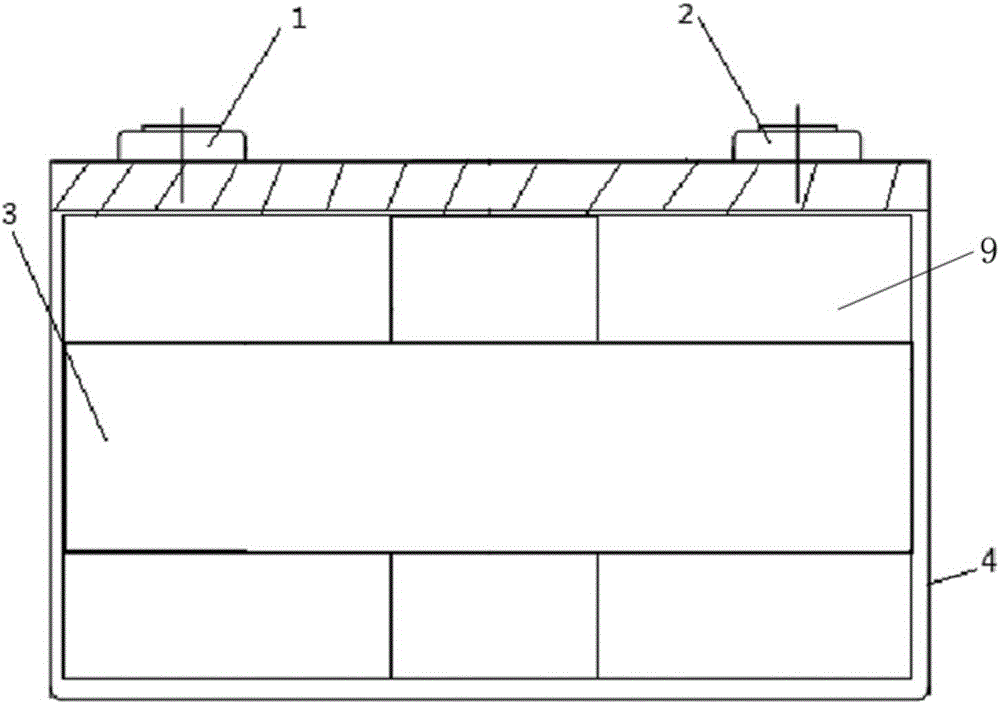

Manufacturing process for non-diaphragm lithium ion cell, and battery

InactiveCN106505255AHigh mechanical strengthAvoid punctureAssembling battery machinesFinal product manufactureLithiumSlurry

The invention provides a manufacturing process for a non-diaphragm lithium ion cell. The manufacturing process comprises the steps of coating the surface of a positive plate and / or negative plate with ceramic powder slurry; and then assembling the positive plate and the negative plate into a cell. According to the manufacturing process, the surface of the positive plate or negative plate is coated with the ceramic powder slurry; and then the positive plate and the negative plate are assembled, so that the existing diaphragm is omitted, the mechanical strength in assembling the positive plate and the negative plate is improved, the phenomenon of battery expansion and explosion caused by puncture in use of the common diaphragm is avoided, and a short-circuit phenomenon is effectively prevented; and furthermore, the non-diaphragm lithium ion cell has microporous omni-directional property, so that the requirements of electronic insulation and ionic conduction characteristic between the positive plate and the negative plate are satisfied. The invention also designs a battery applying the process.

Owner:YINLONG ENERGY CO LTD

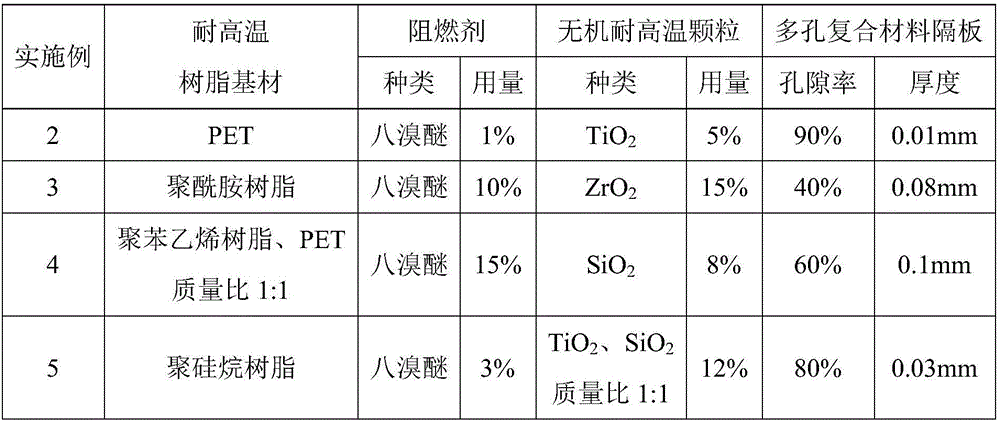

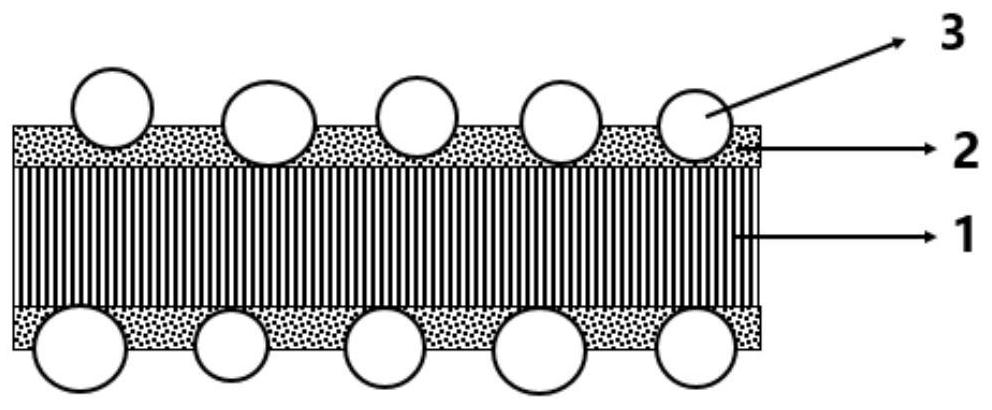

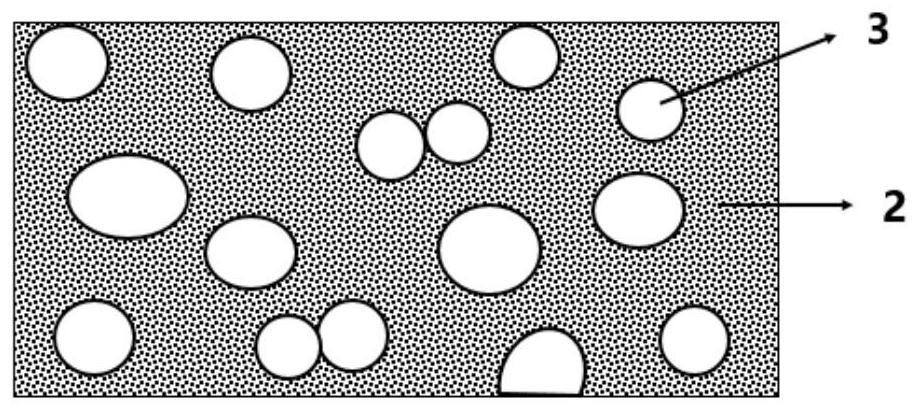

Porous composite material partition and preparation method thereof, composite-structure cell and lithium ion battery

ActiveCN106450105AGuaranteed performanceEasy to useCell seperators/membranes/diaphragms/spacersSecondary cellsPolyethylene terephthalate glycolPolystyrene

The invention discloses a porous composite material partition and a preparation method thereof, a composite-structure cell and a lithium ion battery. The partition comprises a high-temperature-resistant resin substrate, a flame retardant and inorganic high-temperature-resistant particles, wherein the high-temperature-resistant resin substrate is composed of any one or more of a polyamide resin, a polyethylene terephthalate resin, a polyamide resin, a polystyrene resin and a polysilane resin; the flame retardant accounts for 1-15 wt% of the high-temperature-resistant resin substrate; the inorganic high-temperature-resistant particles are at least one of Al2O3, TiO2, ZrO2 and SiO2; and the inorganic high-temperature-resistant particles account for 5-15 wt% of the high-temperature-resistant resin substrate. The porous composite material partition can resist the high temperature of more than 200 DEG C, and has the advantages of flame retardancy, high temperature resistance, corrosion resistance and impact resistance. The porous composite material partition is independently formed, does not need to be applied to a pole piece or diaphragm, can not influence the pole piece or diaphragm in the forming process, and ensures the self performance and service performance of the pole piece and diaphragm.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

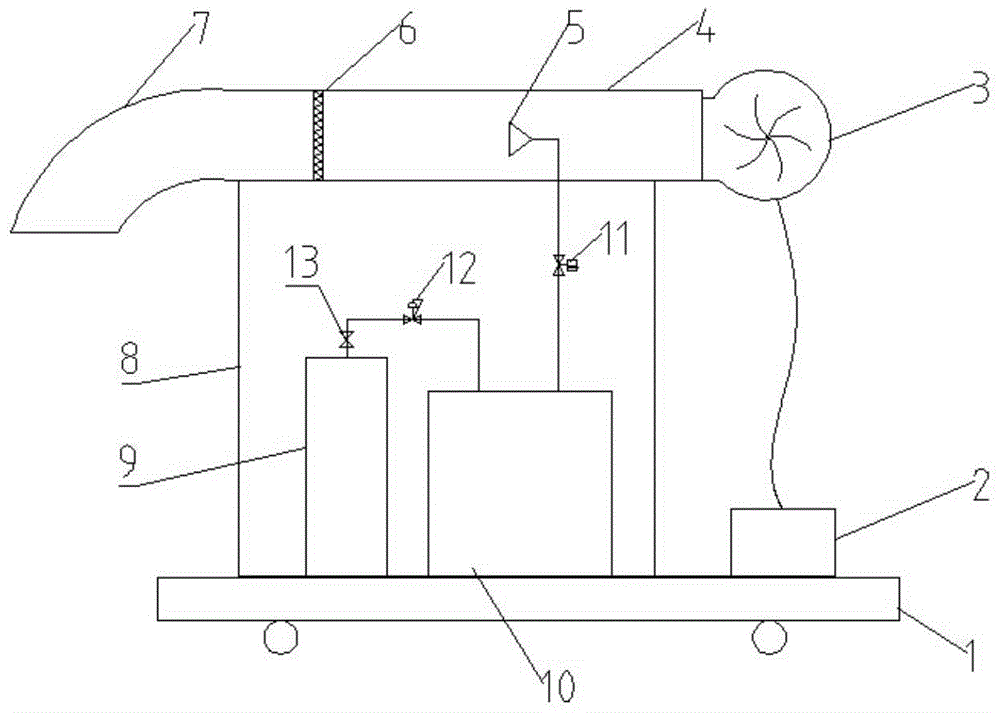

Skid-mounted LNG leakage diffusion restrain and emergency device for LNG stations

InactiveCN104989956AInhibition of evaporative diffusionReduce evaporation ratePipeline systemsNitrogenSafety engineering

The invention discloses a skid-mounted LNG leakage diffusion restrain and emergency device for LNG stations, and belongs to the technical field of safety engineering of liquefied natural gas. The skid-mounted LNG leakage diffusion restrain and emergency device comprises a movable skid-mounted pedestal, the movable skid-mounted pedestal is provided with a foam mixed liquor barrel and a nitrogen steel cylinder, the nitrogen steel cylinder and the foam mixed liquor barrel are connected through a nitrogen delivery pipe. A high-multiple foam generator is disposed over the foam mixed liquor barrel, the foam mixed liquor barrel is connected with the high-multiple foam generator through a foam mixed liquor delivery pipe, an explosion-proof blower is mounted to the rear end of the high-multiple foam generator, the explosion-proof blower is connected with a mobile power supply, and the mobile power supply is disposed on the movable skid-mounted pedestal. The skid-mounted LNG leakage diffusion restrain and emergency device for LNG stations can be applied to places such as an LNG station, an LNG receiving station, a liquefaction factory, an LNG peak-shaving station and a liquefied petroleum gas station. The skid-mounted LNG leakage diffusion restrain and emergency device can be immediately used if large-area leakage occurs in an LNG station, high-multiple foam is generated to restrain the steam cloud in an LNG liquid pool of evaporation and diffusion, the evaporation rate can be reduced, and the severe secondary disaster can be prevented.

Owner:CHINA PETROLEUM & CHEM CORP +1

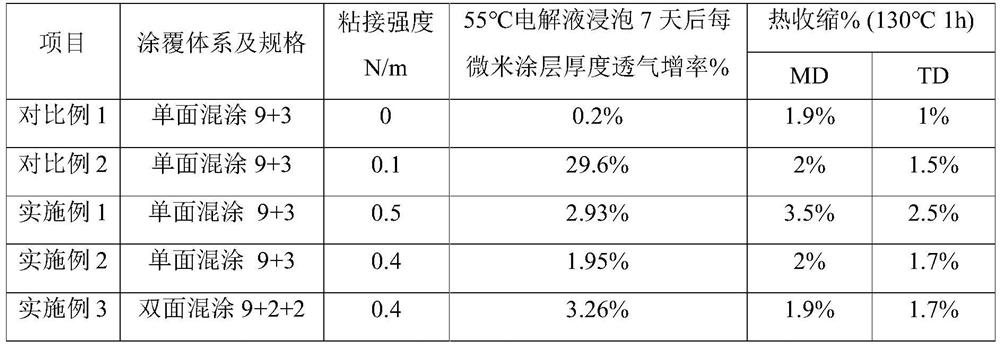

Lithium ion battery diaphragm with high heat resistance and high adhesion and preparation method thereof

PendingCN113972441AGood adhesionImprove securityCell seperators/membranes/diaphragms/spacersPolyolefinLithium-ion battery

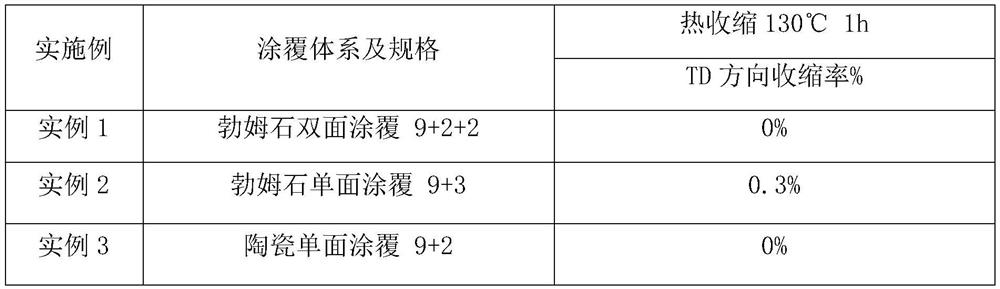

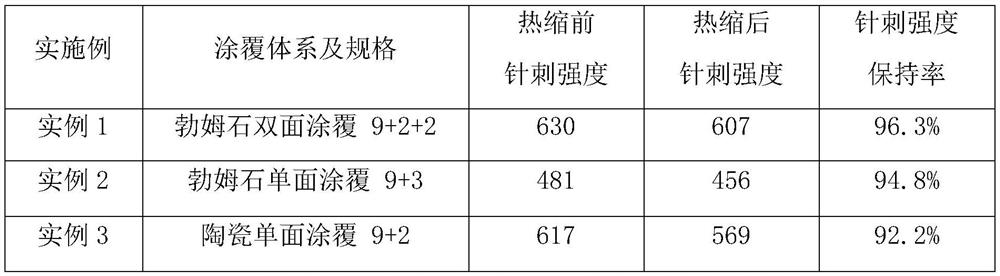

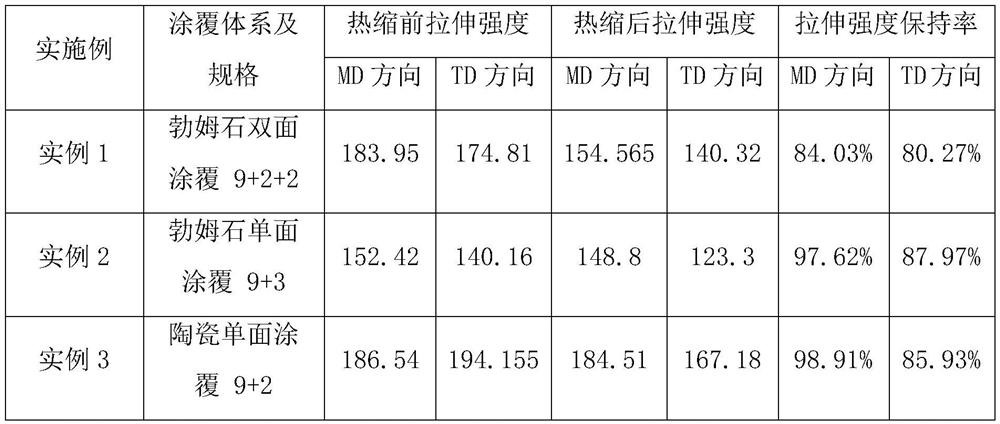

The invention discloses a lithium ion battery diaphragm with high heat resistance and high adhesion and a preparation method of the lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a polyolefin porous base material and a porous composite coating coated on one side surface or two side surfaces of the base material, wherein the thickness of the porous composite coating accounts for greater than 20% of the total thickness of the diaphragm, the bonding strength is greater than or equal to 0.3 N / m, after the diaphragm is soaked in electrolyte at 55 DEG C for 7 days, the permeability increase rate of the coating thickness per micron is less than or equal to 5%, and the thermal shrinkage at 130 DEG C is less than or equal to 4% after 1h. The surface of at least one side of the polyolefin porous base material is coated with the porous composite layer, so the heat resistance and the adhesion of the diaphragm are improved, the flatness and the safety of the lithium ion battery are effectively improved, and the problems of fire and explosion caused by thermal shock, deformation and lithium precipitation in the later period of circulation and the like are prevented; meanwhile, through material screening and formula design, the surface of the polyolefin base material is coated with the inorganic filler and the high-molecular polymer at a time, the production cost is greatly reduced, the obtained diaphragm has heat resistance and adhesion, and the heat resistance is remarkably improved.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

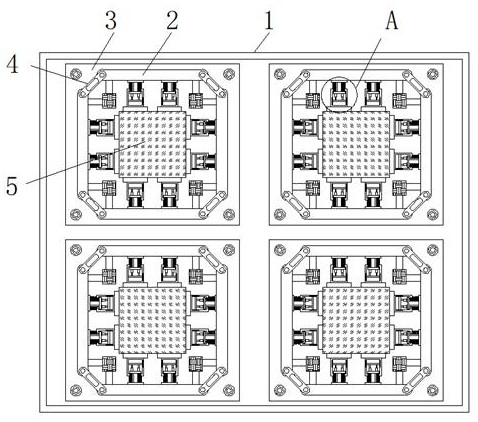

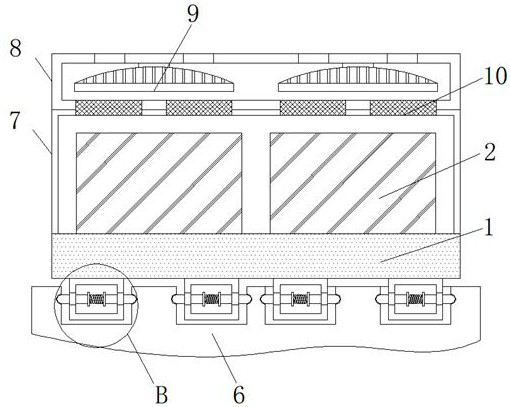

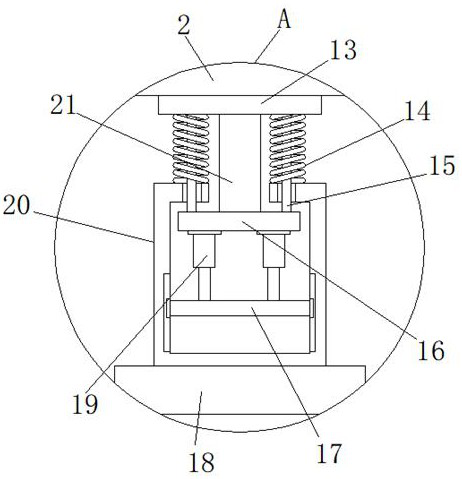

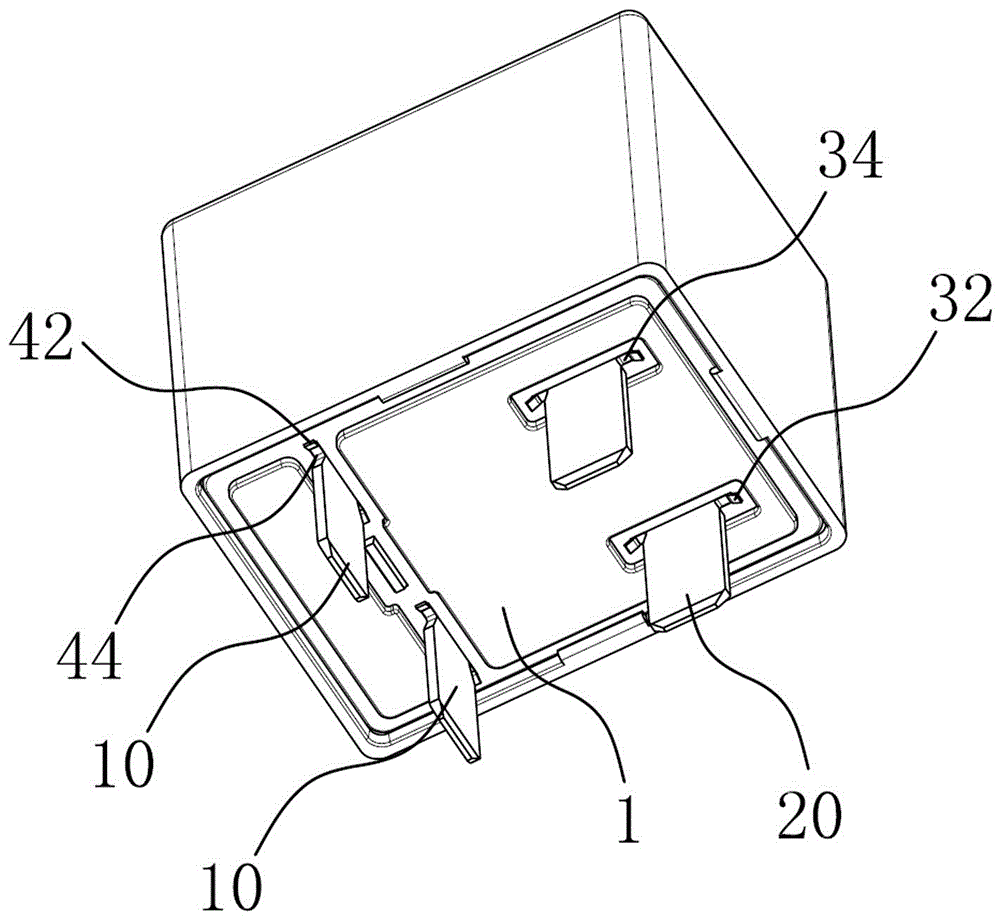

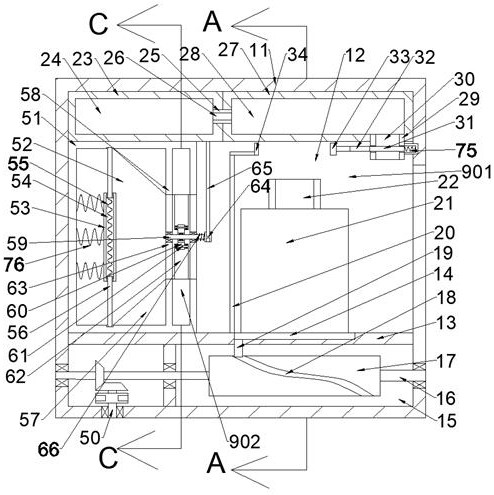

Explosion-proof and flame-retardant device for new energy automobile battery

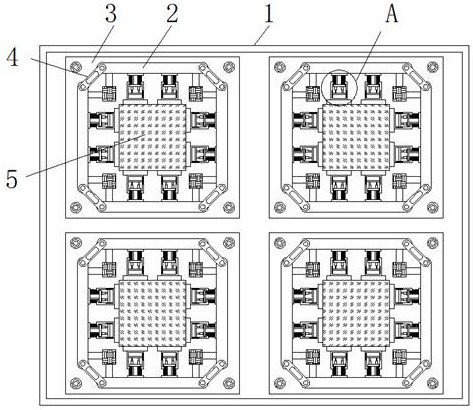

ActiveCN113241496AIt has the effect of explosion-proof and flame-retardantAvoid fire and explosionSecondary cellsFire rescuePost collisionAutomotive battery

The invention discloses an explosion-proof and flame-retardant device for a new energy automobile battery, which relates to the technical field of new energy automobile battery packs, and provides the following scheme aiming at the problems that the battery packs are easy to explode and burn after being collided: the explosion-proof and flame-retardant device comprises a mounting frame and a chassis, and four groups of mounting seats are fixedly mounted at the top of the mounting frame through bolts; a battery is placed at the top of each mounting seat, eight connecting blocks are welded to the periphery of each battery, third boxes are welded to the sides, away from the batteries, of the eight connecting blocks, movable plates are slidably connected to the inner walls of the third boxes, and two hydraulic rods are welded to the sides, away from the batteries, of the movable plates. The explosion-proof and flame-retardant device has the explosion-proof and flame-retardant effects on the battery pack, prevents the battery pack from being easily exploded and fired after strenuous vibration and collision, effectively dampens and fixes the battery pack, simplifies the battery replacement operation of the battery pack, and is high in practicability and suitable for wide popularization.

Owner:SHENZHEN JINZUN ENERGY TECH CO LTD

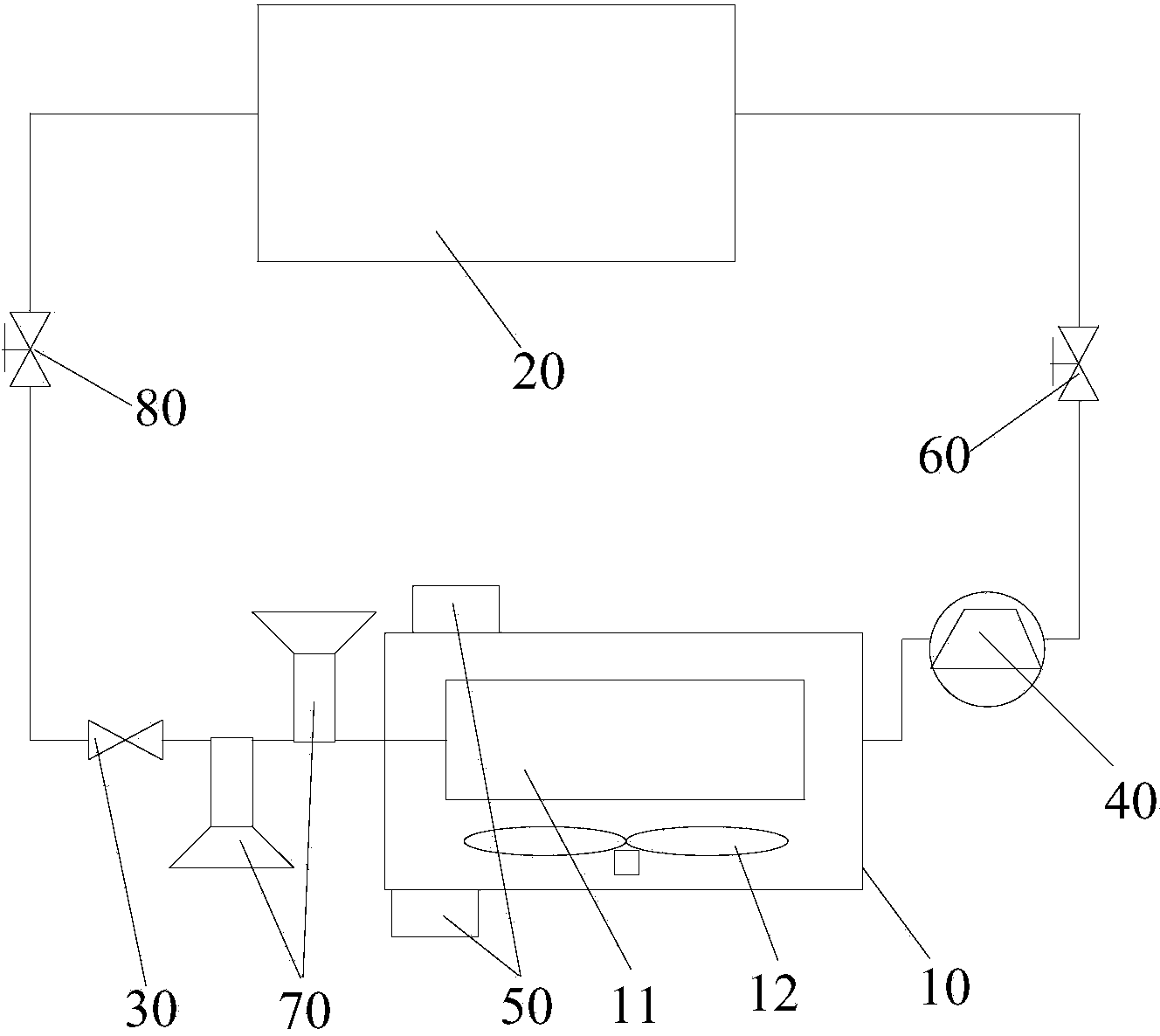

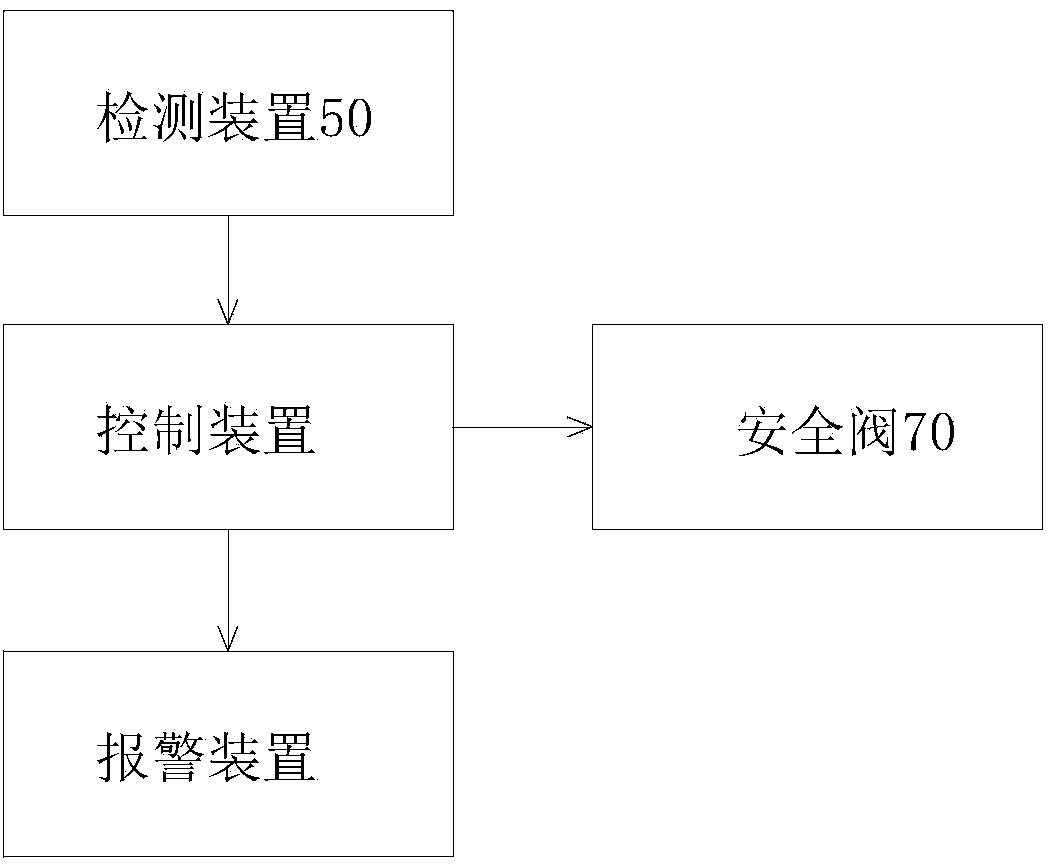

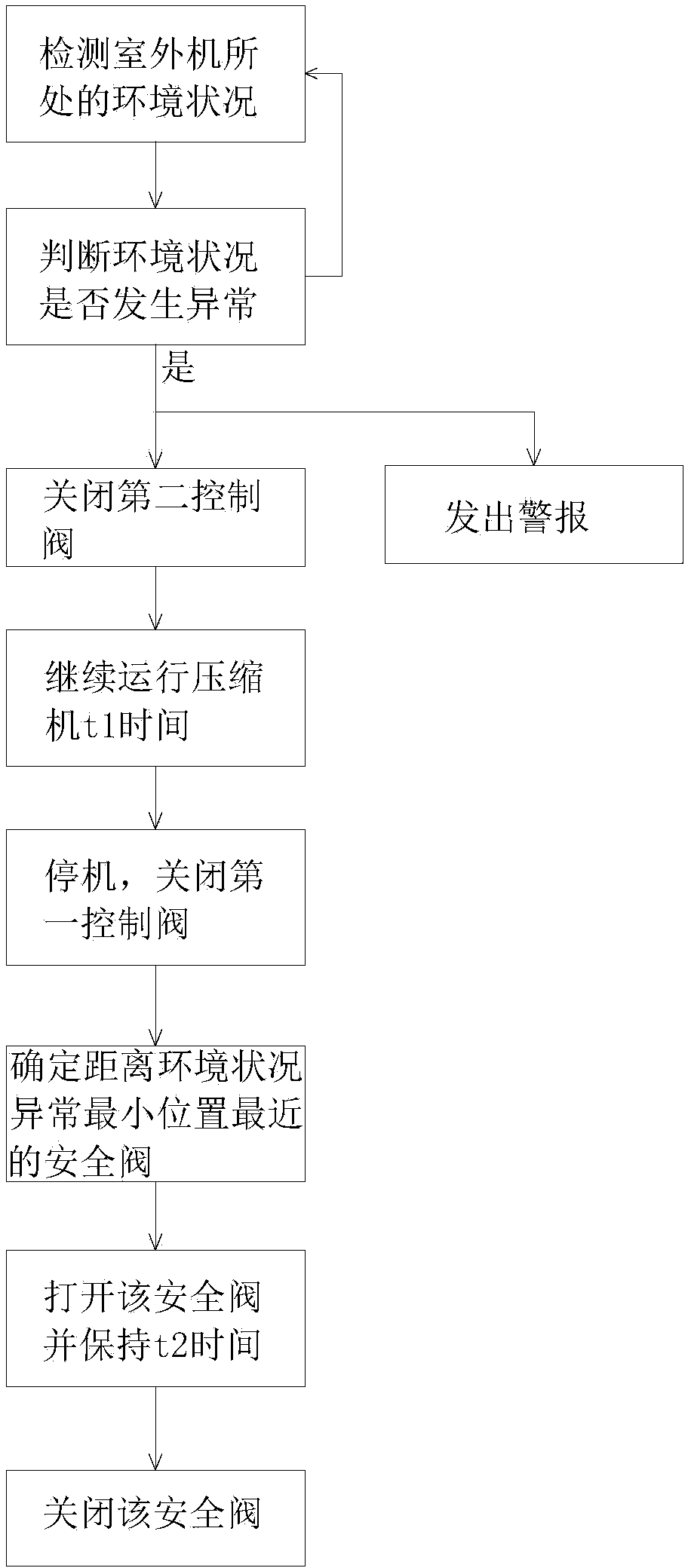

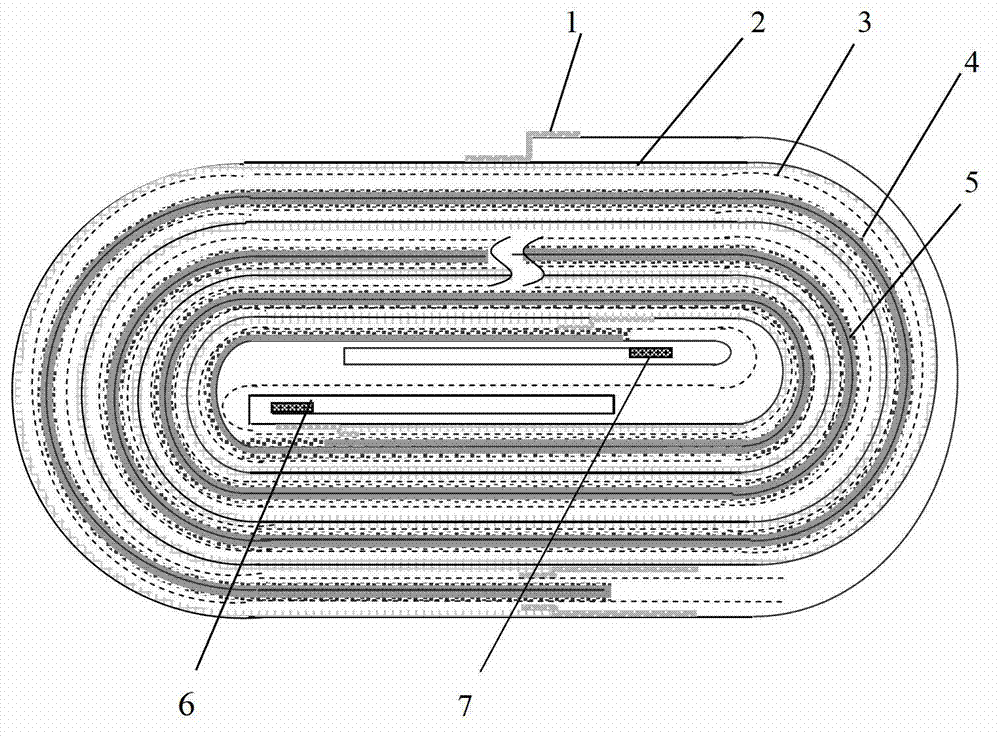

Flammable refrigerant air-conditioner fire protection system and application method thereof as well as air-conditioner

ActiveCN104075420AImprove securityTimely processingSpace heating and ventilation safety systemsLighting and heating apparatusFire protectionEngineering

The invention discloses a flammable refrigerant air-conditioner fire protection system and an application method thereof as well as an air-conditioner. The flammable refrigerant air-conditioner fire protection system comprises a detection device (50) for detecting the environmental conditions of an outdoor unit (10) of the air-conditioner, and a control device which is connected to the detection device (50) and used for determining whether the environmental conditions are abnormal according to the environmental conditions detected by the detection device (50), and enabling a protection action when the environmental conditions are abnormal. The flammable refrigerant air-conditioner fire protection system is capable of effectively preventing fire of the outdoor unit of the air-conditioner from spreading to the indoor unit of the air-conditioner, preventing that the indoor unit of the air-conditioner is on fire and even exploded due to the fire of the outdoor unit, and improving the safety of the air-conditioner in use.

Owner:GREE ELECTRIC APPLIANCES INC

Lithium ion secondary battery and negative pole piece thereof

ActiveCN103199259AAvoid fire and explosionSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryPole piece

The invention provides a lithium ion secondary battery and a negative pole piece thereof. The negative pole piece of the lithium ion secondary battery comprises a negative pole current collector, a negative pole active material layer and a gas generating coating, wherein the negative pole active material layer is formed on the negative pole current collector; and the gas generating coating is formed on the negative pole active material layer. The lithium ion secondary battery comprises a positive pole piece, the negative pole piece, an isolating membrane and electrolyte, wherein the isolating membrane is arranged between the positive pole piece and the negative pole piece which are adjacent to each other. When the lithium ion secondary battery is in improper use, such as acupuncture (comprising burr piercing) and extrusion, gas generated by the gas generating coating can isolate the positive pole piece from the negative pole piece well, so that fire and even explosion caused by internal short circuit of the lithium ion secondary battery are effectively avoided; and when the lithium ion secondary battery is overcharged, the gas generated by the gas generating coating can isolate the positive pole piece from the negative pole piece well and can isolate a lithium ion conveying channel in the lithium ion battery, so that fire and even explosion caused by the lithium ion secondary battery are effectively avoided.

Owner:NINGDE AMPEREX TECH

Crushing and screening device for materials

InactiveCN105521863AGuaranteed high speed operationSmooth speed regulationSievingScreeningFrequency conversionElectric machinery

The invention discloses a crushing and screening device for materials. The crushing and screening device is characterized by comprising a charge device, a crushing device and a screening device, wherein the charge device is communicated with a shell; the crushing device is arranged in the shell, and provided with a filter screen at the periphery; and the screening device is located below the crushing device. Preferably, the materials are alloy sheets; the charge device comprises a charge nozzle and a loop from the filter screen to the charge nozzle; an inert gas inlet is arranged in the top of the charge nozzle and the bottom of a stainless steel elbow pipe respectively; the crushing device is provided with a drive motor; the screening device is provided with a vibration motor; the drive motor is a special frequency conversion motor; and the special frequency conversion motor is controlled by a frequency converter. The crushing and screening device disclosed by the invention is simple in structure, simple and convenient to operate overall, stable and reliable in running, low in noise, less in raising dust, good in field environment, and capable of effectively preventing frictional sparking generated by ultrafine powder grains with a pipe wall during a high-speed rotation process, thus safety performance is greatly improved.

Owner:江西江钨稀有金属新材料股份有限公司

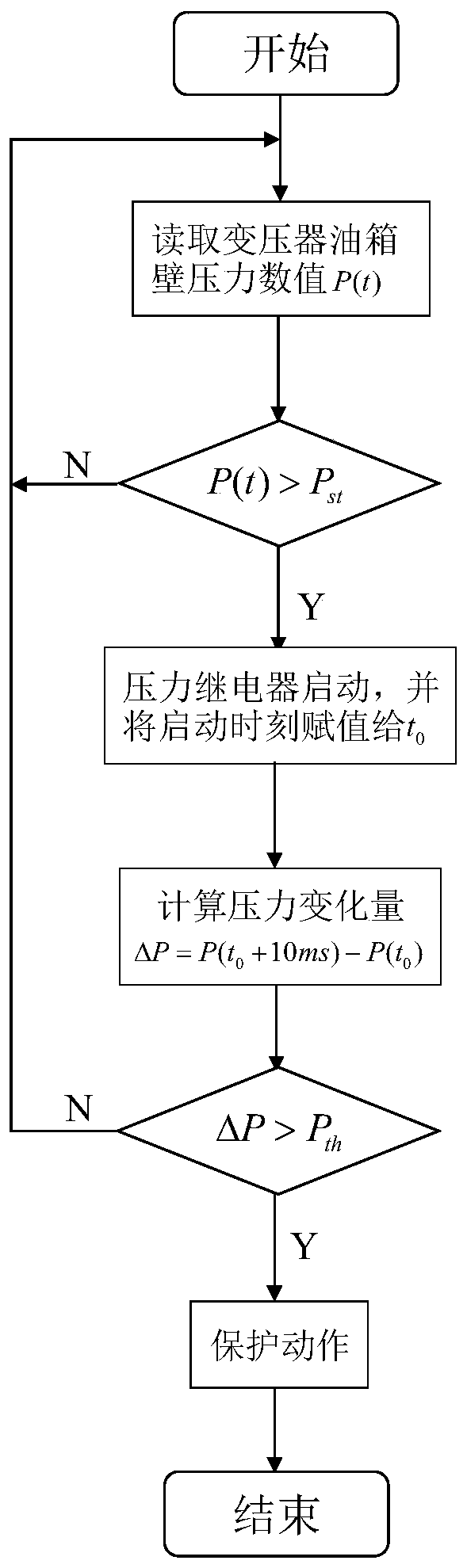

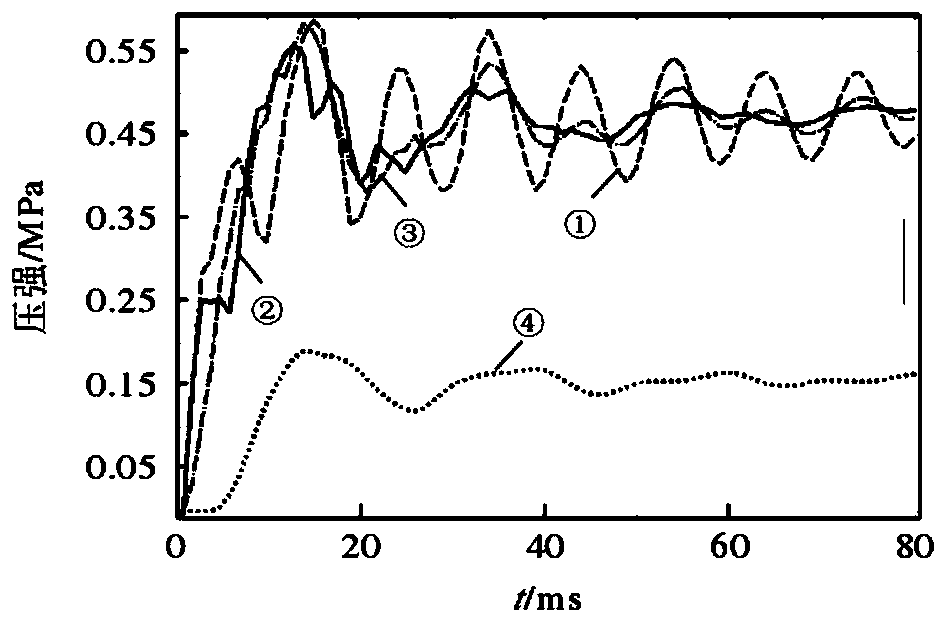

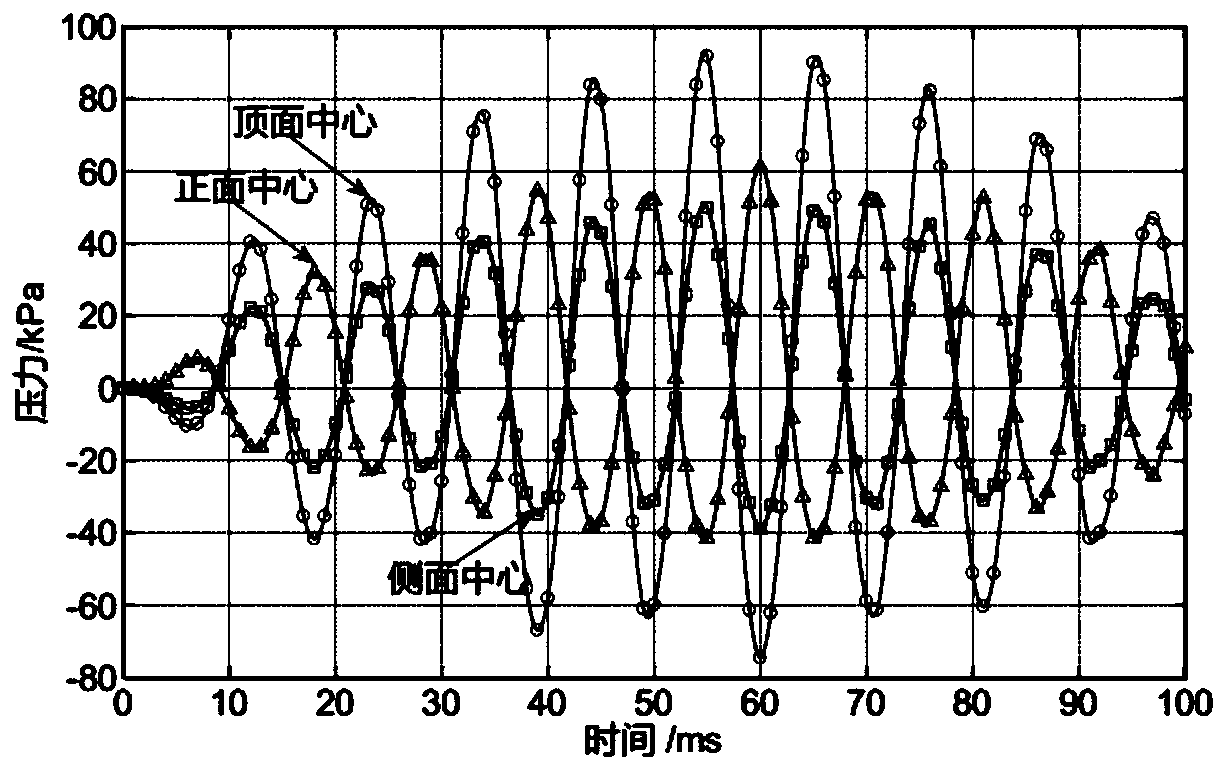

Oil-immersed transformer digital non-electric quantity protection method based on pressure change quantity

InactiveCN109904841AAvoid fire and explosionEmergency protective circuit arrangementsElectricityTransformer

The invention discloses an oil-immersed transformer digital non-electric quantity protection method based on pressure change quantity; the method comprises the following steps that a relay starting threshold value Pst and a protection action threshold value Pth of a protected oil-immersed transformer are set before electrification; next, a signal acquisition device collects the pressure waveform on the wall of an oil tank in real time through a pressure sensor to obtain a pressure instantaneous value P(t) at a measuring point, and whether a pressure relay is started or not is judged by makingcomparison between the pressure instantaneous value P(t) and the relay starting threshold value Pst; if the pressure relay is started, the pressure waveform of data window length when T is equal to 10ms is intercepted from the start moment, and the pressure change quantity delta P is calculated; and finally, by making comparison between the pressure change quantity delta P and the protection action threshold value Pth, the internal state of the oil-immersed transformer is accurately identified. By adoption of the method, the internal faults and external disturbance of the oil-immersed transformer can be accurately distinguished, and misoperation or rejection of the pressure protection device is effectively avoided.

Owner:XI AN JIAOTONG UNIV

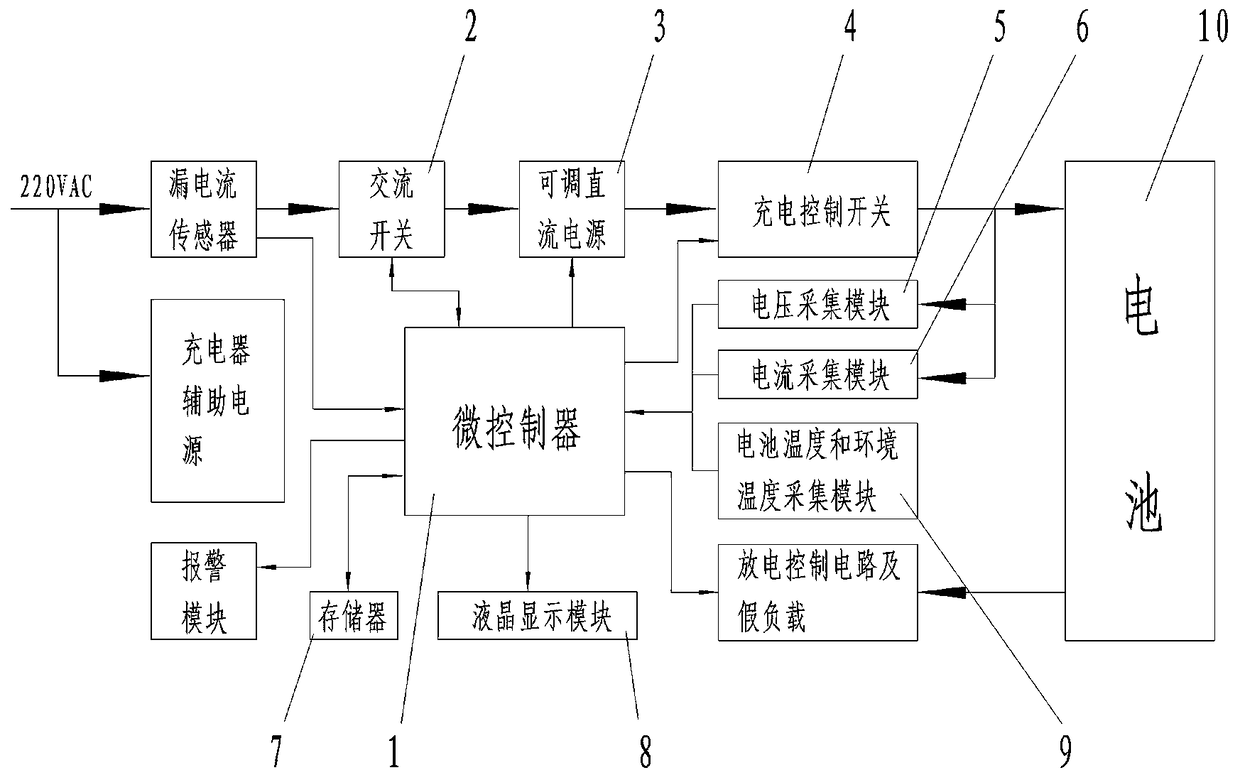

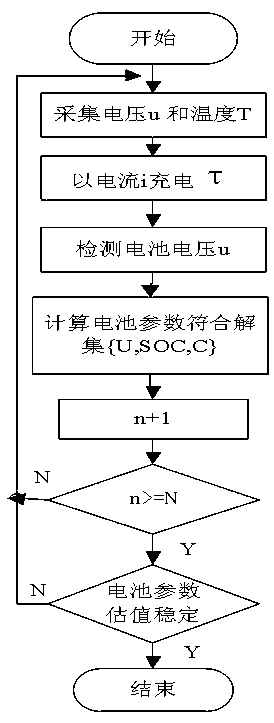

Fireproof and explosion-proof intelligent charger and charging method

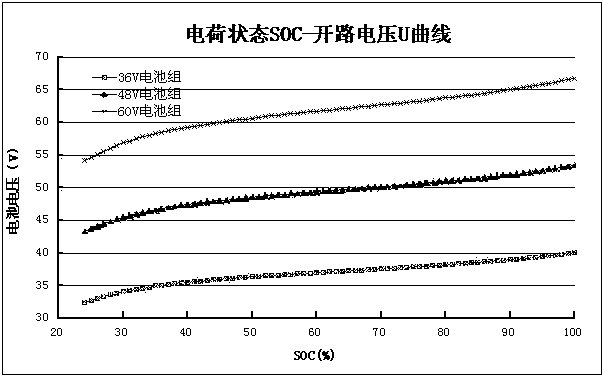

ActiveCN108988450APrevent fire and other safety hazardsAvoid fire and explosionElectric powerBattery overcharge protectionOvervoltageMicrocontroller

The invention discloses an electric bicycle intelligent charger, belonging to the technical field of the electric bicycle, comprising a microcontroller, an alternating current switch connected with the microcontroller, an adjustable direct current power supply, a charging control switch, a voltage acquisition module, a current acquisition module, a memory and a display module. In addition, the invention also provides a charging method of an electric bicycle battery based on the charger. The invention has the advantages that: 1, different types of batteries can be matched, charging parameters can be automatically adjusted, and the problem that the electric bicycle charger is not universal is solved; 2, leakage current protection is provided to ensure the personal safety of users. Protect against overcharge, overvoltage, overcurrent and overheat. Automatic power off when battery is full. So that that battery char process is safe. It has the function of charging voltage and temperature compensation, which ensures that the battery is not under-charged and has less water loss and prolongs the battery life.

Owner:SHIJIAZHUANG KE ELECTRIC

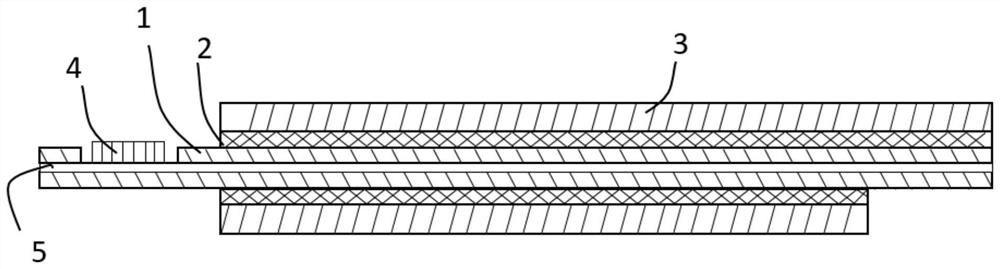

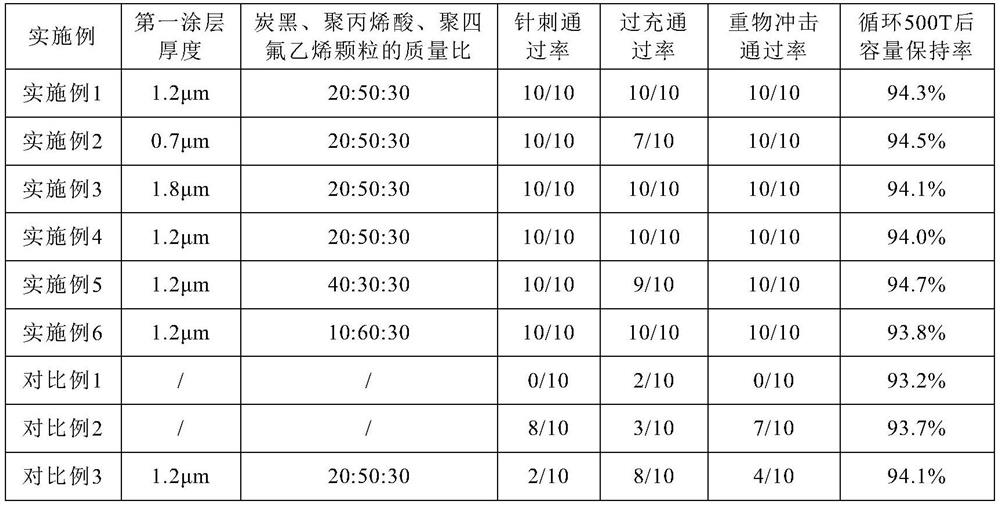

Electrode sheet and electrochemical device

ActiveCN114122320APrevent peeling and other phenomenaGuaranteed bonding performanceElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesPhysical chemistryElectrochemistry

The invention provides an electrode plate and an electrochemical device, the electrode plate comprises a current collector and a functional coating located on at least one surface of the current collector, and the functional coating comprises a first coating, a second coating and an active material layer which are sequentially stacked on the surface of the current collector; the first coating comprises a conductive agent, a binder and a first functional filler; the second coating comprises a conductive agent, a binder and a second functional filler; the mass ratio of the binder in the first coating to the first coating is a1, the mass ratio of the binder in the second coating to the second coating is a2, the mass ratio of the binder in the active substance layer to the active substance layer is a3, and a1 > a2 > a3. According to the invention, the safety, cyclicity and other performances of the electrochemical device can be improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

On-line Repair Method of Corrugated Compensator in Gas Pipeline

InactiveCN102261538AEnsure safetyPlay the role of stretch compensationPipe elementsGas pipelineCoke oven gas

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

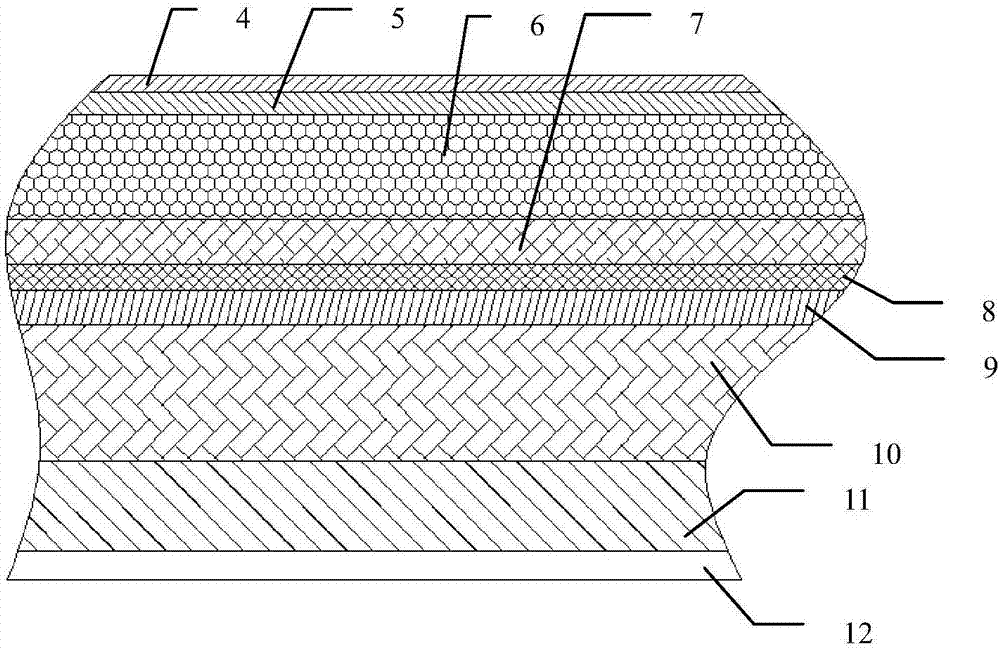

Anti-leakage bulletproof oil tank

ActiveCN107472007ALight in massPrevent cracking and oil leakageUnderstructuresArmour platesFiberSuction tubing

The invention provides an anti-leakage bulletproof oil tank comprising an oil tank body and an oil sucking pipe mechanism. The oil tank body comprises an anti-corrosion coating, a forming metal layer, a first foam metal buffer layer, a rubber layer, a first fireproof layer, an inner steel sheet layer, a second foam metal buffer layer, a fiber fabric bulletproof layer and an outer steel sheet layer which are arranged in sequence from inside to outside. The oil sucking pipe mechanism comprises an oil sucking pipe and a sealing cover body protruding out of the outer surface of the oil tank body, an opened metal cylinder extending into the oil tank body is arranged inside the sealing cover body, and the outer side of the sealing cover body is provided with a heat dissipation mechanism. The anti-leakage bulletproof oil tank is good in bulletproof performance, the lightweight requirements of vehicles are met, oil and gas leakage and oil tank explosion can be effectively prevented, and the reliability is greatly improved.

Owner:BEIJING PT PROTECTION TECH

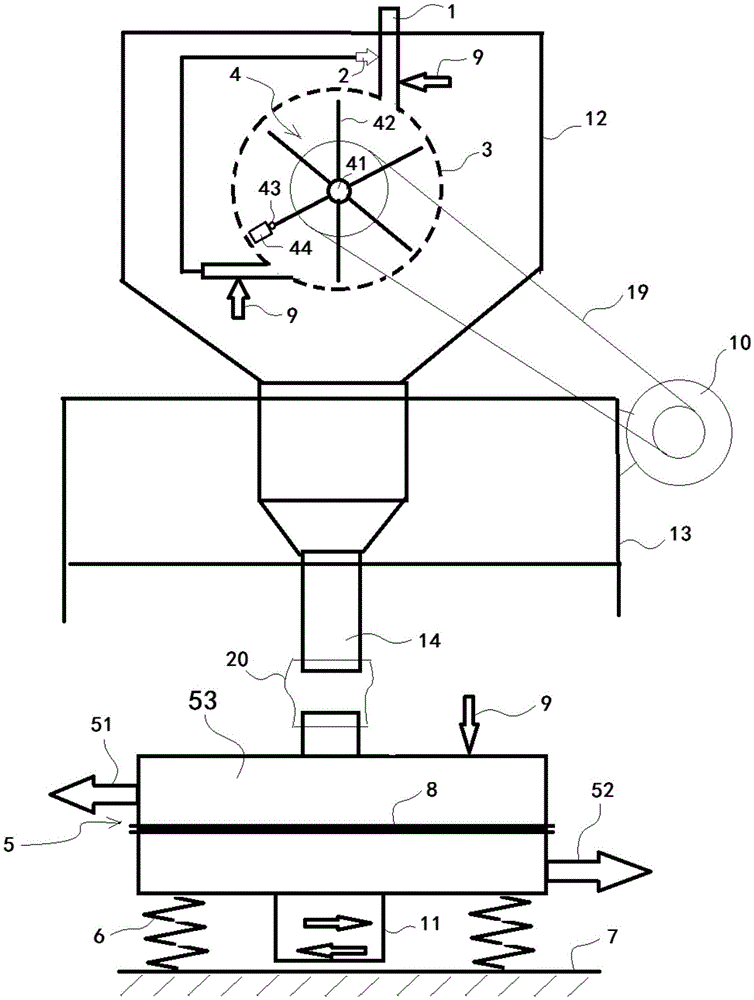

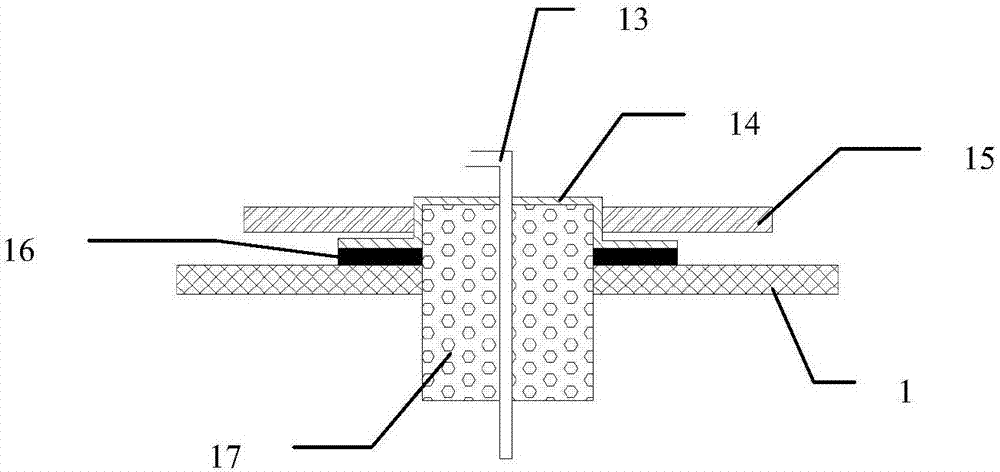

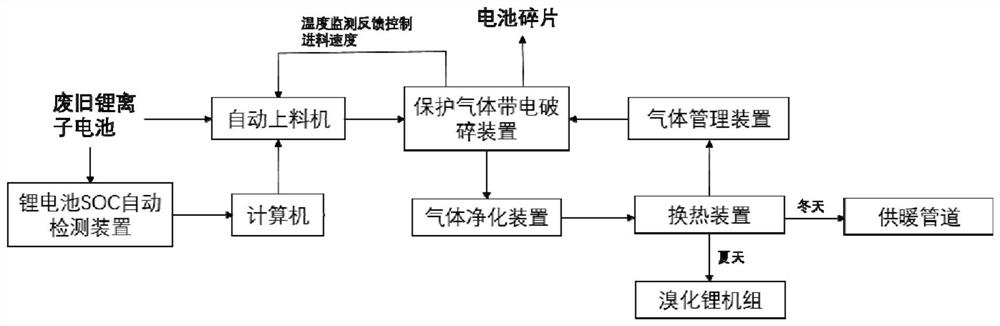

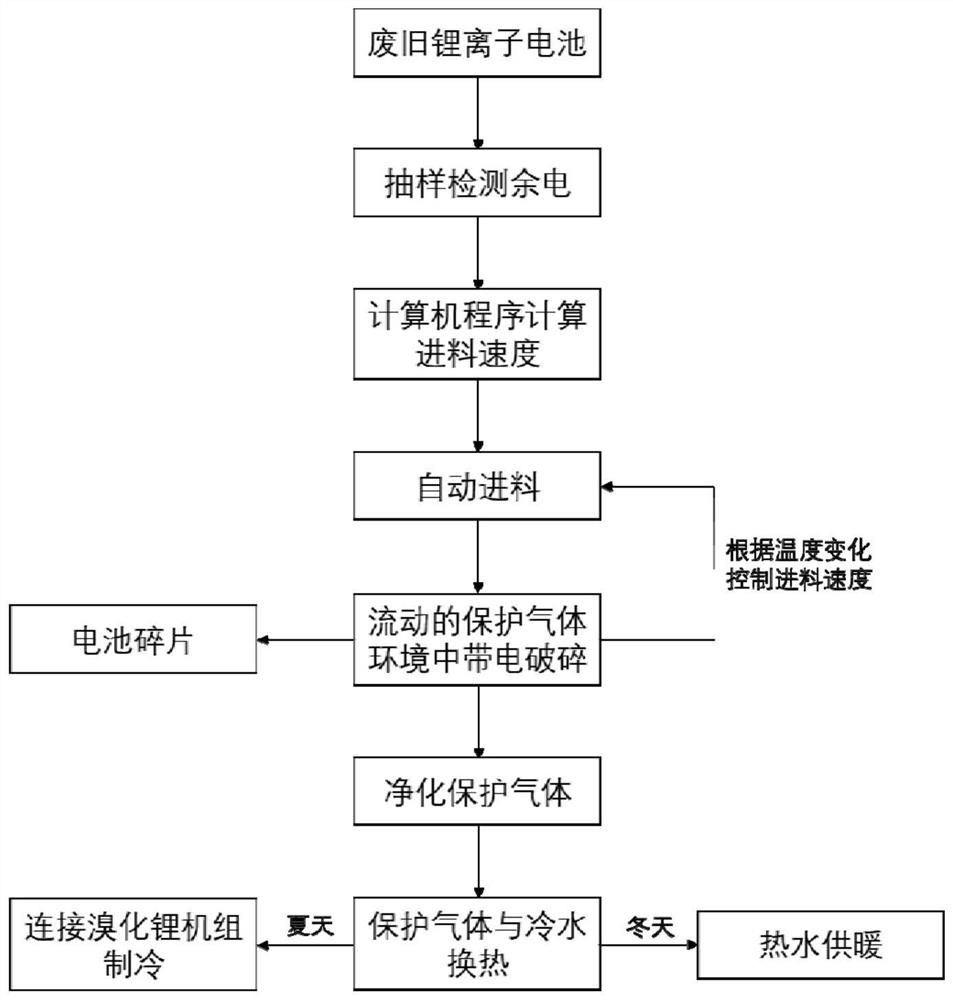

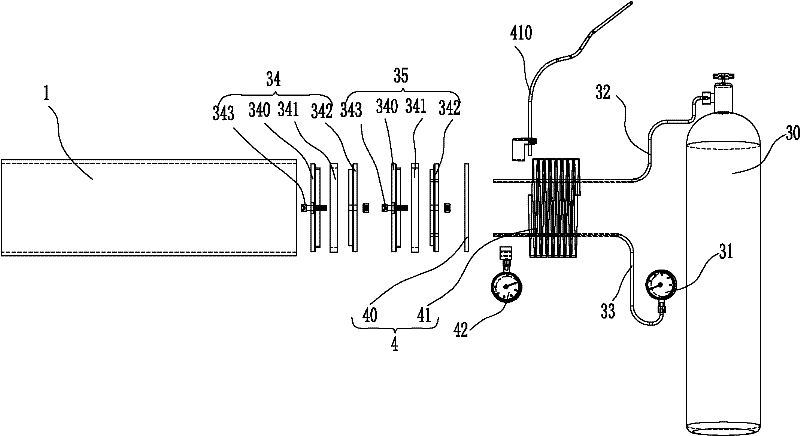

Waste lithium ion battery charged crushing and waste heat recovery integrated system and method

PendingCN113471565AReduce oxygen contentEasy to recycleElectrical testingWaste accumulators reclaimingElectrical batteryLithium-ion battery

The invention discloses a waste lithium ion battery charged crushing and waste heat recovery integrated system and method. The system comprises an automatic feeding machine, a lithium battery SOC automatic detection device, a computer, a protection gas charged crushing device, a gas management device, a gas purification device and a heat exchange device. The method comprises the following steps: putting a waste lithium ion battery into a crushing device in a low-oxygen environment, and carrying out electrified crushing in a protection gas atmosphere; and feeding purified protection gas into a heat exchange device to generate hot water used as a heat source. According to the invention, the waste battery treatment process simplifies the battery recovery process, and avoids the problems that a conventional discharging method is long in time consumption and causes pollution; the waste batteries are placed in the high-flow protection gas to be directly broken and disassembled, so that the oxygen content is reduced while heat released in the disassembling process is taken away so as to avoid the risk of fire and explosion in the crushing process; and the collected energy is effectively utilized, so that the effects of energy conservation and emission reduction are achieved.

Owner:XI AN JIAOTONG UNIV

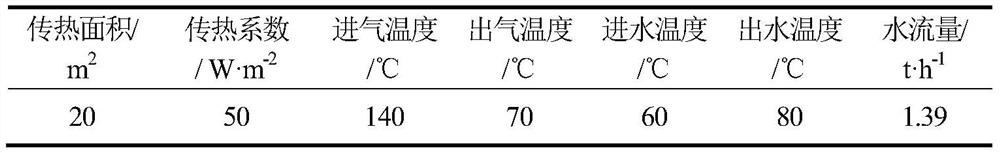

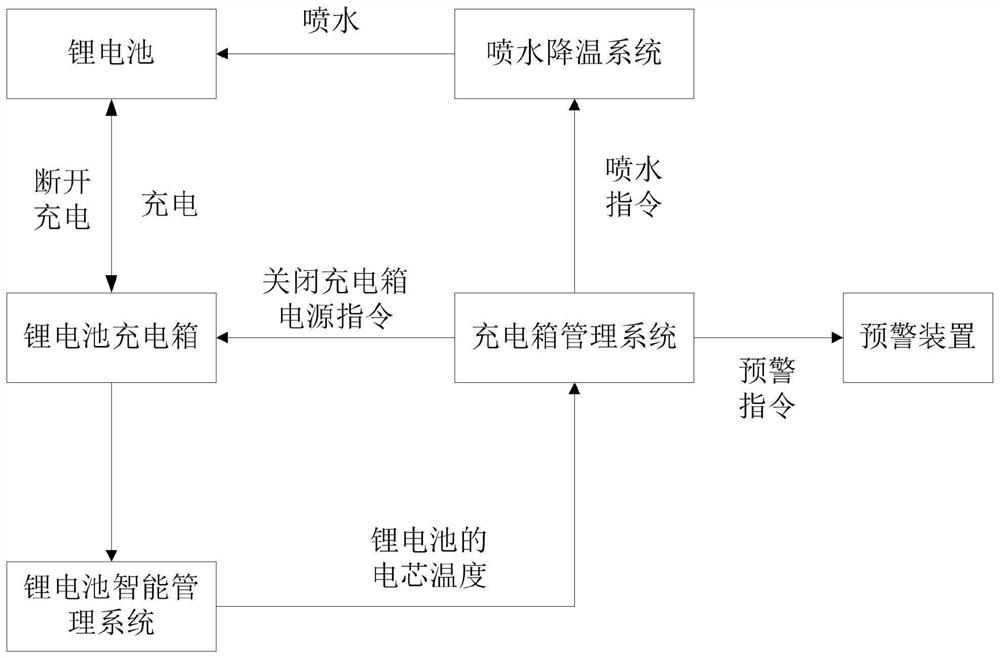

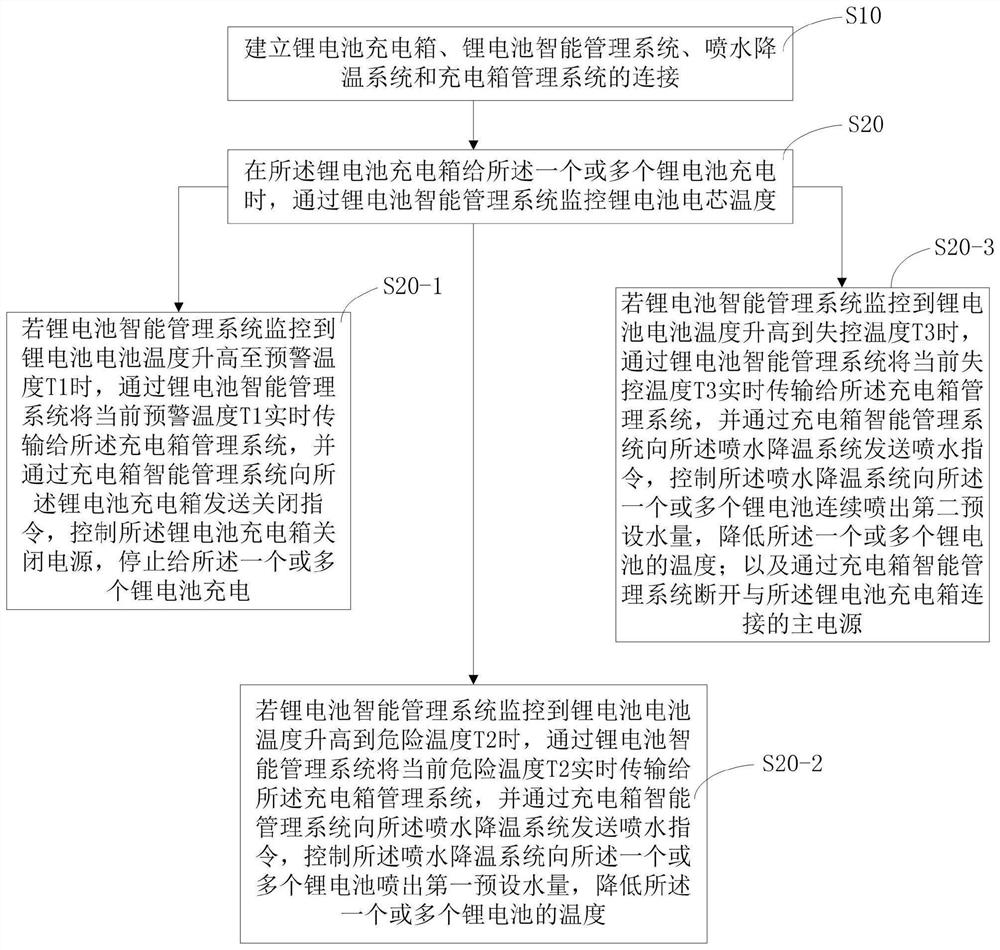

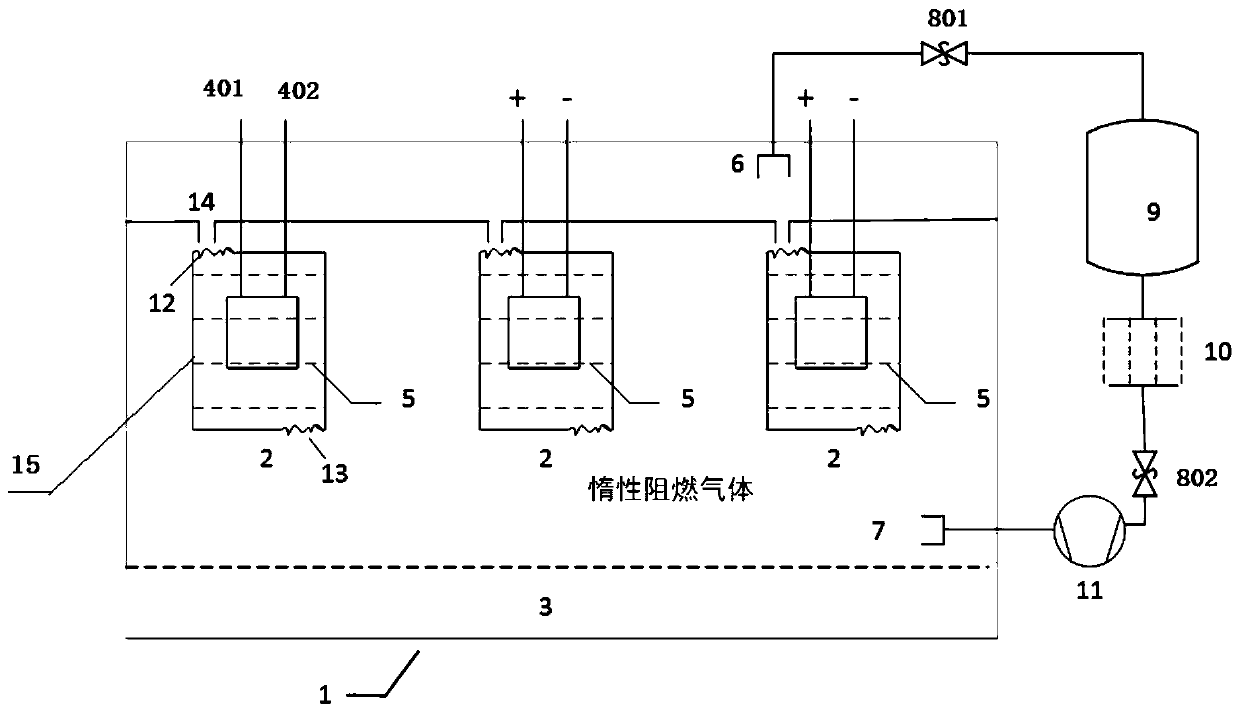

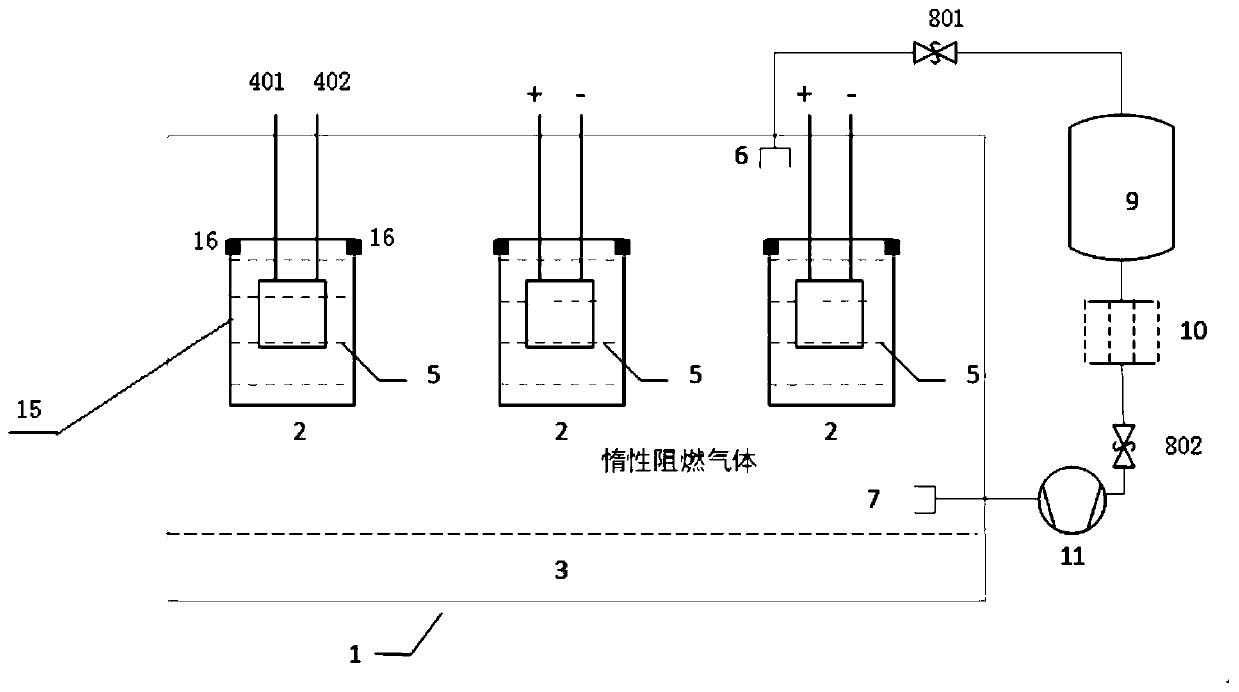

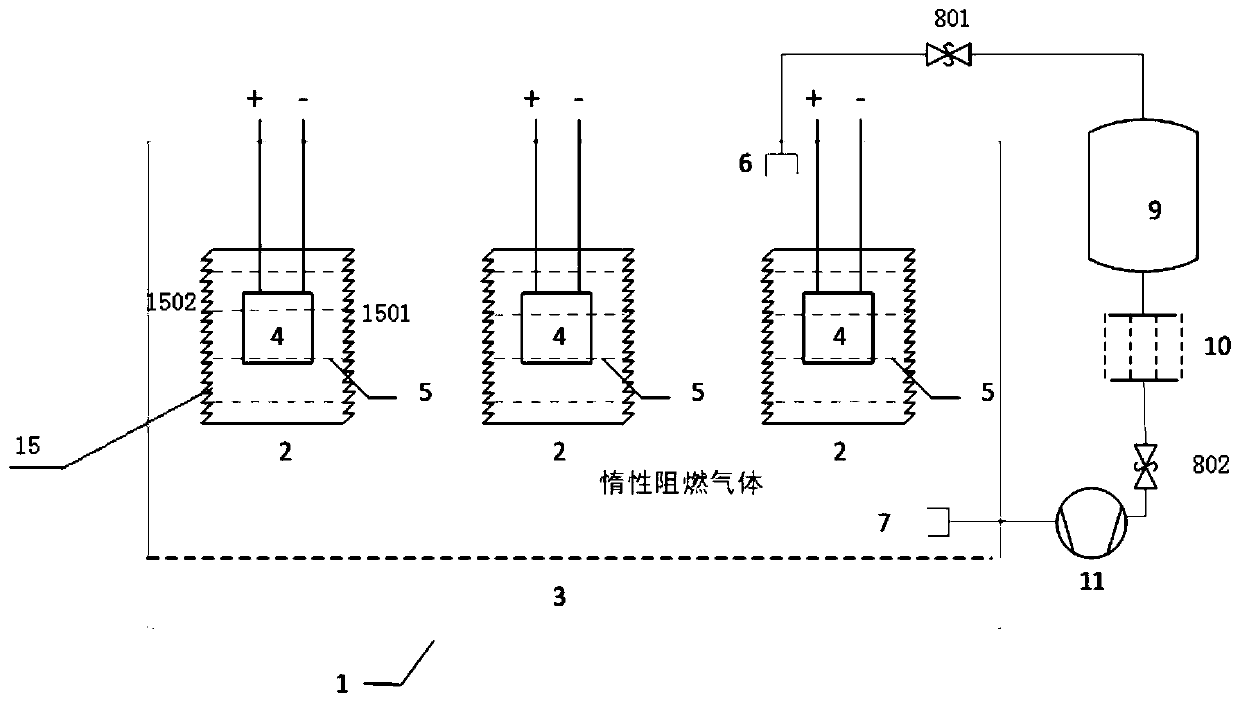

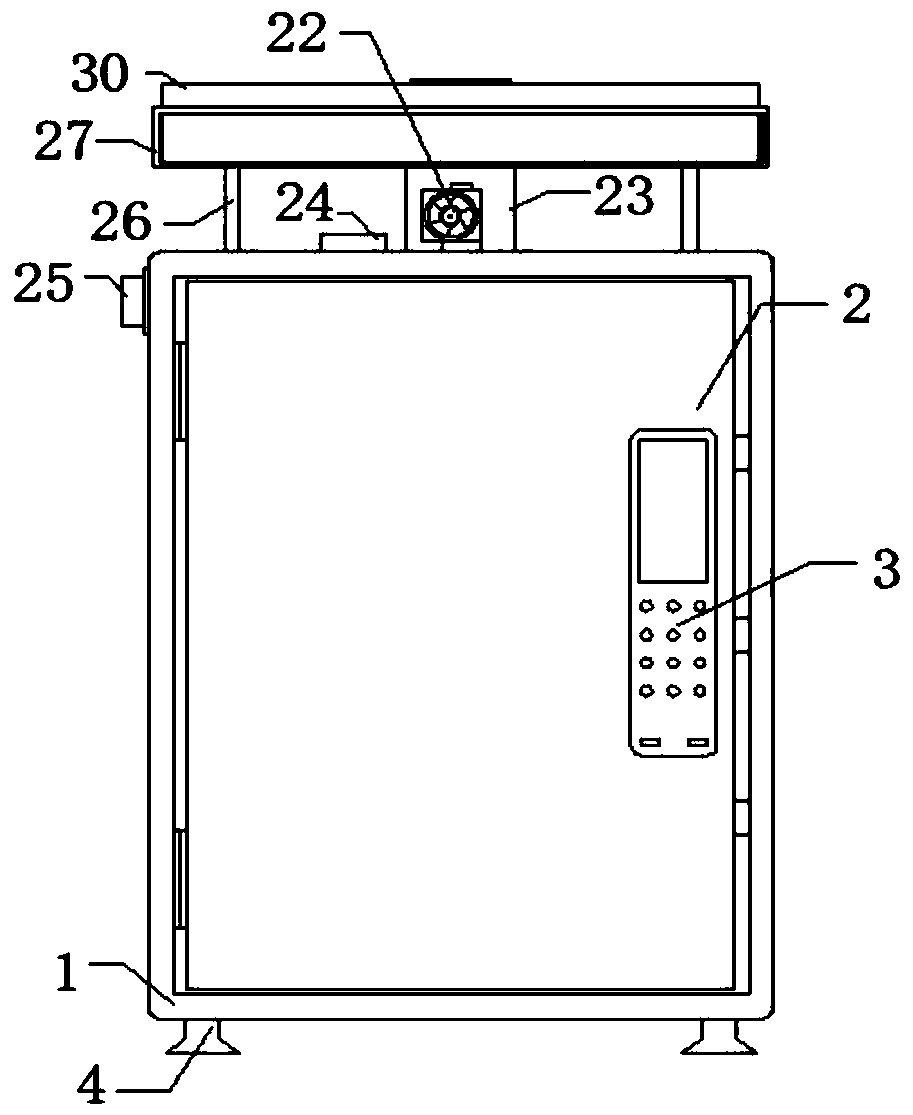

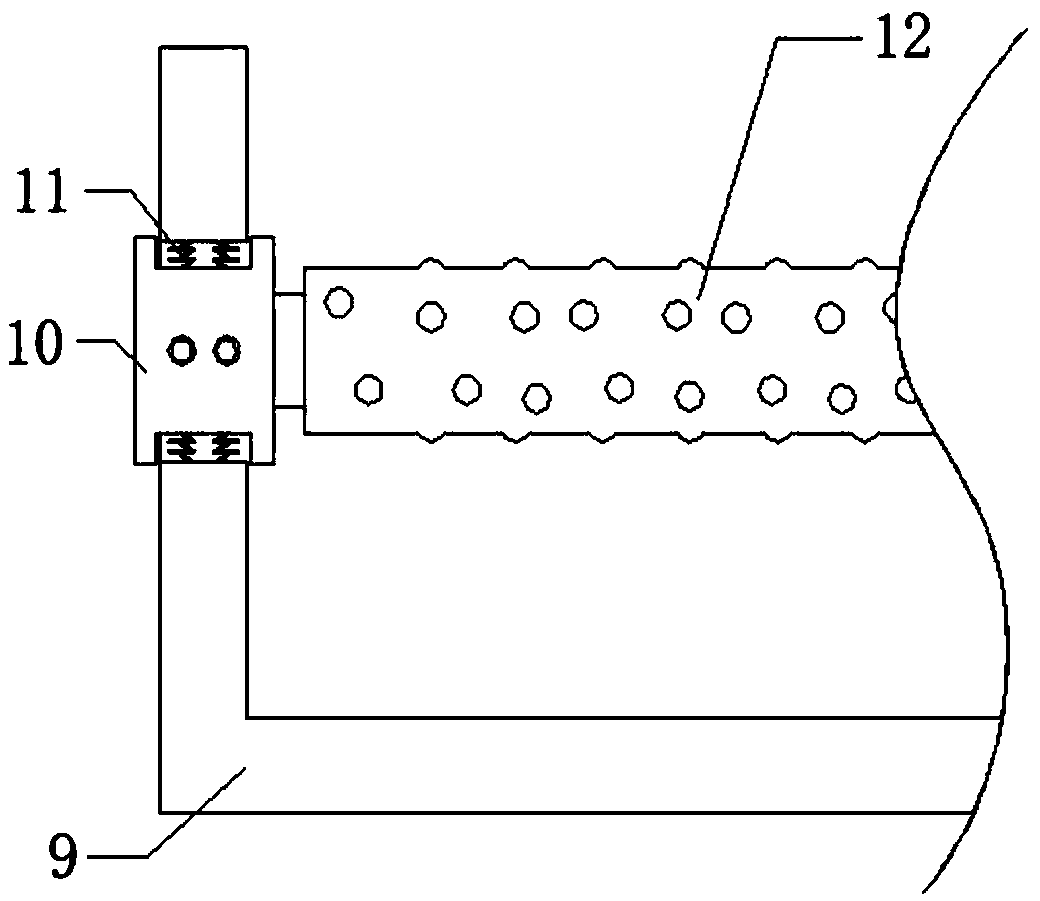

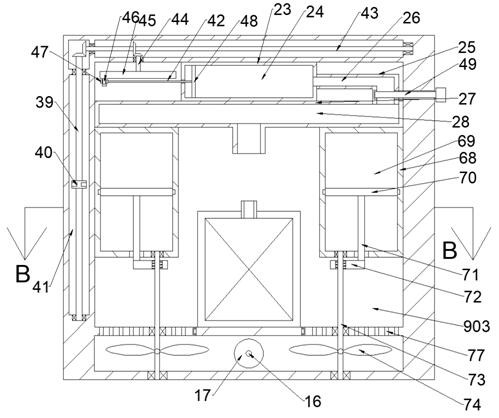

Equipment and method for preventing lithium battery in charging box from fire explosion

PendingCN112635870AReduce the temperatureReduce shared costsBatteries circuit arrangementsFire rescueAutomotive engineeringHeating system

The invention provides equipment and a method for preventing a lithium battery in a charging box from fire explosion; in order to solve a problem of preventing the lithium battery from being on fire and exploding at present, a water spraying cooling and fire extinguishing mode which is recognized to be most effective for the lithium battery is adopted, and the temperature of a battery cell is monitored, early monitoring is emphasized, early discovery is performed and water spraying cooling is intervened in advance. And out-of-control fire explosion of the lithium battery can be effectively prevented. Even if fire and explosion cannot be completely prevented, the effects of controlling the fire behavior and reducing the temperature can be achieved, and the fire disaster is completely controlled in the accident cabin. And the sharing cost is greatly reduced in a mode of sharing a water system pair with a heating system. Therefore, whether the lithium battery has a fire explosion risk or not and whether the lithium battery is out of control or not can be judged by monitoring the temperature of the battery cell of the lithium battery, and the fire explosion of the lithium battery is prevented or the damage caused by the fire explosion of the lithium battery is reduced by a method of spraying water to cool the lithium battery.

Owner:深圳悠久动力科技有限公司

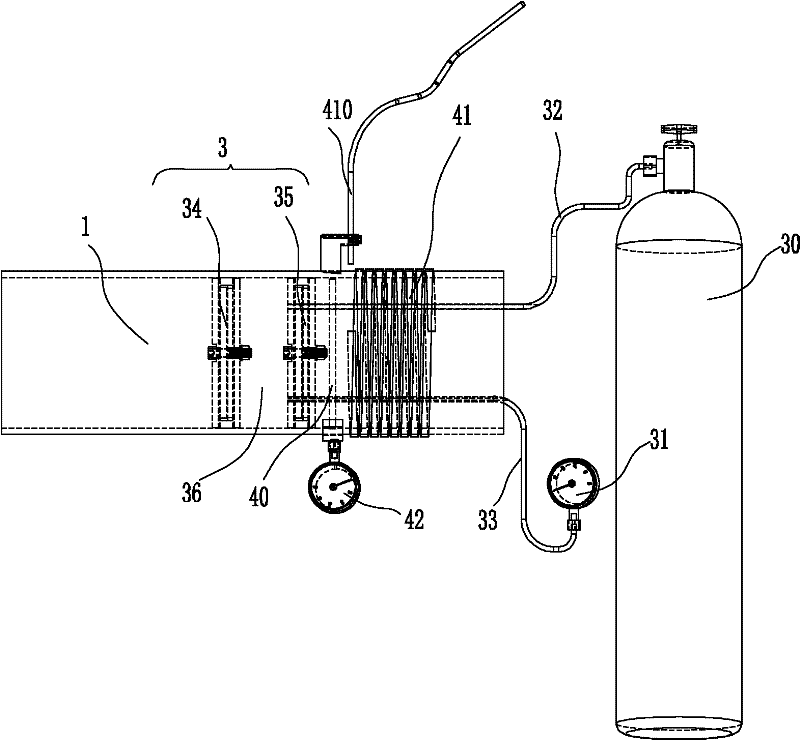

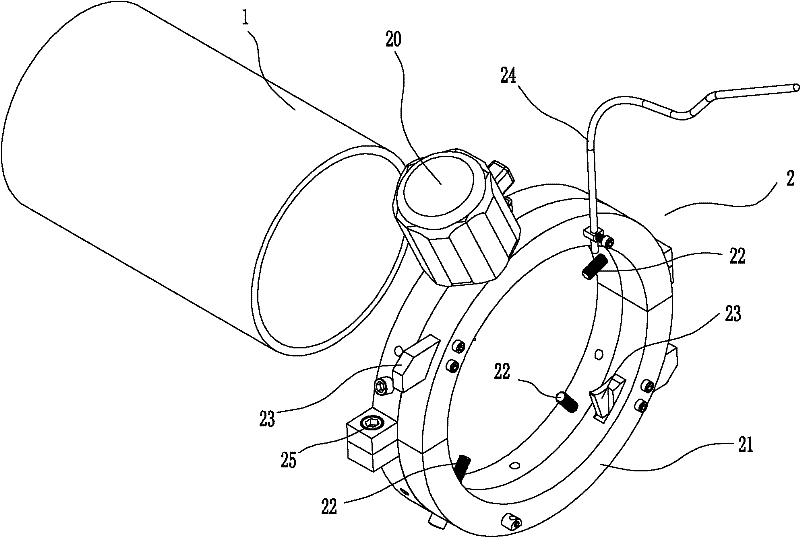

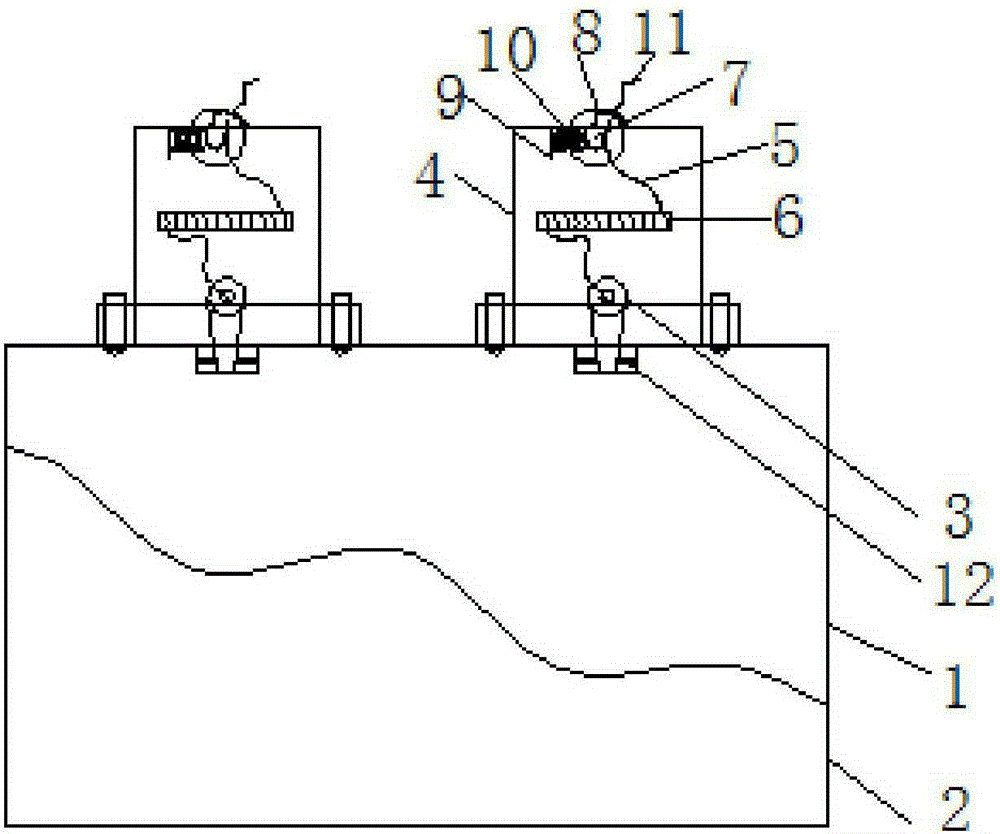

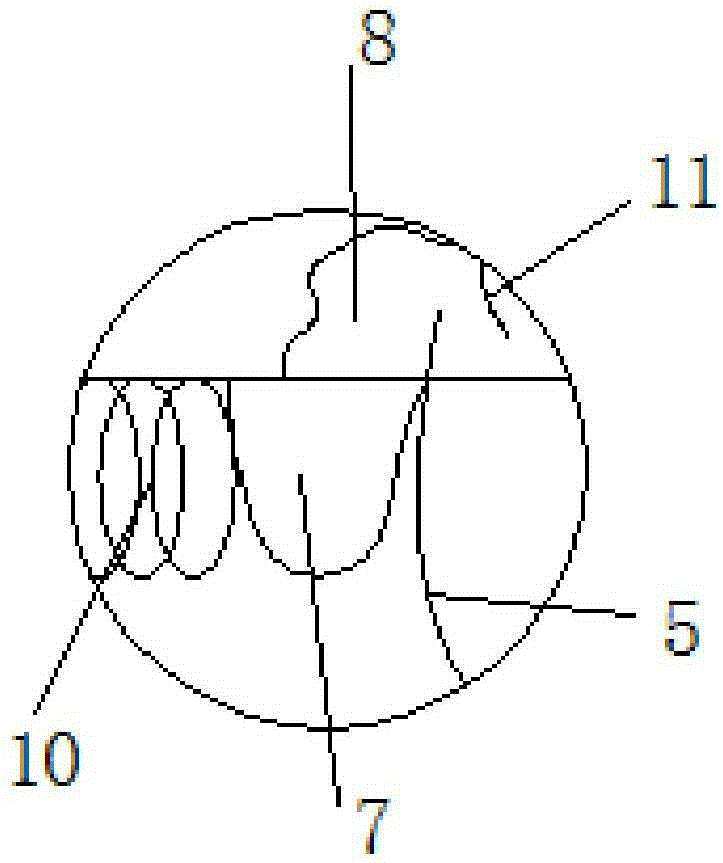

Process and device for welding and cutting flammable-explosive medium pipeline in on-line mode

InactiveCN102229037AAvoid fire and explosionIncreased renovation costsWelding/cutting auxillary devicesAuxillary welding devicesProcess engineeringHot Temperature

The invention provides a process and a device for welding and cutting a flammable-explosive medium pipeline in an on-line mode. By adopting the processing process provided by the invention, a ring rotated cutting device is directly used for carrying out low-temperature cutting; and through adopting a double-disc stopper and a heat insulation cooing device, a pressure online detector and a temperature detector can perform real-time detection and monitoring in the cutting process to prevent the pipeline firing and explosion caused by spark and high temperature from happening. By adopting the technology processing steps and the stopper, the economic losses caused by the stopping and cleaning of fammable-explosive medium pipelines, as well as the production halts and cleaning of an enterprise can be integrally avoided and online technical transformation and promotion can be carried out.

Owner:中化珠海石化储运有限公司

Multifunctional alternating current capacitor

ActiveCN105321709AAvoid fire and explosionEasy to replaceCapacitorsEngineeringElectrical and Electronics engineering

The invention discloses a multifunctional alternating current capacitor. A capacitor core is positioned in a shell; the shell is provided with a pin; the external of the pin is provided with a protective cover; the lower part of the protective cover is connected with the shell; a weight lever is arranged in the protective cover cavity; the weight lever is wrapped with an internal connecting wire; the pin is connected with the lower end of the inner connecting wire; the upper end of the inner connecting wire is welded with an outer connecting wire through an outer welding point; an inner welding point is arranged on the lower end plane of the protective cover; one side of the inner welding point is in contact with the inner connecting wire; a side plate is arranged on the other side of the inner welding point; and a spring is arranged between the side plate and the inner welding point. The multifunctional alternating current capacitor is provided with the weight lever and the outer welding point; when the outer connecting wire is heating and over-burnt, the outer welding point is melted; the inner connecting wire falls off with the weight lever to disconnect a circuit; when the capacitor is inverted, the outer connecting wire is heating and over-burnt, the heat melts the inner welding point, the spring bounces off the inner connecting wire for protecting the capacitor; and the pin is connected with the inner connecting wire by screws, and the pin is clamped with the shell, so that the pin can the inner connecting wire are convenient to replace.

Owner:铜陵市胜美达电子制造有限公司

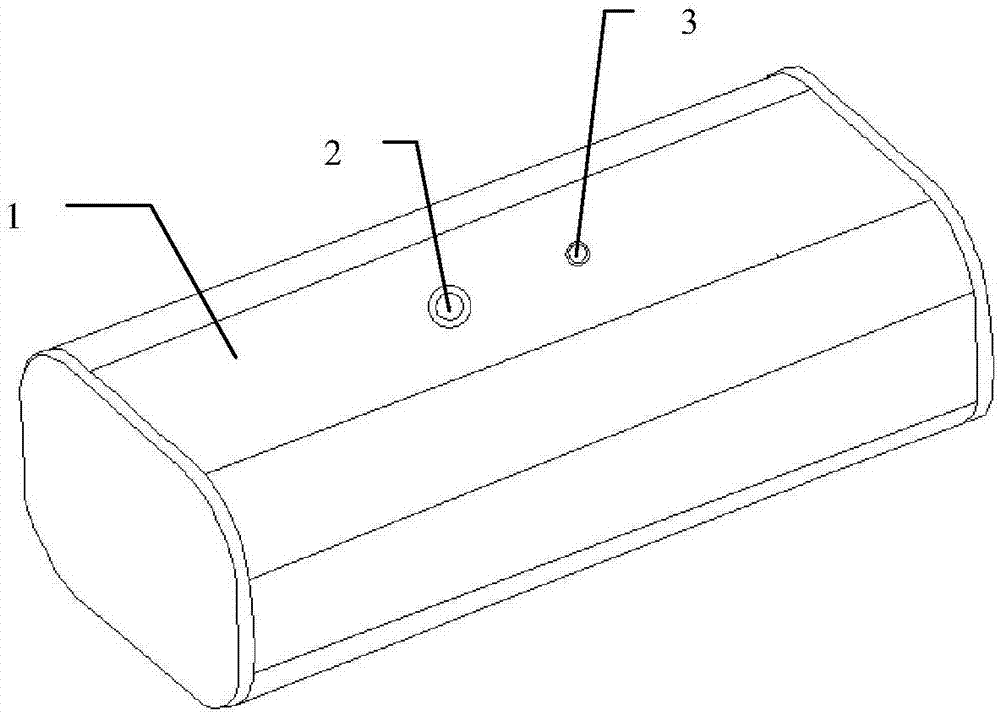

Novel lithium ion battery and battery module

ActiveCN110112329AAvoid fire and explosionSeparation in timeFinal product manufactureJackets/cases materialsEngineeringLithium-ion battery

The invention discloses a novel lithium ion battery and a battery module. The novel lithium ion battery includes a casing, wherein the casing is internally provided with a positive electrode, a negative electrode and electrolyte, a part of the casing is made of a fusible material; when the temperature inside the casing exceeds a set threshold, the region of the casing made of the fusible materialis penetrated, and the electrolyte flows out from a through portion and is separated from the positive electrode and the negative electrode. The novel lithium ion battery is advantaged in that when the temperature of the single lithium ion battery abnormally increases, the electrolyte in the single lithium ion battery is separated in time, ignition or decomposition of the electrolyte is effectively prevented, fire explosion of the novel lithium ion battery is prevented, and damage to other novel lithium ion batteries due to chain reaction caused by abnormal temperature rising of the single novel lithium ion battery is further avoided.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +1

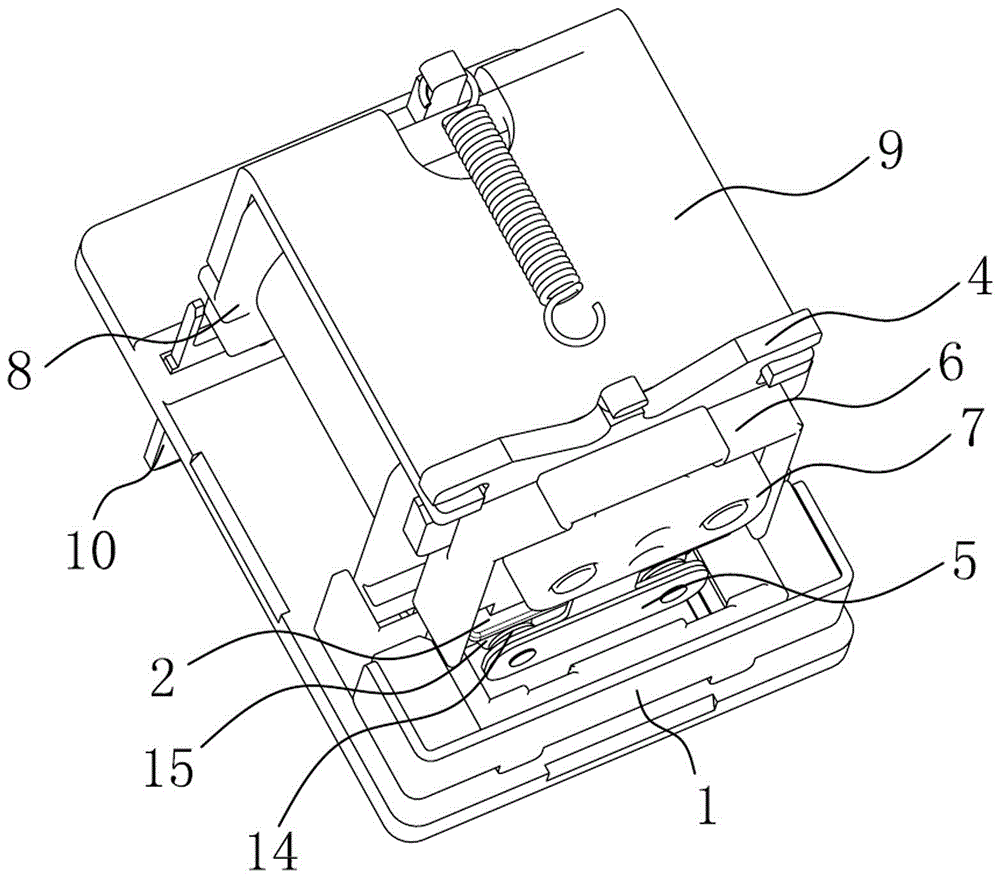

Clapper type relay

InactiveCN106098478AQuick breakBurn out preventionElectric switchesElectromagnetic relay detailsEngineeringMechanical engineering

The invention discloses a snap-in relay, which comprises a base, a moving contact assembly and a static contact assembly are arranged on the upper side of the base, the moving contact assembly includes a moving contact, and the static contact assembly includes a static contact point, the upper side of the dynamic and static contacts is provided with an upper insulating arc-stopper, the base and the upper insulating arc-stopper are made of ceramic materials; the movable contact includes a left movable contact and a right movable contact, the The static contact includes a left static contact and a right static contact. The upper insulating arc stopper is located on the upper side of the junction of the moving and static contacts. The length of the upper insulating arc stopper is greater than the outer edge of the left moving contact and the The maximum distance between the outer edges of the right movable contacts may be greater than the maximum distance between the outer edges of the left static contacts and the right static contacts, and the width of the upper insulating arc shield is greater than the distance between the movable and static contacts.

Owner:ZHEJIANG YINGLUOHUA NEW ENERGY TECH CO LTD

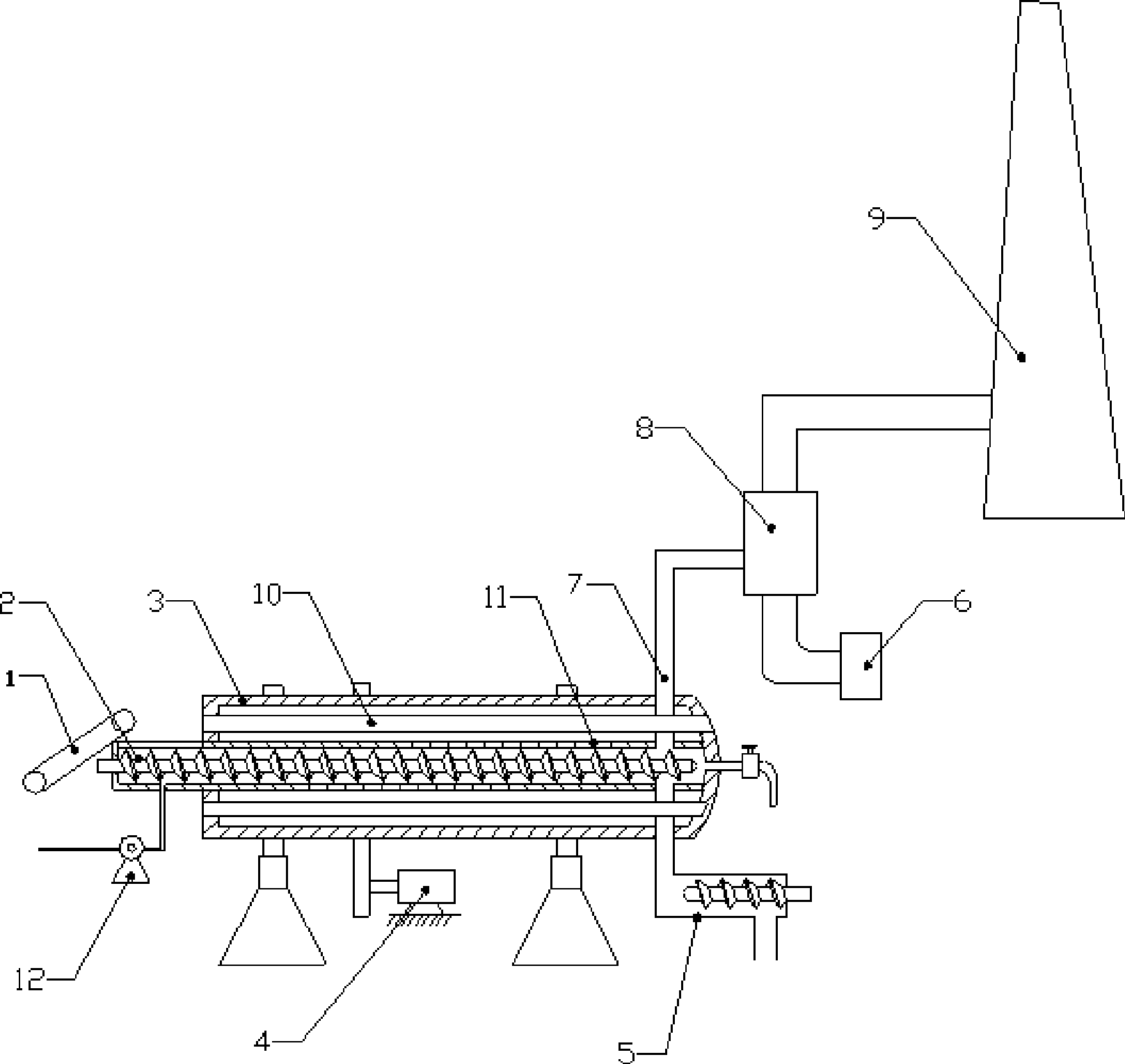

Method for controlling coking coal dampness

InactiveCN101372625AImprove drying efficiencyPrevent moisture condensationCoke ovensSteam powerCoke oven

The invention relates to a method for controlling the humidity of coking coal, belonging to the technical field of coking coal preparation. The technical problem to be solved in the invention is to provide a method for controlling the humidity of coking coal with simple process and less equipment; the method also can effectively reduce the oxygen content of a drying system and guarantee the safety of the system. The method can make full use of the back-pressure steam generated after dry quenching steam power generation or other low-pressure steam and coke oven waste gas in plants, utilizes steam for indirect drying and takes the waste gas generated in the coke oven production process as carrier gas for direct drying at the same time. The method can improve the drying efficiency of a drying machine, prevent the condensation of moisture after drying, reduce the oxygen content in the system (keeping the oxygen content of the system below 13% steadily), prevent the ignition and explosion of the system, improve the running safety of the system, lower the consumption of steam, reduce running cost and have promising market prospect.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

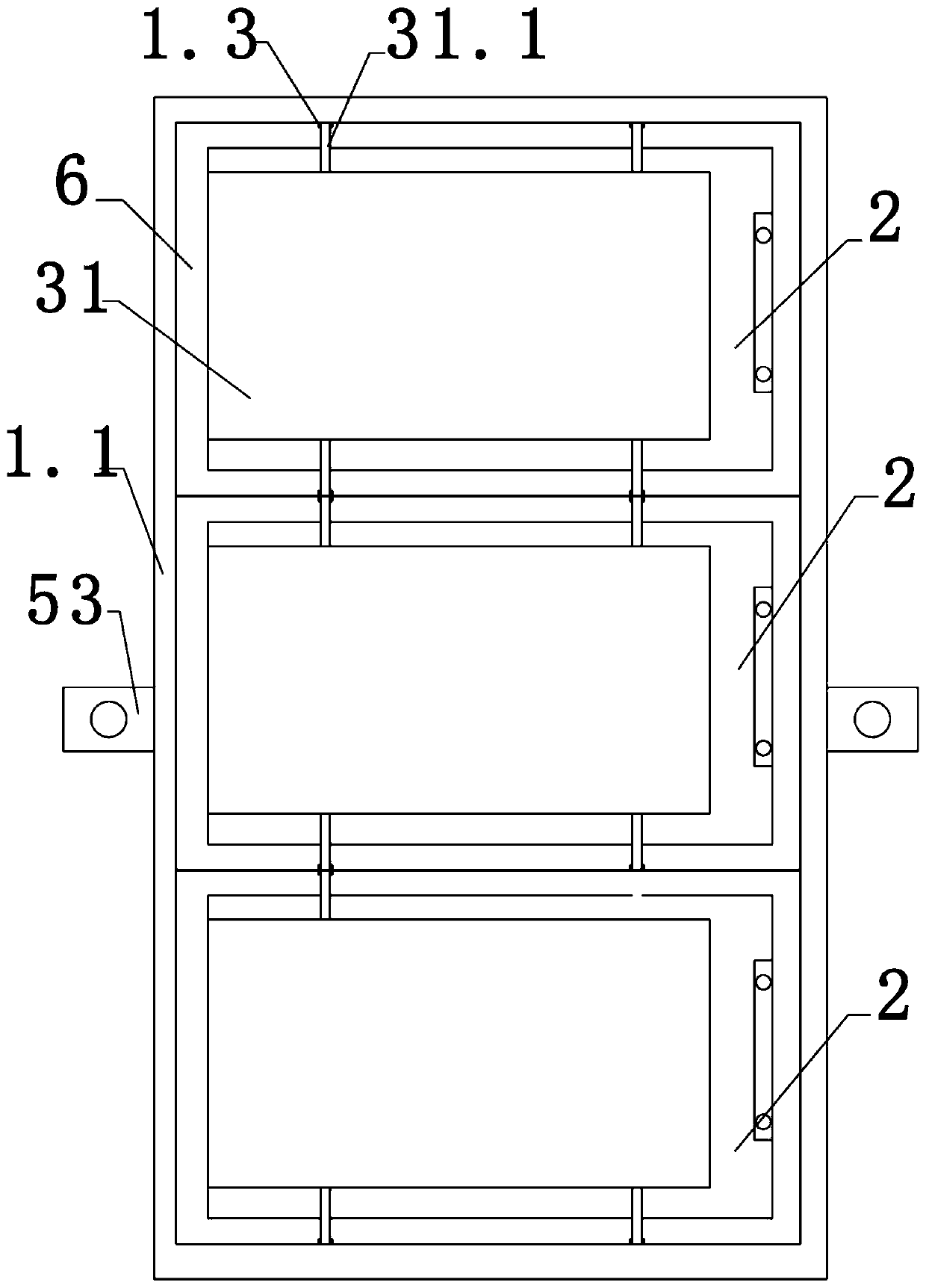

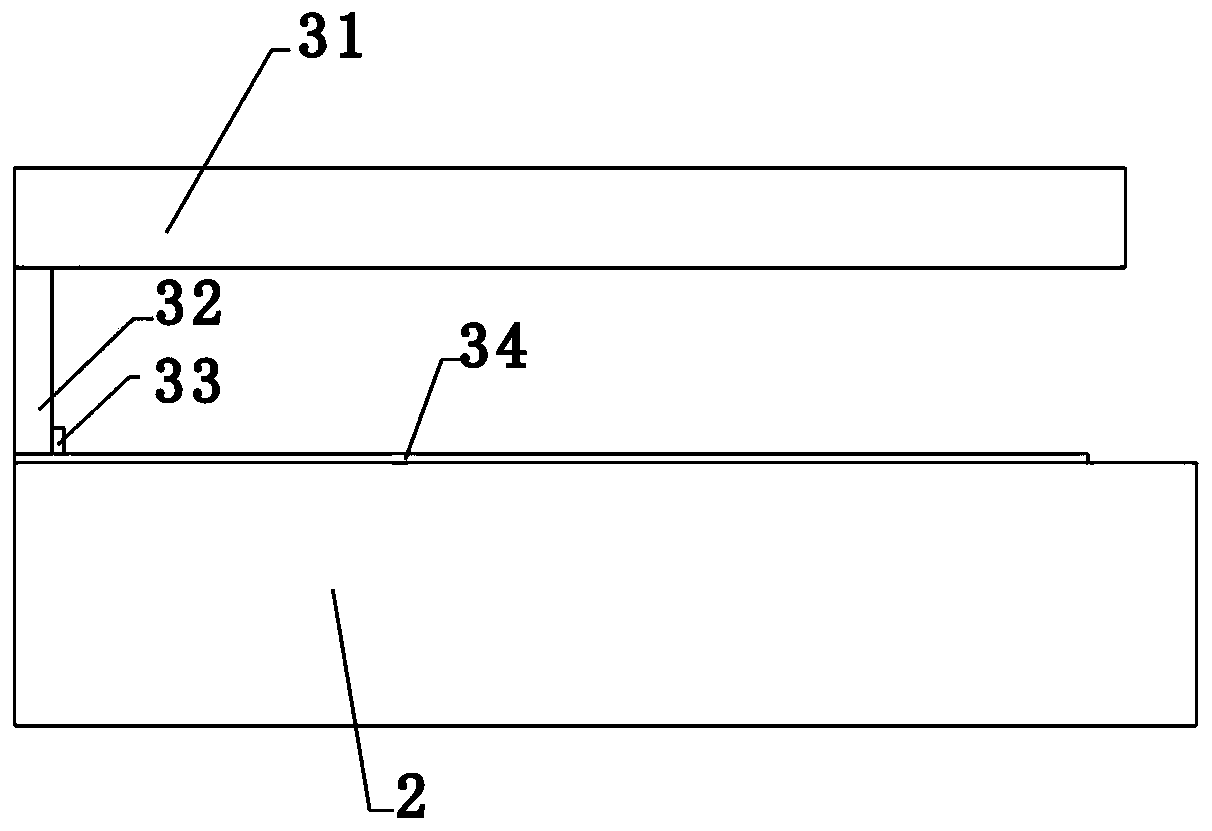

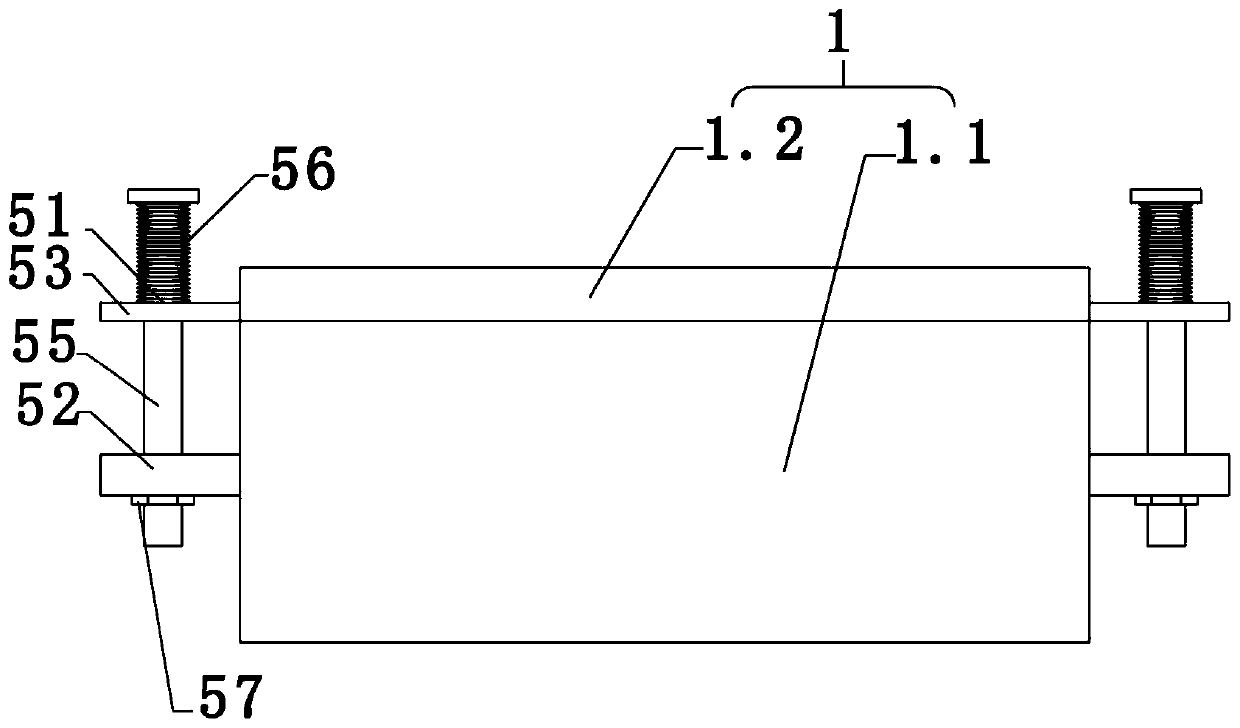

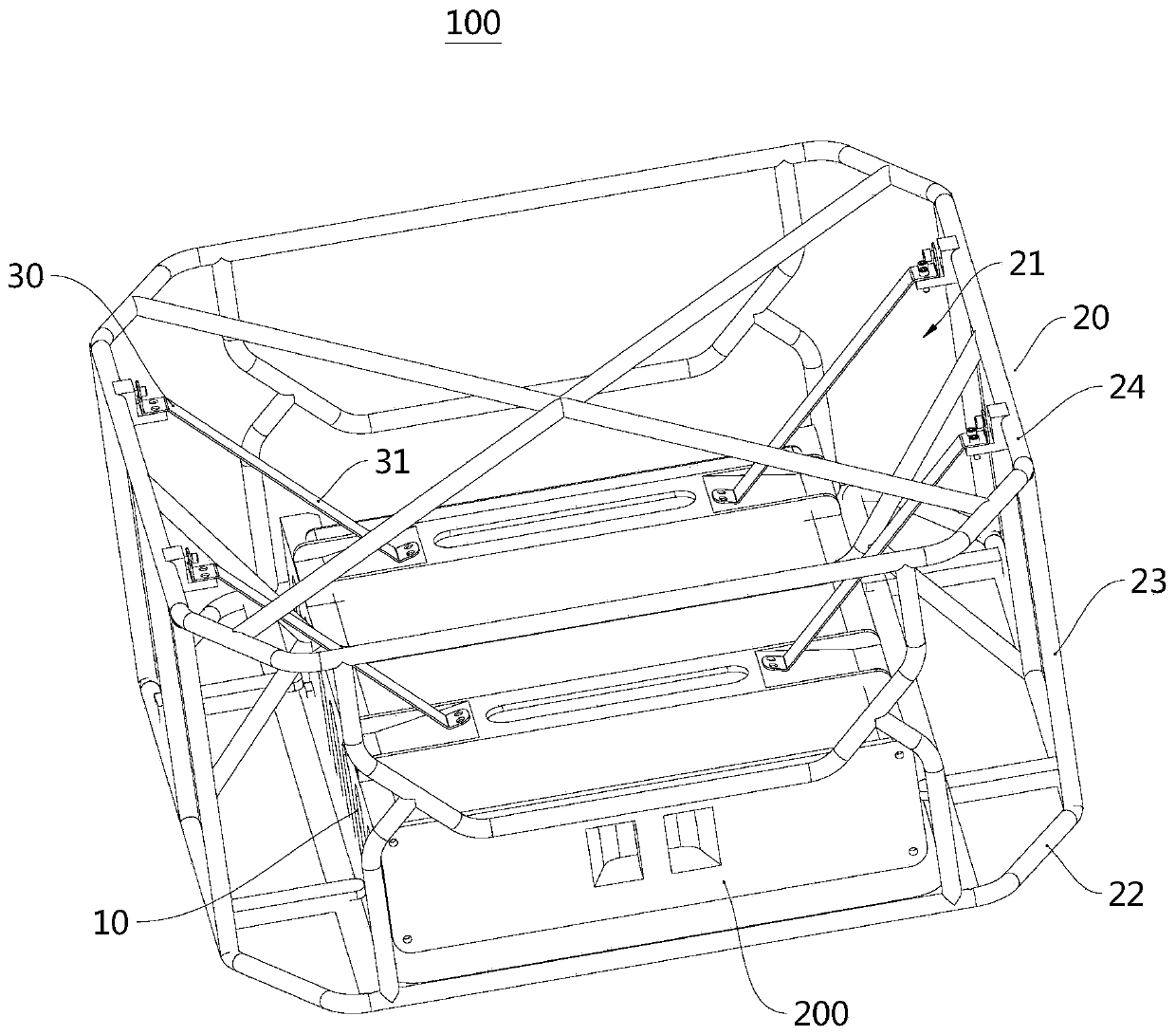

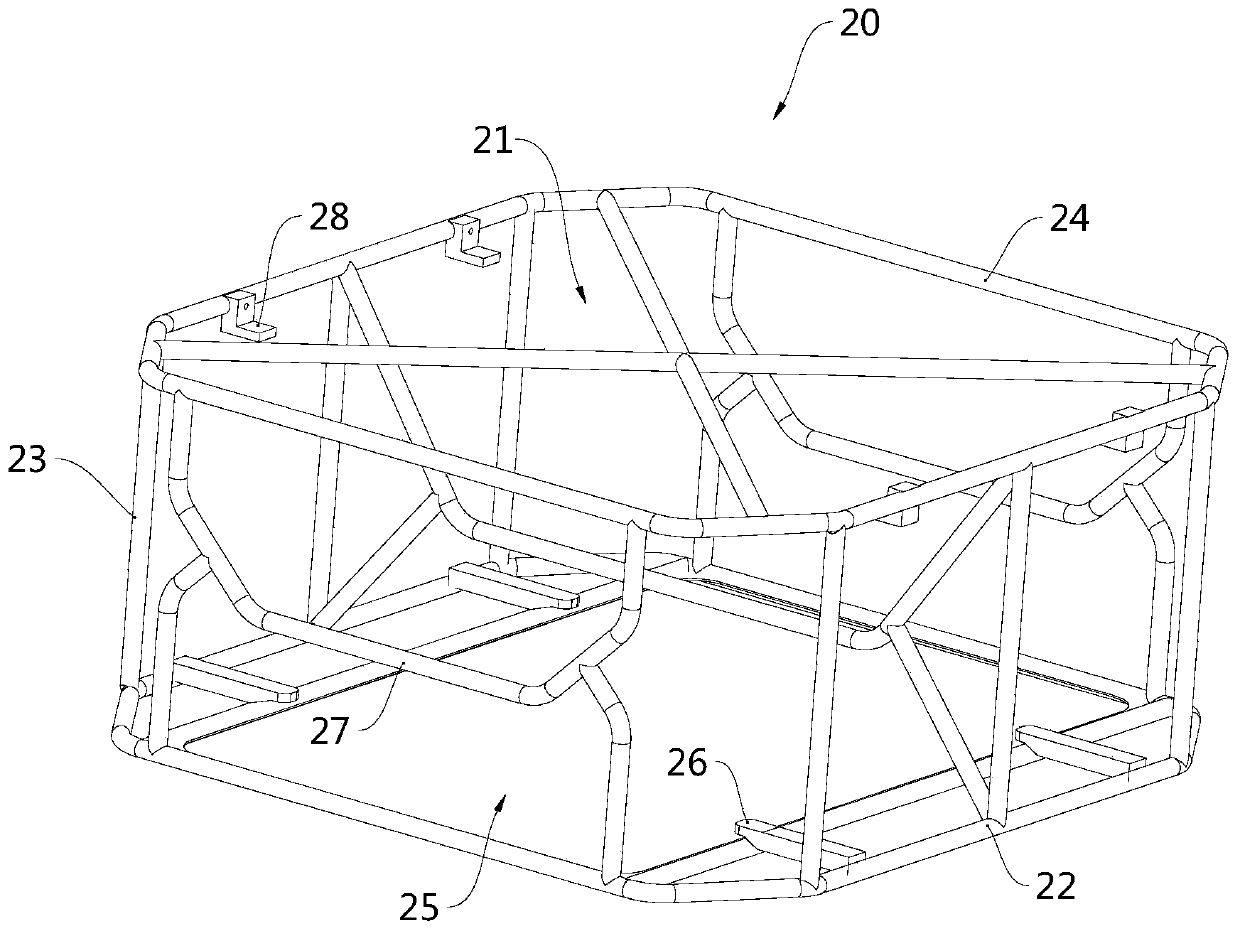

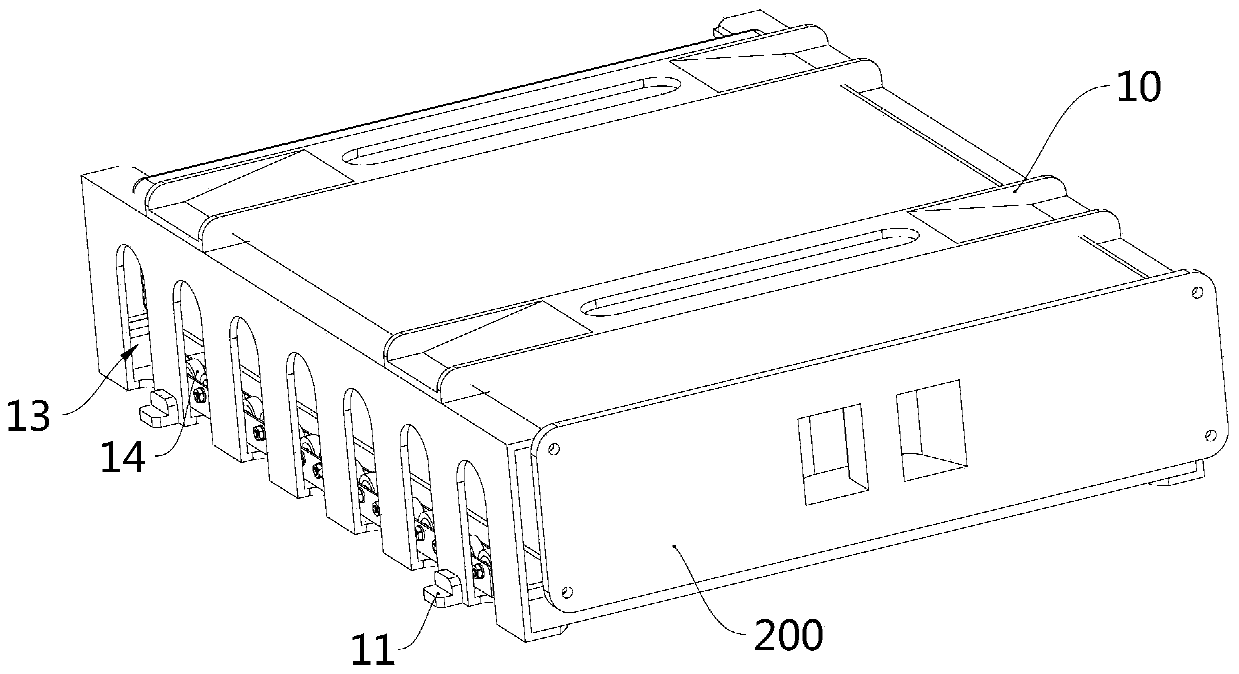

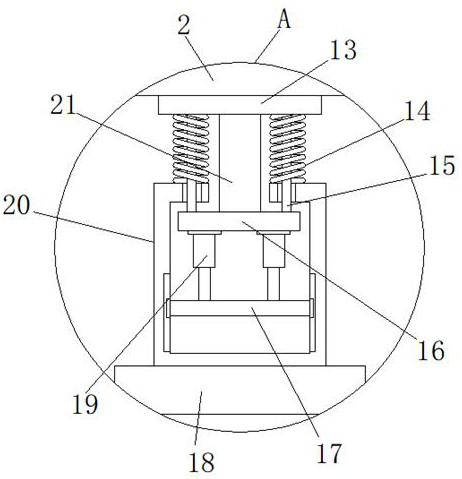

Power battery mounting structure and vehicle

ActiveCN110803011AImprove securitySqueeze fromElectric propulsion mountingCell component detailsPower batteryStructural engineering

The invention relates to a power battery mounting structure and a vehicle. The power battery mounting structure comprises a mounting base body, a connecting assembly and a battery rack for mounting apower battery. The mounting base body has an accommodating space for accommodating the battery rack, and the battery rack is mounted in the accommodating space through the connecting assembly. The mounting base body is provided with a detachment opening for communicating the accommodating space with the outside. The connecting assembly is configured to be driven to deform when the mounting base body deforms so that the battery rack is detached from the accommodating space from the detachment opening. The power battery mounting structure is mounted on the vehicle, and the periphery of the battery rack equipped with the power battery is coated with the mounting base body. When a collision occurs, the mounting base body is extruded to deform first, and then the connecting assembly is driven to deform, so that the battery rack is detached from the extruded and deformed mounting base body from the detachment opening. Therefore, the power battery can be protected from being extruded, the power battery is effectively prevented from being extruded and leaked to cause fire and explosion, and the safety of the vehicle is improved.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

Lithium ion battery membrane with heat resistance and high mechanical strength and preparation method thereof

ActiveCN112635914AImprove heat resistanceHigh mechanical strengthSecondary cellsCell component detailsPolyolefinPhysical chemistry

The invention provides a lithium ion battery membrane with heat resistance and high mechanical strength. The lithium ion battery membrane comprises a polyolefin porous base material and a porous heat-resistant layer coated on one side surface or two side surfaces of the base material, wherein the porosity of the polyolefin porous base material is 20-60%, the needling strength is greater than or equal to 200 gf, and the peel strength of the porous heat-resistant layer is greater than or equal to 10 N / m; and the porous heat-resistant layer comprises inorganic filler, a binder, a thickening agent, a dispersing agent and a wetting agent, the mass of the inorganic filler accounts for 90% or above of the mass of the porous heat-resistant layer, and the mass of the binder accounts for 4%-7% of the mass of the porous heat-resistant layer. The porous heat-resistant layer is coated on the surface of at least one side of the polyolefin porous base material, so that the heat resistance of the diaphragm is improved, the safety of the lithium ion battery is effectively improved, the phenomena of fire explosion and the like caused by thermal shock are prevented, and the problems that the thermal shrinkage rate is high and the strength is greatly reduced after heating are solved.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

A new energy vehicle battery explosion-proof flame retardant device

ActiveCN113241496BIt has the effect of explosion-proof and flame-retardantAvoid fire and explosionSecondary cellsFire rescueAutomotive batteryNew energy

The invention discloses an explosion-proof and flame-retardant device for a new energy vehicle battery, which relates to the technical field of new energy vehicle battery packs. Aiming at the problems that the battery pack is prone to explosion and combustion after being collided, the following scheme is proposed, including an installation frame and a chassis. The top of the installation frame is fixed with four sets of mounting bases by bolts, and batteries are placed on the top of the mounting bases, and eight connecting blocks are welded around the battery, and the sides of the eight connecting blocks away from the battery are all welded There is a third box, the inner wall of the third box is slidably connected with a movable plate, and two hydraulic rods are welded on the side of the movable plate away from the battery. The invention has the effect of explosion-proof and flame-retardant for the battery pack, prevents the battery pack from easily exploding and igniting after violent vibration and collision, achieves effective shock absorption and fixing of the battery pack, and simplifies the operation of battery replacement at the same time. Strong, suitable for widespread promotion.

Owner:SHENZHEN JINZUN ENERGY TECH CO LTD

Pressure sealant and production technology thereof

ActiveCN104629652AGood compatibilityGood chemical stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesFluorocarbonPolytetrafluoroethylene

The invention discloses a pressure sealant and production technology thereof. The sealant comprises 100 parts of polytetrafluoroethylene as a matrix material, 20 parts of a mixture of fluorocarbon oil and dimethicone as a performance additive, 10 parts of expandable graphite as a filler, and 5 parts of carbon fibre as a reinforcing material, and is prepared through steps such as mixing and extruding. According to the invention, a polymer material of polytetrafluoroethylene is taken as the matrix material; the performance additive is screened; and the prepared novel sealant has preferable chemical stability, a low-temperature cold flow property and mouldability. Therefore, the sealant is adaptable to leakage seal of mediums with high temperature, high pressure, ultralow temperature, strong corrosivity, high dissolvability and strong oxidizability to ensure the safety and reliability of a seal construction process with temperature and pressure.

Owner:天津市翔悦密封材料股份有限公司

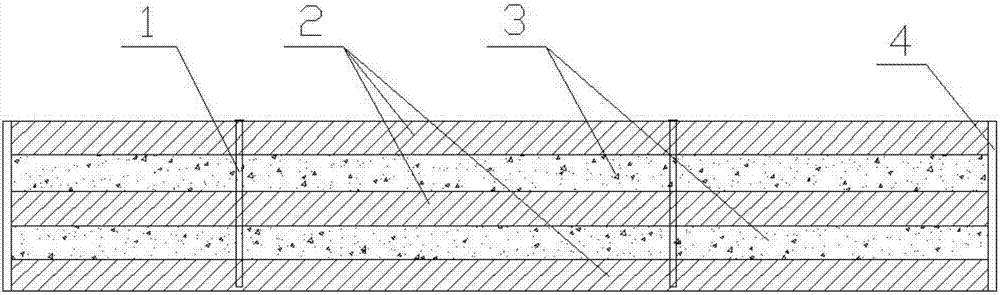

Lightweight electric automobile floor

ActiveCN107263953AAvoid Collision DeformationProtection securityMetal layered productsEnergy absorptionMetal sheet

The invention discloses a lightweight electric automobile floor. The floor is of a five-layer composite structure, the five layers are fixed together by rivets and are a high-strength sheet metal, a foamed aluminum board, a high-strength sheet metal, a foamed aluminum board and a high-strength sheet metal from bottom to top in sequence, and the periphery of the floor is reinforced by adopting a vertical metallic framework in an encircled manner, so that the floor is integrated, the strength is not reduced, and the body weight is greatly reduced. The structural design is simple, a composite vehicle floor technology for alternatively superposing multiple foamed aluminum layers and multiple high-strength sheet metal layers is adopted, collision deformation of the platform floor is avoided, the passenger safety is protected, fire and explosion caused by collided deformation of a battery pack can be avoided, and energy generated by collision can be effectively absorbed. Meanwhile, the traditional foamed aluminum formula is changed, so that the lightweight electric automobile floor has an excellent energy absorption effect, and the application range of the floor is widened.

Owner:界首市中源汽车修造有限公司

Damp-proof bottom plate reinforced bullet cabinet and manufacturing method thereof

The invention discloses a damp-proof bottom plate reinforced bullet cabinet which comprises a cabinet body and a cabinet door. The cabinet door is hinged to an opening in one side of the cabinet body,a human face lock is inlaid into the cabinet door, a firearm storage box is welded on one inner side of the cabinet body, one side, close to the cabinet door, of the firearm storage box is hollow, timed operation of a dehumidifier is controlled by a time delay, so that water vapor inside the cabinet body can be removed at regular time, damage to gunpowder in a cartridge due to the water vapor inair is avoided, and the service life of the cartridge is prolonged. A drying agent storage box is additionally arranged inside the cabinet body and filled with drying agents for absorbing the water vapor inside the cabinet body, so that the inside of the cabinet body is kept dry. A reinforcing plate is additionally arranged at the bottom end of the cabinet body, the thickness of the bottom end ofthe cabinet body is increased, so that the bottom end of the cabinet body is firmer, and the dehumidifier can be more firmly mounted inside the cabinet body.

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

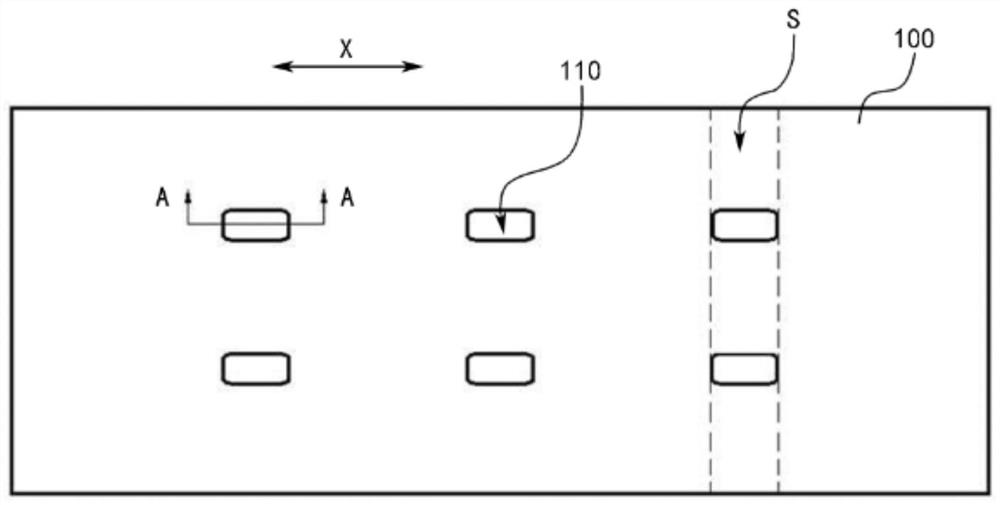

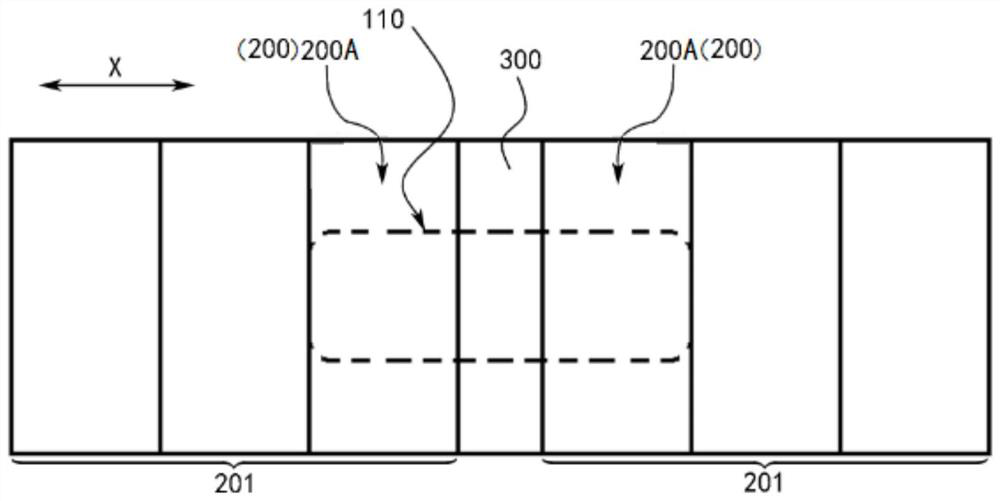

Battery module and battery pack

ActiveCN112687979AReduce deliveryReduce the cross-sectional areaSecondary cellsCell component detailsMechanical engineeringBattery cell

Owner:CALB CO LTD +1

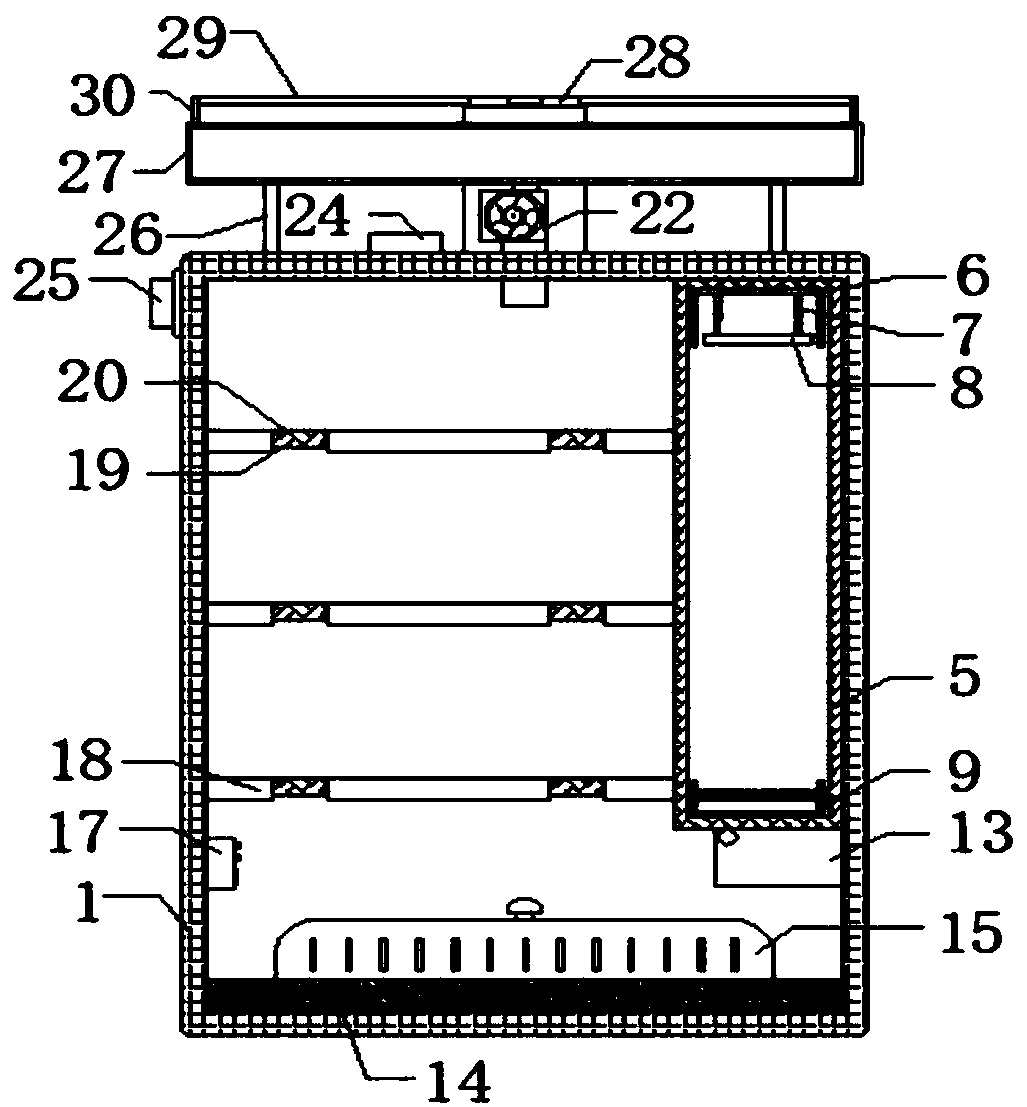

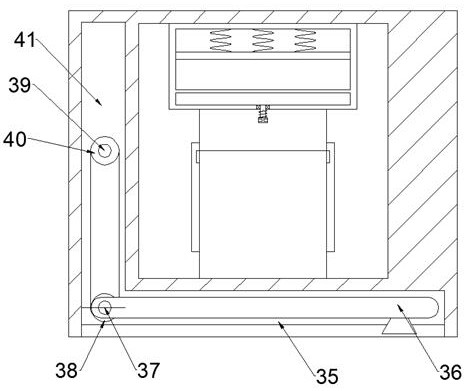

Storage battery safety storage box capable of conveying and automatically adding electrolyte

InactiveCN112582742AEasy accessGet to work soonSecondary cellsFire rescueGear driveProcess engineering

The invention discloses a storage battery safety storage box capable of conveying and automatically adding electrolyte. The storage box comprises a box body shell, a box body inner cavity is arrangedin the box body shell, and an object taking and liquid adding device is arranged in the box body inner cavity. According to a gear transmission principle and a belt transmission principle, rotation ofthe axial center when a door is pushed and pulled is used so that a safely stored battery is automatically sent out, and electrolyte is added according to needs in the sending process, and further the storage battery can enter a working state more rapidly; in addition, a cooling device and fireproof safety protection measures are further designed, the phenomena of explosion, ignition and the likeduring storage of the storage battery are prevented, potential safety hazards are eradicated, and the life and property safety of people is protected.

Owner:义乌市咿佳贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com