Clapper type relay

A relay and snap-fit technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as unusable high-voltage fields, limited use occasions, and burnt-out of snap-fit relays, so as to avoid fire and explosion accidents and break quickly , The effect of rapid breaking of dynamic and static contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

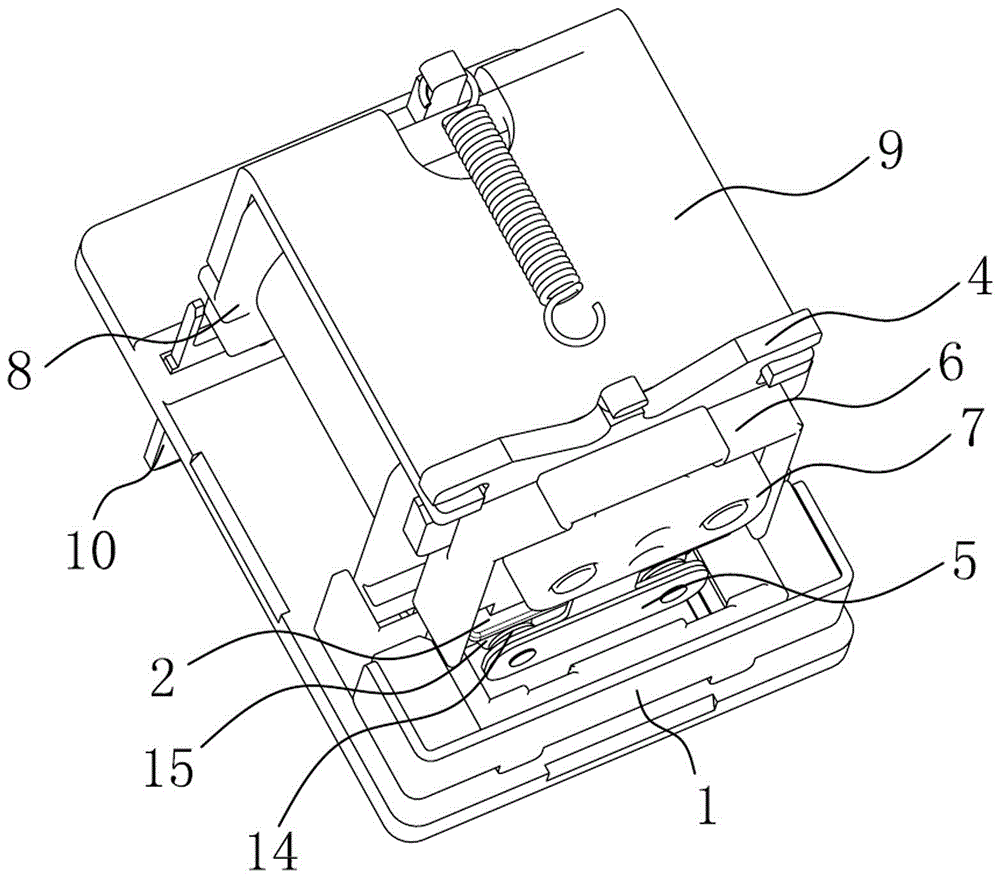

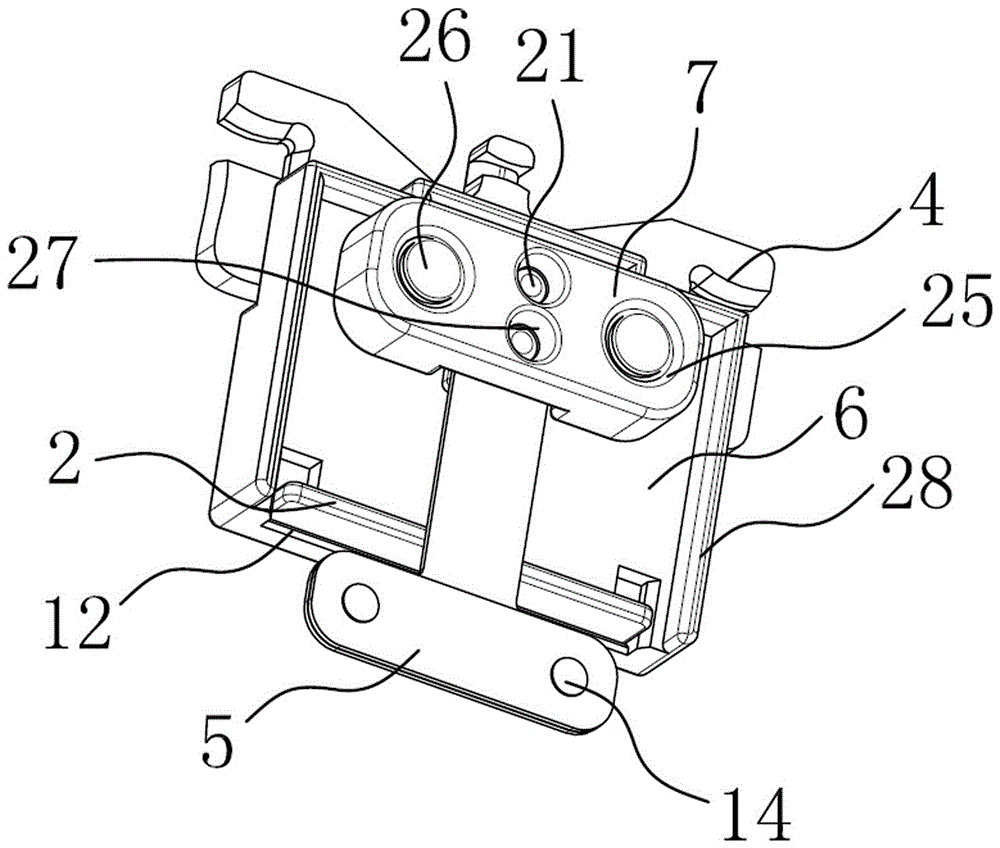

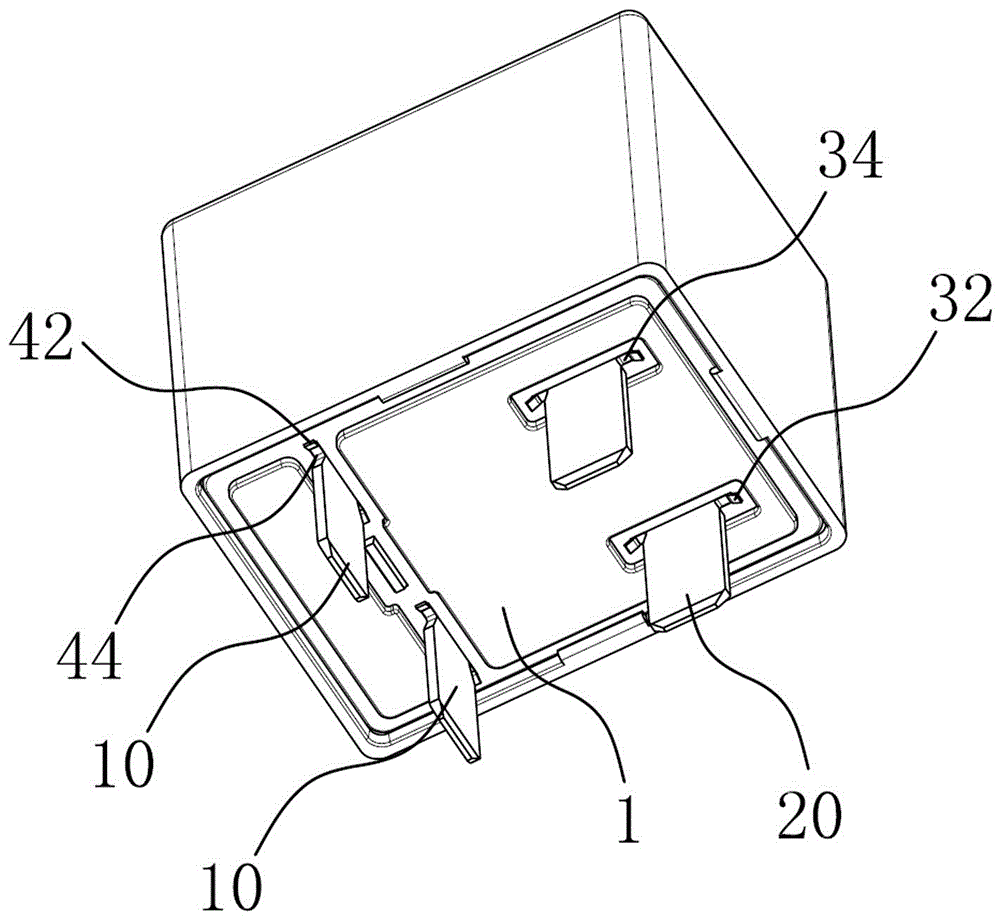

[0027] Depend on figure 1 , figure 2 , Figure 4 As shown, a snap-in relay of the present invention includes a base 1 made of ceramic material, a magnetic circuit part and a contact part, the magnetic circuit part includes a coil, an armature 4, an iron core and a yoke 9; the contact part includes a moving The contact assembly and the static contact assembly, the coil, the iron core and the yoke 9 are fitted together to form the coil part, the coil part, the moving contact assembly and the static contact assembly are installed on the upper side of the base, and the moving contact assembly It includes a moving contact 14, the static contact assembly includes a static contact 15, and the upper side of the joint of the moving and static contacts is provided with an upper insulating arc stop piece 2 made of ceramic material, and the moving conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com